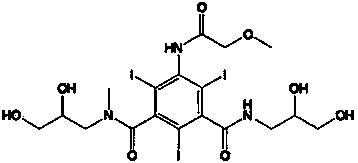

Iopromide decoloring and purifying process

A technology of iopromide and process, applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems of waste water environmental pollution, low yield, complex operation of iopromide decolorization and purification process, etc., and achieve large adsorption capacity , easy industrial production, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Sample preparation: take by weighing 40g iopromide crude product (purity 95%), join in 200ml deionized water, stir to make sample dissolve completely, after using filter paper to filter for subsequent use.

[0024] Iopromide decolorization and purification: use HZ PS 20ss resin as the chromatographic column, equilibrate the chromatographic column with twice the column volume of deionized water at a flow rate of 1 column volume per hour; 2 times the column volume flow rate continuously flows through the column to load the sample. After loading the sample, use deionized water as the mobile phase, elute with 2 times the column volume / hourly flow rate, and after elution of 1 times the column volume, measure the purity with a high-performance liquid chromatograph for every 0.5 times the column volume of elution. The eluent with purity greater than 99% merges to obtain the collected solution; most of the iopromide flows out in the collected solution of 2 times of column volum...

Embodiment 2

[0027] Sample preparation: Weigh 24g of crude iopromide (purity 96.5%), add it to 200ml deionized water, stir to dissolve the sample completely, and then filter it with filter paper for later use.

[0028] Iopromide decolorization and purification: use HZ PS 818 resin as the chromatographic column of the chromatographic filler, equilibrate the chromatographic column with twice the column volume of deionized water at a flow rate of one column volume per hour; The flow rate of 3 times the column volume continuously flows through the chromatographic column to load the sample. After the sample is loaded, use deionized water as the mobile phase and elute at a flow rate of 3 times the column volume / hour. After elution of 1 times the column volume, every elution The column volume is measured once with high-performance liquid chromatography, and the eluent with a purity greater than 99% is combined to obtain a collection solution; in this embodiment, most of the iopromide flows out in ...

Embodiment 3

[0031] Sample preparation: Weigh 64g of crude iopromide (purity 98%), add it to 400ml deionized water, stir to dissolve the sample completely, and then filter it with filter paper for later use.

[0032] Iopromide decolorization and purification: use HZ PS 20ss resin as a chromatographic column, use twice the column volume of deionized water to equilibrate the chromatographic column at a flow rate of one column volume per hour; 4 times the column volume flow rate continuously flows through the chromatographic column to load the sample. After the sample is loaded, use deionized water as the mobile phase and elute at a flow rate of 4 times the column volume / hour. After elution of 1 times the column volume, each elution The column volume measures the purity once with high performance liquid chromatography, and the eluent with a purity greater than 99% is combined to obtain the collected liquid; most of the iopromide flows out in 4 times the column volume eluent (collected liquid) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com