Drying barrel structure for spinning

A drying barrel and drying box technology, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of user loss, reduce drying effect, waste of resources, etc., achieve convenient installation, increase drying Efficiency, the effect of increasing drying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

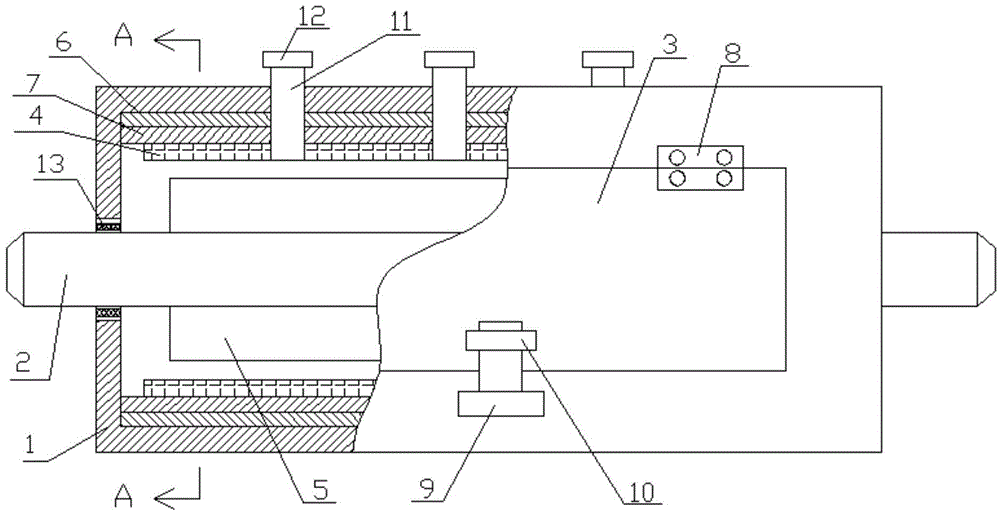

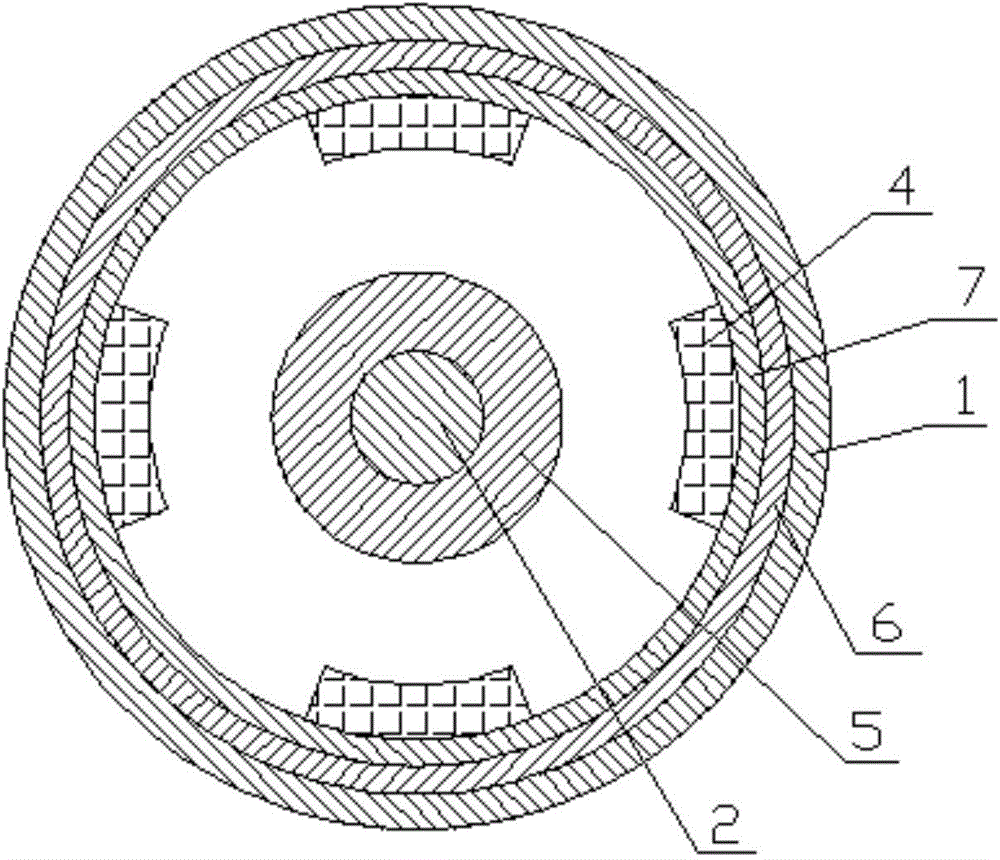

[0013] refer to figure 1 with figure 2 The shown structure of a drying barrel for textiles includes a drying barrel body 1, a rotating shaft 2 arranged on the drying barrel body 1, a door 3 arranged on the drying box body 1, and a The dryer 4 on the drying box body 1, the rotating shaft 2 is set through the drying box body 1, and the rotating shaft 2 in the drying oven body 1 is sleeved with a drum 5 that can wrap textiles. The inner wall of the drying barrel body 1 is provided with a drying film 6, and an insulating layer 7 is arranged on the outer surface of the drying film 6. The dryer 4 is arranged on the drying barrel equipped with the drying film 6 and the insulating layer 7. On the inner wall of the body 1, a living hinge 8 is provided on the drying barrel body 1, the box door 3 is hinged on the living hinge 8, and a first buckle 9 is provided on the drying barrel body 1 , A second buckle 10 matched with the first buckle 9 is provided on the box door 3, and three air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com