Industrial air filtering system convenient for replacing filter element

A technology for air filtration and replacement of filter elements, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of low work efficiency, poor filtration effect, and low use requirements, so as to increase the air purification area and reduce The effect of purifying pressure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

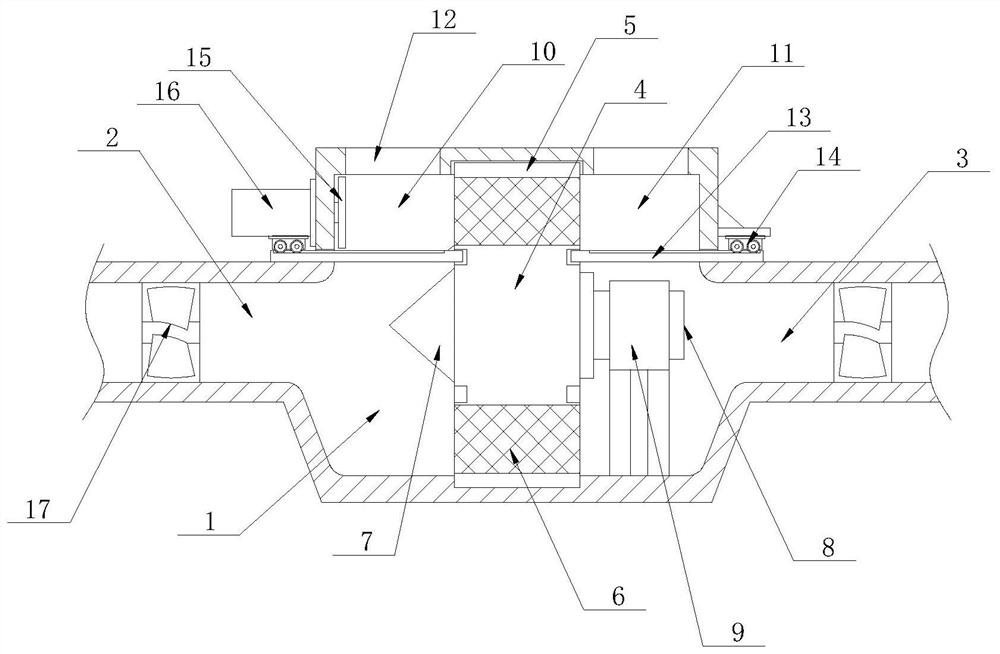

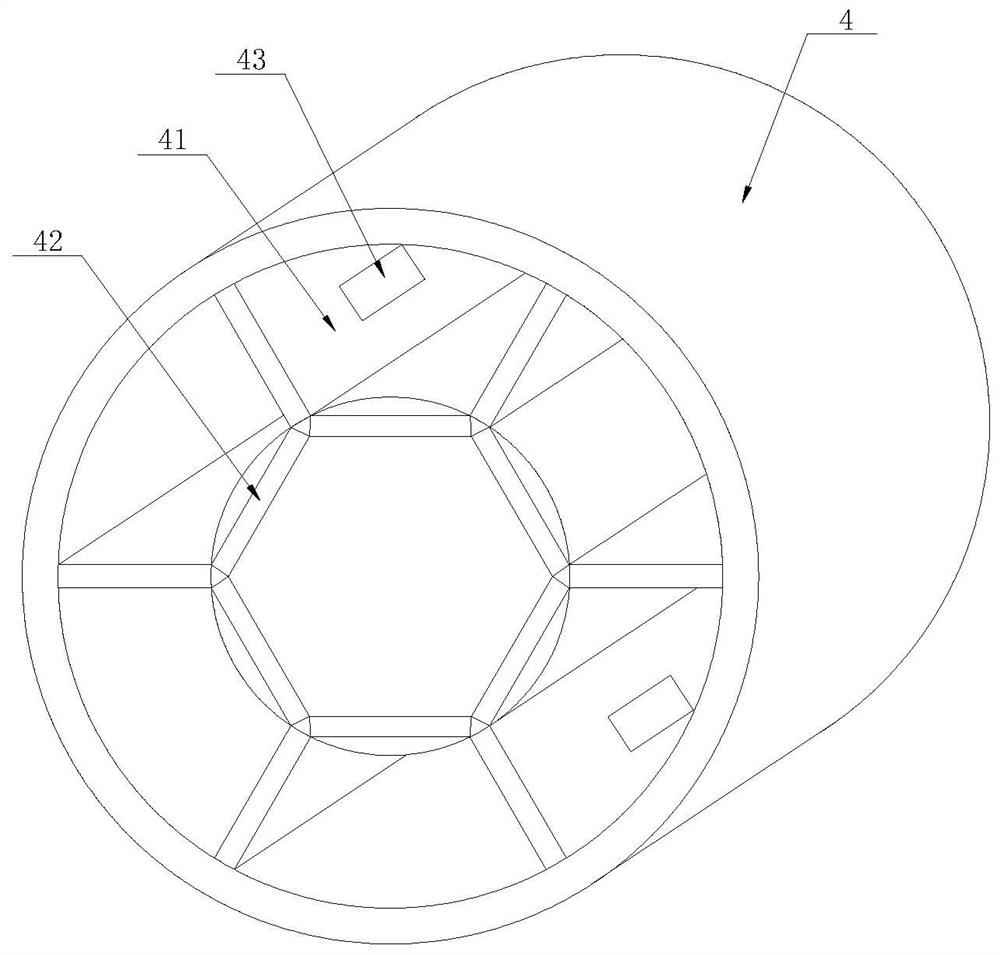

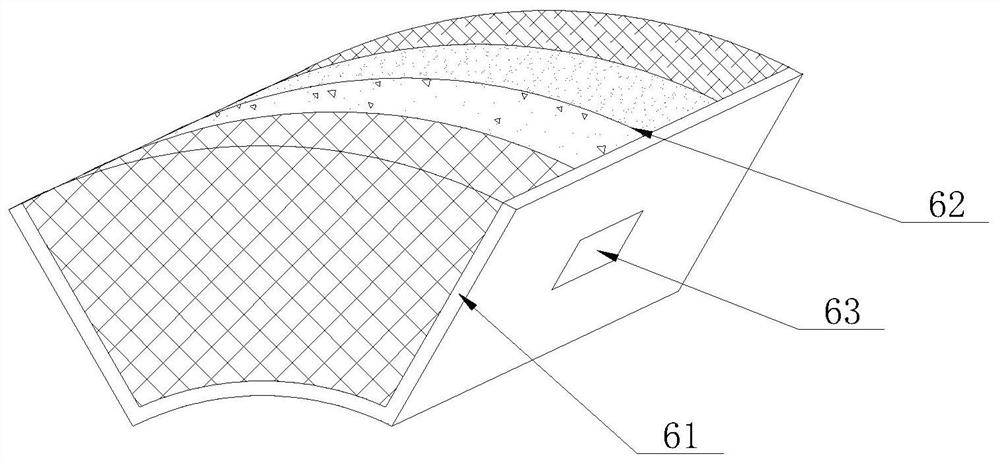

[0030] see as Figure 1-Figure 6 As shown, this specific embodiment adopts the following technical solutions: it includes an air purification filter chamber 1, an air intake passage 2, an air outlet passage 3, a rotating purification disc 4, a sealed bearing 5, an air filter core 6, a guide cone 7, a rotating Drive motor 8, fixed bracket 9, maintenance seal chamber 10, recovery seal chamber 11, seal maintenance door 12, translation baffle plate 13, forward and reverse drive motor 14, extrusion push plate 15, hydraulic telescopic oil cylinder 16; The left and right ends of the purification filter chamber 1 are connected with the air inlet channel 2 and the air outlet channel 3, and the middle of the air purification filter chamber 1 is provided with a rotating purification disc 4, and the outer side of the rotating purification disc 4 is movably connected to the air purification filter through the sealing bearing 5. In the reserved groove in the middle of the warehouse 1; the o...

specific Embodiment approach 2

[0034] see Figure 7 , the difference between this specific embodiment and specific embodiment one: the air filter core 6 can be replaced by a cylindrical structure filter core 45, and the structure of the filter core slot 41 is replaced by a cylindrical slot 44 thereupon; other structures remain constant.

[0035]The working principle of this specific embodiment is: when performing conventional air purification operations, the pressurized conveying fan 17 inside the air inlet passage 2 and the air outlet passage 3 rotates at a high speed, so that the left side of the rotating purification disk 4 forms an intake high pressure, and the rotation The right side of the purification disc 4 forms a negative air outlet pressure; through the cooperation of the pressure difference between the left and right sides, the air quickly passes through the air filter element 6 to achieve rapid purification and filtration; during this process, the rotary drive motor 8 slowly drives the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com