An exhaust system mounting nut

An exhaust system and nut technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of high exhaust temperature, high modal vibration, failure to meet environmental protection requirements, exhaust manifold leakage, etc., to improve the locking effect , Improve the effect of preload and prevent the effect of modal vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

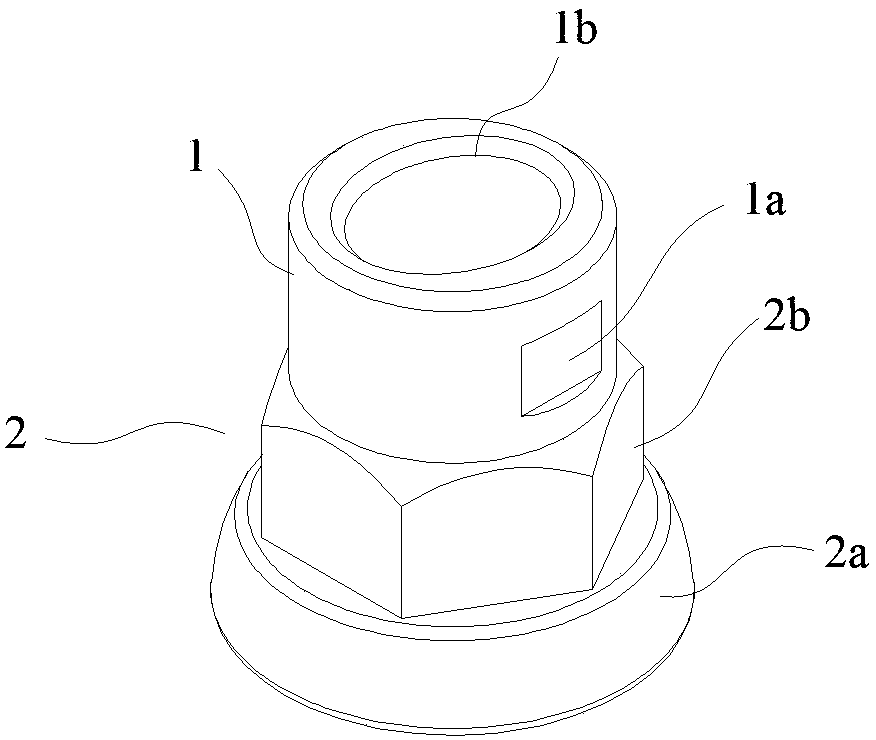

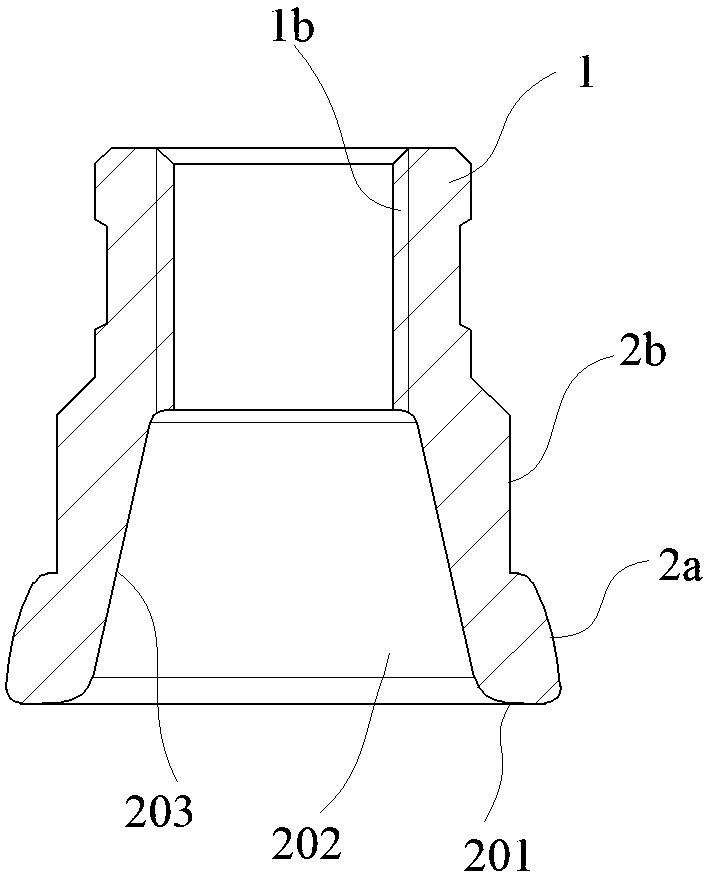

[0019] Such as figure 1 , figure 2 In the shown embodiment, a mounting nut for an exhaust system includes an anti-loose end 1 and a buffer end 2, the buffer end is located below the anti-loose end, and has an integral structure with the anti-loose end. The outer surface of the anti-loosening end is round to achieve a more uniform extrusion force on both sides, preventing the internal thread from being deformed by force and causing the failure of the anti-loosening structure, and improving the qualified rate of batch manufacturing. The anti-loosening end is provided with an internal threaded hole 1b, which can be fixed with the bolt. The outer surface of the anti-loose end is provided with an extrusion groove 1a arranged symmetrically around the axis of the anti-loose end. The extrusion grooves on both sides are extruded in parallel, and the internal thread of the nut is deformed after being stressed. The internal thread hole is elliptical to prevent the nut and bolt from Sw...

Embodiment 2

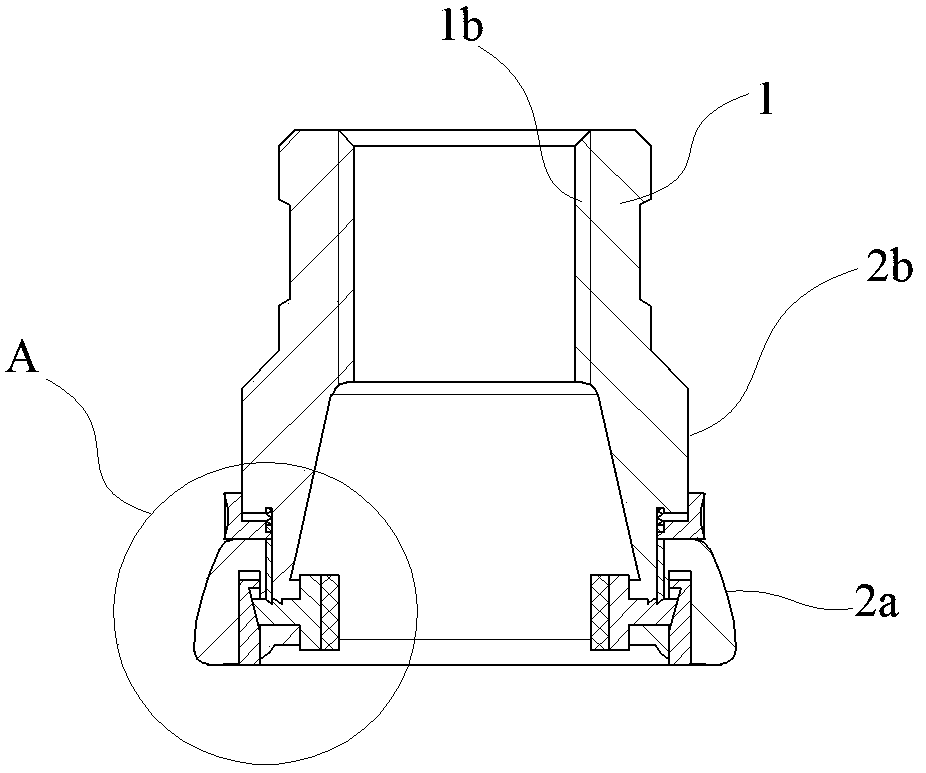

[0023] to combine figure 1 , image 3 In the shown embodiment, a mounting nut for an exhaust system includes an anti-loose end 1 and a buffer end 2 , the buffer end is located below the anti-loose end, and has an integral structure with the anti-loose end. The outer surface of the anti-loosening end is round to achieve a more uniform extrusion force on both sides, preventing the internal thread from being deformed by force and causing the failure of the anti-loosening structure, and improving the qualified rate of batch manufacturing. The anti-loosening end is provided with an internal threaded hole 1b, which can be fixed with the bolt. The outer surface of the anti-loose end is provided with an extrusion groove 1a arranged symmetrically around the axis of the anti-loose end. The extrusion grooves on both sides are extruded in parallel, and the internal thread of the nut is deformed after being stressed. The internal thread hole is elliptical to prevent the nut and bolt from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com