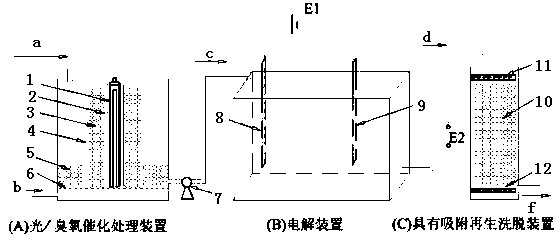

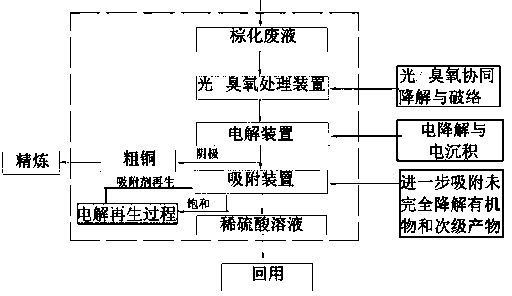

Light/ozone-electricity-adsorption reaction device and method for extracting copper by degrading browning waste liquor

An adsorption reaction and electrolysis device technology, which is applied in the field of light/ozone-electricity-adsorption multi-step synergistic reaction devices, can solve problems such as difficult to break coordination bonds, and achieve the effects of simple manufacturing, cost reduction, and low degradation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] Add 5g of titanium dioxide-supported catalyst, add 20g of manganese dioxide-supported catalyst, add 300ml of the original browning waste liquid (total Cu2+ concentration, 48.5g / L, COD value is about 50000) from (a) tube, and pass it into (b) OZ type ozone generator blows into 3mg / L ozone, and treats it under 8w ultraviolet lamp for 4h; then puts all the ozone into the electrolysis chamber, and adjusts the cathode liquid junction area under the constant current of 0.8A, so that the current density is 4A / dm 2 , adjust the distance between the two poles to 3-8cm, make the voltage in the range of 3-5V, carry out electrolysis for 10 hours, after electrolysis, the solution is passed into the adsorption chamber for 2 hours, the COD value drops to 1208, the copper recovery rate reaches 57.3%, and the copper removal rate in the solution It reached 72.5%, and the current efficiency of electrolytic copper deposition was 53.7%. The electrolysis energy consumption per unit volume of...

Embodiment approach 2

[0039] Add 500ml of the original browning waste liquid (total Cu2+ concentration is 48.5g / L, COD value is about 50000) to the light / ozone chamber treatment room after scheme 1, and treat it under 8w ultraviolet lamp and ozone concentration of 4mg / L 4h, under 1A constant current, adjust the cathode liquid junction area, so that the current density is 5A / dm 2 , and adjust the distance between the two poles to be 3-8cm, so that the voltage is in the range of 3-5V, and the electrolysis is carried out for 10 hours. After electrolysis, the solution is passed into the adsorption chamber for 2 hours, the COD value drops to 1349, the copper recovery rate reaches 49.6%, and the copper in the solution is removed The rate reached 65.3%, and the current efficiency of electrolytic copper deposition was 52.7%. The electrolysis energy consumption per unit volume of browning solution is 0.059KW·h / L, and the total energy consumed for degrading unit volume of browning waste solution is 0.637KW·h...

Embodiment approach 3

[0041] Add 500ml of the original browning waste liquid (total Cu2+ concentration is 40g / L, COD value is about 55000) to the light / ozone chamber treatment room after scheme 2, and treat it under 8w ultraviolet lamp and ozone concentration of 5mg / L for 4h , under 1A constant current, adjust the cathode liquid junction area to make the current density 3A / dm 2 , and adjust the distance between the two poles to 3-8cm, so that the voltage is in the range of 3-5V, and the electrolysis is performed for 10 hours. After electrolysis, the solution is passed into the adsorption chamber for 2 hours, the COD value drops to 2000, the copper recovery rate reaches 52.3%, and the copper in the solution is removed The rate reached 52.3%, and the current efficiency of electrolytic copper deposition was 53.9%. The electrolysis energy consumption per unit volume (1L) of browning solution is 0.055KW·h, and the total energy consumed for degrading a unit volume (1L) of browning waste solution is 0.633...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com