Method for degrading crude oil with bacillus

A technology based on bacillus and crude oil, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of difficult removal of crude oil pollution, crude oil leakage and pollution, environmental and ecological damage, etc., to achieve Low cost, good effect, and low degradation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

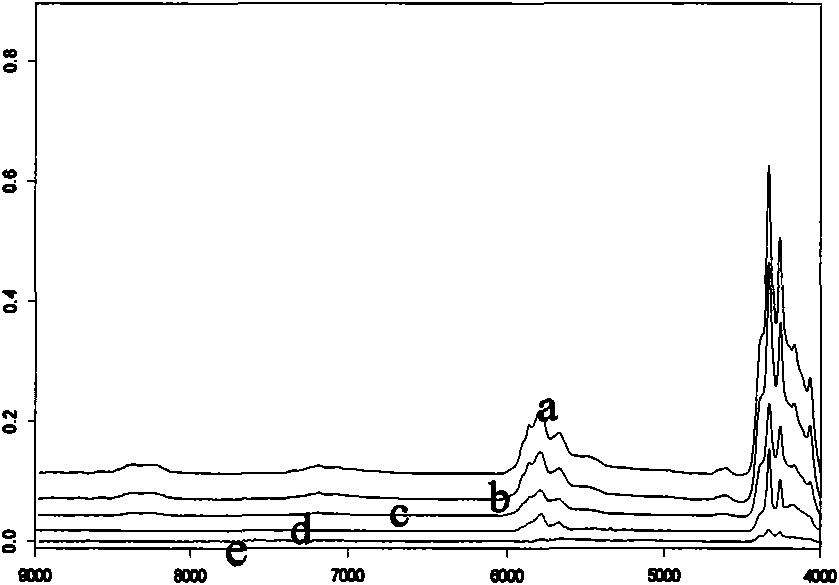

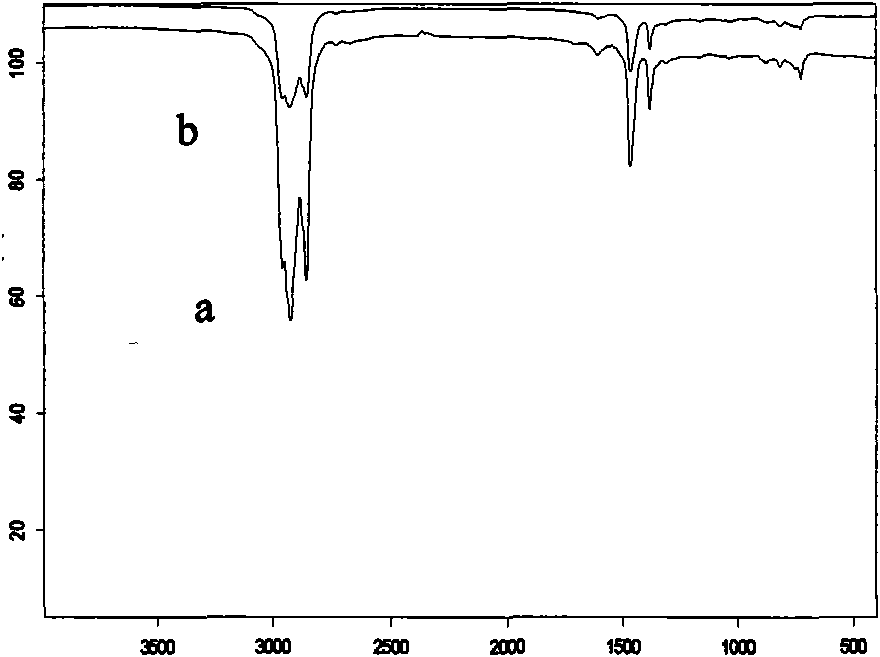

[0020] Set the concentration to 10 7 ~10 8 1ml Bacillus licheniformis bacteria solution per ml was inoculated into 100ml crude oil culture solution with a mass concentration of about 2% to prepare a degradation solution, and the degradation solution was degraded for 10 days at a temperature of 30-37°C and a shaking condition of 180r / min , using an infrared spectrometer to detect the degraded solution for 10 days, and the near-infrared spectrum is obtained as figure 1 As shown in c, the mid-infrared spectrum is shown in figure 2 shown in b.

Embodiment 2

[0022] Set the concentration to 10 7 ~10 8 Inoculate 1ml Bacillus licheniformis bacteria solution per ml into 100ml crude oil culture solution with a mass concentration of about 2% to prepare a degradation solution, and degrade the degradation solution for 15 days at a temperature of 30-37°C and a shaking condition of 180r / min , using an infrared spectrometer to detect the degraded solution for 15 days, and the near-infrared spectrum is obtained as figure 1 d as shown in

Embodiment 3

[0024] Set the concentration to 10 7 ~10 8 Inoculate 1ml Bacillus licheniformis bacteria solution per ml into 100ml crude oil culture solution with a mass concentration of about 2% to prepare a degradation solution, and degrade the degradation solution for 20 days at a temperature of 30-37°C and a shaking condition of 180r / min , using an infrared spectrometer to detect the degradation solution degraded for 20 days, the near-infrared spectrum is obtained as figure 1 e as shown in

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com