Temperature control type loop heat pipe evaporator assembly

A loop heat pipe and evaporator technology, applied in the field of spacecraft thermal control, can solve the problems of temperature rise of the controlled heat source, drastic temperature change of the condenser, exceeding the index, etc., and achieve enhanced heat transfer coefficient and heat flux density, precise control The effect of heat source temperature and layout is flexible and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

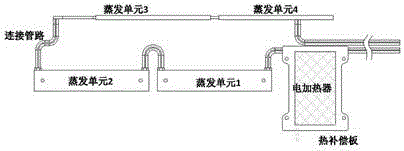

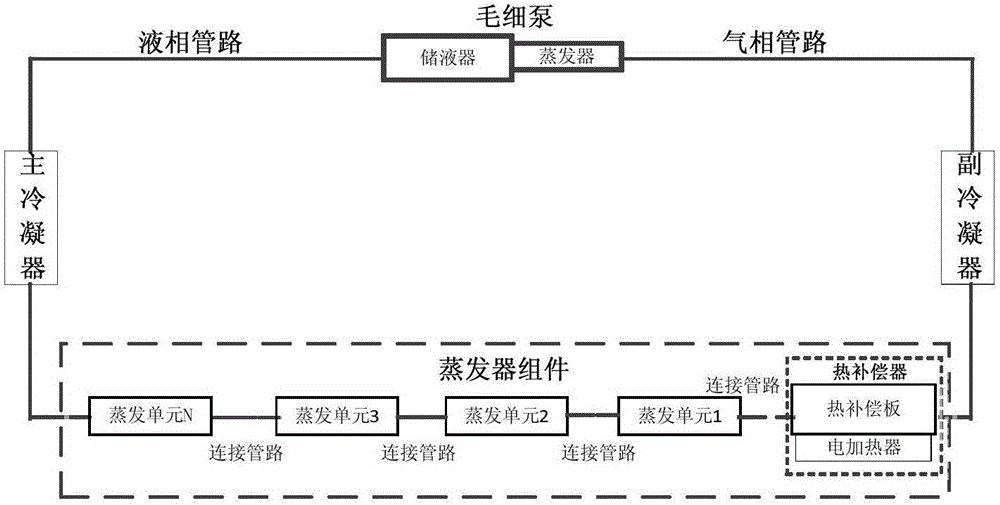

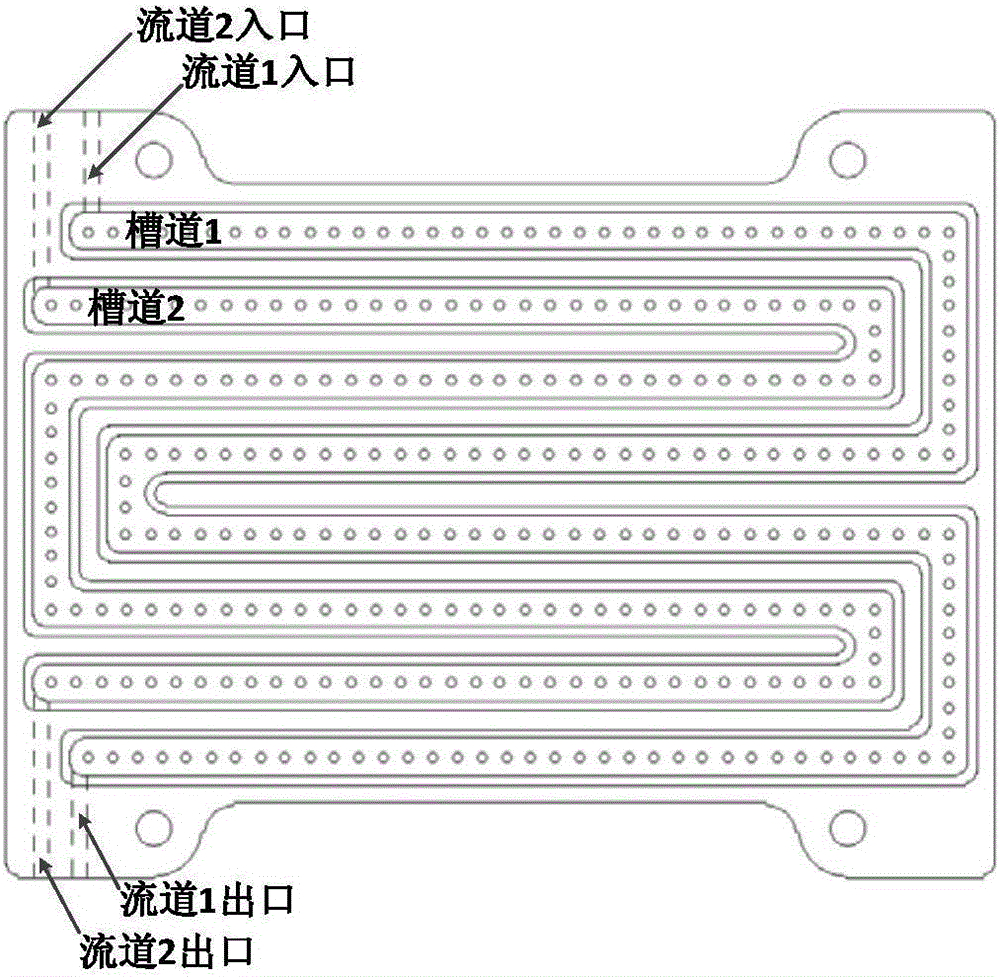

[0022] As a modified product of the traditional loop heat pipe, the temperature-controlled loop heat pipe realizes the separation of the capillary pump and the heat source, and carries heat by designing the evaporator assembly (heat source cold plate assembly) to couple with the heat source. The evaporator assembly consists of multiple evaporating units, which are connected in series / parallel by flexible pipes. The advantages of high temperature accuracy. This makes the advantages of the loop heat pipe more prominent when it is applied to the precise temperature control of the distributed heat source of the spacecraft.

[0023] Such as figure 1 As shown, the temperature-controlled loop heat pipe is mainly composed of a capillary pump, an auxiliary condenser, an evaporator assembly, a main condenser, a gas phase pipeline, and a liquid phase pipeline. When the surface of the capillary core (the right end of the capillary pump) in the capillary pump is heated, the liquid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com