Comprehensive recovery method for oxygen pressure alkaline leaching calcium salt tin precipitation of tin-containing material

A technology of oxygen pressure alkali leaching and recovery method, applied in the field of machinery, can solve the problems of low leaching rate, time-consuming, unsatisfactory comprehensive recovery, etc., and achieve the effect of improving comprehensive recovery efficiency, comprehensive recovery rate and product income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

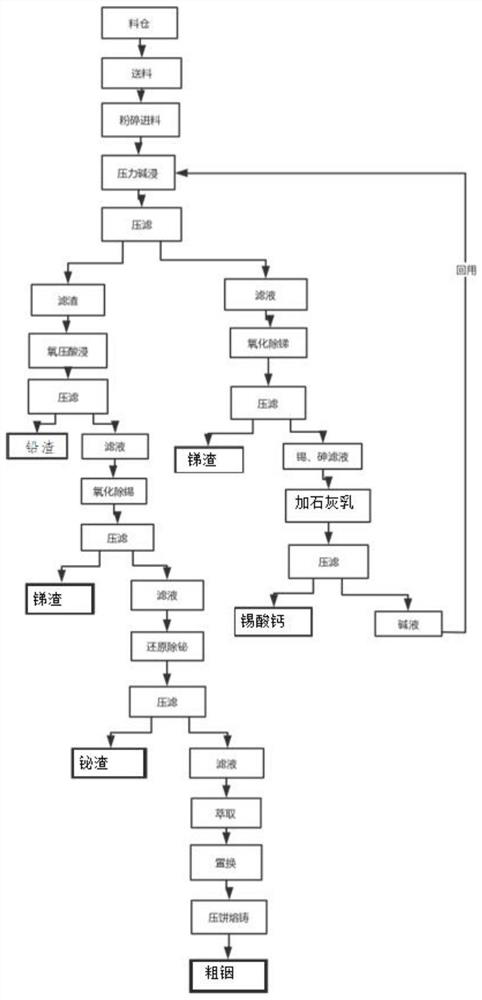

[0022] Such as figure 1 A kind of comprehensive recovery method of oxygen pressure alkali leaching calcium salt precipitation tin of the shown a kind of tin-containing material is characterized in that, comprises the following steps:

[0023] Step 1, pulverize the tin-containing material, and sieve to obtain the pulverized material;

[0024] Step 2: Add 0.2A kg of water into the pulping kettle as bottom water, then put A kg of pulverized material into the pulping kettle, then add 0.15A-0.25A kg of caustic soda to the pulping kettle to form a leachate, and react 1 hour to obtain the reaction material;

[0025] Step 3. Add the reaction materials in the slurry tank to the autoclave to pressurize to 0.5-0.8MPa, and raise the temperature to 120°C-150°C for 3 hours;

[0026] Step 4, depressurizing and lowering the temperature, then transferring the material in the autoclave to a transfer kettle and adding water to obtain a solid-liquid mixture for pressure filtration to obtain fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com