Protection pile construction process special for motor train unit train body impact test platform

It is a technology of impact test and construction technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc. It can solve the problems of mechanical damage at the rear of the motor car, threat to the safety of testers, and impact on buildings, etc., to achieve good pretension effect and ensure The effect of safety and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

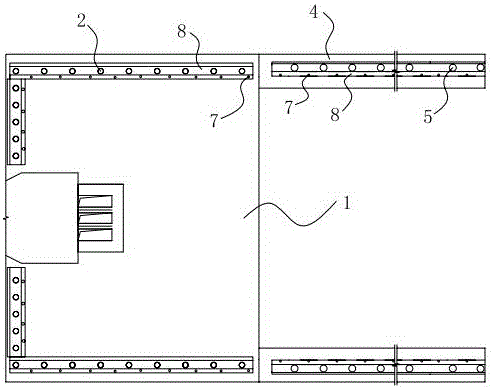

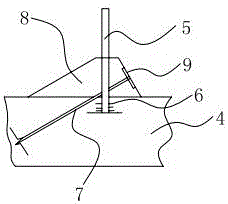

[0023] Such as figure 1 , 2 , 3, 4, and 5, the construction process of the special protective piles for the impact test platform of the EMU car body includes the following steps:

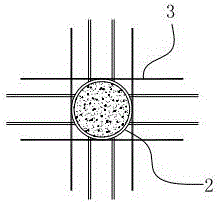

[0024] (1) Set up the main protection pile casing: erect the main formwork for pouring the impact platform foundation 1, each main formwork forms the main pouring area, and lay horizontal and steel bars and support in advance along the edge of the impact platform foundation 1 in the main pouring area The main protective pile casing 2 is laid, and the distance between two adjacent main protective pile casings 2 is 1.5m. The bottom of the main protective pile casing 2 is welded to strengthen and impact the platform foundation 1. The reinforcing steel bar 3 of connection strength is fixed with the horizontal and vertical steel bars, and the bottom end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com