Method for preparing Fe3+doped TiO2 hollow sphere catalyst and application thereof

A technology of hollow spheres and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problems of no literature reports, etc., to improve utilization rate and reduce The effect of degradation cost and degradation efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

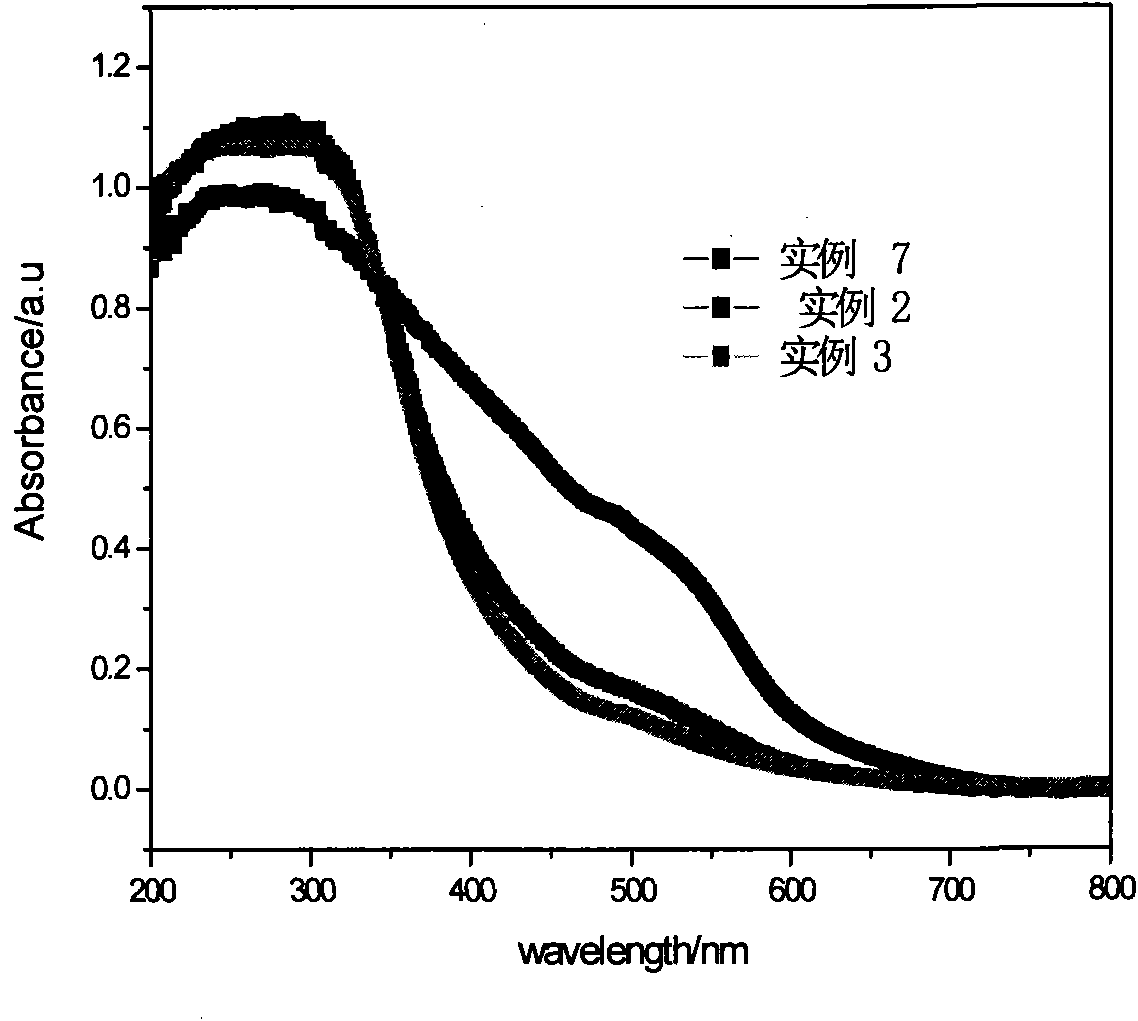

example 1

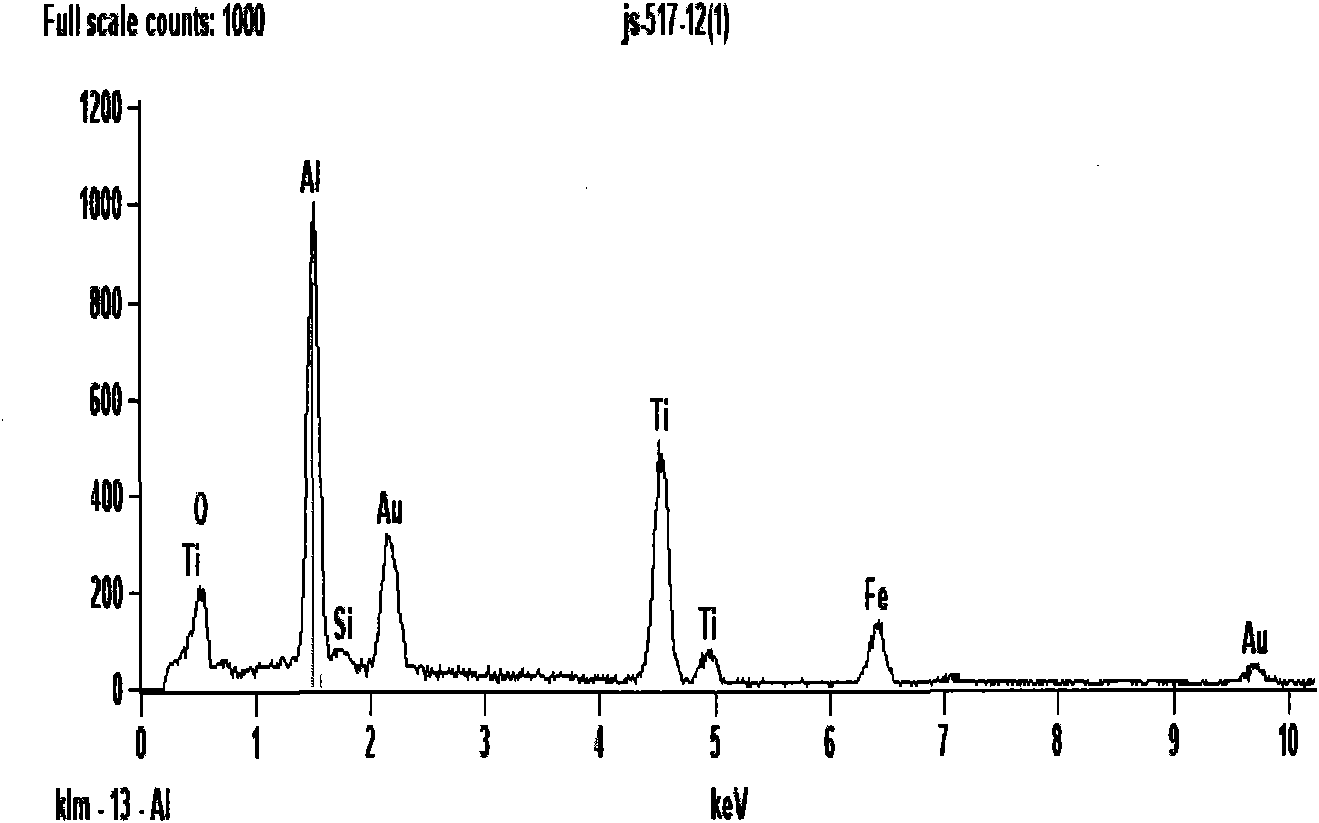

[0022] 1) Weigh 0.00119g of ferric chloride hexahydrate into a three-necked flask with stirring, measure 30ml of absolute ethanol, and prepare an ethanol solution of ferric chloride. Then weigh 0.06g of nano-carbon spheres, the diameter of which is in the range of 100-200nm, add 0.3ml of distilled water into it, and ultrasonically disperse until evenly mixed.

[0023] 2) Add 30 ml of absolute ethanol into a dry constant pressure dropping funnel, measure 0.3 ml of n-butyl titanate and add it to prepare an ethanol solution of n-butyl titanate.

[0024] 3) Slowly add n-butyl titanate ethanol solution into the mixed solution obtained in step 1) under stirring condition, stir, and heat to reflux at 80° C. for 6 h. After the reflux is completed, continue to stir for 30 minutes, centrifuge, wash, and dry to obtain Fe 3+ Carbon / titania core-shell particles.

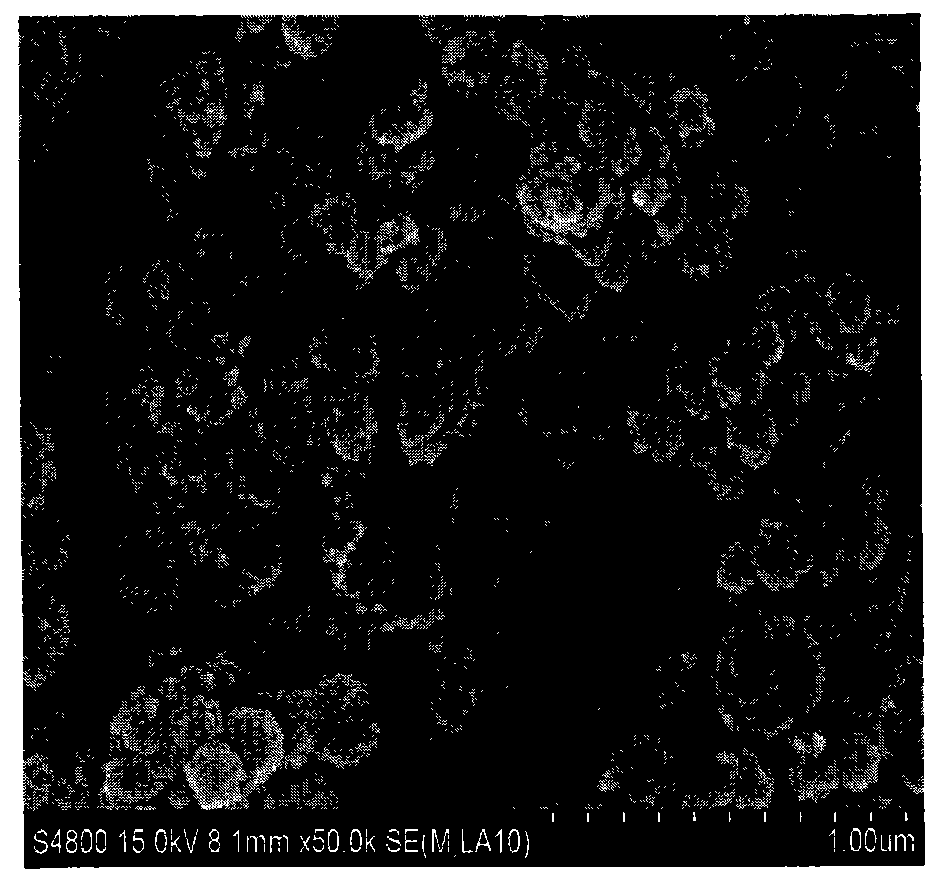

[0025] 4) with the Fe obtained in step 3) 3+ Doped carbon / titanium dioxide core-shell particles are burned in a mufur furnac...

example 2

[0028] 1) Weigh 0.00238g of ferric chloride hexahydrate into a three-necked flask with stirring, measure 50ml of absolute ethanol, and prepare an ethanol solution of ferric chloride. Then weigh 0.06g of nano-carbon spheres, the carbon spheres have a diameter ranging from 100 to 200nm, add 0.5ml of distilled water into it, and ultrasonically disperse until they are evenly mixed.

[0029] 2) Add 50 ml of absolute ethanol into a dry constant-pressure dropping funnel, measure 0.3 ml of n-butyl titanate and add it to prepare an ethanol solution of n-butyl titanate.

[0030] 3) Slowly add n-butyl titanate ethanol solution into the mixed solution obtained in step 1) under stirring condition, stir, and heat to reflux at 80° C. for 6 h. After the reflux is completed, continue to stir for 30 minutes, centrifuge, wash, and dry to obtain Fe 3+ Doped carbon / titania core-shell particles.

[0031] 4) with the Fe obtained in step 3) 3+ Fe 3+ Doped TiO 2 Open or closed hollow sphere photo...

example 3

[0034] 1) Weigh 0.0119g of ferric chloride hexahydrate into a three-necked flask with stirring, measure 80ml of absolute ethanol, and prepare an ethanol solution of ferric chloride. Then weigh 0.6g of nano-carbon spheres, the diameter of which is in the range of 100-200nm, add 3ml of distilled water into it, and ultrasonically disperse until uniformly mixed.

[0035] 2) Add 80 ml of absolute ethanol to a dry constant pressure dropping funnel, measure 3 ml of n-butyl titanate and add it to prepare an ethanol solution of n-butyl titanate.

[0036] 3) Slowly add n-butyl titanate ethanol solution into the mixed solution obtained in step 1) under stirring condition, stir, and heat to reflux at 90° C. for 5 h. After the reflux is completed, continue to stir for 2 hours, centrifuge, wash, and dry to obtain Fe 3+ Doped carbon / titania core-shell particles.

[0037] 4) with the Fe obtained in step 3) 3+ Fe 3+ Doped TiO 2 Open or closed hollow sphere photocatalyst, wherein Fe / Ti mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com