Six-dimensional force sensor of integral pre-tightening double-layer top and bottom asymmetry eight-rod parallel connection structure

A six-dimensional force sensor, the overall technology, is applied in the direction of instrument, measurement force, measurement of the property force of piezoelectric devices, etc. To solve the problems such as the complex structure of the tight branch, the effect of reducing stress coupling, increasing stiffness and simple structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

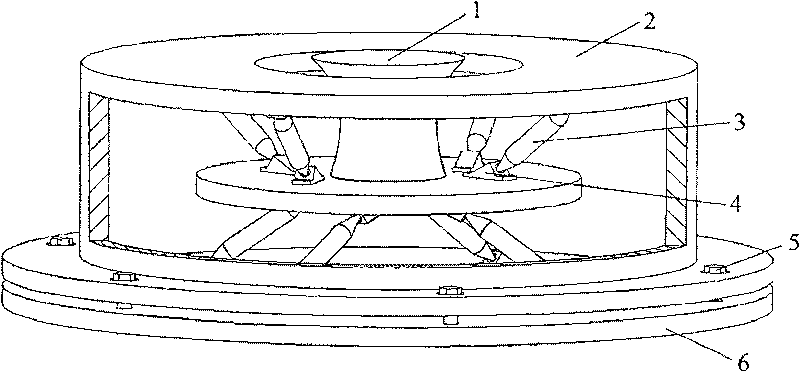

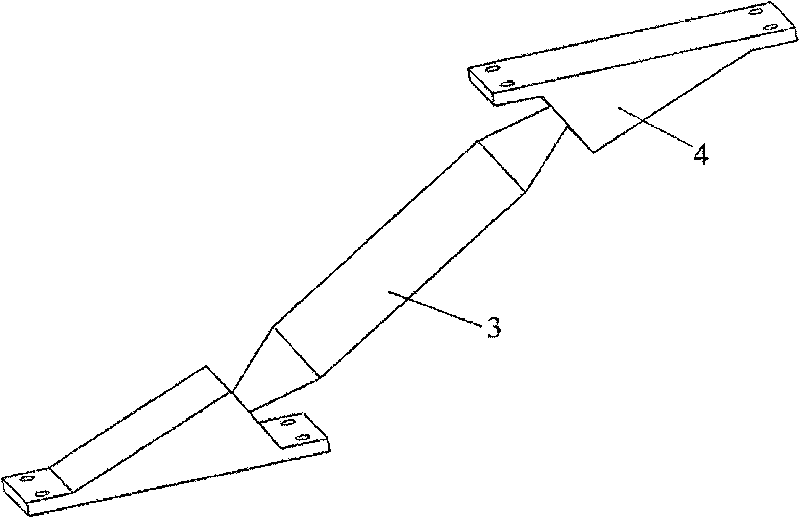

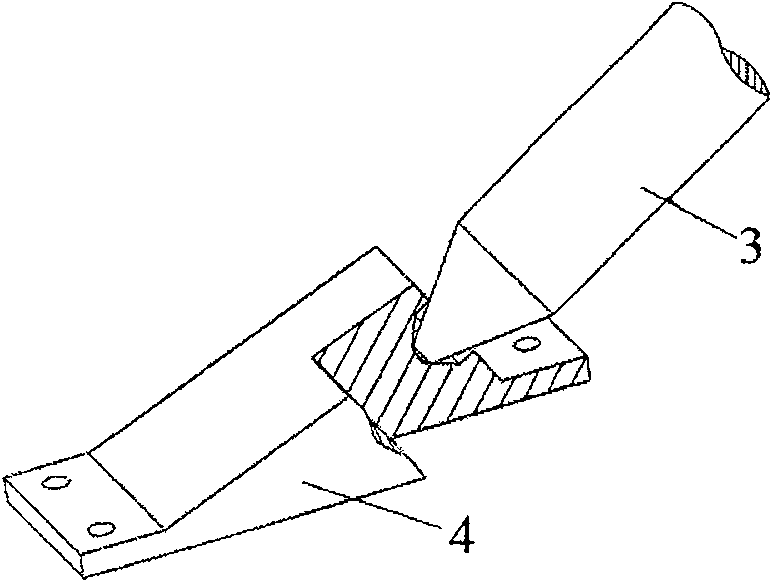

[0012] figure 1 It is an embodiment disclosed by the present invention. The six-dimensional force sensor of the overall pretensioned double-layer upper and lower symmetrical eight-bar parallel structure consists of a force measuring platform 1, a pretensioning platform 2, a base 6, eight detection members 3, and sixteen balls. The socket 4 and the pre-tightening bolt 5 are formed. The force-measuring platform 1 is composed of a chassis with overlapping axes and a load-bearing disc. Four ball-and-socket seats 4 are distributed on the upper and lower surfaces of the chassis of the force-measuring platform 1, and they are respectively located on the same circumference; the pre-tightening platform 2 is a shell body member, four ball-socket seats 4 are distributed on the circumference of the inner ring surface of the top, and bolt holes are evenly distributed on the flange of the bottom; four ball-socket seats 4 are distributed on the same circumference of the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com