Incineration technology system for petrochemical cured materials

A process system and solidification technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as start-up, long shutdown time, excessive exhaust gas of incineration equipment, and impact on exhaust gas treatment pressure, so as to improve incineration efficiency and reduce CO and NO content, and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

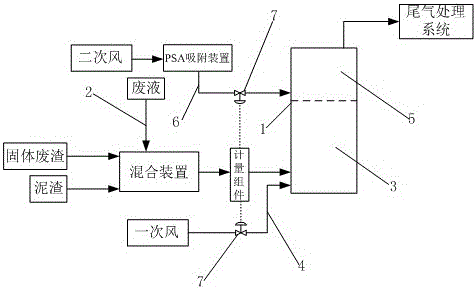

[0025] This embodiment proposes a petrochemical solidification incineration process system, such as figure 1 As shown in the structure, it includes an incinerator 1 and a mixing device. The mixing device is connected to the solid waste feeding pipe 2. The outlet of the mixing device is connected to the incinerator 1 primary combustion zone 3 feeding port. Petrochemical solid waste such as waste liquid, solid waste residue, sludge, etc. The solid waste is sent to the mixing device through the solid waste feeding pipe 2. In this embodiment, the mixing device is equipped with a spiral stirring blade. When working, the solid waste and sludge are broken and mixed evenly with the waste liquid by the rotation of the spiral stirring blade. , the helical design of the stirring blades will send the mixed waste to the incinerator 1 for incineration while stirring and crushing, and the tail gas generated by the incinerator 1 will be sent to the tail gas treatment system.

[0026] Since th...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the mixing device involved in this embodiment adopts a movable rotating device that rotates along a horizontal axis, and the petrochemical solid waste such as waste liquid, solid waste residue, sludge, etc. sent into the mixing device rotates with the device. Mix well, and then sent to the incinerator 1 for incineration.

Embodiment 3

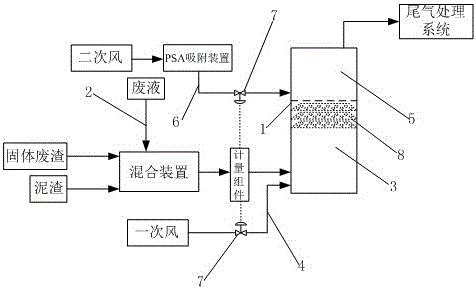

[0031] This embodiment proposes the design of the deflector 8 on the basis of the first embodiment. Such as figure 2 As shown in the structure, a deflector 8 is arranged on the inner wall of the incinerator 1, and the deflector 8 is located on the top of the primary combustion zone 3, and is obliquely arranged on the inner wall of the incinerator 1, and the included angle with the inner wall of the incinerator 1 is 45°.

[0032] In this embodiment, three layers of deflectors 8 are arranged circularly along the inner wall of the incinerator 1 , and at the same time, diversion holes are provided on the deflectors 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com