Method for catalytic alcoholysis of PLA (Polylactic Acid) by CaO/MCF (Mesocellular silica Foam) mesoporous basic molecular sieve

A technology of molecular sieve catalyzing alcohol and polylactic acid, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult separation of catalysts, complicated synthesis steps, harsh reaction conditions, etc., and achieves reusable performance. Good, simple recovery process, stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0045] Catalyst preparation:

[0046] P 123 (EO20PO70EO20) (MW: 5000) was purchased from Sigma; orthoethyl silicate (TEOS), 1,3,5 trimethylbenzene (analytical pure) and tetrahydrate and calcium nitrate (analytical pure) were purchased from Shanghai Sinopharm Chemical Reagent Co., Ltd. Company; concentrated hydrochloric acid (HCl) (36%-38%) analytically pure, purchased from Laiyang Economic and Technological Development Zone Fine Chemical Plant.

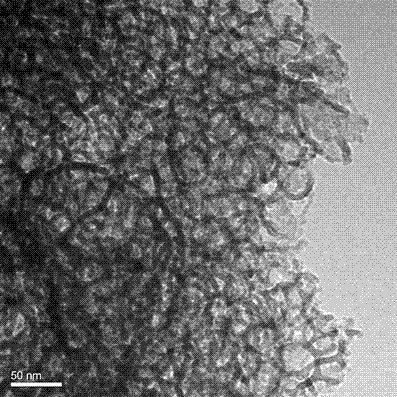

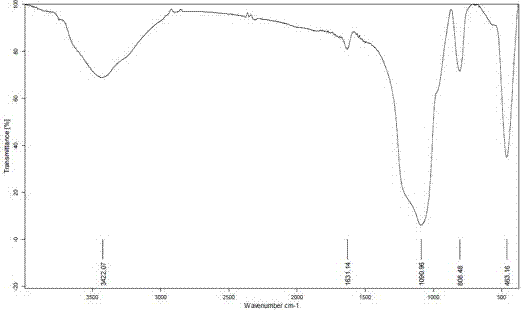

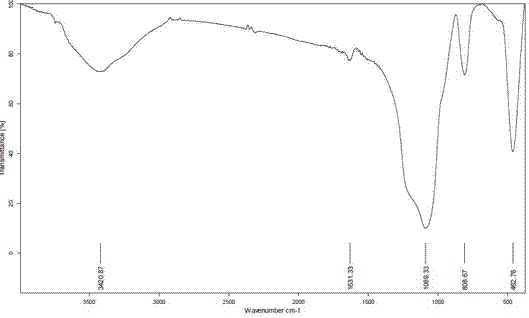

[0047] Preparation of MCF: Weigh 2 g of commercially available P123 as a template, soak it in an aqueous HCl solution with a concentration of 1.6 mol / L, stir at 38°C for 2 hours until P 123 Dissolve completely, add 2g of mesitylene and 23mg of NH 4 F is a pore-enlarging agent. After continuing to stir for 2 hours, add 4.5g of TEOS (tetraethyl orthosilicate) dropwise and acidify for 24 hours, then transfer it to a hydrothermal synthesis kettle for crystallization at 100°C for 24 hours, and filter, wash and dry the product , roasting...

Embodiment 12

[0052] In an autoclave with a thermometer, add 5g of PLA in sequence (the molecular weight of PLA is 2.0×10 4 ~6.0×10 4 g / mol), 11.2g methanol, 0.83g CaO / MCF (prepared in Example 1.1), stirred and reacted (300 rpm) at 120°C for 3h, after the reaction, filtered under reduced pressure to filter out unreacted polylactic acid The unreacted methanol is recovered by atmospheric distillation at 70°C with the catalyst and filtrate, and the product methyl lactate is obtained by distillation under reduced pressure at 100°C. The product 6.2 g of methyl lactate was obtained. The alcoholysis rate of polylactic acid is 92%, and the selectivity of methyl lactate is 85.90%.

Embodiment 13

[0054] In an autoclave with a thermometer, add 5g of PLA, 11.2g of methanol, and 0.66g of CaO / MCF (prepared in Example 1.1) in sequence, and stir the reaction (300 rpm) at 125°C for 3h. Filtrate under reduced pressure to filter out unreacted polylactic acid and catalyst. The filtrate is distilled at 70°C under normal pressure to recover unreacted methanol, and then distilled under reduced pressure at 100°C to obtain the product methyl lactate. The product 6.1 g of methyl lactate was obtained. The alcoholysis rate of polylactic acid was 91.4%, and the selectivity of methyl lactate was 84.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com