Patents

Literature

41results about How to "Reduce the pressure of purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

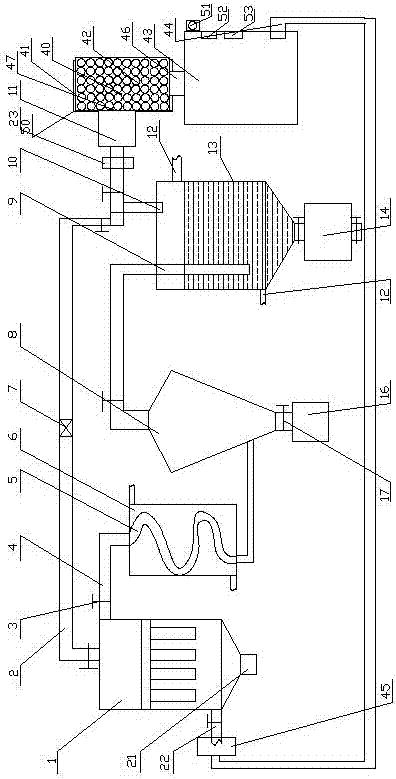

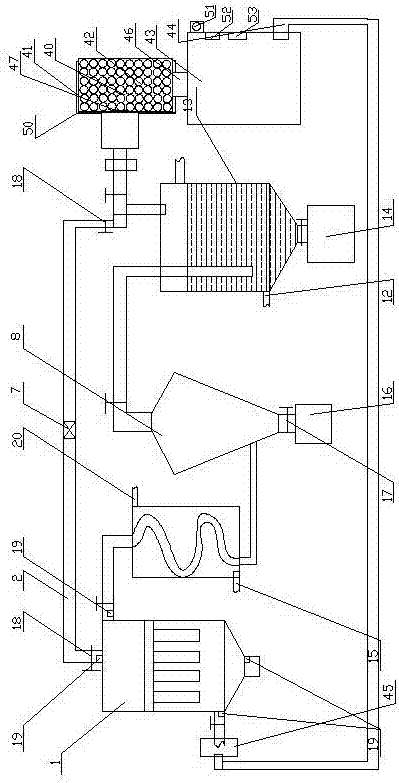

On-line waste gas treatment system of waste cable high-temperature treatment device

InactiveCN107376559AStable and efficient workEfficient recyclingCombination devicesEngineeringHot Temperature

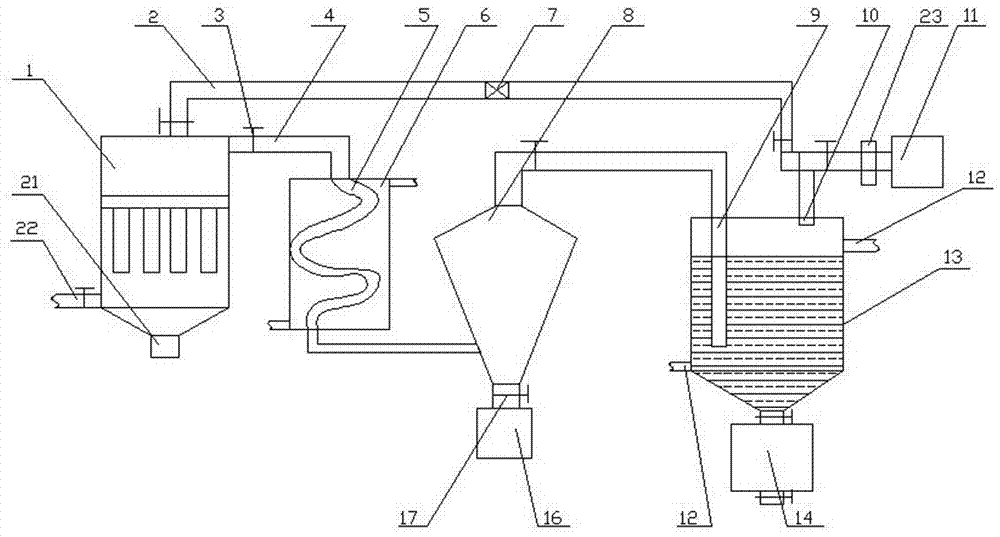

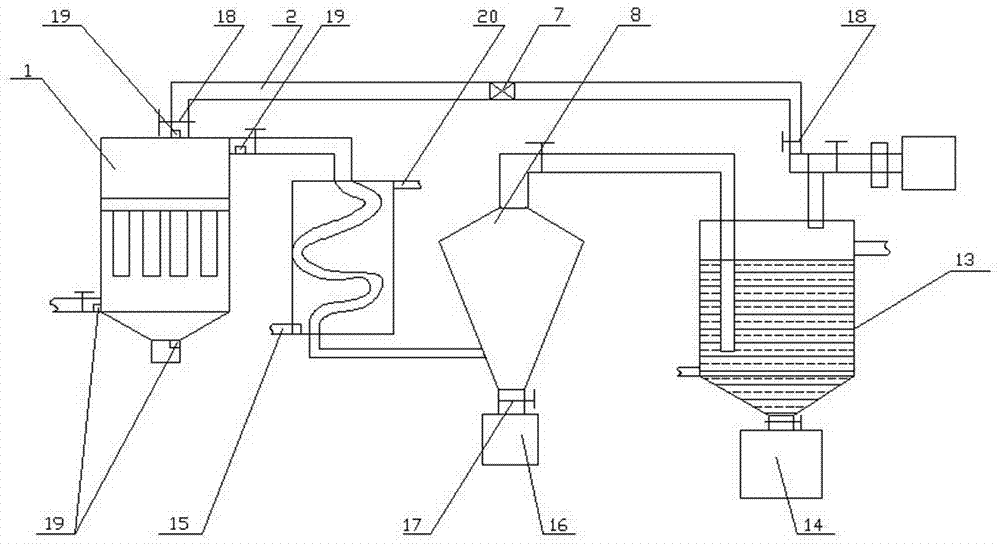

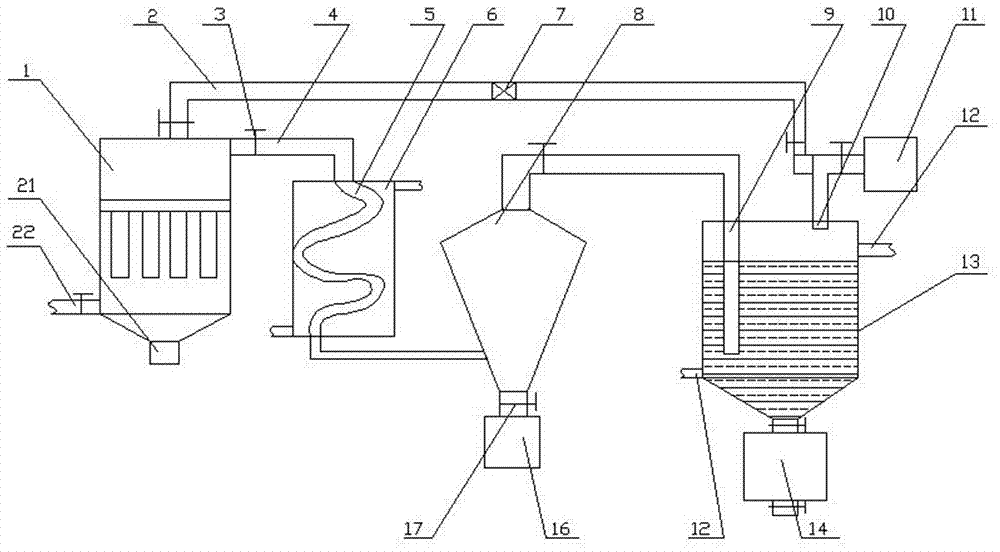

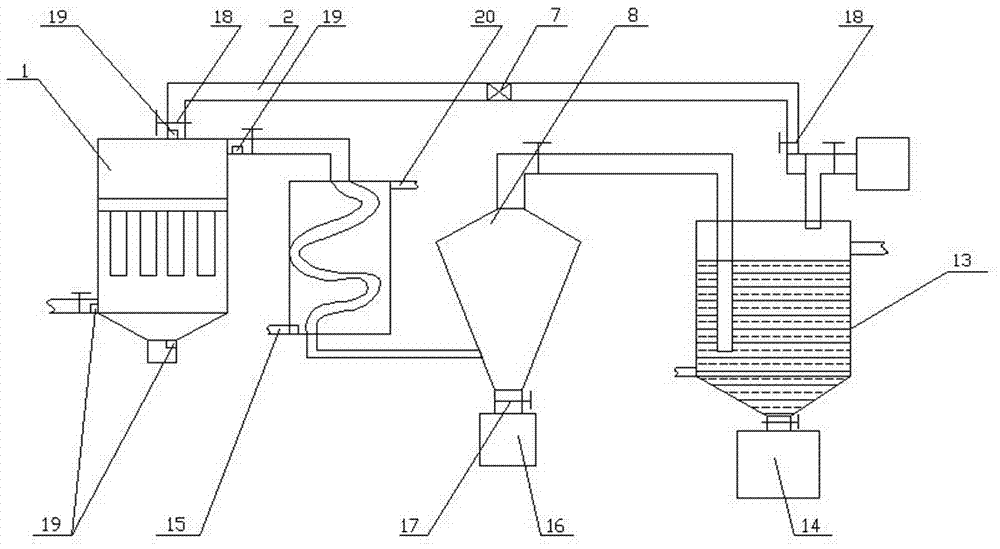

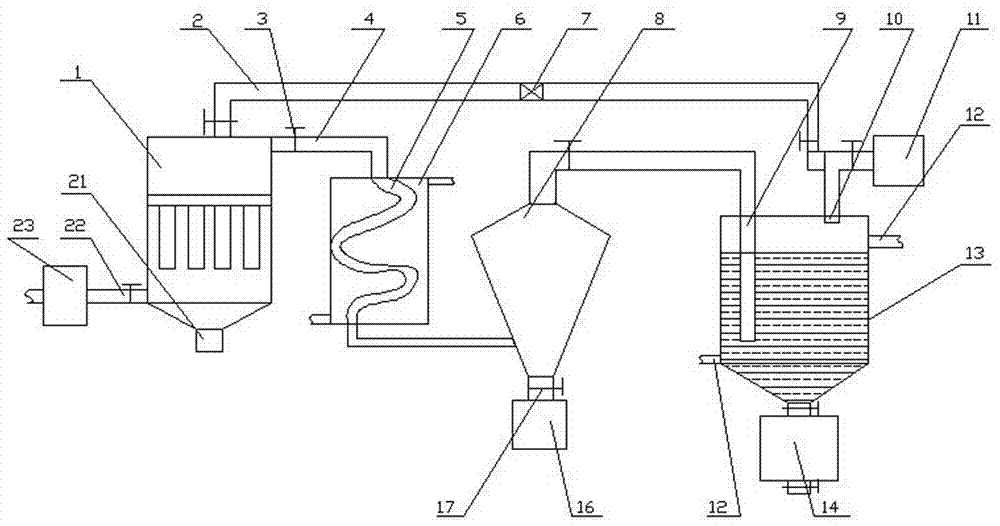

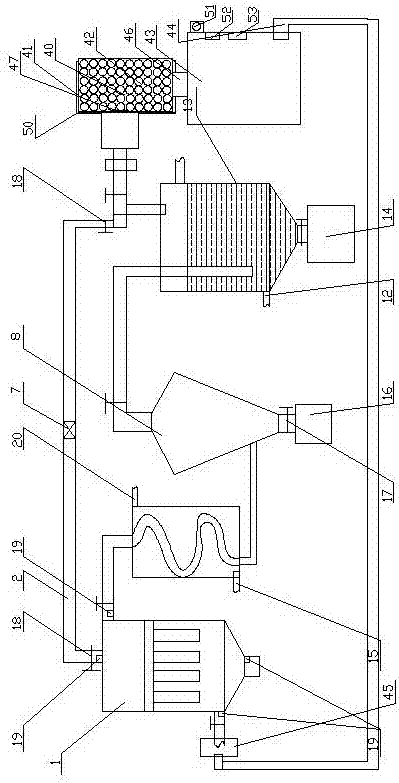

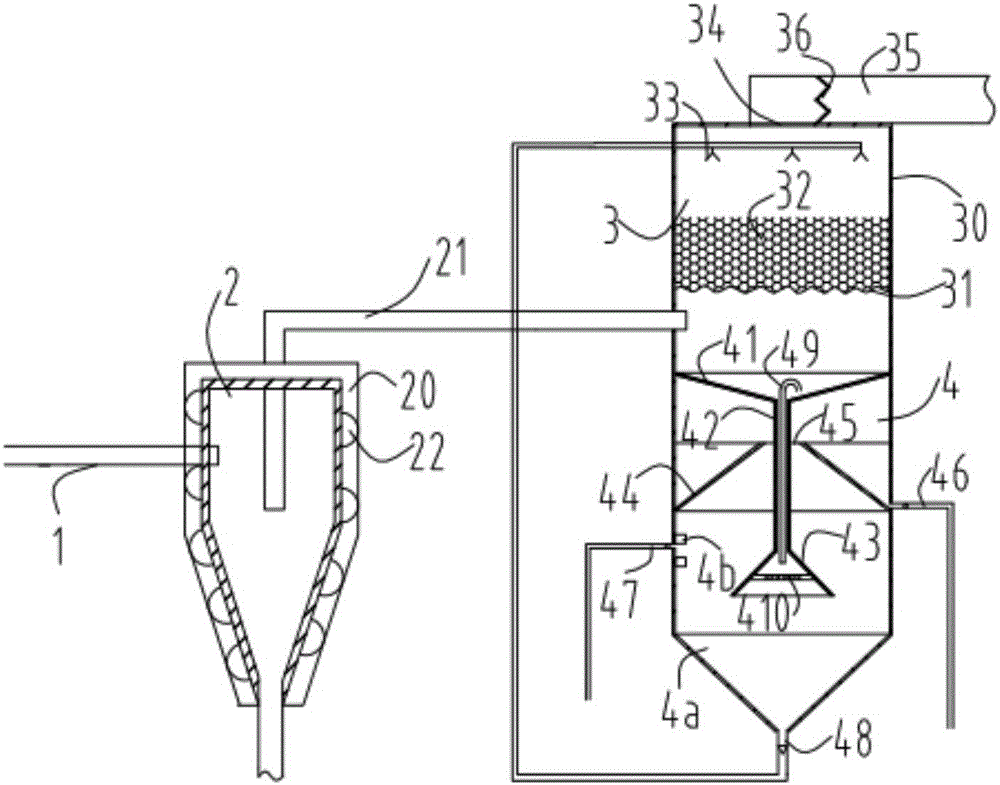

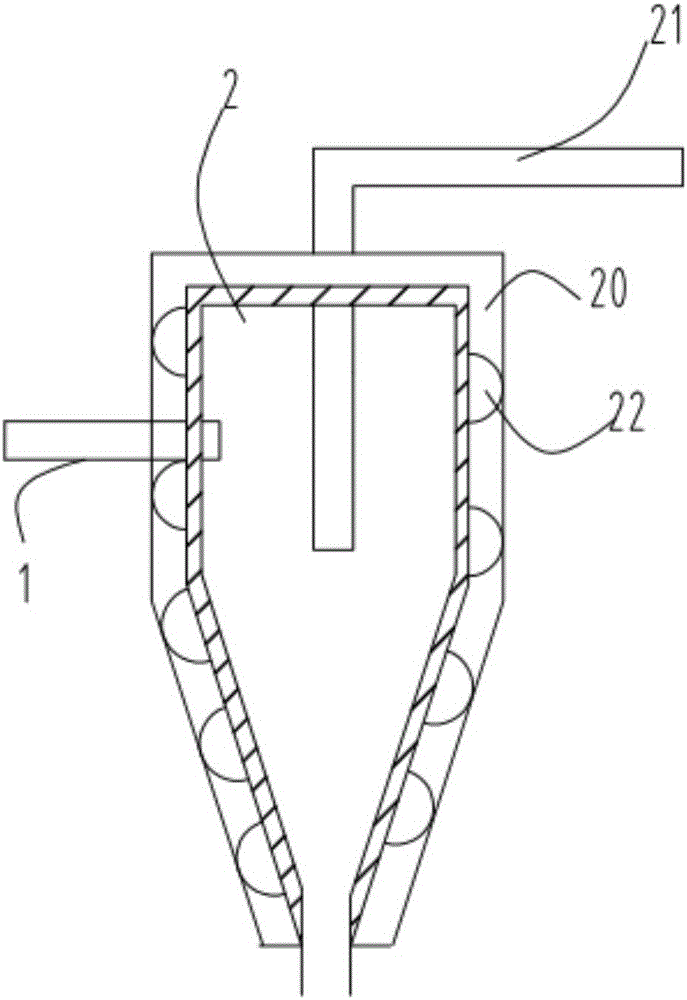

The invention discloses an on-line waste gas treatment system of a waste cable high-temperature treatment device. The on-line waste gas treatment system comprises a first dust collection mechanism, an energy transduction mechanism, a first regeneration mechanism, a settling mechanism, a dust collection module, an absorption mechanism, a discharging mechanism, a circulation mechanism, an unloading module and an adsorption filtering mechanism, wherein the energy transduction mechanism is communicated with the first end of the first dust collection mechanism; the first regeneration mechanism is communicated with the second end of the first dust collection mechanism; the settling mechanism is communicated with the energy transduction mechanism; the dust collection module is arranged below the settling mechanism; the absorption mechanism is arranged behind the settling mechanism; the discharging mechanism is arranged above the absorption mechanism; the circulation mechanism is communicated with the absorption mechanism; the unloading module is arranged below the absorption mechanism; the adsorption filtering mechanism is arranged between the absorption mechanism and the discharging mechanism. Aiming at the phenomena that by using a conventional dust collection system, wastes cannot be efficiently utilized and waste gases is discharged into the natural environment, the modules cooperate with one another, not only are waste gases efficiently recycled, but also substances in the waste gases are recycled, and environment pollution is avoided.

Owner:国网河南省电力公司西峡县供电公司

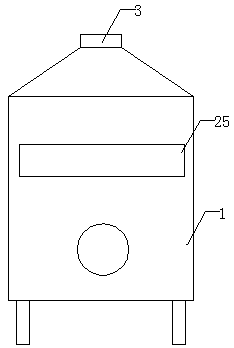

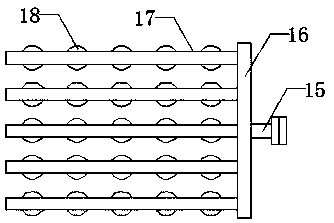

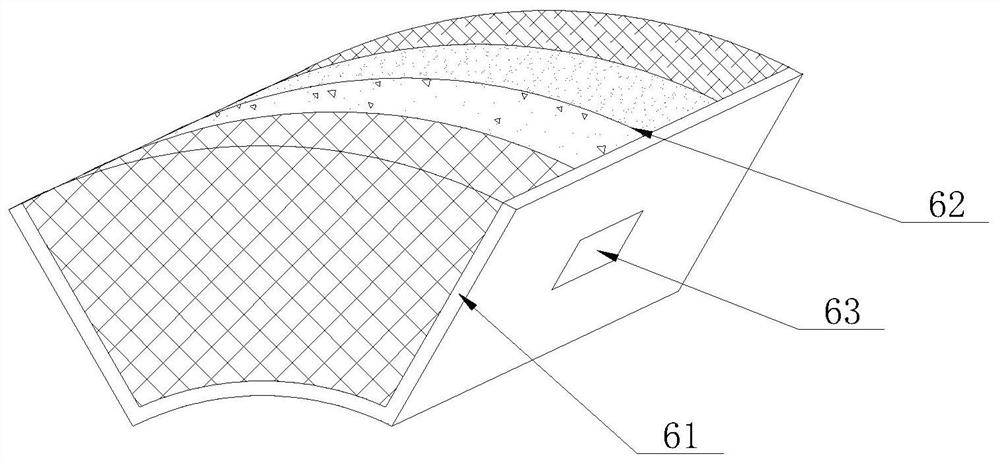

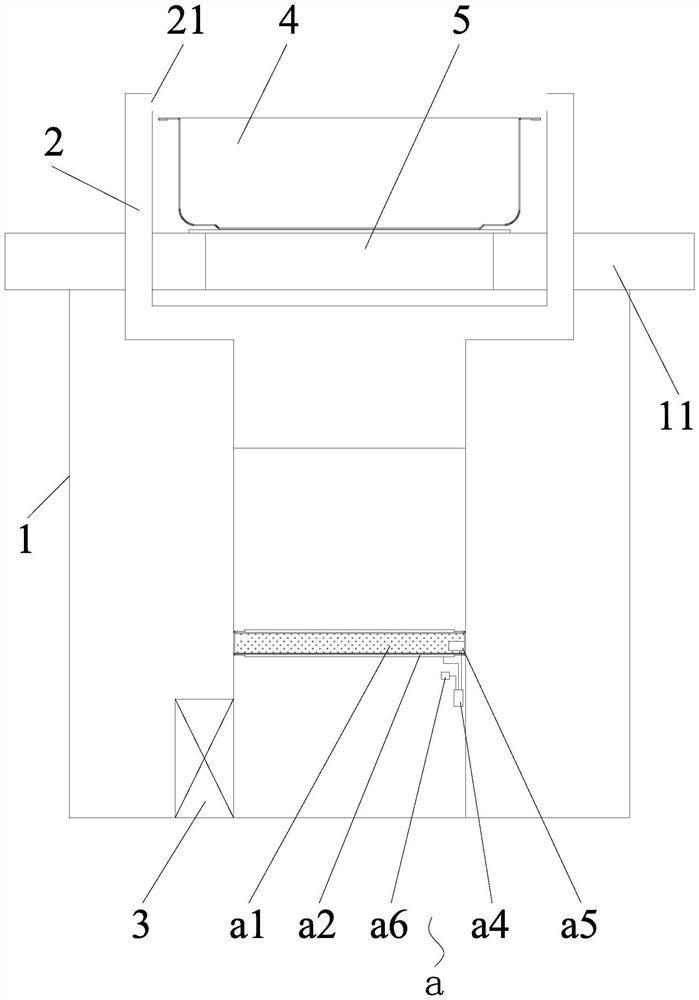

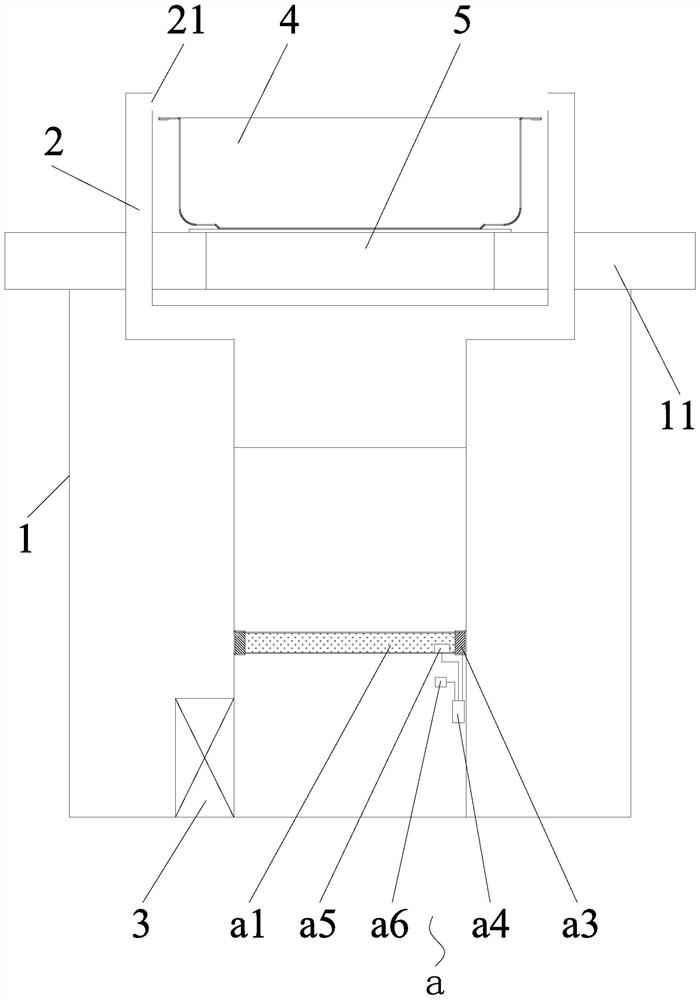

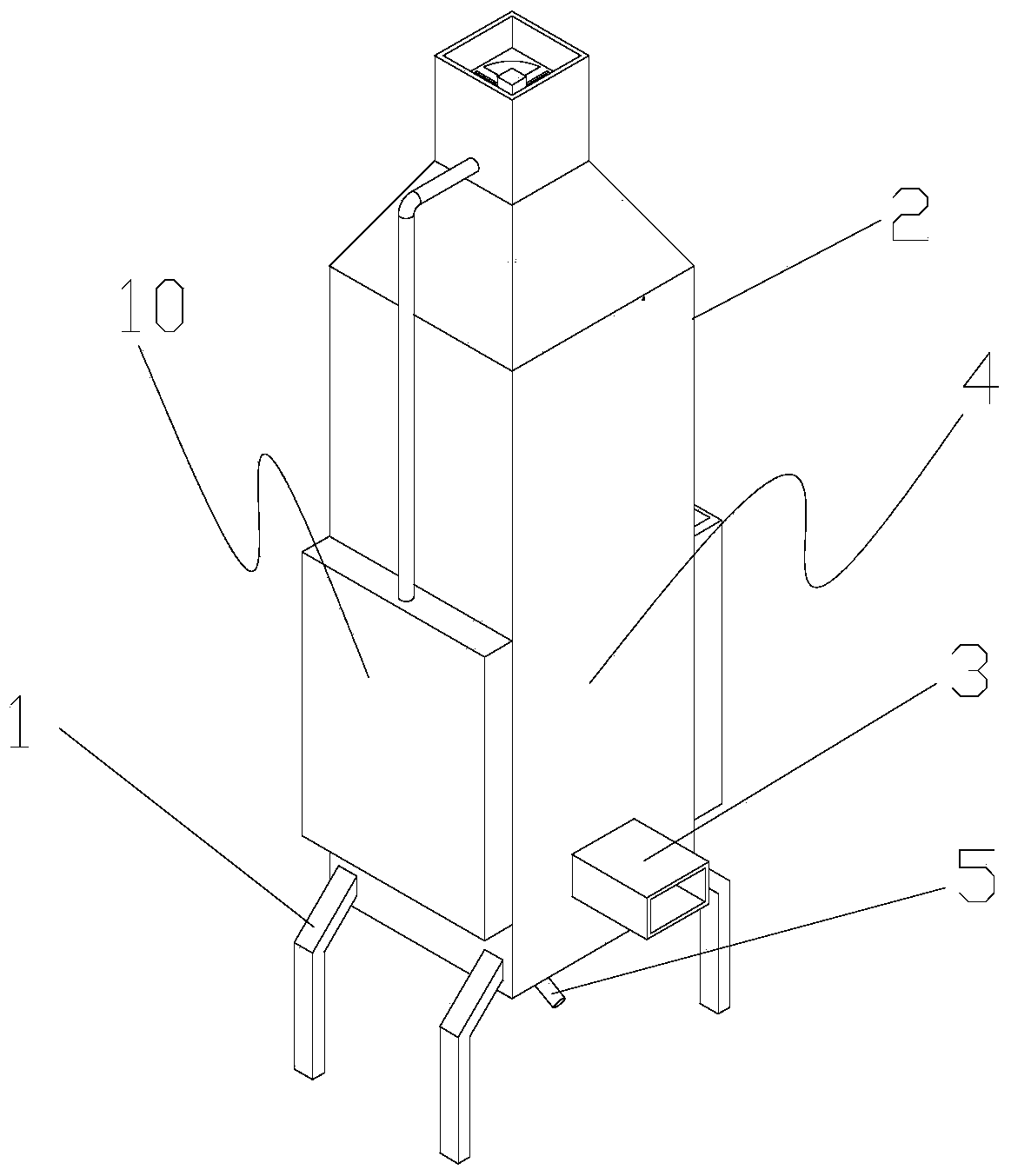

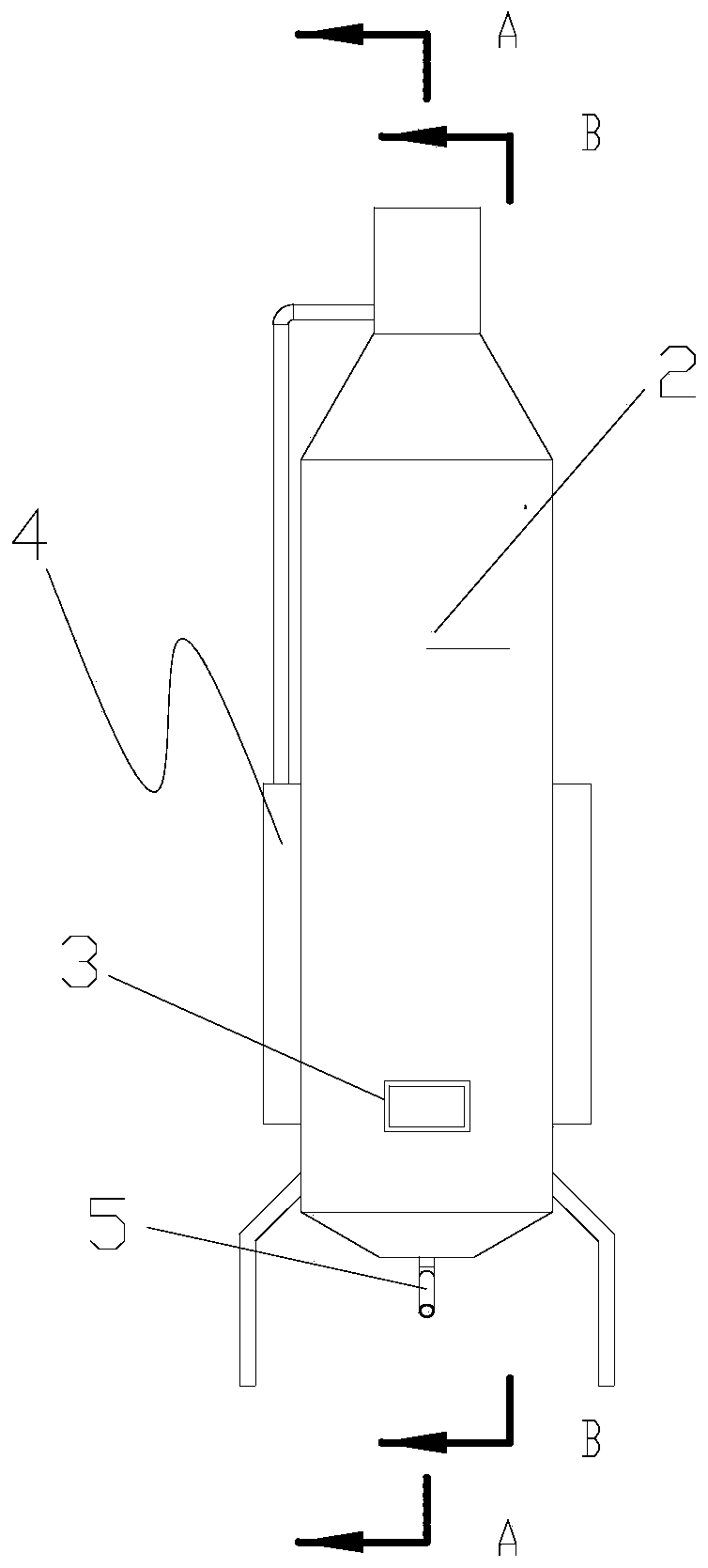

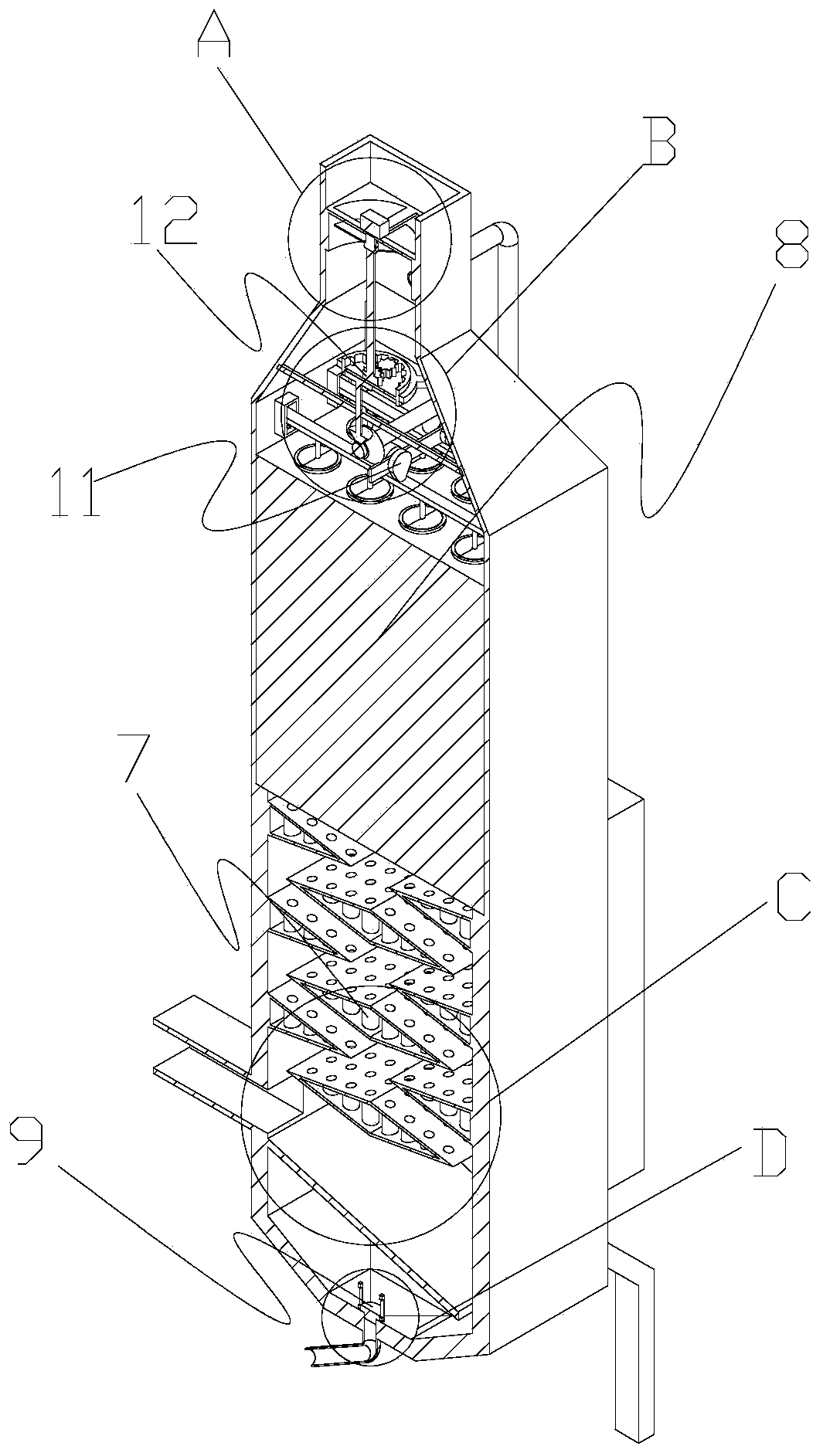

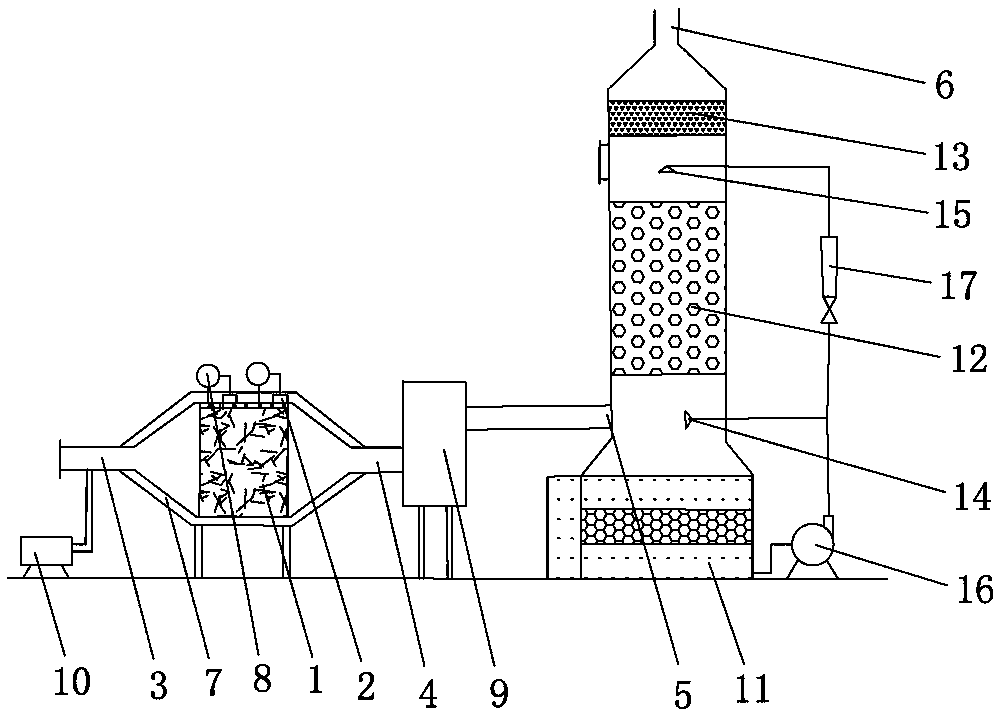

Spray tower for methane chloride tail gas treatment

InactiveCN109529551AEasy to replaceImprove adsorption capacityDispersed particle separationStationary filtering element filtersFiberWater storage tank

The invention discloses a spray tower for methane chloride tail gas treatment. The spray tower comprises a spray tower body and a water storage tank, a spray tower bracket is fixedly installed at thebottom of the spray tower body, one side bottom of the spray tower body is fixedly equipped with an air inlet, the top of the spray tower body is fixedly equipped with an air outlet, and a water outlet of the spray tower body is in fixed connection with one side bottom of the water storage tank through a connecting pipe. The spray tower for methane chloride tail gas treatment provided by the invention is provided with activated carbon fiber to facilitate adsorption and purification of tail gas, and the activated carbon fiber has stronger adsorption capacity on organic gas than granular activated carbon, thus improving the adsorption efficiency. Regular opening of a box door enables extraction of a tail gas adsorption mechanism, thus facilitating replacement of the activated carbon fiber between an upper cover plate and a lower cover plate. A water curtain formed by a water trough, a first flow guide plate and a second flow guide plate facilitates preliminary purification of the tail gas and reduces the purification pressure of activated carbon fiber.

Owner:JIANGSU LEE & MAN CHEM

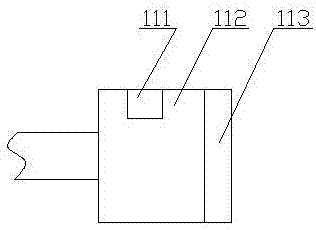

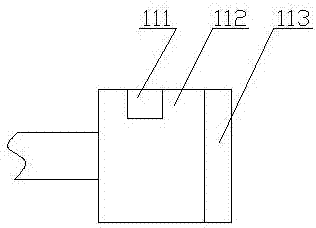

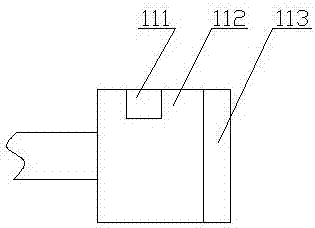

Steel-cored aluminum strand end aluminum strand cutting tool

ActiveCN107186340AEfficient recyclingAvoid pollutionLaser beam welding apparatusNatural environmentBreather

The invention discloses a steel-cored aluminum strand end aluminum strand cutting tool. The steel-cored aluminum strand end aluminum strand cutting tool comprises a box body and a cutting machine which is arranged in the box body. A walking mechanism is arranged below the box body, a dust removing system is arranged on the box body, and a breather mask is arranged in the box body and connected with a box body air inlet pipe through a hose. An air outlet hole of the box body is connected with an air inlet of a blower, an air outlet of the blower is connected with a first air inlet pipe, and an exhaust mechanism is connected with an air inlet of the box body. The dust removing system comprises a first dust removing mechanism, an energy exchanging mechanism communicating with the first end of the first dust removing mechanism and a first regeneration mechanism communicating with the second end of the first dust removing mechanism. For the phenomenon that an existing dust removing system cannot efficiently use waste and waste gas enters the natural environment, under the synergistic action of all the modules, the waste gas can be efficiently recovered, substances in the waste gas can be recovered, and pollution to the environment is avoided.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER +1

Purification process of monofluoromethane

ActiveCN109251124AReduce the pressure of purificationImprove qualityHalogenated hydrocarbon preparationSorbentImpurity

Owner:FOSHAN HUATE GASES +1

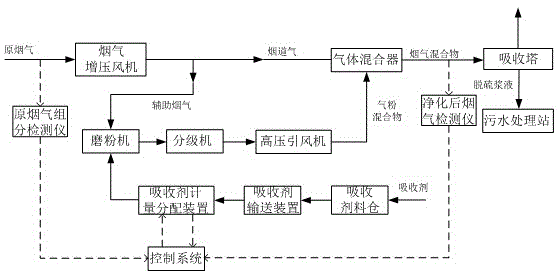

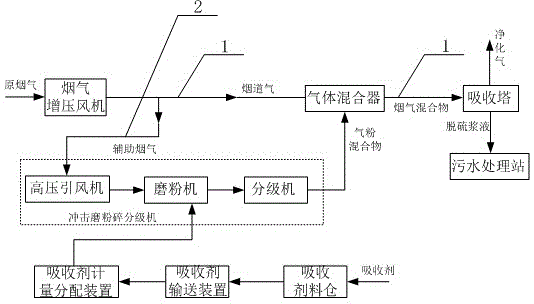

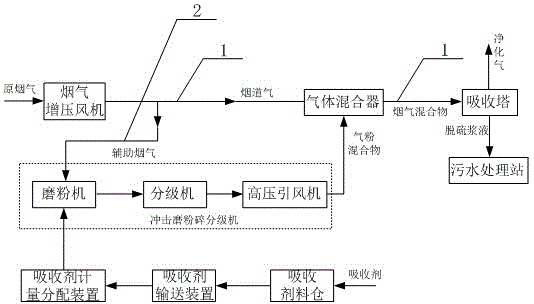

Smoke purification technology implemented based on adsorbent pretreatment

ActiveCN104353350AActiveImprove desulfurization and denitrification efficiencyDispersed particle separationPowder mixtureFlue gas

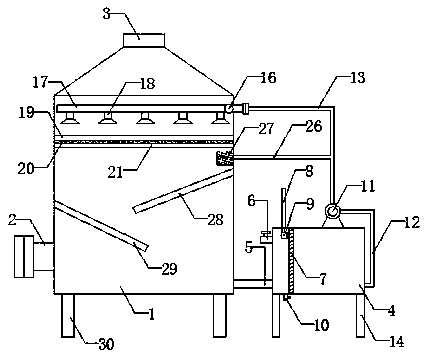

The invention discloses a smoke purification technology implemented based on adsorbent pretreatment. According to the smoke purification technology, raw smoke in a main flue is conveyed into a SO2 absorption system through a smoke system; the smoke system mainly comprises an auxiliary flue and the main flue which are communicated with each other; an impact pulverizing grading machine is arranged in the auxiliary flue; the raw smoke comprises auxiliary smoke passing through the auxiliary flue and flue gas passing through the main flue; an absorbent is conveyed into the impact pulverizing grading machine along with the auxiliary smoke, and an obtained gas-powder mixture enters the main flue and is subjected to mixing reaction with the flue gas; the obtained mixture is conveyed to the SO2 absorption system. The smoke purification technology is designed specially for rough purification of the flue gas, so that the desulfuration and denitration efficiency of the absorbent is greatly improved; the smoke purification technology has an extremely effect for promoting the treatment efficiency of a subsequent desulfuration and denitration technology.

Owner:CHENGDU HUAXITANG INVESTMENT

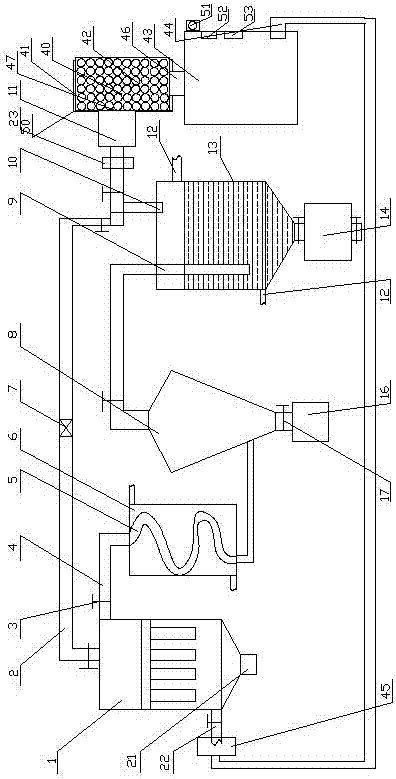

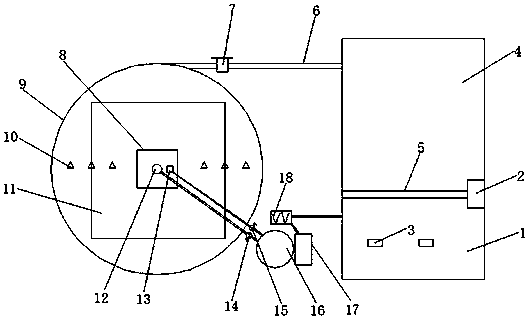

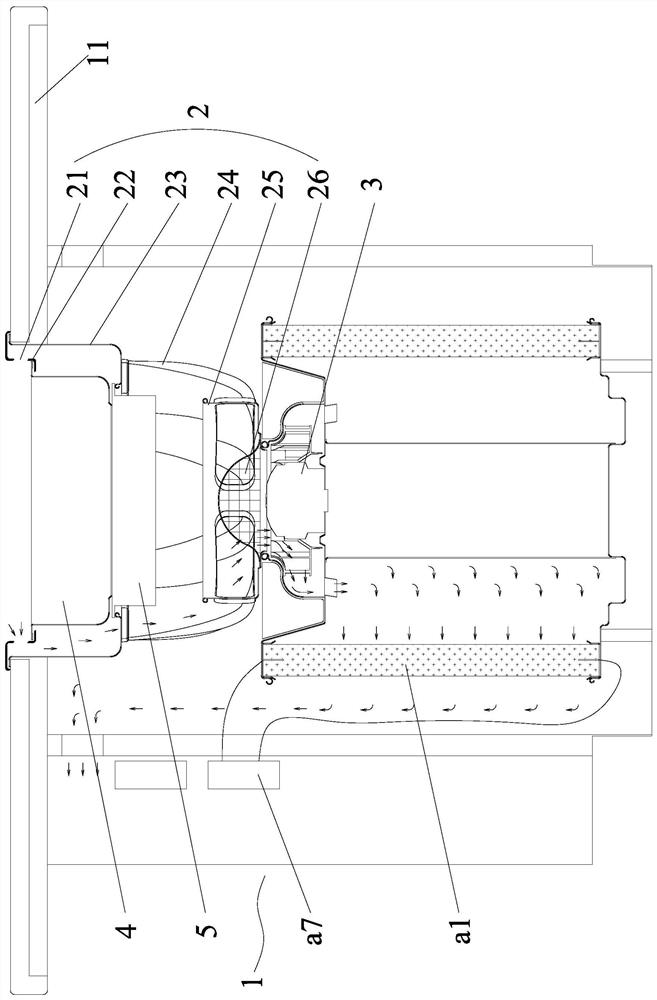

High-efficiency dedusting system for high-temperature separation device of recycled cables

InactiveCN107174914AEfficient recyclingAvoid pollutionCombination devicesDispersed particle filtrationPulp and paper industryElectric cables

The invention discloses a high-efficiency dedusting system for a high-temperature separation device of recycled cables, and the dedusting system comprises a first dedusting mechanism, a transducing mechanism, a first regenerating mechanism, a settling mechanism, a dust deposition module, an absorption mechanism, an exhaust mechanism, a circulating mechanism and an unloading module, wherein the transducing mechanism is communicated with a first end of the first dedusting mechanism, the first regenerating mechanism is communicated with a second end of the first dedusting mechanism, the settling mechanism is communicated with the transducing mechanism, the dust deposition module is arranged at the lower part of the settling mechanism, the absorption mechanism is arranged at the rear part of the settling mechanism, the exhaust mechanism is arranged at the upper part of the absorption mechanism, the circulating mechanism is communicated with the absorption mechanism, and the unloading module is arranged at the lower part of the absorption mechanism. Aiming at the phenomena that the existing dedusting system cannot carry out high-efficiency utilization of waste and waste gas is exhausted into the natural environment, the mutual synergistic effect of the first dedusting mechanism, the transducing mechanism, the first regenerating mechanism, the settling mechanism, the dust deposition module, the absorption mechanism, the exhaust mechanism, the circulating mechanism and the unloading module is used, so waste gas can be efficiently recycled, and also the substances in the waste gas can be recycled.

Owner:国网河南省电力公司西峡县供电公司

Low-temperature calcining process for pot furnace

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

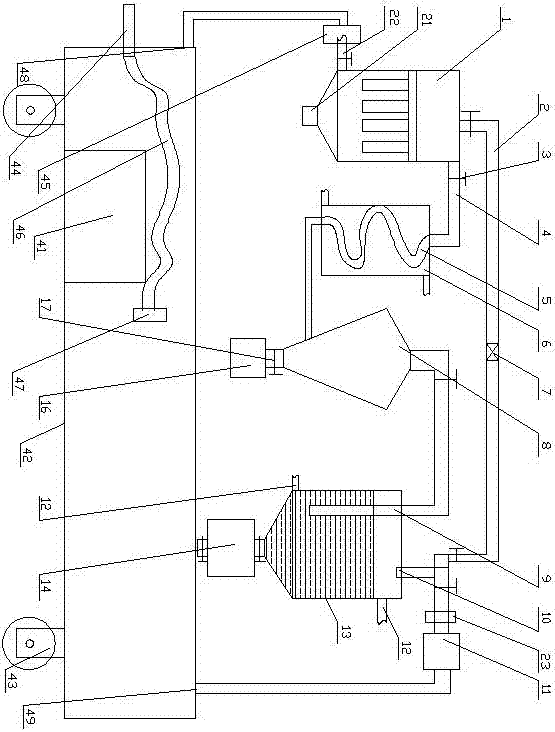

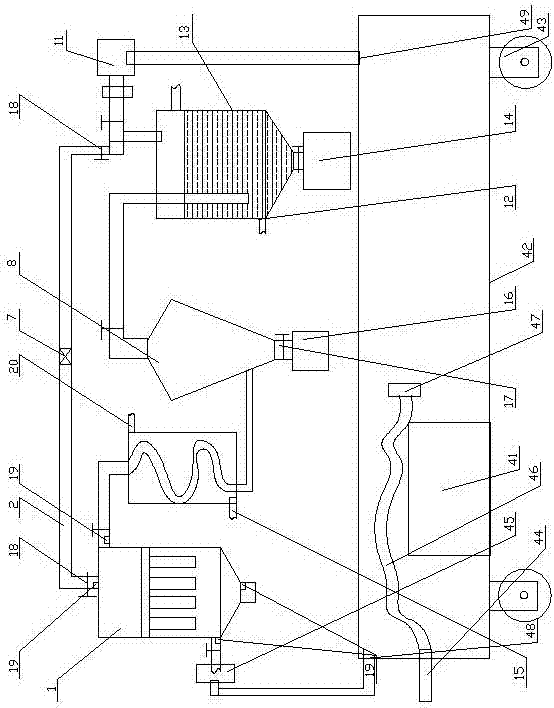

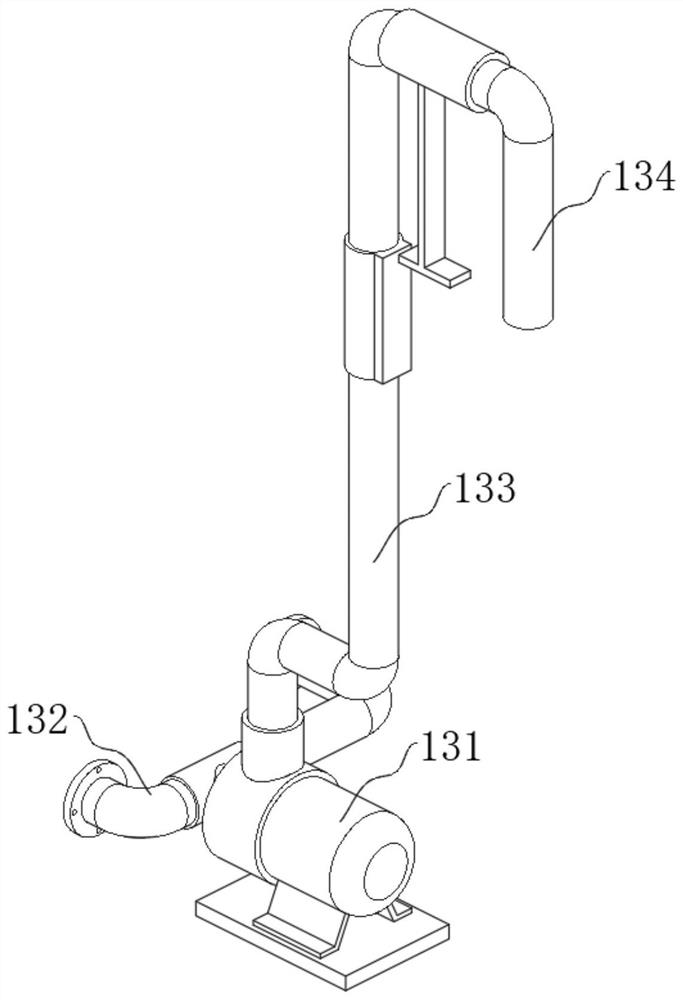

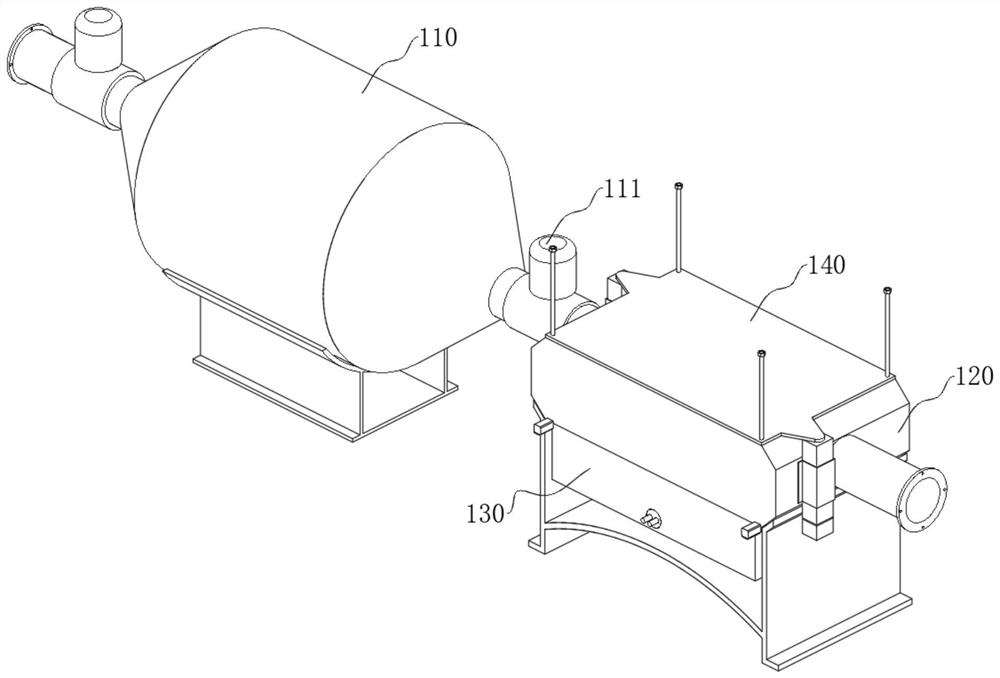

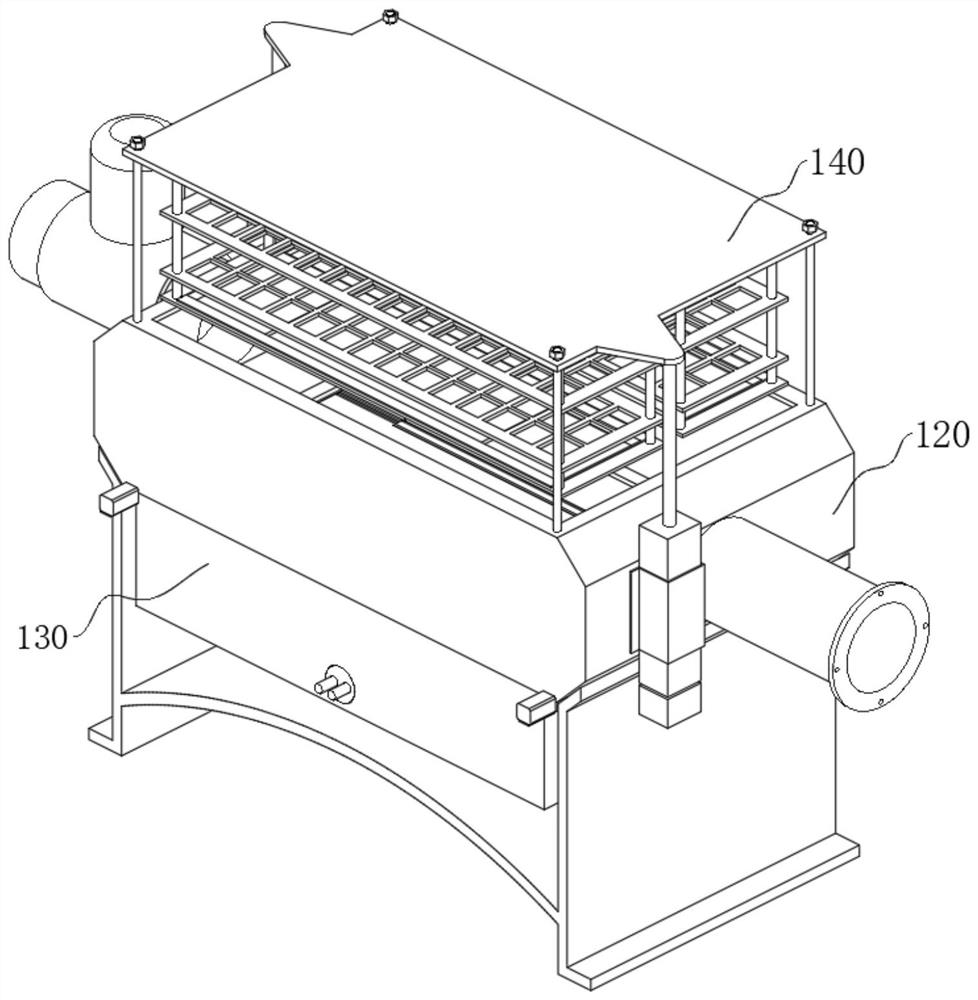

Tail gas treatment system of high-temperature separation device of recycled cables

InactiveCN107174915AEfficient strippingEnsure the effect of energy conversionCombination devicesDispersed particle filtrationPulp and paper industryElectric cables

The invention discloses a tail gas treatment system of a high-temperature separation device of recycled cables, and the treatment system comprises a primary dedusting mechanism, a first dedusting mechanism, a transducing mechanism, a first regenerating mechanism, a settling mechanism, a dust deposition module, an absorption mechanism, an exhaust mechanism, a circulating mechanism and an unloading module, wherein the first dedusting mechanism is communicated with the primary dedusting mechanism, the transducing mechanism is communicated with a first end of the first dedusting mechanism, the first regenerating mechanism is communicated with a second end of the first dedusting mechanism, the settling mechanism is communicated with the transducing mechanism, the dust deposition module is arranged at the lower part of the settling mechanism, the absorption mechanism is arranged at the rear part of the settling mechanism, the exhaust mechanism is arranged at the upper part of the absorption mechanism, the circulating mechanism is communicated with the absorption mechanism, and the unloading module is arranged at the lower part of the absorption mechanism. Under the mutual synergistic effect of the primary dedusting mechanism, the first dedusting mechanism, the transducing mechanism, the first regenerating mechanism, the settling mechanism, the dust deposition module, the absorption mechanism, the exhaust mechanism, the circulating mechanism and the unloading module, waste gas can be efficiently recycled, and also the substances in the waste gas can be recycled, thereby avoiding pollution of the environment.

Owner:国网河南省电力公司西峡县供电公司

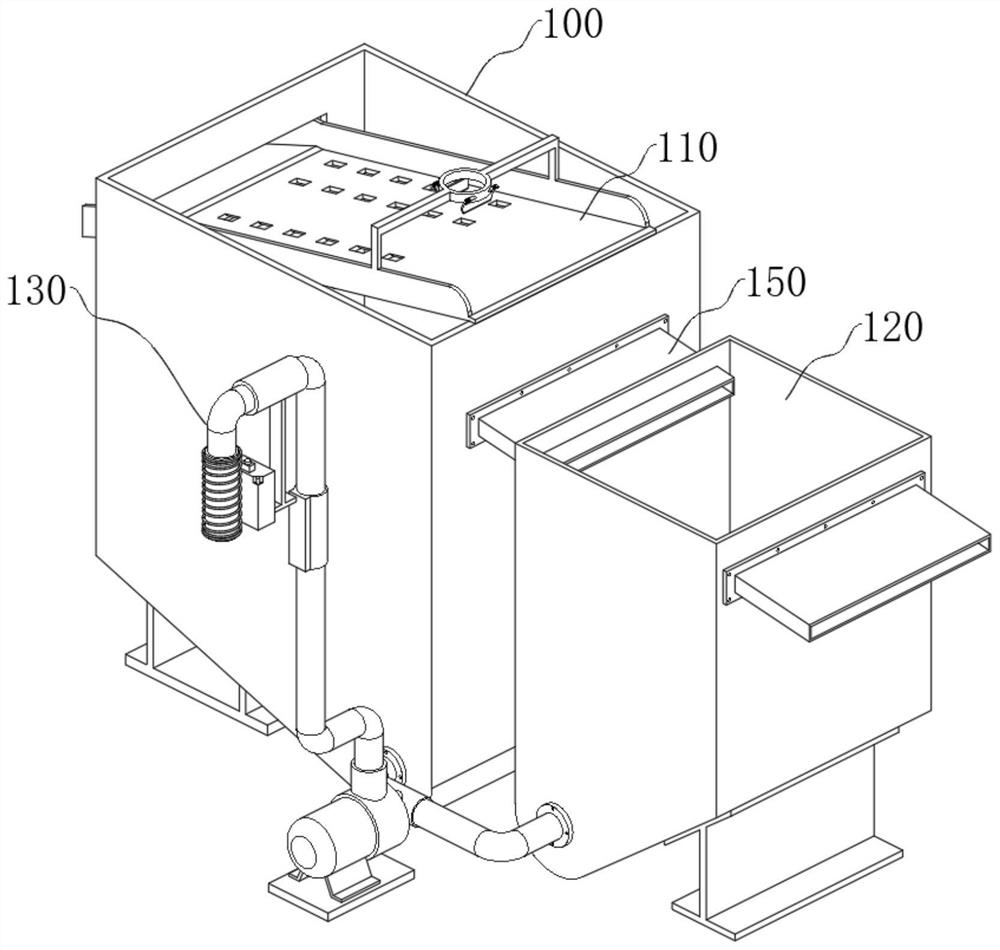

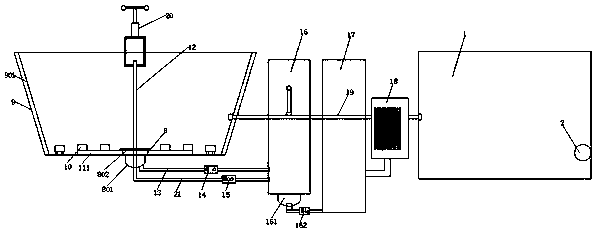

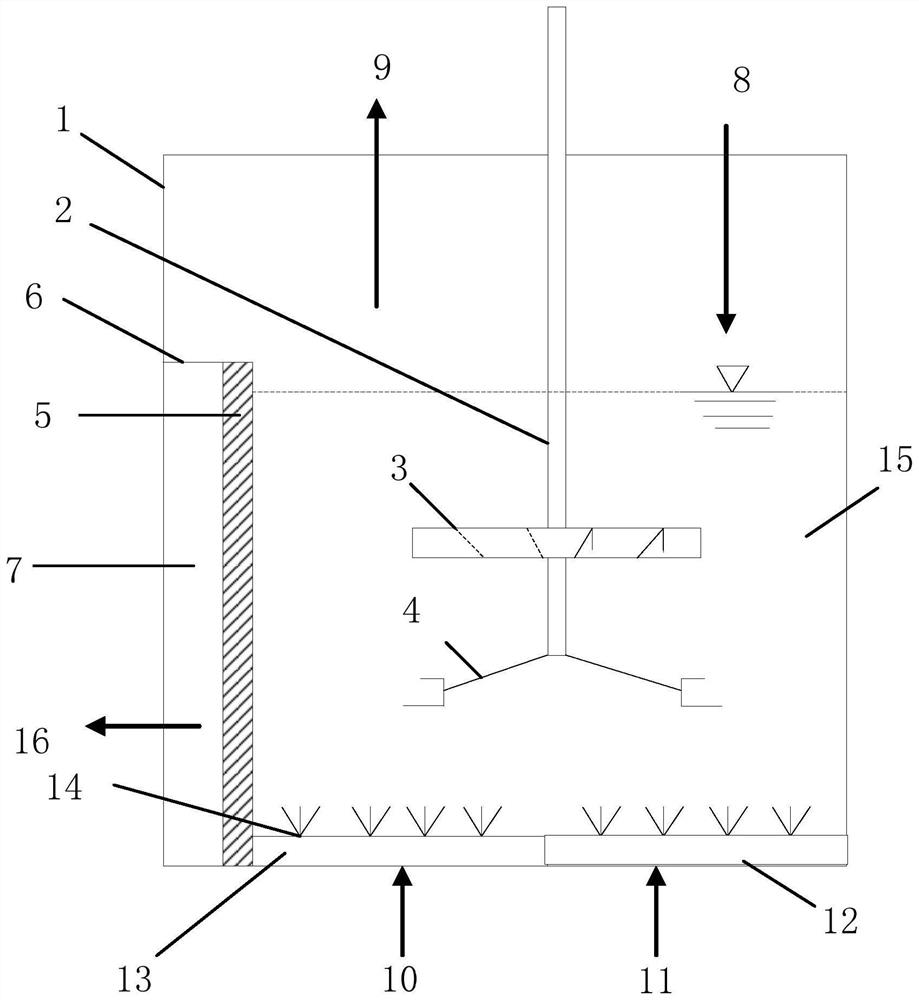

Process for recycling wastes in sewage treatment

InactiveCN112340957AReduce the pressure of purificationClear the blockage in timeSpecific water treatment objectivesClimate change adaptationTreatment pondElectric machinery

The invention discloses a process for recycling waste in sewage treatment, which comprises the steps of separating waste water from waste through a screening tank, precipitating mud in a precipitationtank of the screening tank, sucking the mud by using a mud pumping device, and removing metal, starting a speed reducing motor to perform rotary push type extrusion on the mud pumped into the mud pit, then the mud is dehydrated into powder, the powder is collected and reused, and meanwhile, purified water in the precipitation tank tank overflows into an MBR membrane treatment tank to be thoroughly purified and collected. Waste and waste water of sewage of the primary treatment system are separated through the screening tank, so that the waste water is precipitated and purified in the screening tank and the precipitation tank, the precipitated mud is pumped into the mud pit through the mud pumping device, metal removal and purification are conducted on the mud, and the mud entering the mudpit is dehydrated and extruded into powder and is collected for later use, so that the treatment process enables the mud to be recycled and has popularization value.

Owner:潘申潮

Recycling method for high-hardness high-salinity recycled paper paper-making wastewater

ActiveCN108483761AReduce the pressure of purificationEmission reductionTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsSulfate radicalsSulfate radical

The invention discloses a recycling method for high-hardness high-salinity recycled paper paper-making wastewater. Firstly, pre-softening treatment is carried out on high-hardness wastewater by usinglime powder, and efficient interception is carried out on divalent ions and multivalent ions in the wastewater by using a membrane separation method to remove calcium, magnesium, silicon, sulfate radical and other ions. In the process of using the membrane separation method, the characteristics of the ions in the wastewater are changed by using an electromagnetic method, thereby changing deposition speed of calcium carbonate and physical characteristics of deposition to prevent the formation of hard scale so as to greatly reduce the possibility of the scale formation, the separation effect isgood, the inner treated sewage is recycled, the purification treatment pressure of the sewage is reduced, the out-emission of the sewage is reduced, and the production process is cleaner and more environmentally-friendly.

Owner:DONGGUAN TAICHANG PAPER CO LTD

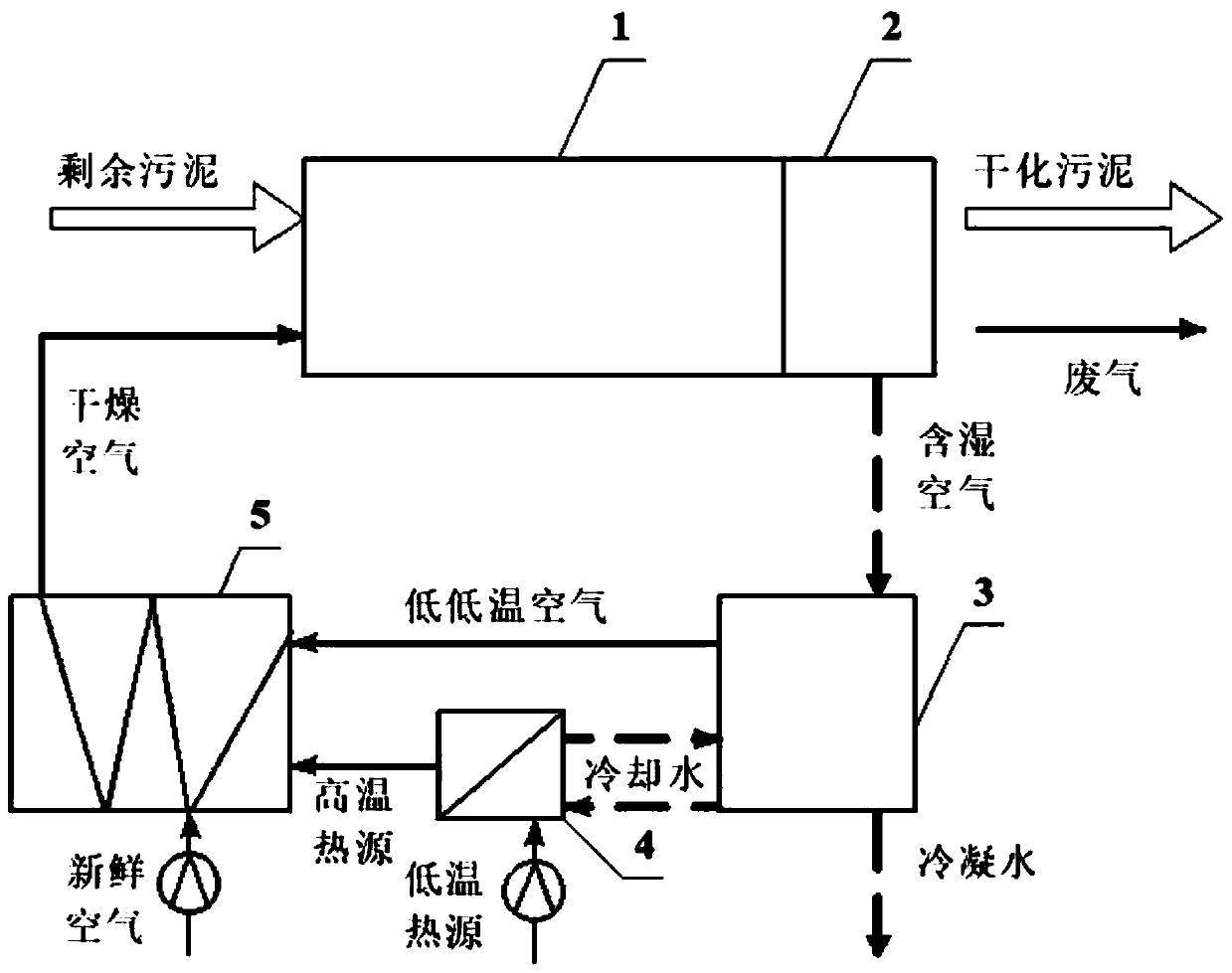

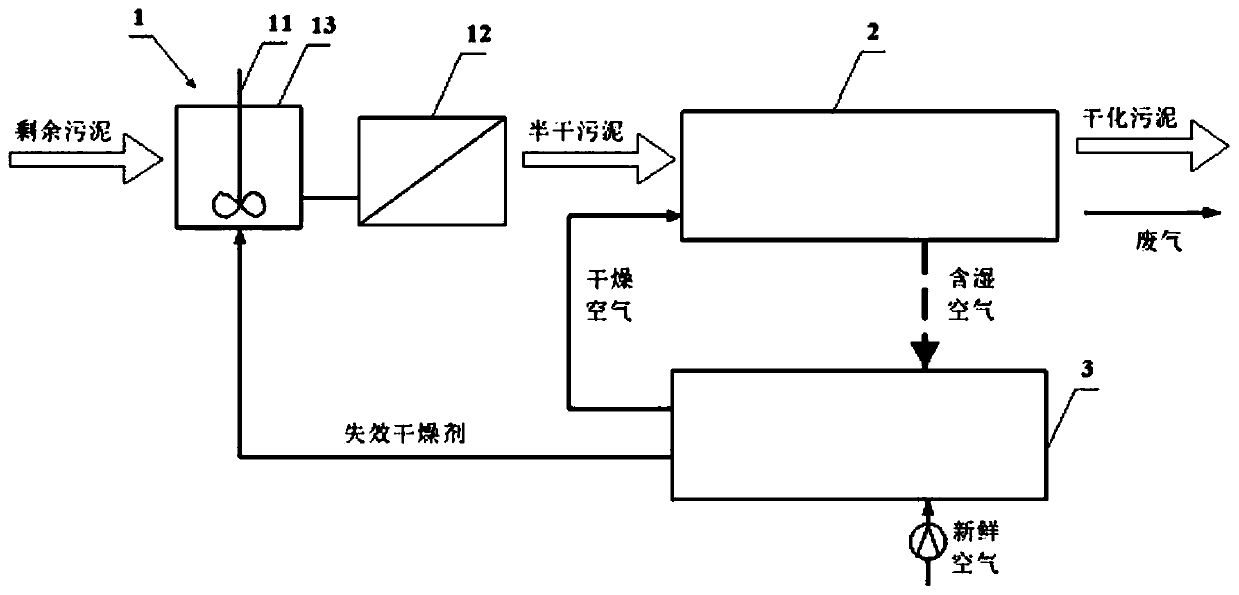

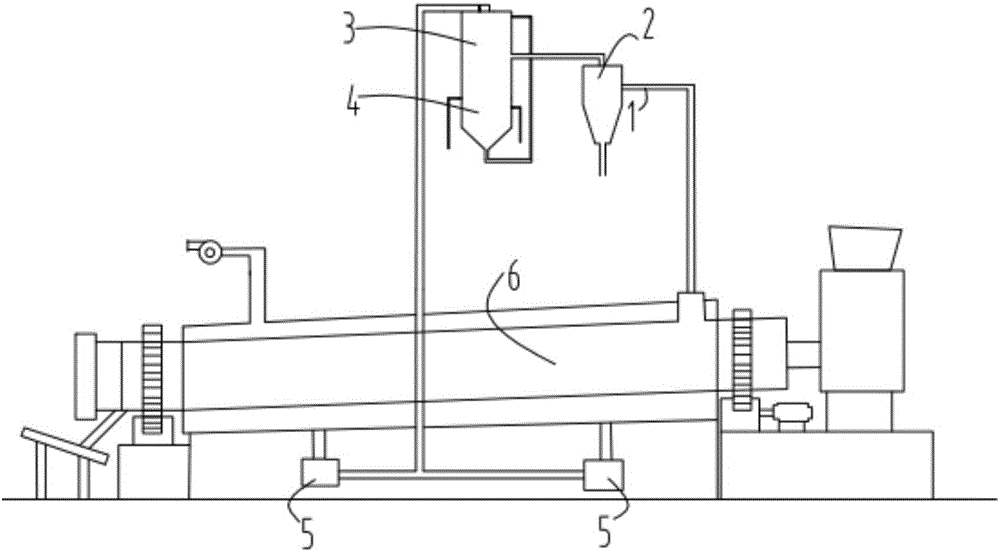

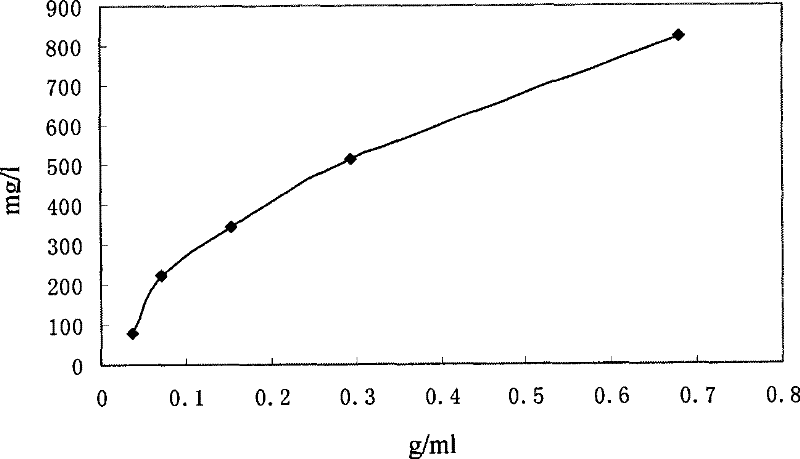

Sludge deep drying method and system based on low-temperature heat source circulation

PendingCN109928599AEconomic moisture content dropEmission reductionSludge treatment by de-watering/drying/thickeningSludgeMoisture

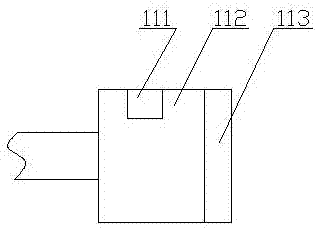

The invention discloses a sludge deep drying method and system based on low-temperature heat source circulation. The method comprises the following steps: 1) adding excess sludge to be treated into asludge pulverization and drying device, and pulverizing and crushing the sludge to be treated into sludge powder particles with the particle size of 50-300 [mu]m; 2) then feeding dry air, mixing the dry air with the sludge powder particles under a stirring condition, drying the sludge powder particles to obtain dry sludge powder, wherein the dry air becomes low-temperature humid air carrying the dry sludge powder; 3) carrying out gas-powder separation on the low-temperature humid air carrying the sludge dry powder through a gas-powder separation device, wherein the separated solid substance isthe sludge dry powder; 4) feeding the separated low-temperature moisture-containing air into a condensation dehumidifier for condensing water removal to form low-temperature and low-temperature air;5) feeding low-low-temperature air into a heat exchanger to be heated for forming dry air again to be repeatedly used, wherein heat absorbed by cooling water is subjected to heat exchange with a low-temperature heat source and the low-low-temperature air is heated after the temperature of the low-low-temperature air is raised, so that the method has the advantages of sludge deep drying, low wastegas generation amount and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

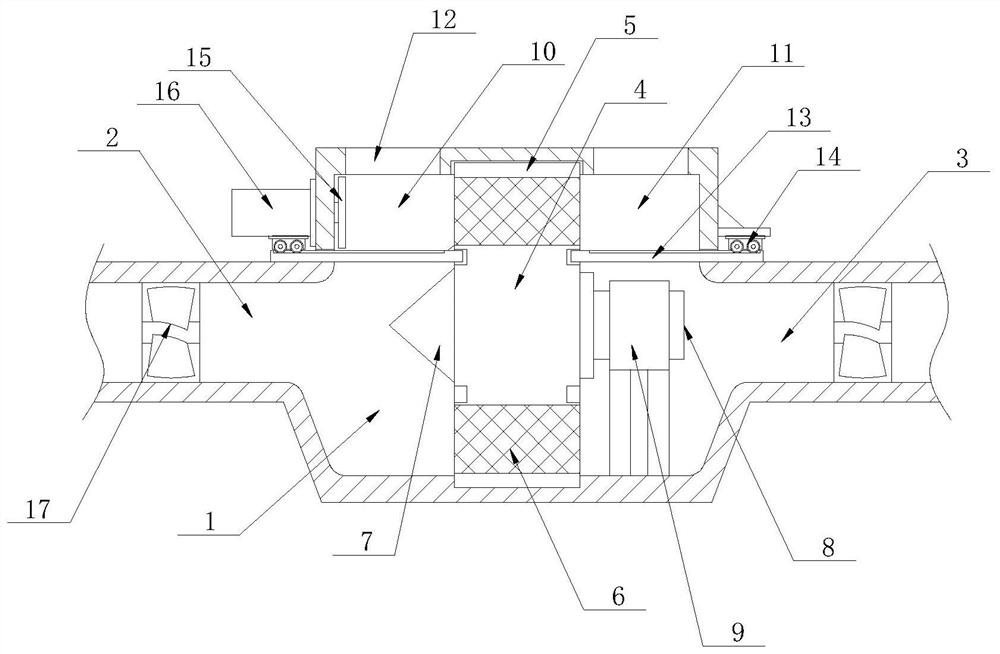

Temperature measuring device for power high voltage switch cabinet trolley switch

InactiveCN107196197AStable and efficient workKeep dryCombination devicesBoards/switchyards circuit arrangementsEngineeringHigh voltage

The invention discloses a temperature measuring device for a power high voltage switch cabinet trolley switch. The temperature measuring device comprises a switch cabinet and an infrared temperature sensor which is arranged in the switch cabinet and is used for detecting the temperature of the switch. The infrared temperature sensor is connected with a programmable controller. The programmable controller is connected with a sound and light alarm. The programmable controller is connected with a blower. The switch cabinet is equipped with a dust removing system. The dust removing system comprises a first dust removing mechanism, a transduction mechanism communicated with a first end of the first dust removing mechanism, a first regeneration mechanism communicated with a second end of the first dust removing mechanism, and a sedimentation mechanism communicated with the transduction mechanism. For the phenomenon that waste gas enters a natural environment due to the fact that an existing dust removing system cannot carry out efficient utilization on waste, through mutual cooperation effect of various modules, the waste gas can be recycled efficiently, substances in the waste gas can be recycled, and the pollution to the environment is avoided.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

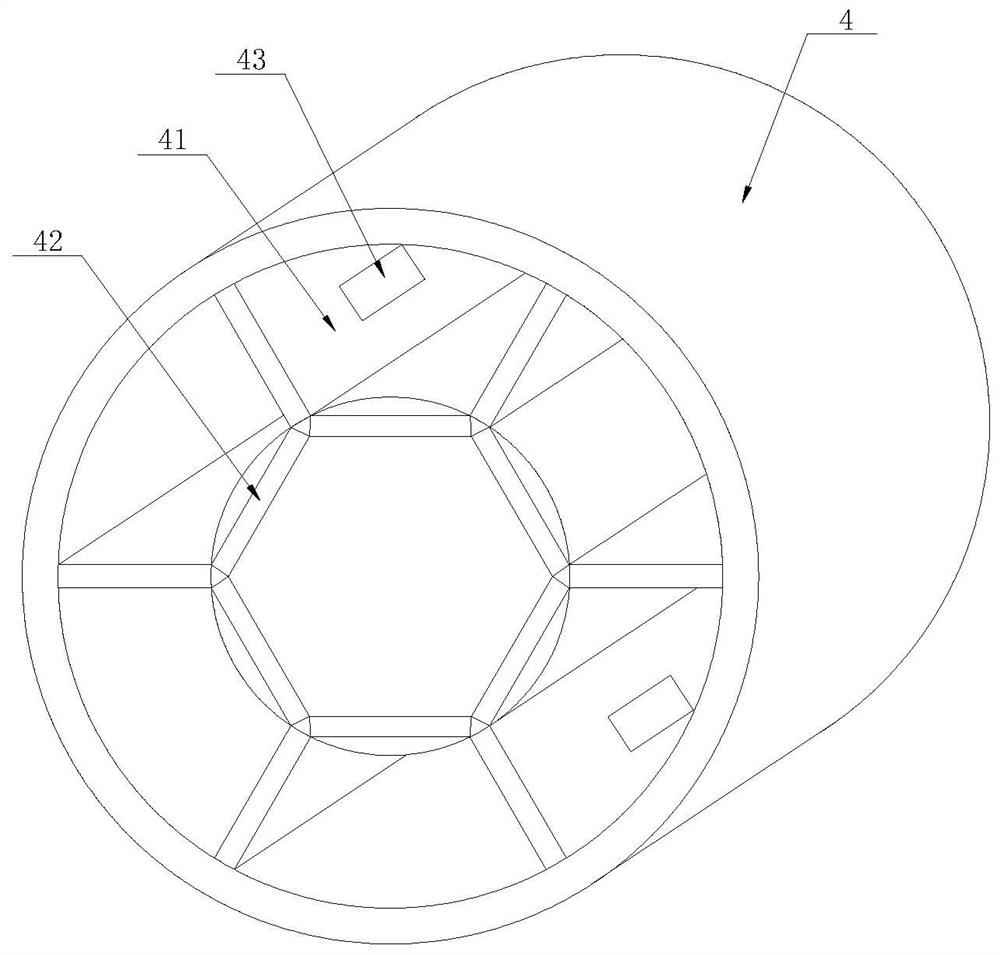

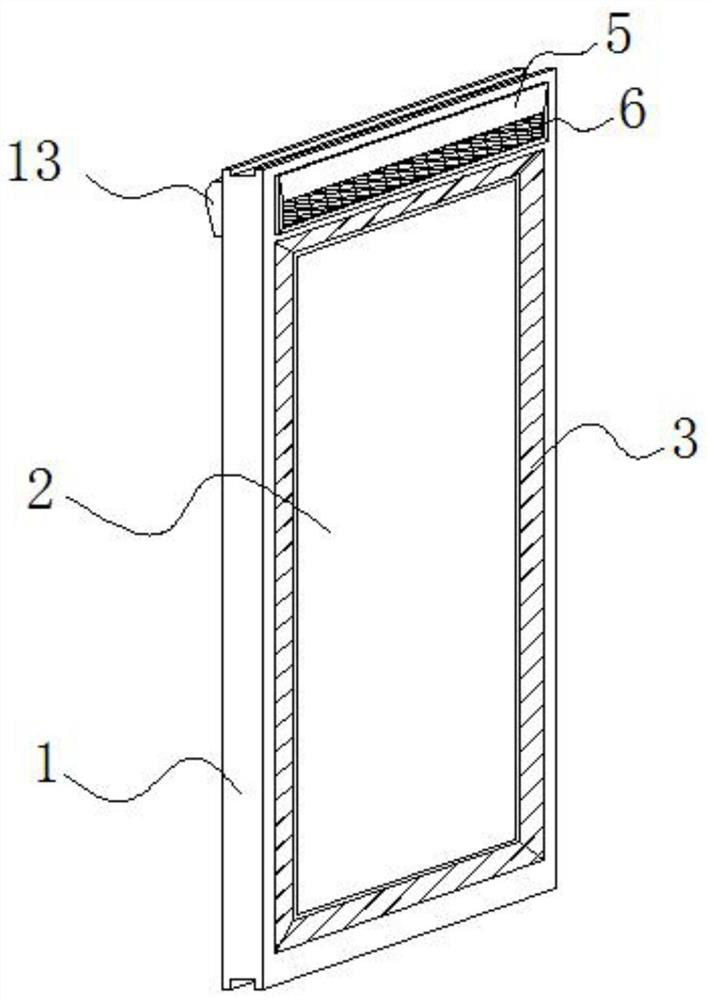

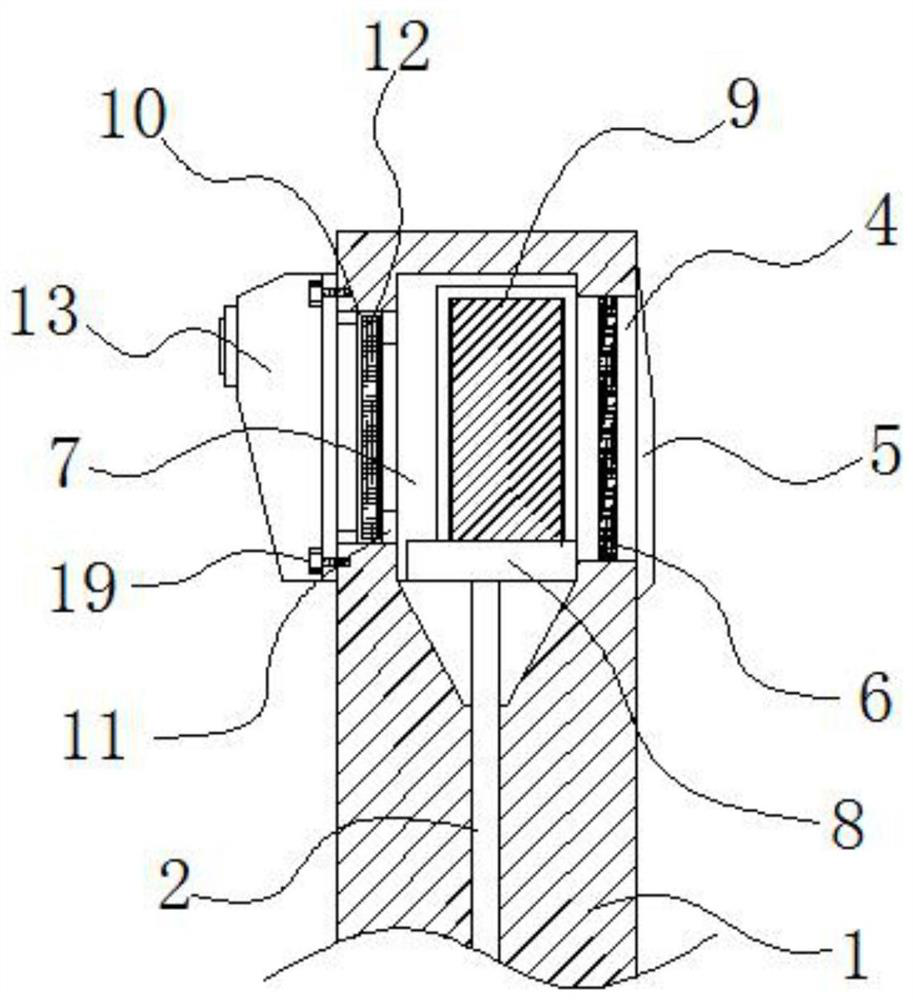

Industrial air filtering system convenient for replacing filter element

InactiveCN113731038AIncrease the purification areaReduce the pressure of purificationDispersed particle filtrationAir filtrationAir filter

The invention belongs to the technical field of air filtration and purification, and particularly relates to an industrial air filtration system convenient for replacing a filter element. A rotary purifying disc is arranged in the middle of the air purifying and filtering bin; a circle of air filter element is movably clamped on the outer ring of the rotary purification disc; a maintenance sealing cabin and a recovery sealing cabin are symmetrically arranged on the inner side of the upper end of the air purification filtering cabin, and the maintenance sealing cabin and the recovery sealing cabin are distributed on the left side and the right side of the rotary purification disc correspondingly; translation baffles are movably inserted into the bottoms of the maintenance sealing bin and the recovery sealing bin in a penetrating mode and are controlled to stretch out and draw back through an external forward and reverse rotation driving motor; an extrusion push plate is arranged in the maintenance sealing bin and connected with a hydraulic telescopic oil cylinder fixed to the outer side wall. According to the system, the air purification disc of a rotating disc type structure is adopted, the air purification area can be increased, and the air purification efficiency is improved by cooperating with the pressurized air inlet and outlet effect; and meanwhile, the independent maintenance cabin can realize shutdown-free maintenance.

Owner:南京田宏新材料科技有限公司

Working method capable of lowering outage rate during electrical equipment overhaul

InactiveCN107344050AEfficient recyclingAvoid pollutionCombination devicesSubstation/switching arrangement casingsEnvironmental engineeringFiltration mechanism

The invention discloses a working method capable of lowering outage rate during electrical equipment overhaul. The working method comprises a first dust removal mechanism, a transducing mechanism communicated with a first end of the first dust removal mechanism, a first regeneration mechanism communicated with a second end of the first dust removal mechanism, a settlement mechanism communicated with the transducing mechanism, a dust deposition module arranged at the lower part of the settlement mechanism, an absorption mechanism arranged at the rear part of the settlement mechanism, a discharge mechanism arranged at the upper part of the absorption mechanism, a circulating mechanism communicated with the absorption mechanism, a discharging module arranged at the lower part of the absorption mechanism and an adsorption filtration mechanism arranged between the absorption mechanism and the discharge mechanism. Under the synergistic interaction of all the modules, not only is waste gas efficiently recycled, but also substances in the waste gas can be recycled, so that pollution to the environment is avoided, and the phenomena that an existing dust removal system can not efficiently utilize waste and the waste gas enters into natural environment can be avoided.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

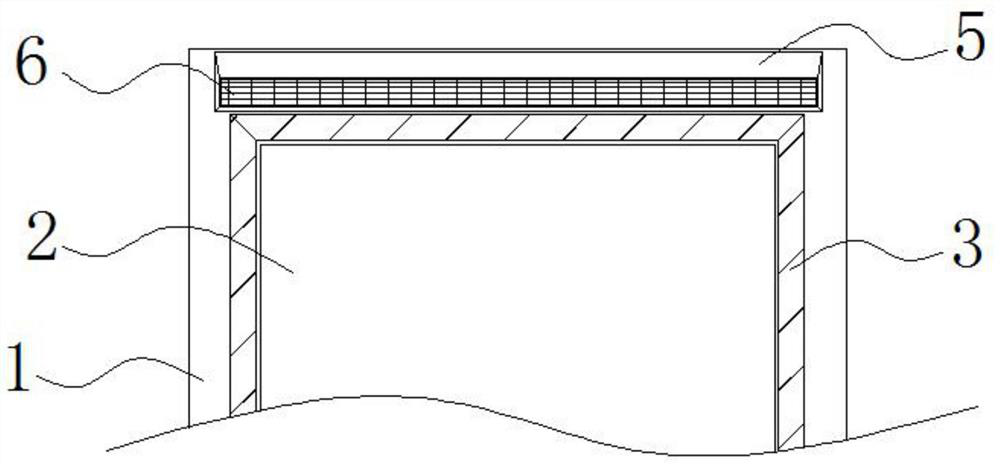

Air changing and ventilating equipment for energy conservation and emission reduction of building

InactiveCN111827853AAvoid stockpilingReal-time detection of dust contentCombination devicesDispersed particle filtrationAwningAir change

The invention discloses air changing and ventilating equipment for energy conservation and emission reduction of a building, and relates to the technical field of building door and windows. The air changing and ventilating equipment particularly comprises a door and window frame, an awning and a dust detecting sensor. Transparent glass is embedded into the door and window frame, the awning is arranged on the edge of an outdoor air opening, a static electromagnetic plate is arranged in a sliding groove part, and an indoor air opening is formed in the top of the inner surface of the door windowand frame. The two sides of the inner wall of a fan shell are connected with micro damping rotary shafts, and the dust detecting sensor is fixed to the middle of the surface of the fan shell. According to the air changing and ventilating equipment for energy conservation and emission reduction of the building, the dust content in indoor air can be detected through the dust detecting sensor in realtime; when the dust content is higher than a preset value, the micro exhaust fans on the two sides in the fan shell are started to exhaust the indoor air and dust out of a room; and the air changingand ventilating equipment is beneficial to detecting the dust content of the indoor air in real time and guaranteeing the quality of the indoor air, dust accumulation is avoided, and a good environment is provided for the human body to live in.

Owner:北京建企动力科技工程有限公司

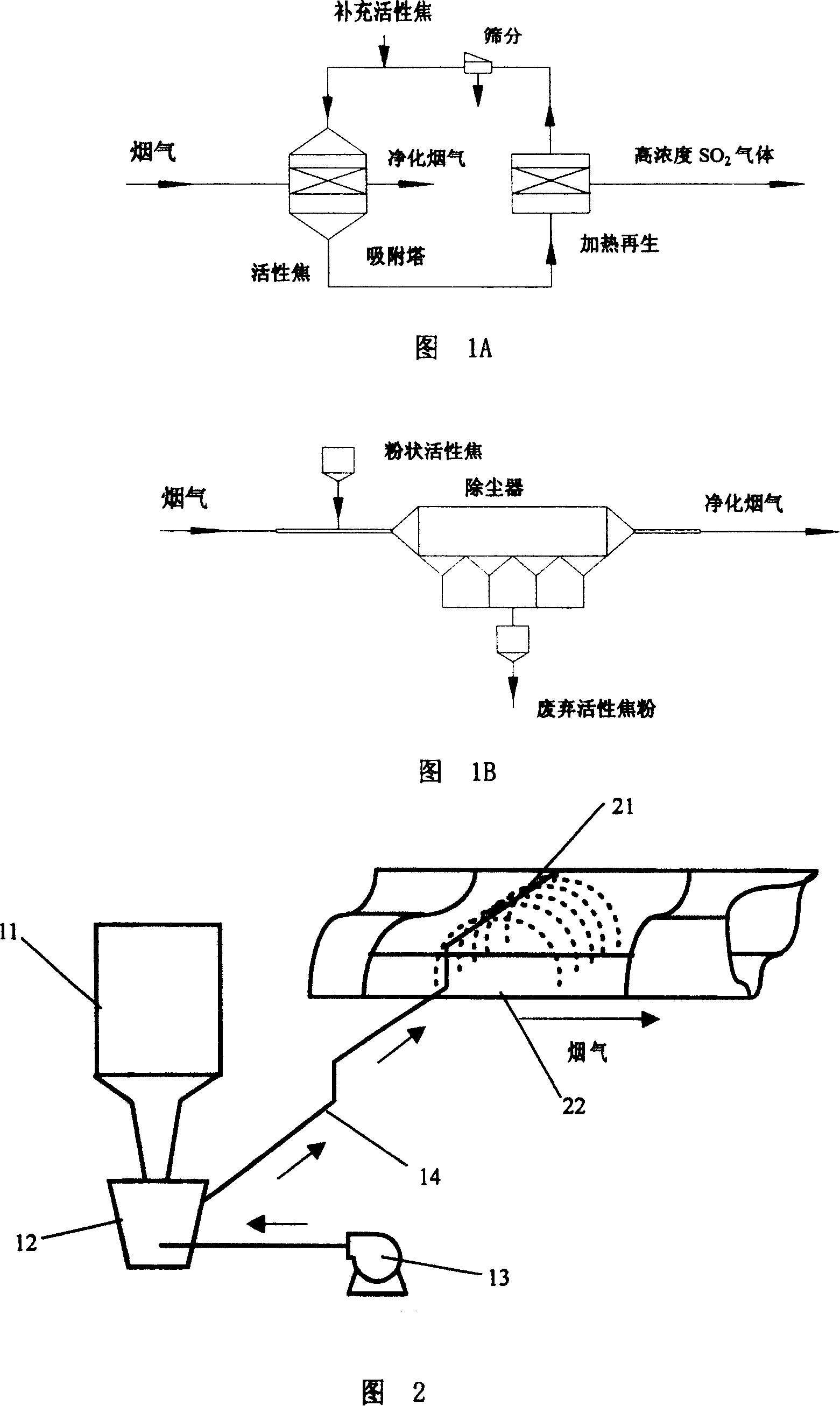

Method for purifying flue gas by application of active coke

ActiveCN100377763CImprove purification efficiencyReduce wasteDispersed particle separationPurification methodsFlue gas

The invention discloses a method for using active carbon to purify the smoke, relating to the smoke purification method. The inventive method comprises that the denitration-desulfurization reactor formed by two sections of moving bed reactor can purify the passed smoke, while said smoke be purified when it passes the channel which can spray the active carbon. The invention can remove the heavy metal pollutions of SO2, NOX and Hg at one time; therefore, it has the advantages of high smoke purification efficiency, and lower program investment while it avoids the consumption of water in the purification process. The invention has wider application prospect.

Owner:CHINA SHENHUA ENERGY CO LTD

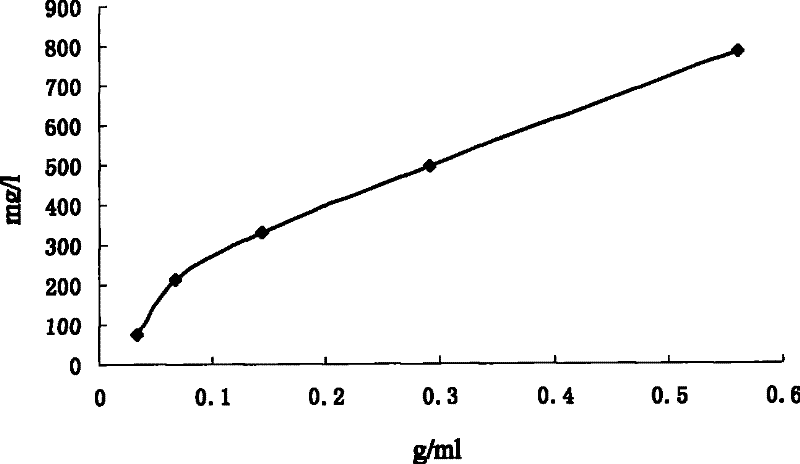

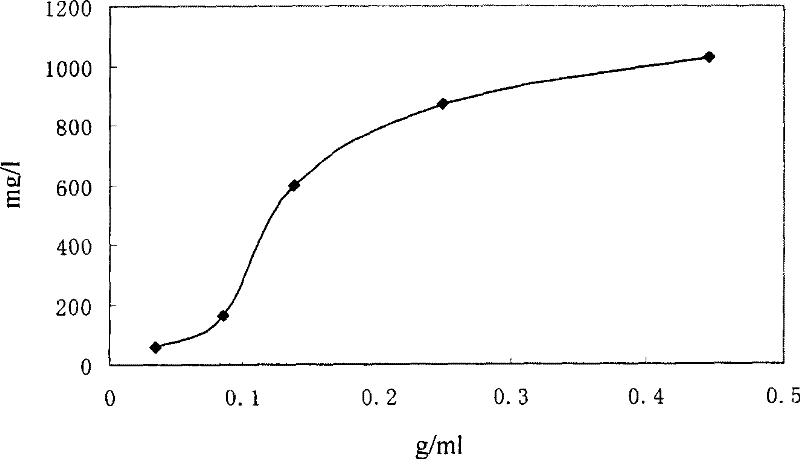

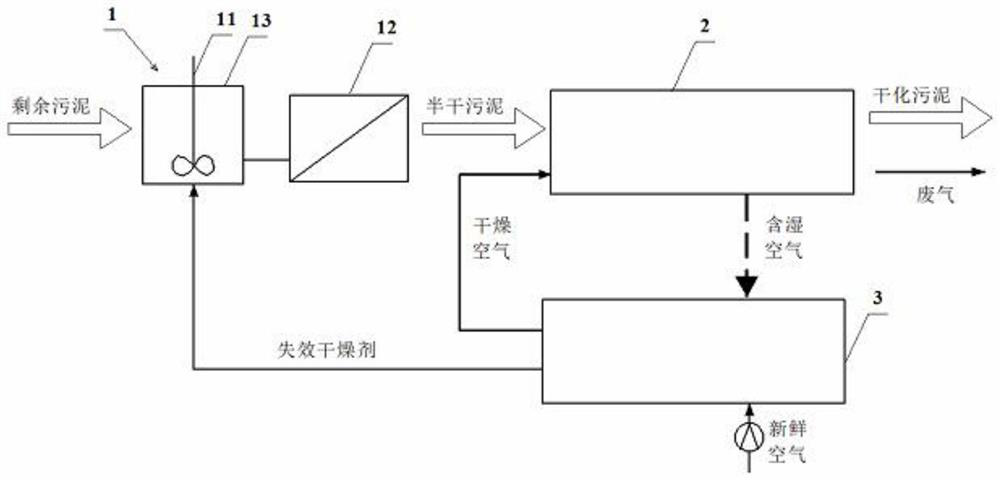

Sludge deep drying method and system based on air medium circulation

ActiveCN109928598AAchieve deep dryingImprove economySludge treatment by de-watering/drying/thickeningSludgeEnvironmental engineering

The invention discloses a sludge deep drying method and system based on air medium circulation. The system comprises a sludge conditioning and dewatering device, a sludge pulverization and drying device, and a dryer. The method comprises the following steps: 1) adding a proper amount of an alkali-skeleton structure composite conditioner into the excess sludge with the water content of 90-95%, andstirring the excess sludge for 5-15 minutes to condition the excess sludge; dewatering the conditioned excess sludge to form a semi-dry mud cake with the water content of 45-60%; pulverizing and crushing the semi-dry mud cake into sludge powder particles with the particle size of 10-200 [mu]m, feeding dry air to dry the sludge powder particles to obtain dry sludge powder and generate moist air atthe same time; and then drying the moist air, recycling the moist air, and recycling the ineffective drying agent as the alkali-skeleton structure composite conditioner again. The method has the advantages of deep drying of sludge, low waste gas generation amount, high utilization rate of a drying agent and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Process for extracting and purifying narirutin from bitter orange processing waste liquid

PendingCN111423476AReduce the pressure of purificationSugar derivativesSugar derivatives preparationNaringinWater treatment system

The invention provides a process for extracting and purifying narirutin from bitter orange processing waste liquid. The process comprises the following steps: using bitter orange processing waste liquid as a raw material, and performing filtering with a ceramic membrane, macroporous adsorption resin chromatography, concentrating, macroporous adsorption resin chromatography, concentrating, vacuum drying, pulverizing and packaging. The method has the advantages that: the waste is turned into wealth, the purification pressure of a sewage treatment system can be effectively reduced, products witheconomic value are obtained, and human beings are benefited.

Owner:桂林三棱生物科技有限公司

Double-fishpond circulating water ecological culture system

PendingCN109526849ACan't solveSolve the problem of uncleanlinessPisciculture and aquariaFiltrationWater quality

The invention discloses a double-fishpond circulating water ecological culture system. The system comprises a natural environment area, a convergence area, a central sewage discharge area, a precipitation filtration area, a comprehensive air floatation area and an original ecological regulation area, and is characterized in that the convergence area is arranged on the inner side of the natural environment area, the central sewage discharge area is arranged in the middle of the convergence area, an overflow pipe is arranged at the center of the central sewage discharge area, the bottom end of the overflow pipe is connected with a drainage pipe, a sewage discharge pipe is laid at the bottom end of the central sewage discharge area, the drainage pipe is connected to the precipitation filtration area through a water pump, the sewage discharge pipe is connected to the precipitation filtration area through a sewage suction pump, and the precipitation filtration area is connected to the comprehensive air floatation area through a pipe. Culture water is purified more thoroughly, purification pressure of a water diversion area is reduced, so that water quality of the whole circulating waterbody is more stable, organic matter in ponds can be timely removed, the problems of oxygen consumption and release of toxic substances during organic matter degradation are solved, and the culture environment is better.

Owner:浙江庆渔堂科技有限公司

Diesel machine waste gas purification process

InactiveCN112065543ALow input costReduce concentrationGas treatmentExhaust apparatusMolecular sieveDenitrifying bacteria

The invention discloses a diesel engine waste gas purification process. The diesel engine waste gas purification process comprises the following steps that firstly, waste gas just discharged by a diesel engine is re-combusted and decomposed through a combustion box, then enters a filter tower to react with an alkaline solution to generate precipitates, then is adsorbed and purified through a molecular sieve under the pressure action of a push cylinder, and finally is denitrified by denitrifying bacteria in a denitrification box to generate nitrogen to be discharged. According to the diesel engine waste gas purification process, the waste gas is discharged into the combustion box and is subjected to secondary combustion decomposition, so that the concentration of carbon particles and combustible particles in the waste gas is reduced, then the waste gas is discharged into the filter tower and reacts with the alkaline solution in the filter tower to generate the precipitates, the waste gas are massively purified, then the gas is adsorbed by the molecular sieve and selectively passes through under the pressure action of the push cylinder, then the gas is dissolved into the alkaline solution in the denitrification box and reacts with the denitrifying bacteria to generate the nitrogen, so that thorough purification is achieved, the waste gas is purified step by step through the structure, equipment purification pressure can be relieved, the practicability is high, and the popularization is easy.

Owner:沈高金

Dining table with lampblack purification system

PendingCN111955925APrevent escapeImprove the pumping effectCombination devicesDomestic stoves or rangesActivated carbonTemperature control

The invention discloses a dining table with a lampblack purification system. An oil fume purification system is integrated in the table body; the oil fume purification system is provided with an oil fume inlet formed in the circumferential periphery of the cookware on the table body; the sucked oil smoke is purified by the purification assembly; the purification assembly comprises an activated carbon purification mechanism, the activated carbon purification mechanism comprises an activated carbon layer and a temperature control assembly used for controlling the temperature of the activated carbon layer, when lampblack penetrates through the activated carbon layer to be subjected to adsorption purification treatment, the temperature control assembly controls the activated carbon layer to beat a first temperature, and the first temperature is higher than the dew point temperature of the lampblack. According to the dining table with the lampblack purification system, lampblack can be timely and fully pumped away; the dining table guarantees the body health of consumers, improves the quality of the dining environment, does not occupy extra space, does not hinder the consumers to normally pick up dishes, is better in dining experience, purifies cooking fume through the purification assembly, avoids environmental pollution caused by outward discharge of the cooking fume, and is goodin environmental protection property.

Owner:成都市珑熙科技有限公司

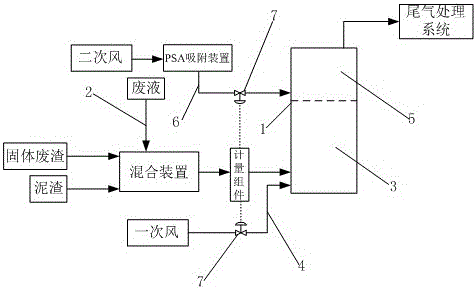

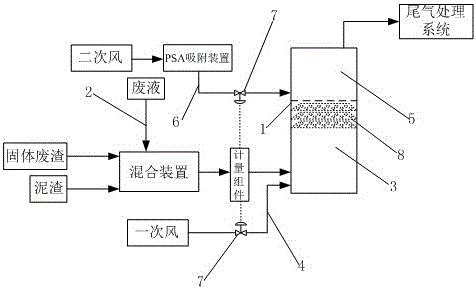

Incineration technology system for petrochemical cured materials

InactiveCN106122971AImprove incineration efficiencyIncrease the degree of mixingIndirect carbon-dioxide mitigationIncinerator apparatusCombustionAir volume

The invention discloses an incineration technology system for petrochemical cured materials. The incineration technology system comprises an incinerator and a mixing device, wherein the mixing device is connected with a solid waste incoming pipe; an outlet end of the mixing device is connected with a feeding opening of a primary combustion zone of the incinerator; a metering component is arranged on the outlet end of the mixing device; a primary air duct is arranged on the primary combustion zone of the incinerator; a secondary air duct is arranged on a secondary combustion zone of the incinerator; the metering component is interlocked with a primary air duct air volume valve and a secondary air duct air volume valve; a PSA adsorption device is arranged at the front end of the secondary air duct; and secondary air is fed into the secondary combustion zone of the incinerator after passing through the PSA adsorption device. According to the incineration technology system, after the mixing device uniformly mixes the petrochemical solid waste, the mixed petrochemical solid waste is fed into the incinerator through the metering component, air is fed into the primary combustion zone, rich oxygen prepared through the PSA adsorption device is fed into the secondary combustion zone, the metering component can perform interlocking control on air inlets of the primary air duct and the secondary air duct, the oxygen content inside the incinerator is reasonably controlled, full combustion is achieved, and the tail gas purification pressure is reduced.

Owner:四川省德阳昌盛至轩石油化工厂

A recycling method for recycled papermaking wastewater with high hardness and high salinity

ActiveCN108483761BReduce the pressure of purificationEmission reductionTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsSulfate radicalsWastewater

The invention discloses a recycling method for high-hardness high-salinity recycled paper paper-making wastewater. Firstly, pre-softening treatment is carried out on high-hardness wastewater by usinglime powder, and efficient interception is carried out on divalent ions and multivalent ions in the wastewater by using a membrane separation method to remove calcium, magnesium, silicon, sulfate radical and other ions. In the process of using the membrane separation method, the characteristics of the ions in the wastewater are changed by using an electromagnetic method, thereby changing deposition speed of calcium carbonate and physical characteristics of deposition to prevent the formation of hard scale so as to greatly reduce the possibility of the scale formation, the separation effect isgood, the inner treated sewage is recycled, the purification treatment pressure of the sewage is reduced, the out-emission of the sewage is reduced, and the production process is cleaner and more environmentally-friendly.

Owner:DONGGUAN TAICHANG PAPER CO LTD

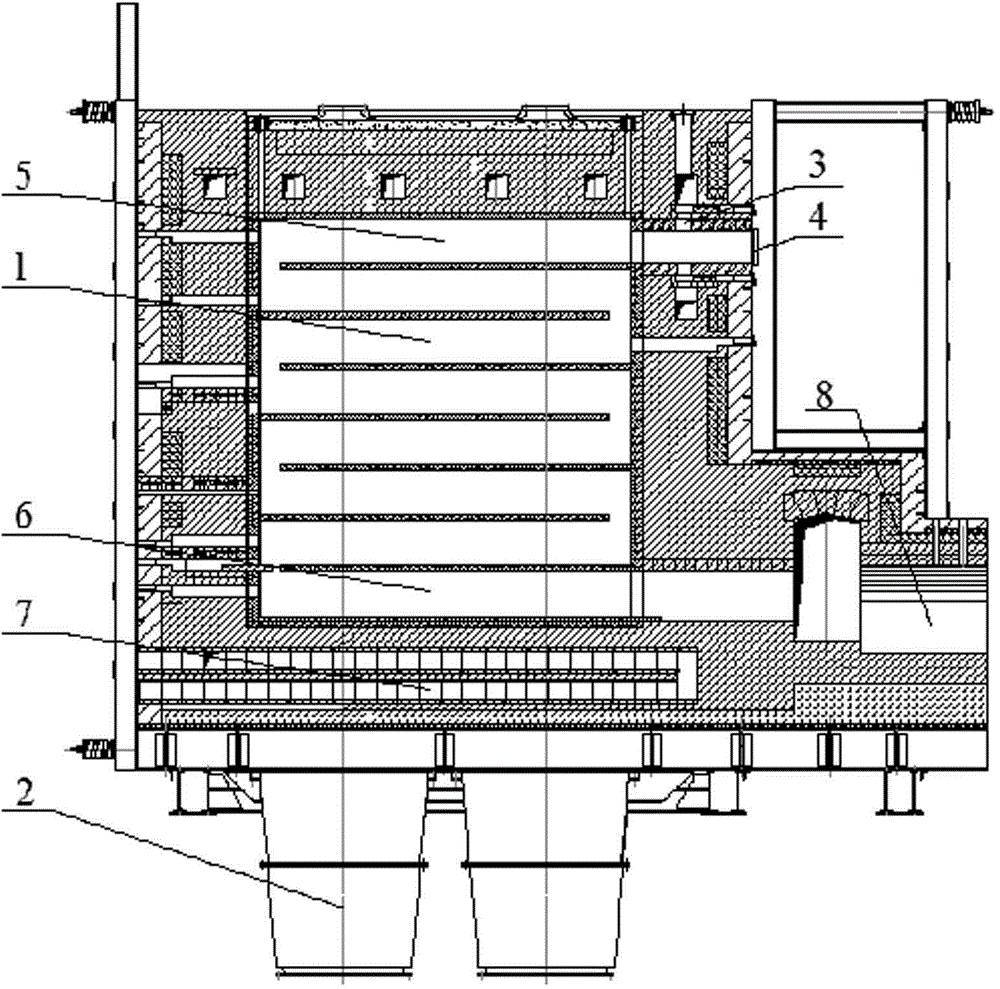

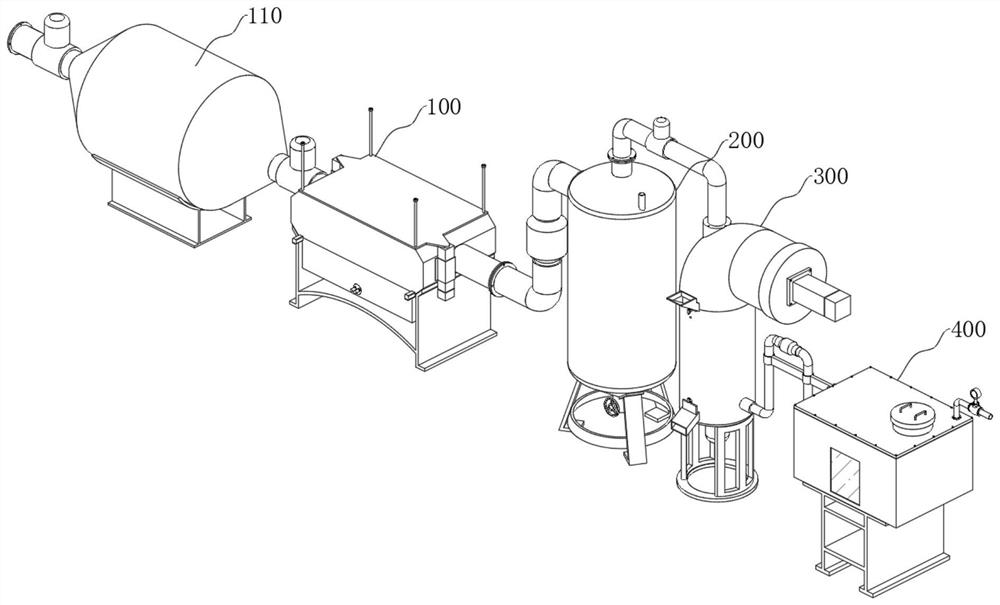

Diseased animal pyrolysis and charring treatment system

InactiveCN105688575AAvoid separationSeparation avoids increasingBurner safety arrangementsCombination devicesNitrogen oxidesCombustor

The invention relates to a diseased animal pyrolysis and charring treatment system. The diseased animal pyrolysis and charring treatment system comprises a cyclone deduster, a spraying treatment tower, an oil and water separator, a combustor and a pyrolysis and charring furnace, wherein the oil and water separator comprises a conical inlet, a vertical passage, a conical outlet and a conical separating plate; a sediment chamber is arranged at the lower end of the oil and water separator, and a water drain passage is arranged at the lowermost end of the sediment chamber, and is connected with a spraying nozzle in the spraying treatment tower; a heating sleeve is arranged at the outer surface of the cyclone deduster, and a heating coil is arranged between the heating sleeve and the cyclone deduster; the combustor comprises a fuel discharge assembly, an air pipeline, a combustor wall and an igniter, the fuel discharge assembly comprises a discharge end, a fuel lifting pipe and a flame stabilizing structure, and the flame stabilizing structure is arranged at the first inside of one side of the axis of the combustor wall. The diseased animal pyrolysis and charring treatment system has the advantage that the problem of large emission amount of NOX (nitrogen oxide) is solved, the gas produced by pyrolysis and charring is sufficiently utilized, and the purifying stress of tail gas is decreased.

Owner:CHANGXING JINNUO MACHINERY CO LTD

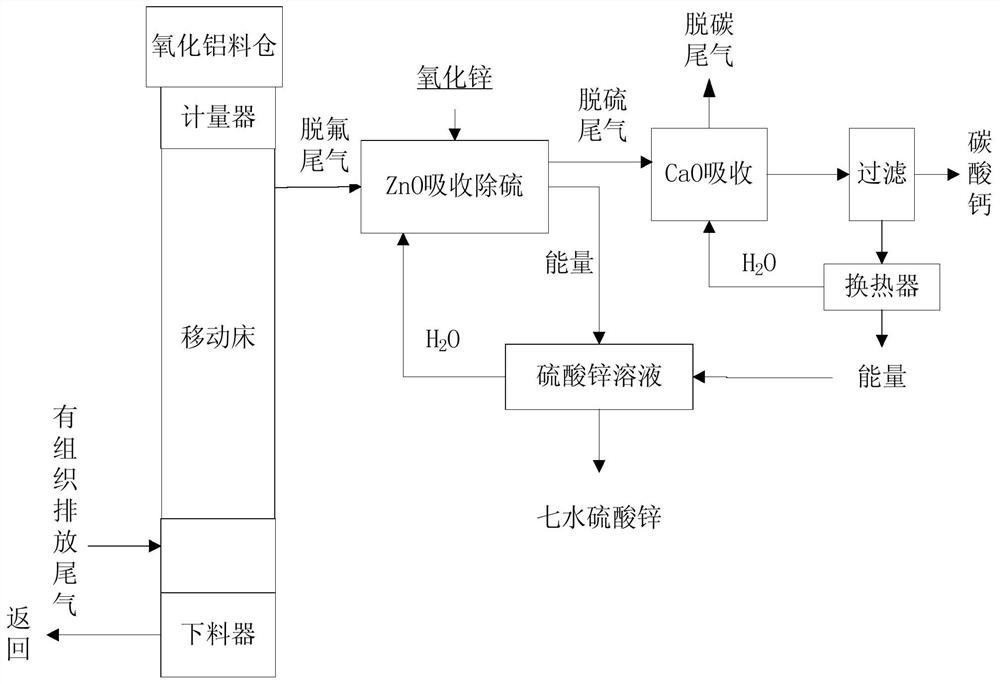

A deep purification method for organized tail gas discharge during aluminum electrolysis production process

ActiveCN107803108BReduce the pressure of purificationSolve the problem of excess fluoride and sulfurCalcium/strontium/barium carbonatesProductsSulfate zincAluminium electrolysis

Owner:NORTHEASTERN UNIV LIAONING

Integrated oil mist purifier based on environmental engineering

ActiveCN111545002AReduce the pressure of purificationImprove purification effectCombination devicesElectric machineryFan blade

The invention discloses an integrated oil mist purifier based on environmental engineering. The integrated oil mist purifier comprises a first bracket, a shell, an air inlet, an oil stain purificationdevice and an oil discharge pipeline; the oil mist purifier also comprises a second bracket arranged above the shell, a motor arranged on the second bracket, fan blades arranged on the motor, a primary purification chamber arranged in the shell, a secondary purification chamber arranged above the primary purification chamber and an oil discharge structure arranged below the primary purification chamber; and the secondary purification chamber is positioned right above the primary purification chamber. The primary purification chamber and the secondary purification chamber are arranged; the primary purification chamber is used for primarily purifying the oil mist gas; the purification pressure of the secondary purification chamber is reduced, oil liquid generated in the secondary purification chamber falls down, the purification effect of the primary purification chamber is enhanced in a raining mode, the purification effect is enhanced when final gas is exhausted, the air quality in aworkshop is guaranteed, and the occupied space is saved.

Owner:绍兴煦橙环保设备有限公司

A microwave catalysis-biochemical vocs emission reduction combined equipment

InactiveCN105944529BImprove purification efficiencyReduce the pressure of purificationGas treatmentDispersed particle separationMicrowave emissionPollution

Owner:东莞市环境科学研究所

Process for purifying benzo pollutants in waste water

InactiveCN101284686BHigh recovery rateReduce the pressure of purificationWater contaminantsWater/sewage treatment by extractionAlkaneBenzene

The invention discloses a method for purifying benzene pollutants in wastewater. The method comprises the steps as follows: adding low carbon alkane to the wastewater containing benzene by the volume proportion between the low carbon alkane and the wastewater containing benzene of 0.2 to 2 or 0.05 to 1; intensely churning and mixing for 5 to 180 minutes; standing for stratification; and taking the lower water layer. The purifying method can be applied in the industry to purify the wastewater containing benzene, and has low requirements for environmental conditions. The purification can be completed at the room temperature with simple tools; the operation is simple and safe; the purifying effect is prominent. The method is suitable for high-purity purification of the wastewater containing benzene; the wastewater purified by the method can meet the national standard for industrial water; the recycling rate for the wastewater is increased, so that the energy-saving and environmental-protection functions are effectively served. The method can also reduce the pressure on microbe treating ponds for purifying the wastewater containing benzene, minimize the treatment cost for environmental protection and enhance the economic benefits of the equipment.

Owner:BEIJING INST OF CLOTHING TECH +1

Sludge deep drying method and system based on air medium circulation

ActiveCN109928598BAchieve deep dryingImprove economySludge treatment by de-watering/drying/thickeningSludgeDesiccant

The invention discloses a sludge deep drying method and system based on air medium circulation. The system comprises a sludge conditioning and dewatering device, a sludge pulverization and drying device, and a dryer. The method comprises the following steps: 1) adding a proper amount of an alkali-skeleton structure composite conditioner into the excess sludge with the water content of 90-95%, andstirring the excess sludge for 5-15 minutes to condition the excess sludge; dewatering the conditioned excess sludge to form a semi-dry mud cake with the water content of 45-60%; pulverizing and crushing the semi-dry mud cake into sludge powder particles with the particle size of 10-200 [mu]m, feeding dry air to dry the sludge powder particles to obtain dry sludge powder and generate moist air atthe same time; and then drying the moist air, recycling the moist air, and recycling the ineffective drying agent as the alkali-skeleton structure composite conditioner again. The method has the advantages of deep drying of sludge, low waste gas generation amount, high utilization rate of a drying agent and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

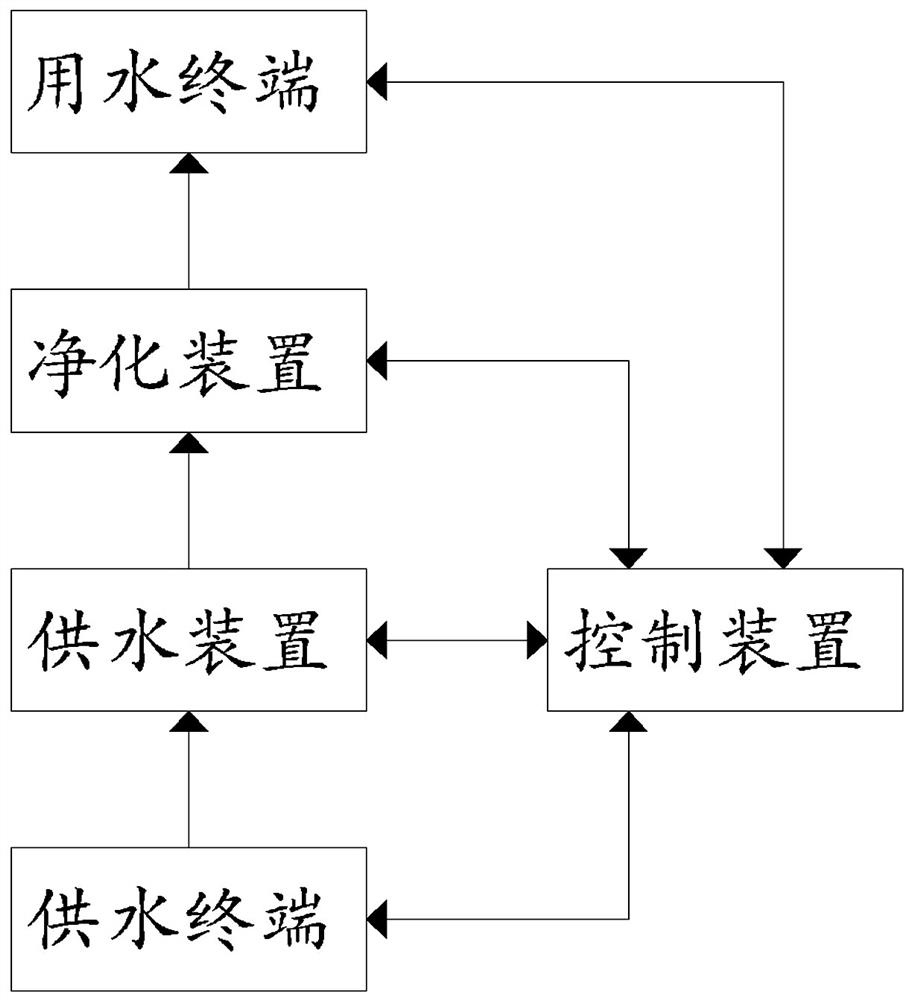

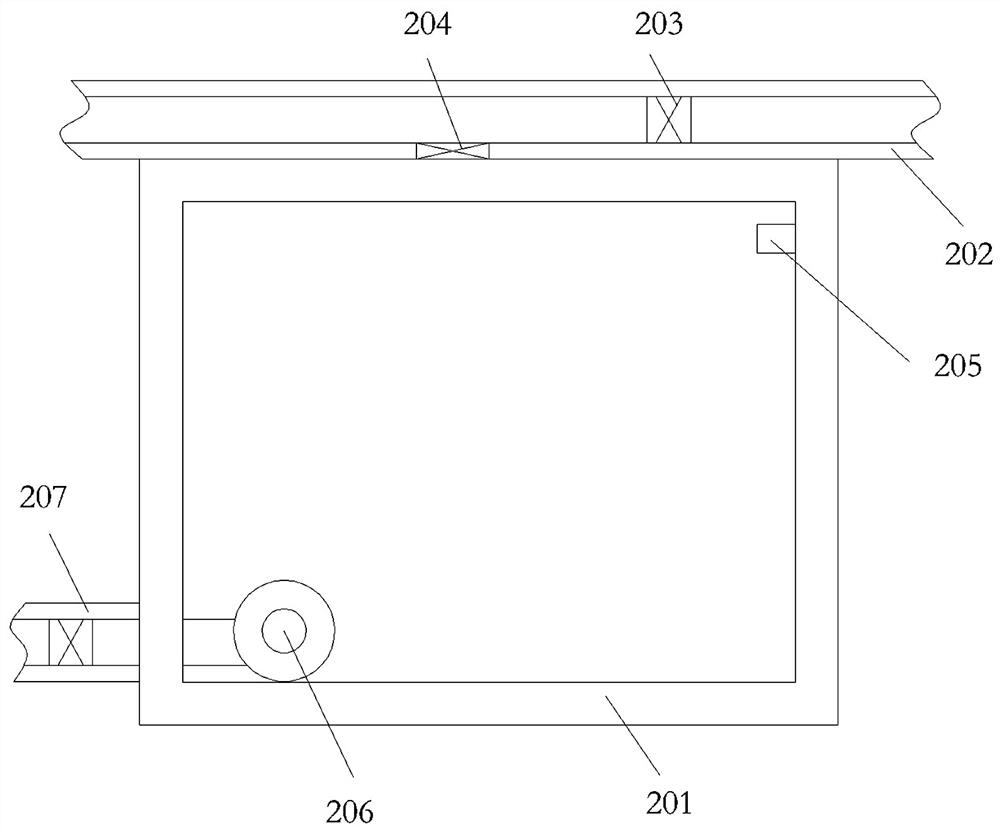

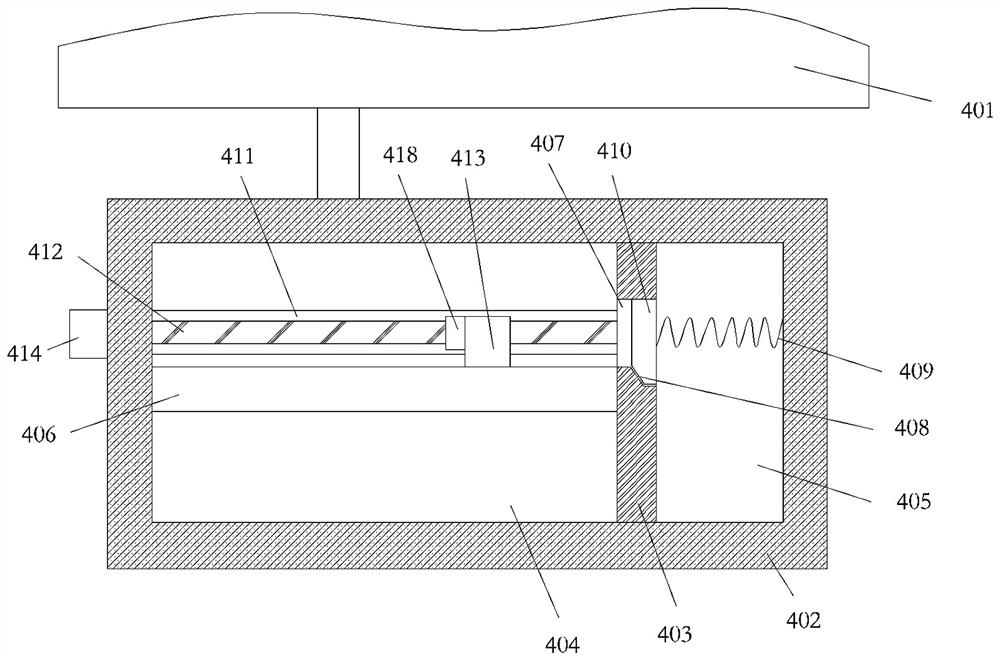

Water supply system and pipeline thereof

PendingCN114809192AGuaranteed uptimeImprove connection strengthService pipe systemsWater mainsWater useWater storage tank

The water supply system comprises a water supply device, a purification device and a control device, the water supply device comprises a water storage tank, a main pipeline, an auxiliary pipeline and control valves arranged in the main pipeline and the auxiliary pipeline, and the two ends of the main pipeline communicate with the purification device and a water supply terminal correspondingly; two ends of the auxiliary pipeline are respectively communicated with the water storage tank and the purification device, the control device is used for controlling the water supply device, the purification device is used for carrying out purification operation on the water supply device, and the purification device is connected with the water using terminal. The water source is controlled to send water to the water supply device through the main pipeline, the water is purified by the purification device and then is discharged from the water using terminal, and the water is primarily purified when being discharged from the water source, so that the purification pressure in the later period is greatly reduced, and the water supply system runs more smoothly.

Owner:蚌埠市建筑设计研究院集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com