Novel drying cylinder for producing PVC rolling film

A technology of calendering film and drying cylinder, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of affecting processing effect, uneven drying of raw materials, and lack of drying effect of raw materials, so as to achieve maintenance Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

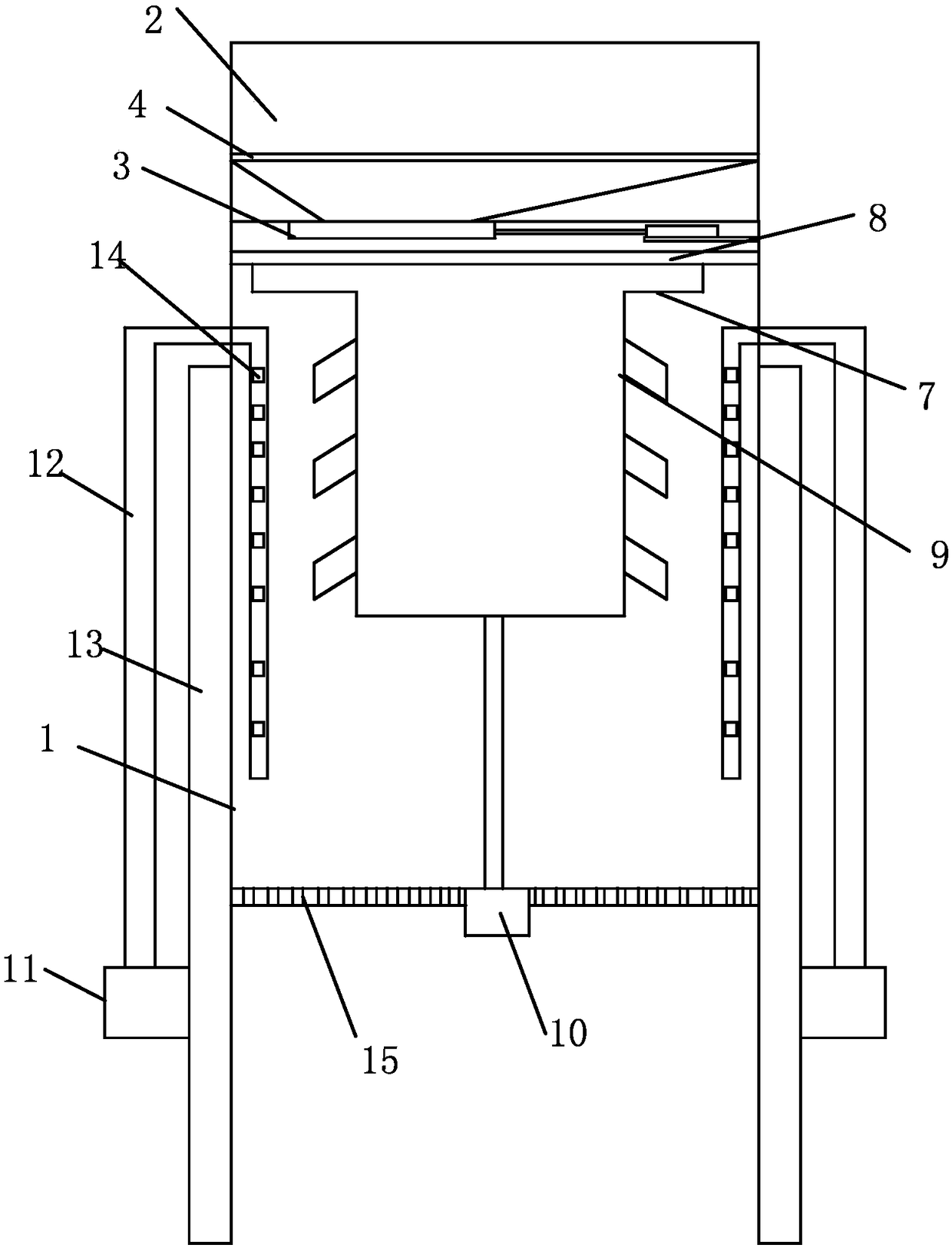

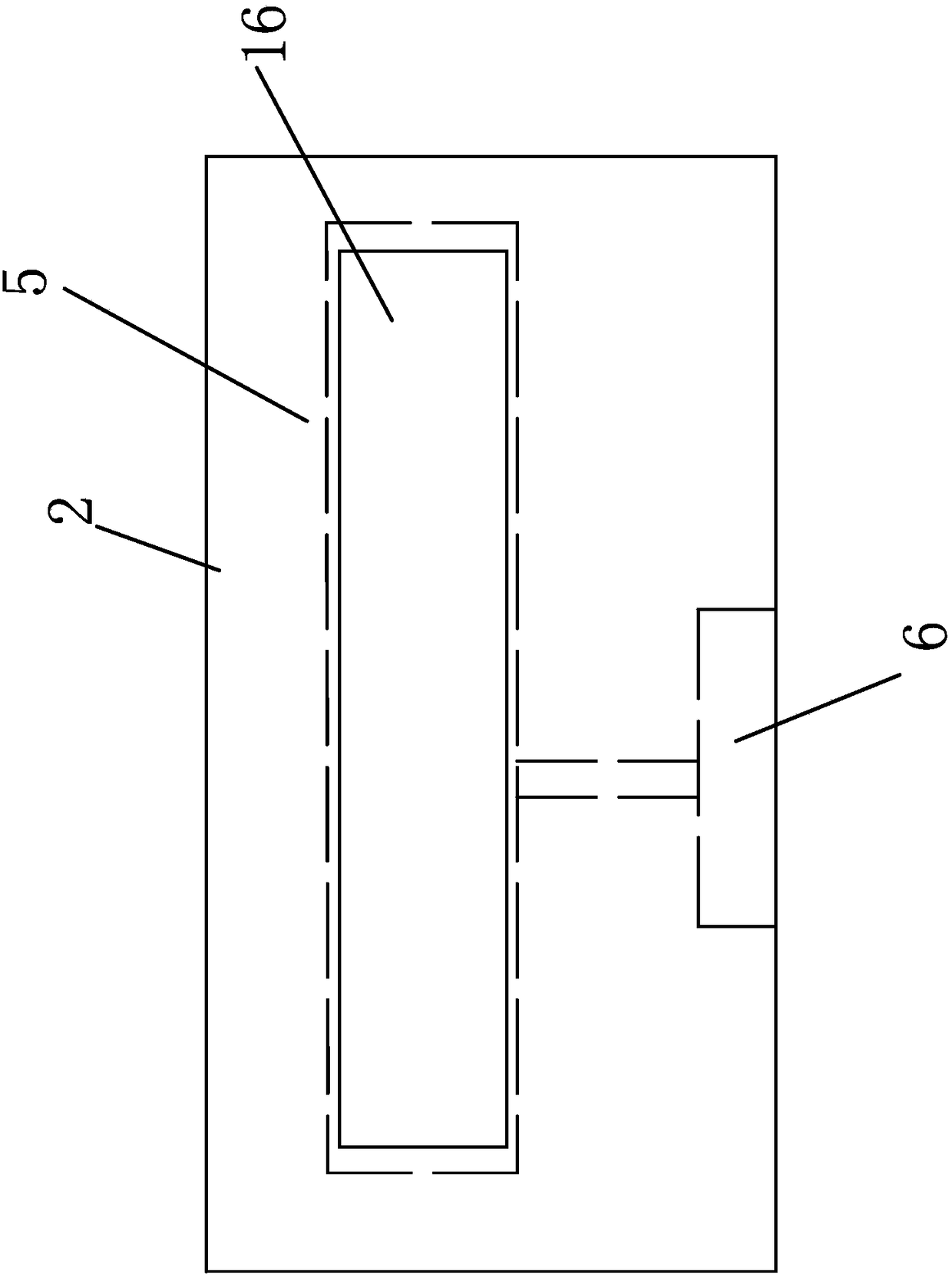

[0019] Such as figure 1 , 2 As shown, the technical solution of the present invention is a new type of drying cylinder for producing PVC calendered film, including a cylinder body 1, and the cylinder body 1 is sequentially provided with a storage hopper 2, a seasoning mechanism 3, and a discharge mechanism from top to bottom. Mechanism, a filter screen 4 is provided at the storage outlet 16 at the lower end of the storage hopper 2, and the filter screen 4 plays the role of screening raw materials. The seasoning mechanism 3 includes a moving plate 5 and a cylinder 6. The moving plate 5 is located directly below the material storage outlet 16 at the lower end of the storage hopper 2. The piston rod of the cylinder 6 is connected to the moving plate 5. When there are too many raw materials to be dried in the cylinder 1, the cylinder 6 can be activated at this time. , so that the moving plate 5 is stuck at the material storage outlet 16, so that the flow of raw materials can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com