Degradation method of konjac glucomannan

A technology of konjac glucomannan and konjac flour, which is applied in the field of degradation of konjac glucomannan, can solve the problems of energy consumption and time-consuming, and achieve the effect of saving degradation cost and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

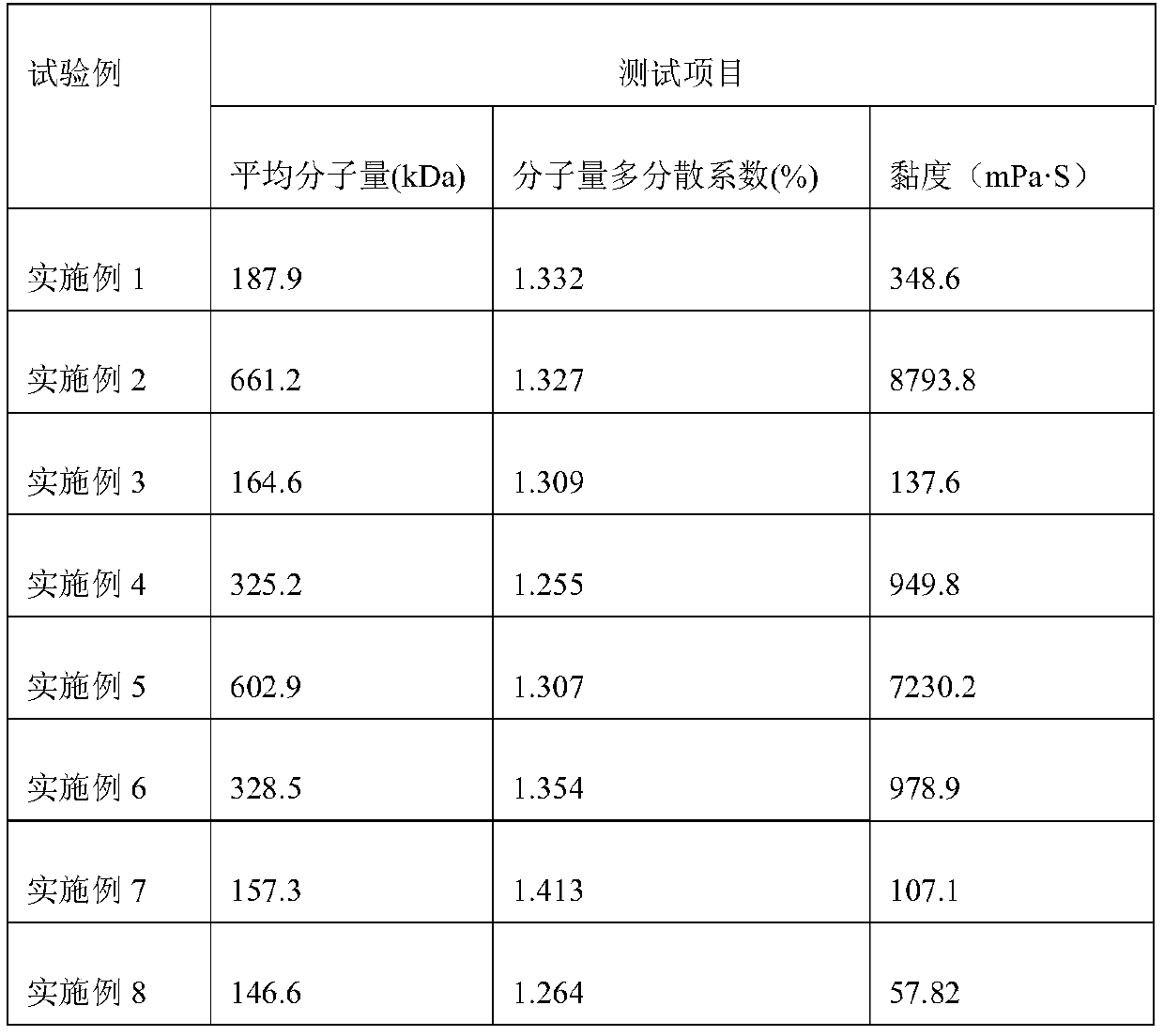

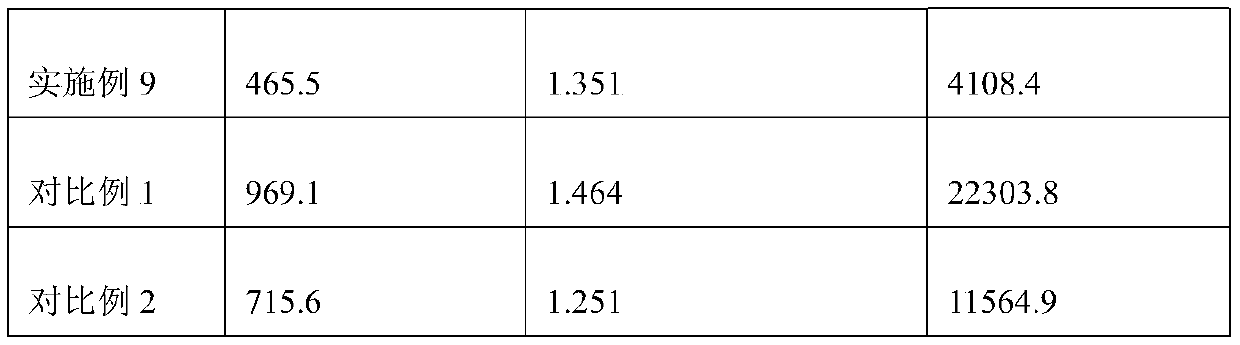

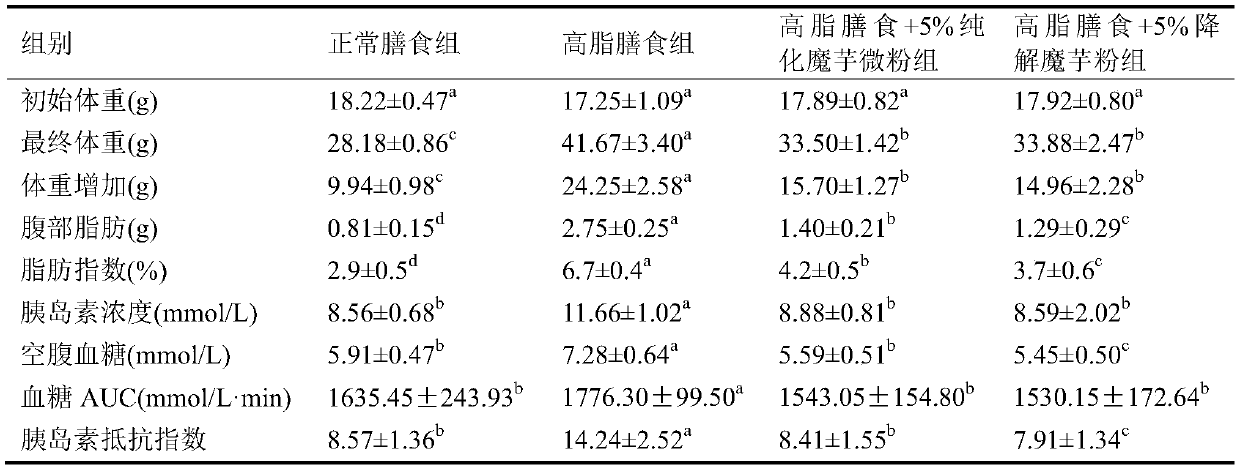

Examples

Embodiment 1

[0032] The present embodiment provides a kind of degradation method of konjac glucomannan, comprising the following steps:

[0033] S1, preparation of water-containing konjac flour mixture: take 0.5kg of purified konjac powder (glucomannan content ≥ 90%, molecular weight 1133.6kDa), add 20% distilled water by weight, grind to make water and polysaccharide fully mix, get water-containing konjac powder mixture.

[0034] S2, heterogeneous wet heat degradation: the aqueous konjac flour mixture prepared in step S1 was placed in a sealed heating device, and the following process parameters were adopted: degradation temperature of 130°C, degradation pressure of 0.275 MPa, and degradation time of 30 minutes to obtain low molecular weight konjac polysaccharides.

[0035] S3, drying: take the low-molecular-weight konjac polysaccharide prepared in step S2 and place it in a blast drying oven, and dry it at 80° C. to a constant weight to obtain degraded konjac glucomannan, that is, degrade...

Embodiment 2

[0037] The present embodiment provides a kind of degradation method of konjac glucomannan, comprising the following steps:

[0038] S1, preparation of aqueous konjac flour mixture: 0.5kg of purified konjac powder (glucomannan content ≥ 90%, molecular weight 1133.6kDa), add 5% distilled water by weight, grind to make water and polysaccharide fully mix, get aqueous konjac flour mixture .

[0039] S2, heterogeneous wet heat degradation: the aqueous konjac flour mixture prepared in step S1 was placed in a sealed heating device, and the following process parameters were adopted: degradation temperature of 130°C, degradation pressure of 0.275 MPa, and degradation time of 30 minutes to obtain low molecular weight konjac polysaccharides.

[0040] S3, drying: take the low-molecular-weight konjac polysaccharide prepared in step S2, place it in a forced air drying oven, and dry it at 80° C. to constant weight to obtain degraded konjac flour.

Embodiment 3

[0042] This example provides a degradation method of konjac glucomannan, the raw materials and process steps used are basically the same as those in Example 1, the difference is that in step S1, the water-containing konjac flour mixture contains 40% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com