Elastic support installation method for wind power plant and its elastic element

A technology of wind power generation equipment and elastic support, applied in the field of vibration isolation connection and gearbox support, to achieve the effect of safe installation process, small structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

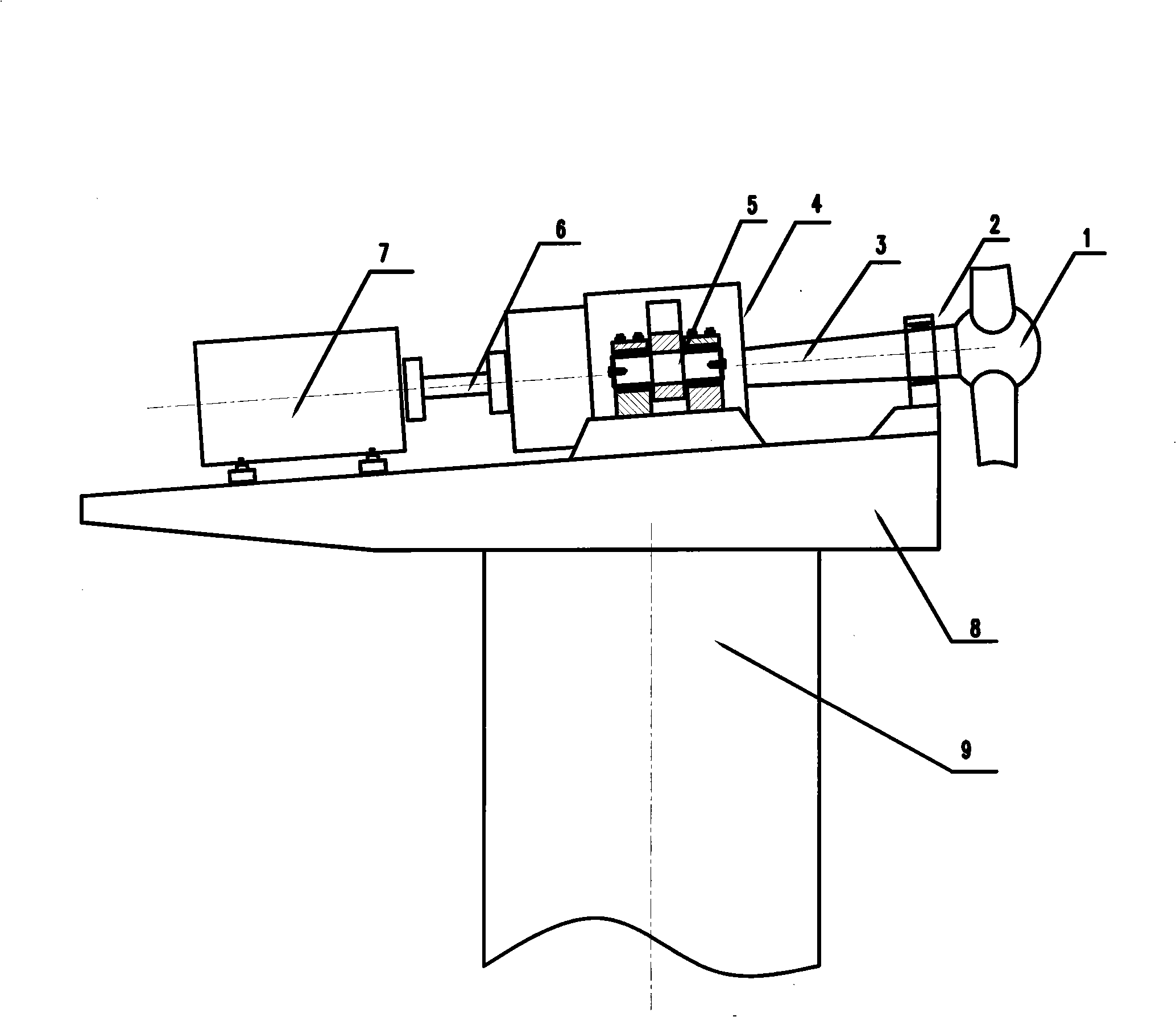

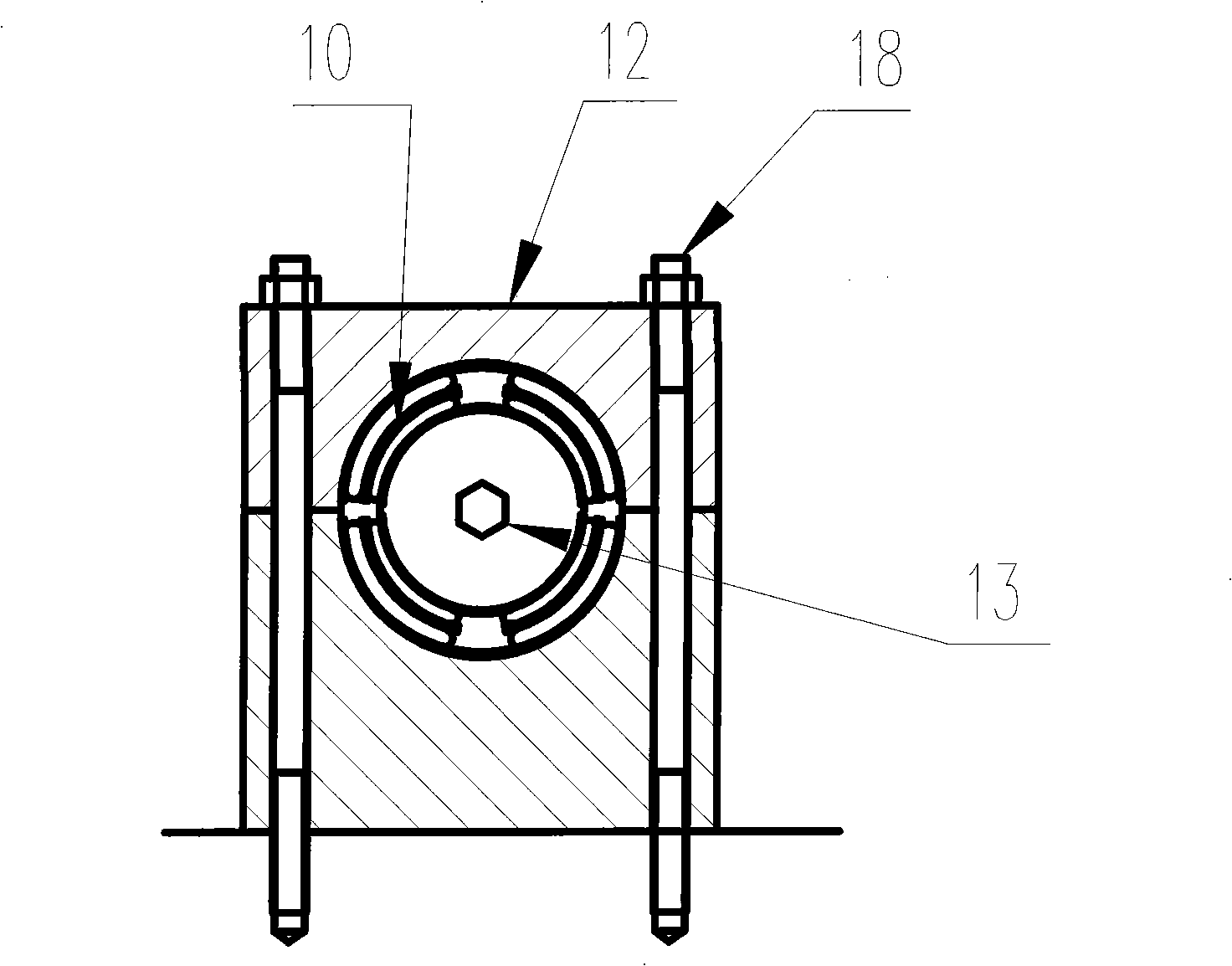

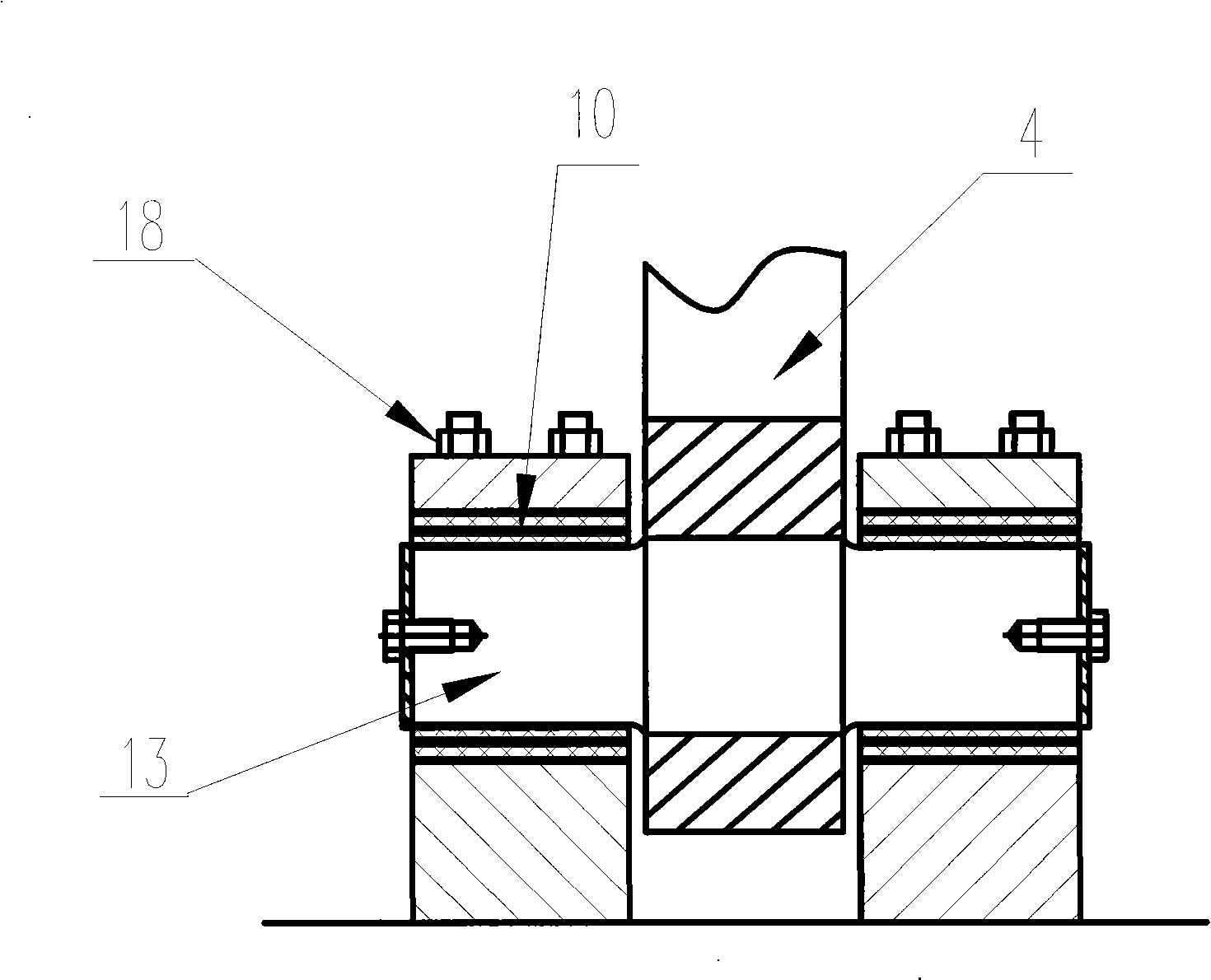

[0020] attached figure 2 And attached image 3 It shows a method for installing the elastic support of the gearbox of a wind power generating set according to the present invention. The elastic support 10 of the gearbox of the wind generating set is installed on the gearbox 11 of the wind generating set. The elastic support of the two-lobed structure is adopted, and the elastic support 10 is installed on the gear On both sides of the box 11, and through the support 12 of the upper and lower halves, the elastic support is installed in the support 12 by means of radial pre-tightening compression, forming an elastic support for the wind turbine gearbox. The radial pre-tightening compression method is as follows: first place the two elastic supports 10 in the upper and lower two halves of the support 12, and compress radially to make the outer ring of the elastic support 10 stick to the inner circle of the support 12. Together, the mandrel 13 is placed on the inner ring of the e...

Embodiment 2

[0023] Image 6 It shows another installation method for the elastic support of the gearbox of the wind power generating set, adopting the elastic support 210 in the form of integral structure, installing the elastic support 210 on both sides of the gearbox 211, and the support 212 is the support of the integral structure, adopting radial The elastic support 210 is installed in the support 211 in a tight compression method to form an elastic support for the gearbox of the wind power generating set. The radial pre-tightening compression method is to put the inner ring of the elastic support 210 on the mandrel 213, then radially compress the outer ring and place it in the support, so that the elastic support 210 generates a certain pre-compression force and installs it on the support. 212 inside. The implementation of radial compression refers to the use of a special compression tool to radially compress the outer tile of the elastic support 210 from the outer tile or the end t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com