Seed drying system

A drying system and seed technology, applied in drying, dryers, drying solid materials, etc., can solve the problems of large investment in fixed tower dryers, difficulty in guaranteeing grain quality, and affecting seed quality, etc., to reduce drying The effect of dry workload, small footprint, and prevention of germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

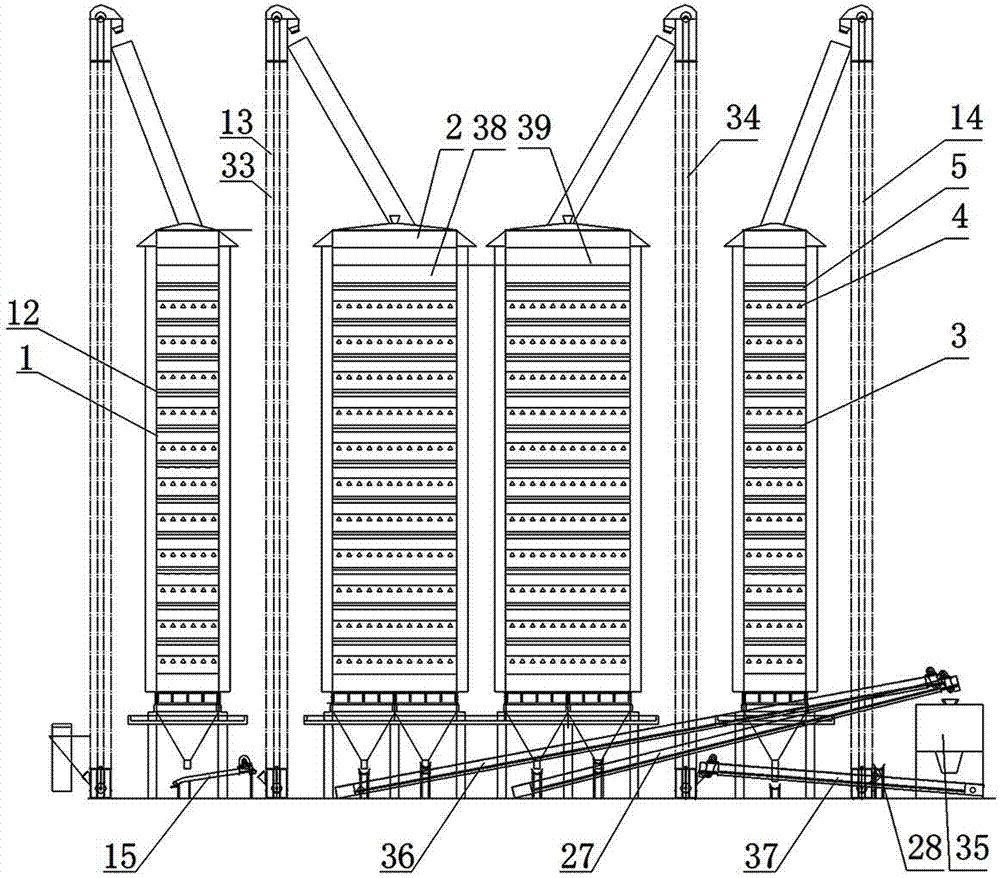

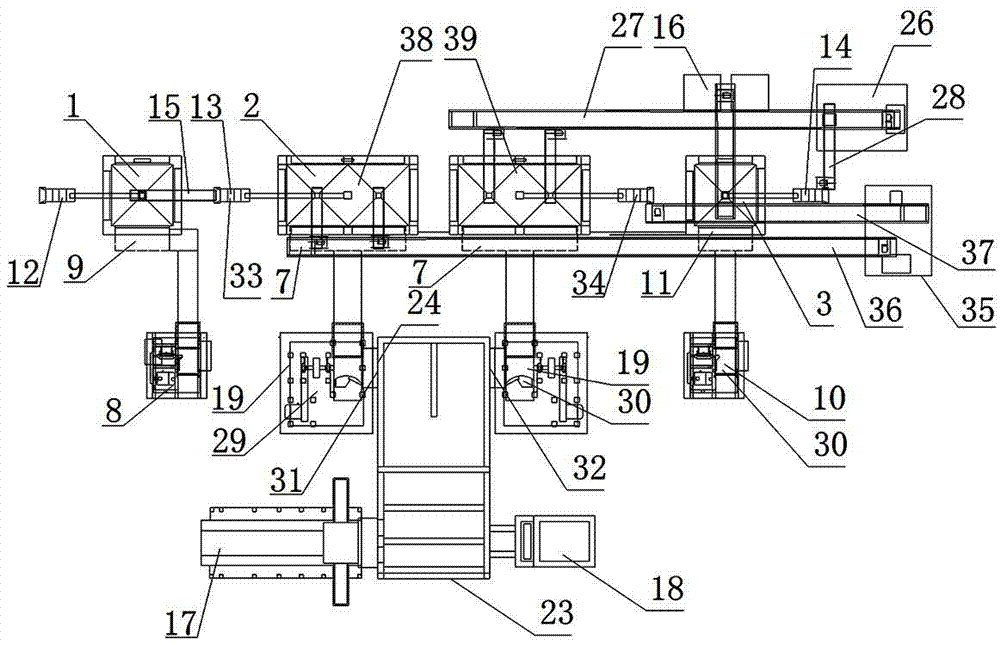

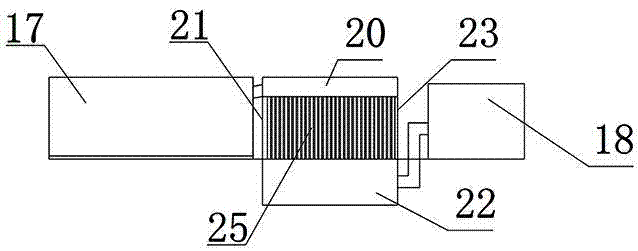

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the seed drying system, the seed drying system, includes a pre-storage tower 1, a drying tower 2, a cooling tower 3, a hot air blast device for blowing hot air into the drying tower 2, and two cold air blowers , the pre-storage tower 1, the drying tower 2, and the cooling tower 3 all include a tower body, a feed inlet arranged at the upper part of the tower body, a discharge outlet arranged at the lower part of the tower body, and an inlet arranged at the front side outside the tower body. The air cavity and the air inlet pipe 4 and the air outlet pipe 5 arranged inside the tower body, the air inlet chamber is a closed cavity, and the air inlet pipe 4 and the air outlet pipe 5 are arranged at intervals along the direction from bottom to top in the tower body. The distance between the adjacent air inlet pipe 4 and the air outlet pipe 5 in the height direction is 0.5 ~ 1m. Ventilation holes 6 are arranged on...

Embodiment 2

[0031] Such as Figure 5 , Figure 4 Shown, seed drying system, it comprises pre-storage tower 1, drying tower 2, cooling tower 3, is used to blow into the hot air blast device of hot blast in drying tower 2 and two cold blast blowers, described pre-storage Tower 1, drying tower 2, and cooling tower 3 all include a tower body, a feed inlet arranged on the upper part of the tower body, a discharge outlet arranged on the lower part of the tower body, an air inlet chamber arranged on the front side outside the tower body, and an The air inlet pipe 4 and the air outlet pipe 5 inside the tower body, the air inlet chamber is a closed cavity, the air inlet pipe 4 and the air outlet pipe 5 are arranged at intervals along the direction from bottom to top in the tower body, adjacent to the air inlet pipe 4 The distance from the air outlet pipe 5 in the height direction is 0.5-1m. The air inlet pipe 4 is arranged vertically and horizontally, and the air outlet pipe 5 is arranged horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com