Pre-tightening device

A one-part, oblique wedge technology, applied in installation, friction clamping detachable fasteners, optics, etc., can solve the problems of inconvenient adjustment and maintenance, and achieve the effect of simple structure, good pre-tightening effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

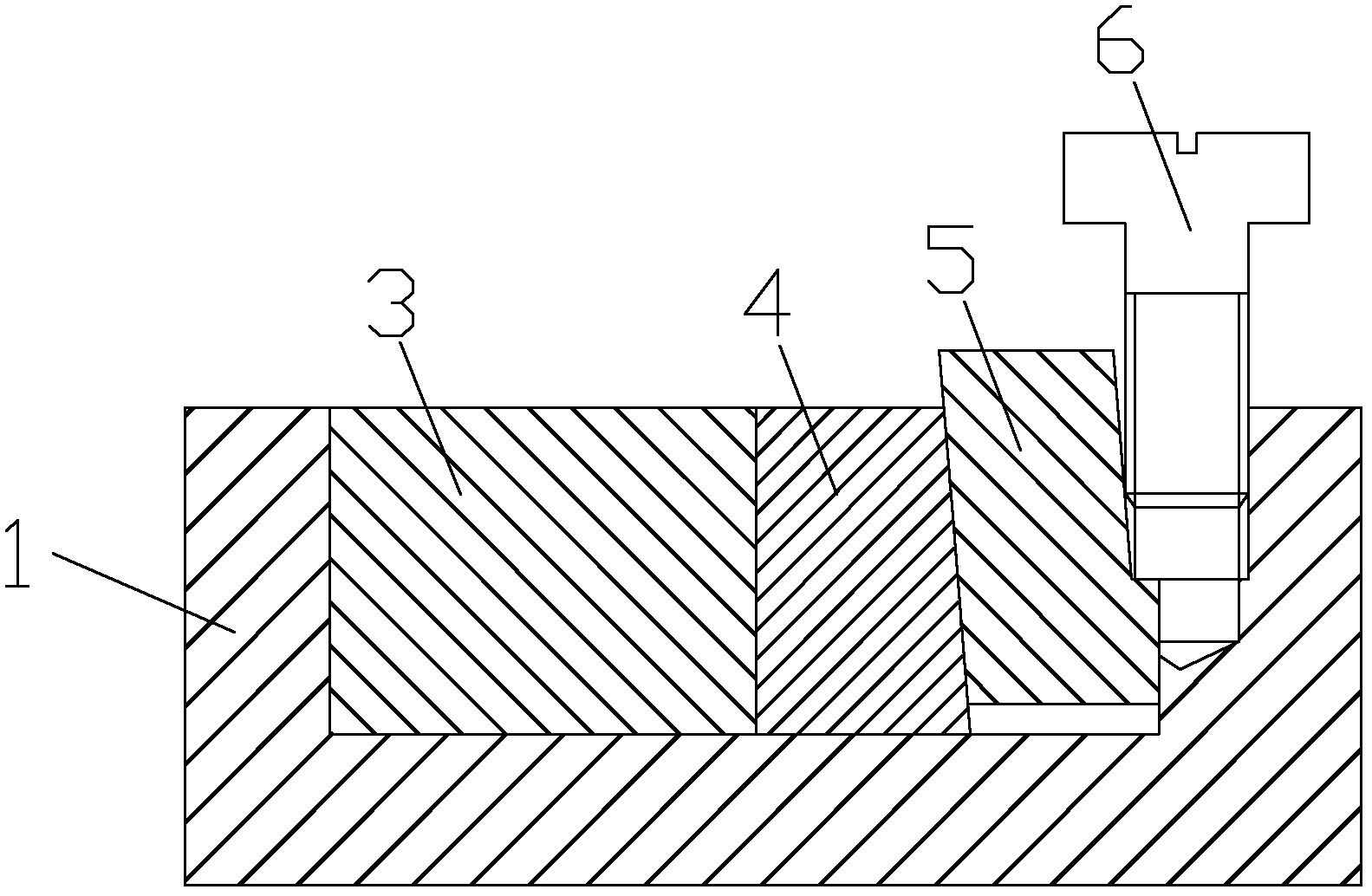

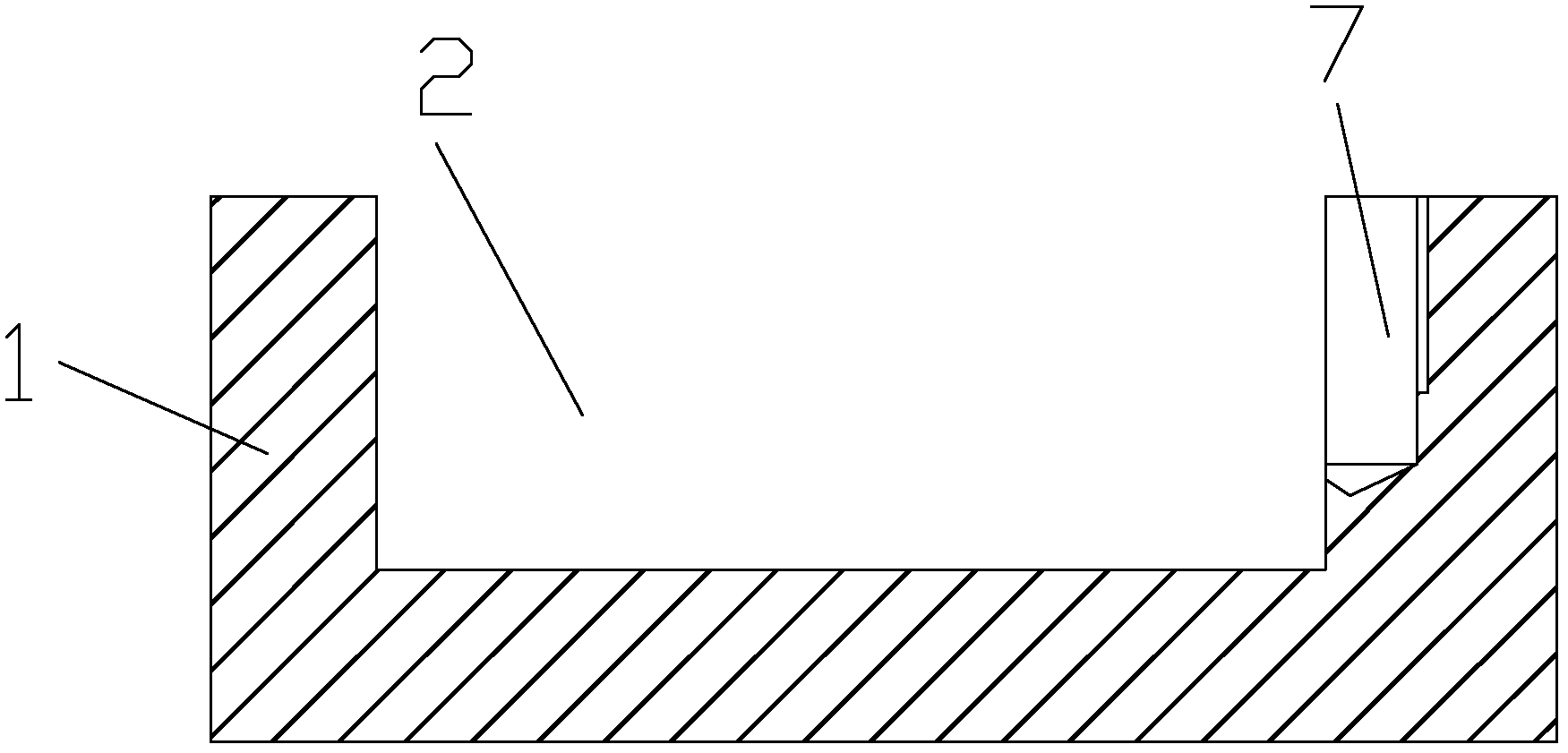

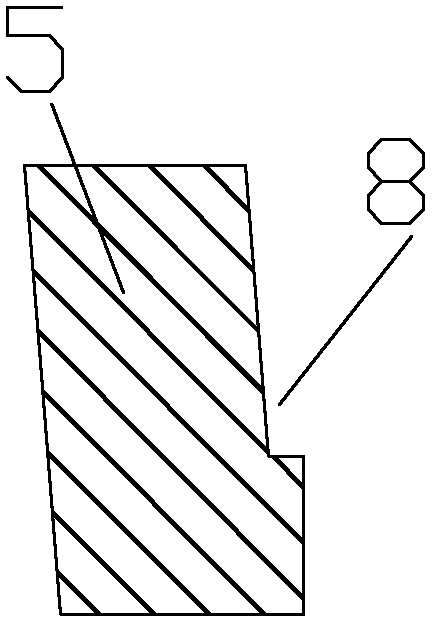

[0011] as attached figure 1 , 2 A pretensioning device according to the present invention shown in , 3 includes a body 1, a piezoelectric ceramic 3, a static wedge 4, a moving wedge 5, a screw 6, a screw hole 7, and a tapered hole 8; the body 1 is provided with a groove 2; the piezoelectric ceramic 3 is arranged on one side of the groove 2; one side of the piezoelectric ceramic 2 is adjacent to the side of the groove 2, and the other side is adjacent to the side of the static wedge 4. The vertical surfaces are adjacent; the other end of the groove 2 is provided with a screw hole 7; the moving cam 5 is inserted into the space between the static cam 4 and the other end of the groove 2; The inclined surface is adjacent to the inclined surface of the static wedge 4; the end of the vertical surface of the movable wedge 5 is provided with a tapered hole 8; the screw 6 is screwed into the screw hole 7, and a part of the screw 6 is also inserted into the tapered hole 8 ; When the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com