Tea oven-drying equipment with dehumidification module

A kind of drying equipment and tea technology, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of local overdrying, uneven temperature of the device, poor drying effect, etc., achieve uniform drying effect, good drying effect, and benefit saved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

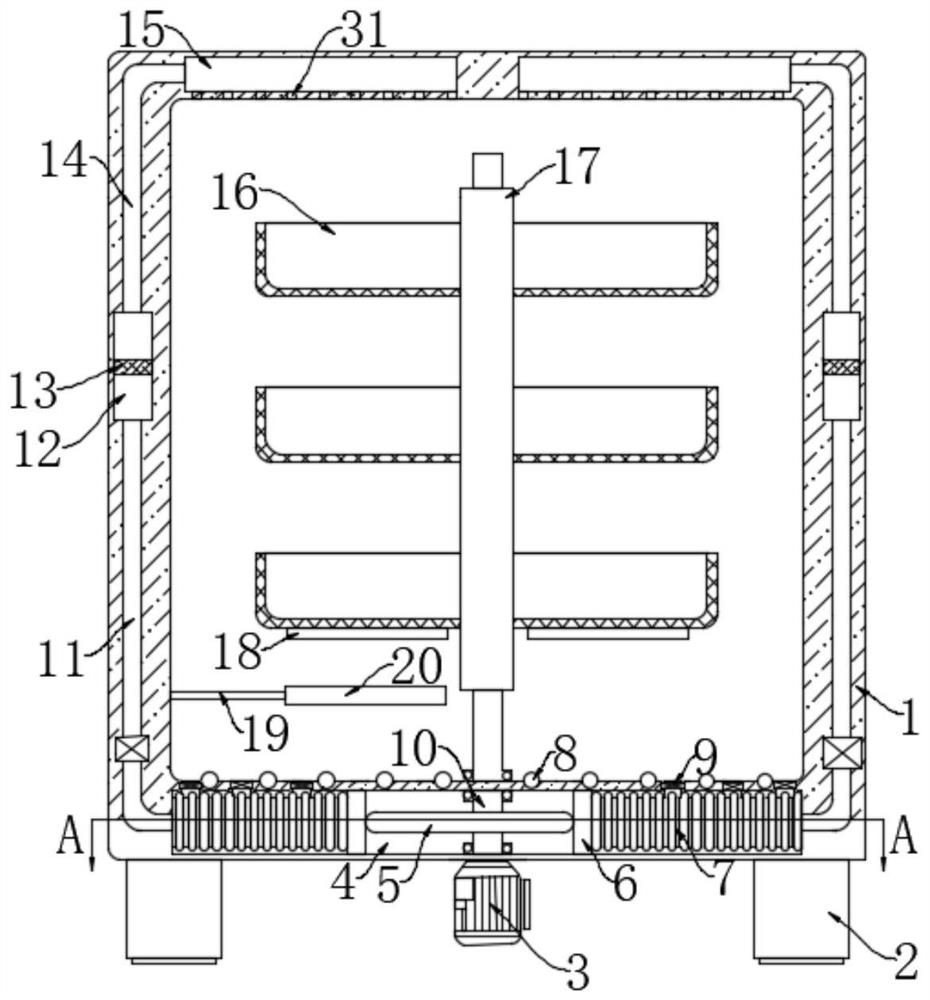

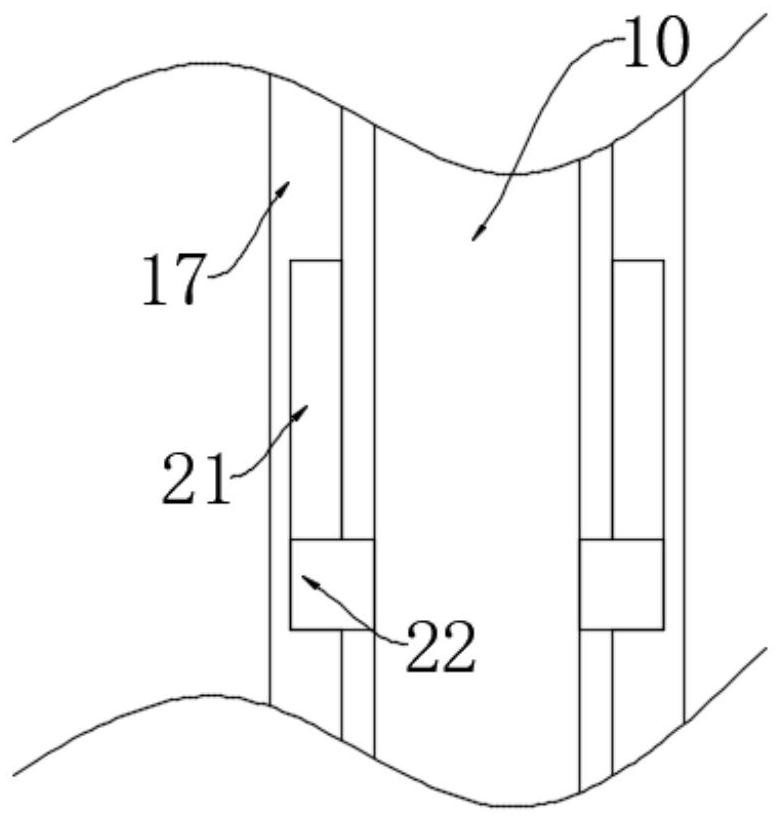

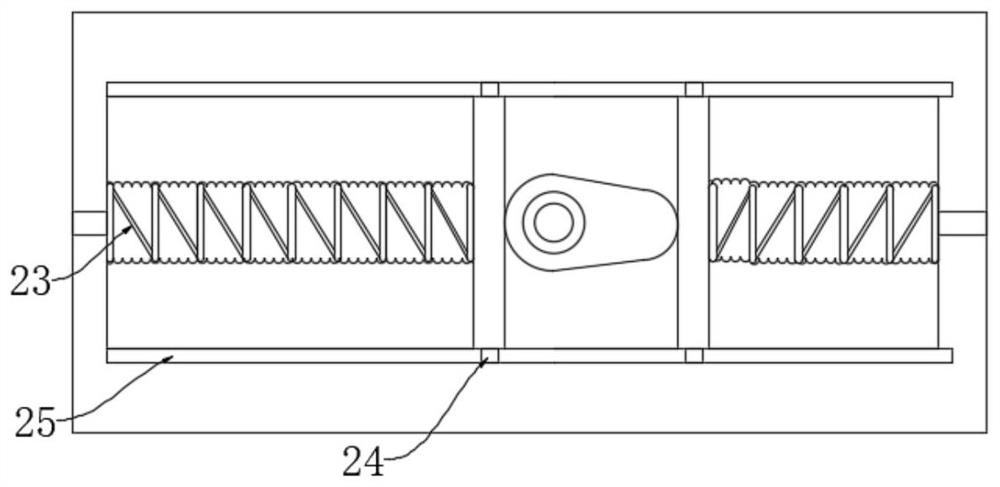

[0026] refer to Figure 1-4 , a tea drying device with a dehumidification module, comprising a housing 1, two supporting blocks 2 are symmetrically arranged at the lower end of the housing 1, the supporting blocks 2 support the housing 1, and the housing 1 is provided with a drying Chamber 30, telescopic chamber 4 and two long chambers 15, the two long chambers 15 are located above the drying chamber 30, the telescopic chamber 4 is located below the drying chamber 30, and the housing 1 is symmetrically provided with two dehumidification chambers 12 , the two dehumidification chambers 12 are respectively located on both sides of the drying chamber 30, the inner bottom of the drying chamber 30 is provided with a heating wire 8, and the heating wire 8 is energized to heat the gas in the drying chamber 30;

[0027] Compression mechanism, the compression mechanism includes a drive motor 3 arranged under the housing 1, the end of the output shaft of the drive motor 3 extends into th...

Embodiment 2

[0035] refer to Figure 5-7 , The difference between this embodiment and Embodiment 1 is that the upper end of the first rotating rod 10 is fixedly connected with a worm 26, and the upper end of the worm 26 is rotatably connected with the inner top of the drying chamber 30, and the drying chamber 30 is horizontally provided with The second rotating rod 28, the two ends of the second rotating rod 28 are connected with the inner walls on both sides of the drying cavity 30 in rotation, the second rotating rod 28 is fixedly connected with the worm wheel 27 matched with the worm screw 26, and the rotation of the worm screw 26 can drive The worm wheel 27 rotates at a low speed, and the second rotating rod 28 is provided with a plurality of disturbing rods 29 along its circumference.

[0036] In this embodiment, the rotation of the first rotating rod 10 drives the rotation of the worm screw 26, the rotation of the worm screw 26 drives the rotation of the worm wheel 27, the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com