Control method and device for hot-forming plasticity distribution of high-strength steel

A technology of distributed control and hot forming, which is applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult to determine the position of the weld seam, difficult to realize curve splicing, three-dimensional splicing and widening splicing, and high processing cost of tailor welded blank blanks, etc. problems, to achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

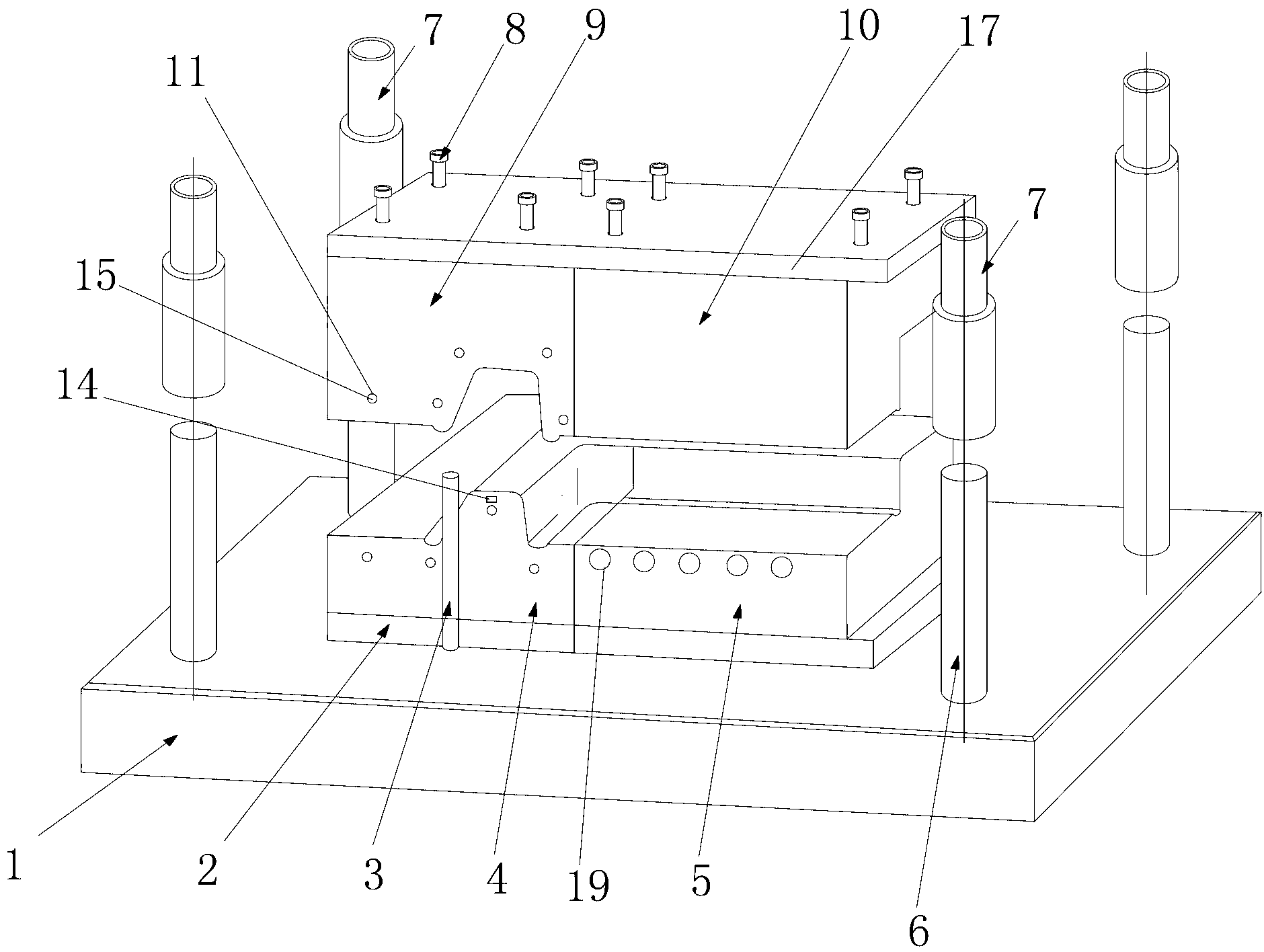

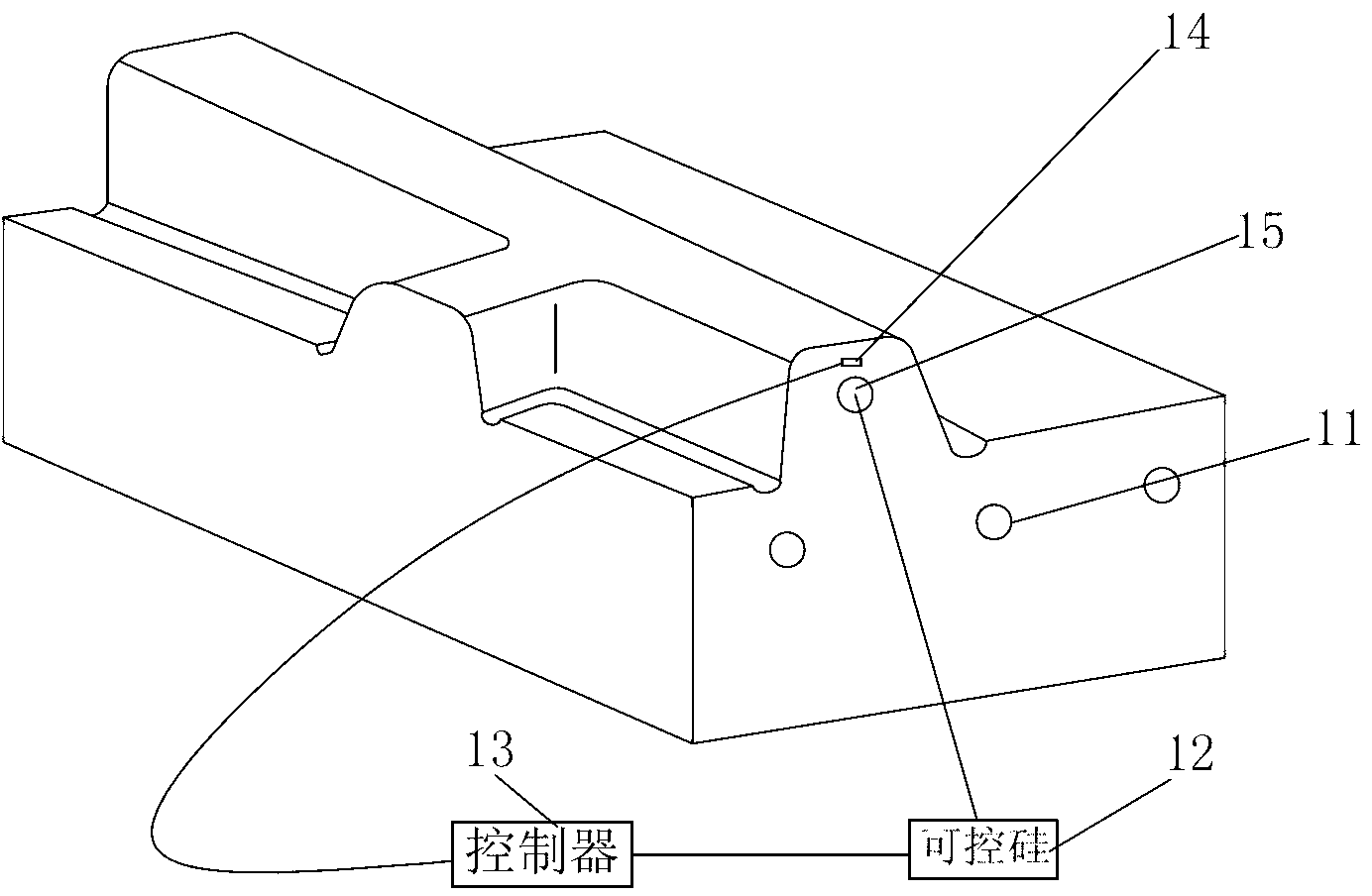

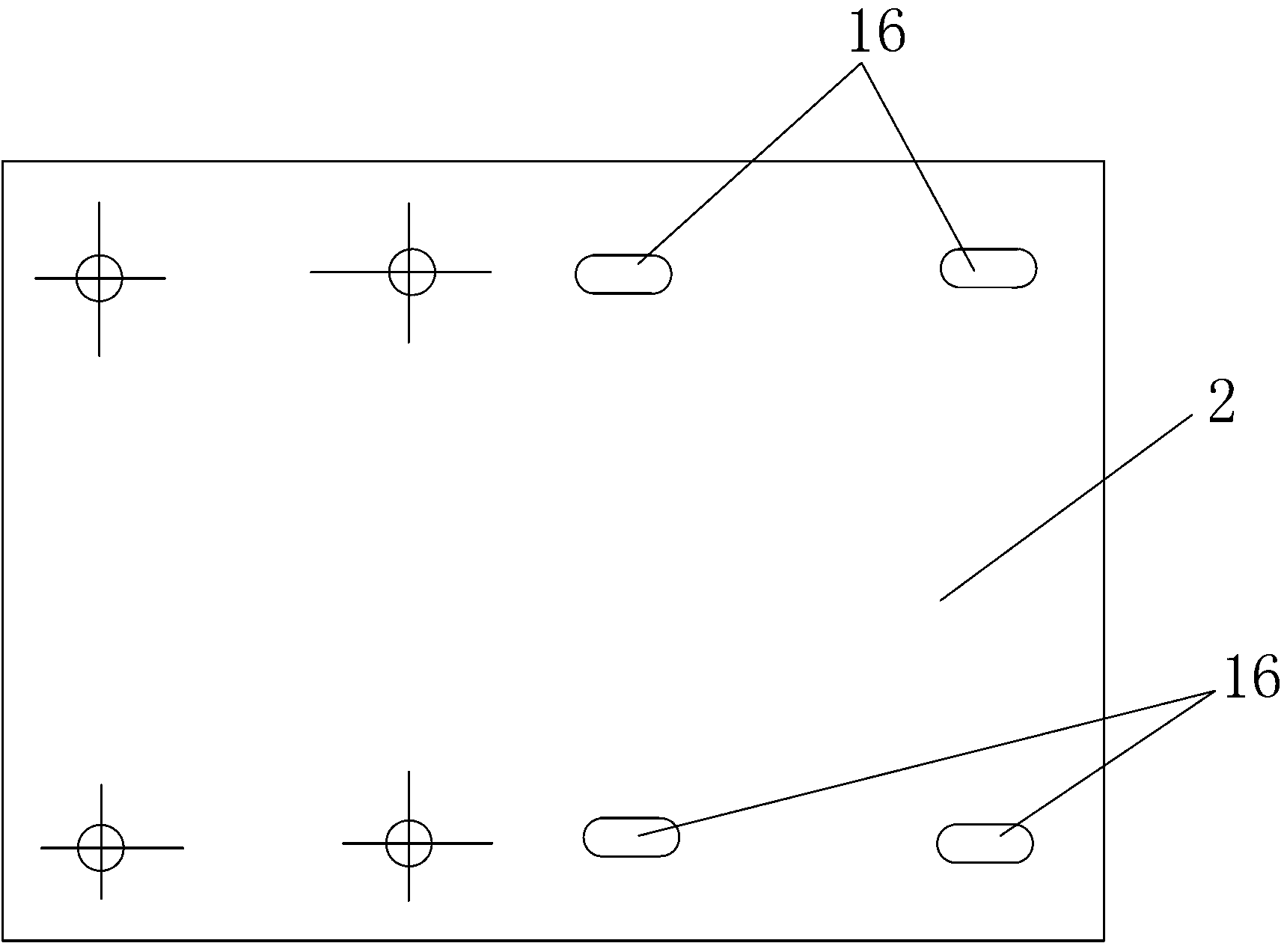

[0029] Such as Figure 1~5 The shown high-strength steel thermoforming plasticity distribution control device includes a silicon controlled silicon 12, a controller 13, a thermocouple 14, a lower mold base plate 1, a heating rod 15, and a lower pressure-resistant heat insulation plate laid on the lower mold base plate 1 2. The lower mold heating zone insert 4 and the lower mold cooling zone insert 5 arranged side by side on the lower pressure heat insulation board 2, the upper mold heating zone insert 9 matching the lower mold heating zone insert 4, and the lower mold heating zone insert 9 The cooling zone insert 5 matches the upper mold cooling zone insert 10, wherein, the lower mold heating zone insert 4 is provided with a plurality of heating rod holes 11 passing through the lower mold heating zone insert 4 along the width direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com