Method for separating iron and precious metals from iron residue

A technology for separating iron and precious metals, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of the limitation of secondary utilization of iron, the impurity of iron in iron slag, and the reduction of economic benefits, so as to save costs and improve Recycling benefits, the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

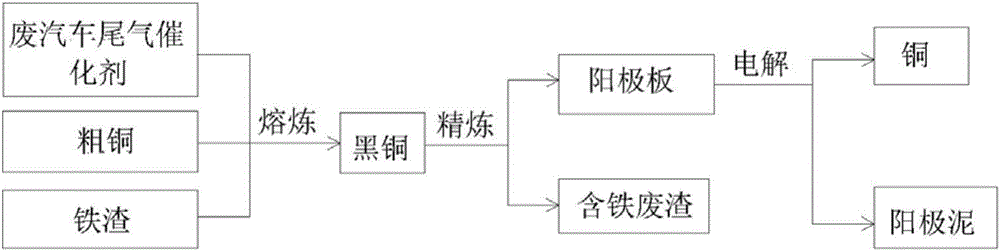

[0015] In the automobile dismantling and recycling process, such as figure 1 It is a process for partial metal recovery and smelting.

[0016] Among them, the iron slag is the metal iron and some magnetic iron oxides that are magnetically separated by the iron remover in the process of metal recycling and transmission, and a small amount of precious metals such as copper, nickel, cobalt, etc. mixed in the iron slag. compound.

[0017] Wherein the waste automobile exhaust catalyst is a catalyst containing silicon oxide.

[0018] The copper-containing carbon powder is a mixture of metal copper and carbon powder obtained by cracking waste circuit boards, and the mass ratio of metal copper and carbon powder is 1.8:2.2.

[0019] Put the above iron slag, waste automobile exhaust catalyst, and copper-containing carbon powder together into the electric furnace for smelting. The temperature in the furnace is 1350-1450°C. Under this temperature condition, metallic copper can be used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com