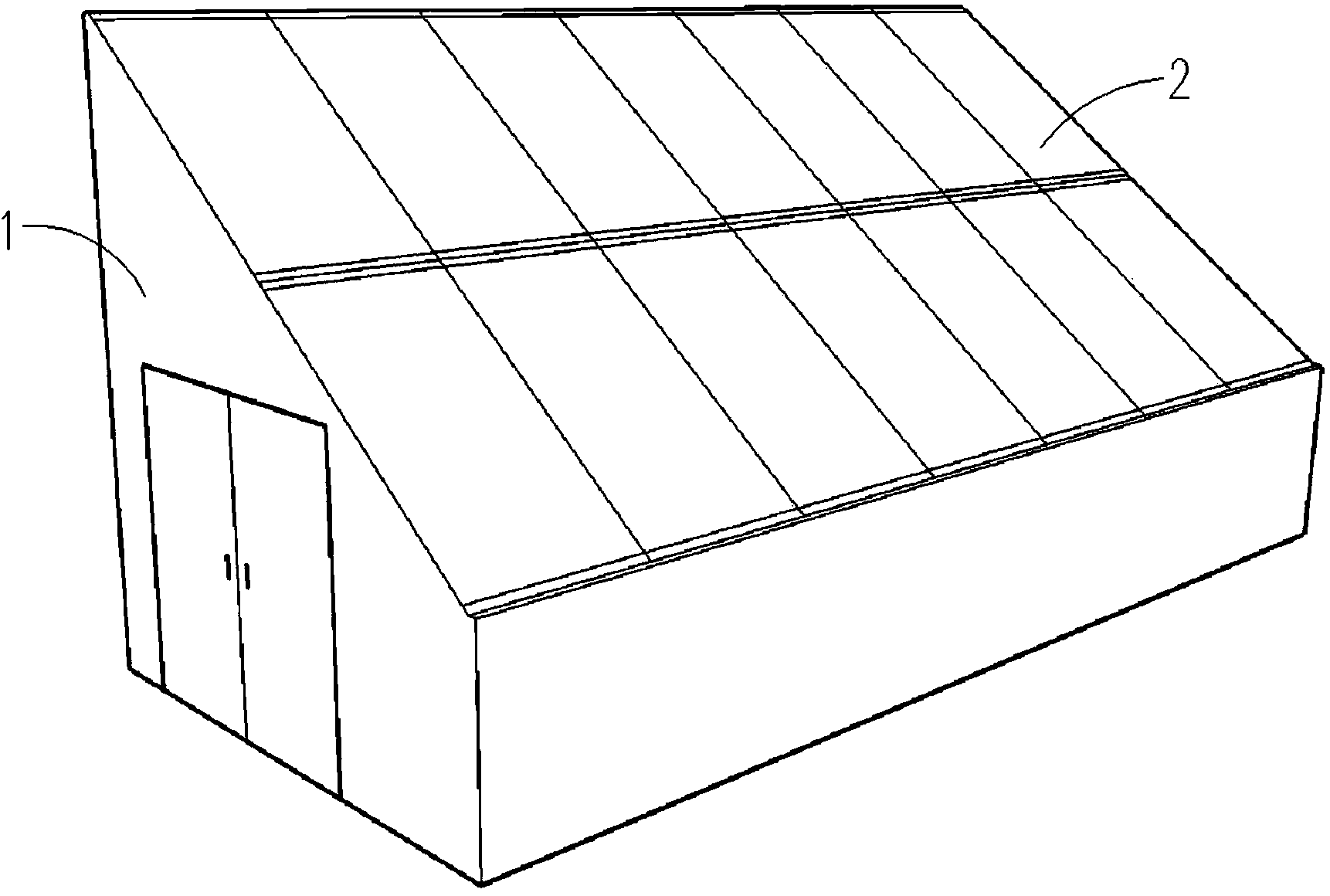

Monolithic moveable energy-saving drying room

A mobile drying room technology, applied in the field of solar energy utilization, can solve the problems of uneven drying process and high energy consumption cost of the drying room, and achieve the effects of convenient movement, uniform drying effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

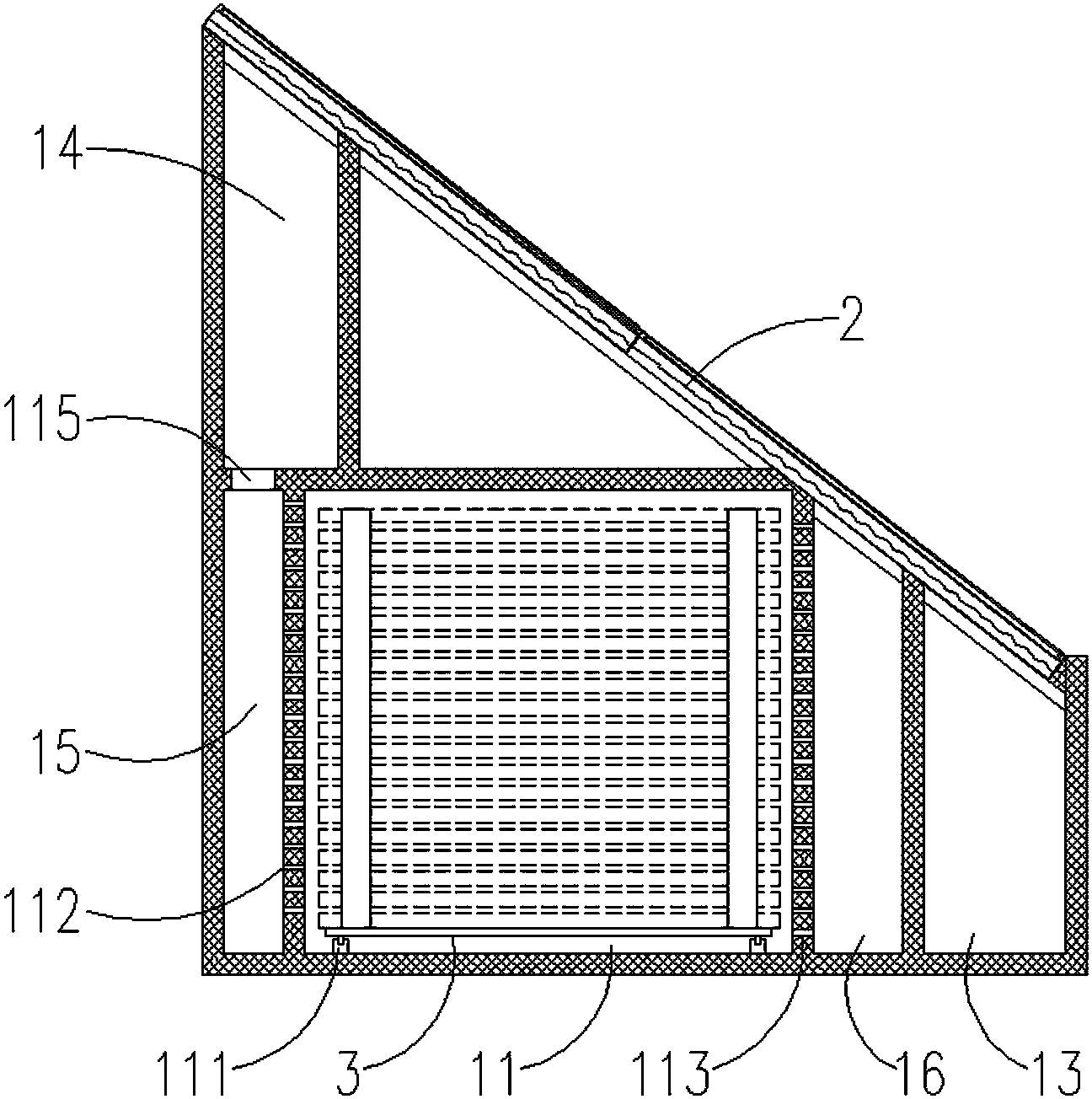

[0025] 1. Open the door 114 on the outer wall of the drying chamber 11, spread the products that need to be dried evenly in the drying tray, and place them layer by layer on the drying rack 3 in the drying chamber 11, and dry them The frame 3 is reasonably moved and arranged along the guide rail, and the door 114 is closed to make the inside of the drying room in a sealed state.

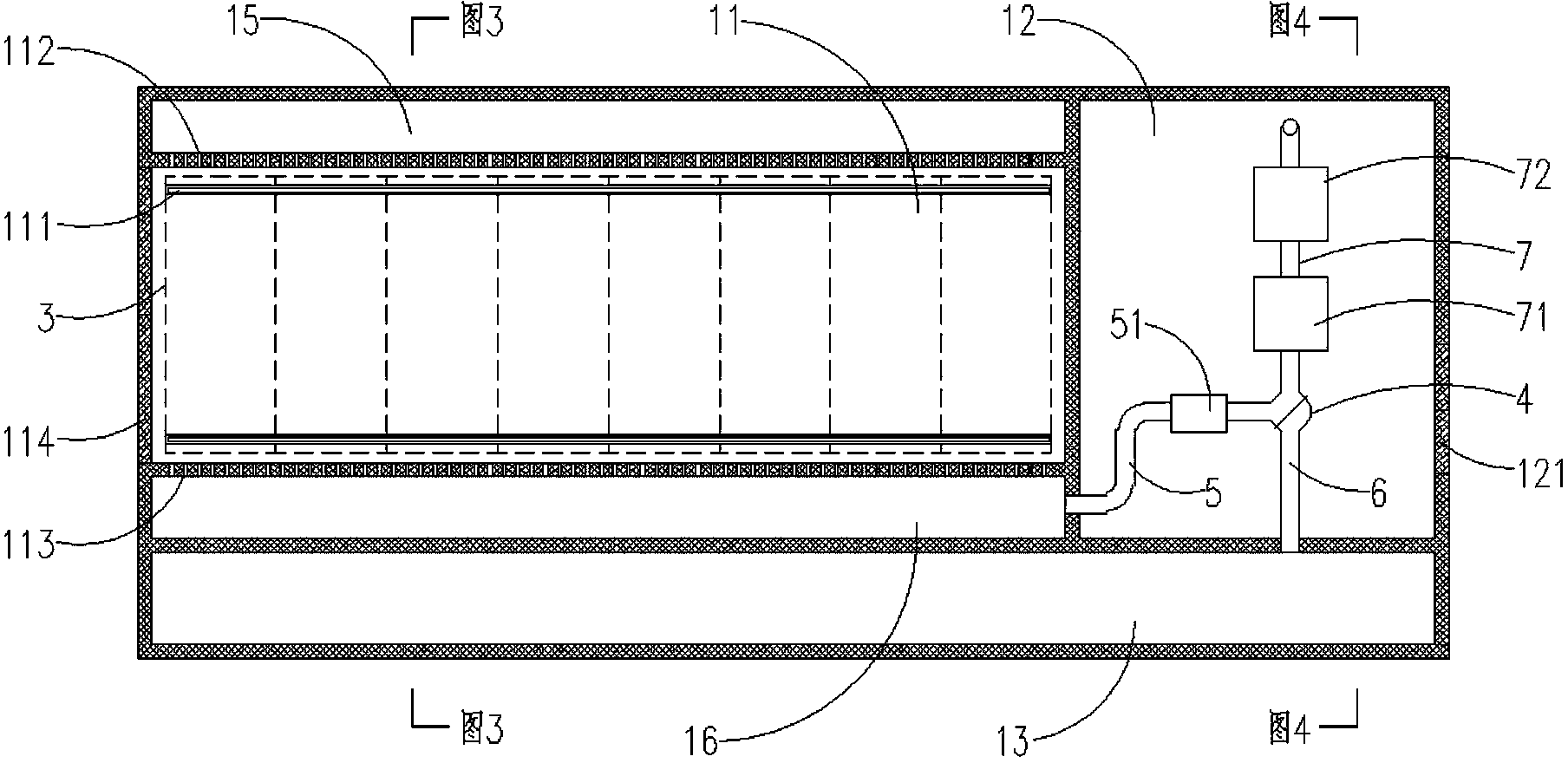

[0026] 2. Turn on the circulation pressure pump 51 installed on the exhaust pipe 5, adjust the pipeline diversion device 4 to set the loop air flow in the solar circulation pipeline 6 and the auxiliary heating circulation pipeline 7, and divide into two circulations: one way is from the solar circulation pipeline 6 through the solar air The heat collector inlet passage 13 flows into the solar air heat collector plate 2 to be heated, then flows into the drying chamber air inlet passage 15 through the solar air heat collector outlet passage 14, and then blows evenly to the drying chamber through the air...

Embodiment 2

[0029] The overall mobile energy-saving drying room adopts an intelligent control system to separately control the circulating pressure pump 51, the pipeline diversion device 4, the auxiliary heating device 71, and the gas dehumidification device 72. The measured value of the temperature is used to set the opening of the circulation pressure pump 51, the size of the split flow of the pipeline splitting device 4 and the opening of the auxiliary heating device 71. The system can automatically control the opening of the gas dehumidification device 72 by setting the humidity of the gas in the auxiliary heating circulation pipeline 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com