Patents

Literature

103results about How to "Achieve softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly craft furniture processing method

ActiveCN103204029AAchieve softeningImprove anti-agingDecorative surface effectsWood treatment detailsCarbonizationProcess engineering

The invention discloses an environment-friendly craft furniture processing method. By processing trunks, branches and roots with conditioning fluid, softening, disinfecting and sterilizing of raw materials are realized and anti-ageing and physical performances of the raw materials are improved. By the processing method, utilization rate of the raw materials can be increased by 8-12%, and by high-temperature carbonization, disinfection and prevention of molding and being damaged by worms can be further realized.

Owner:六安皖智知识产权运营有限公司

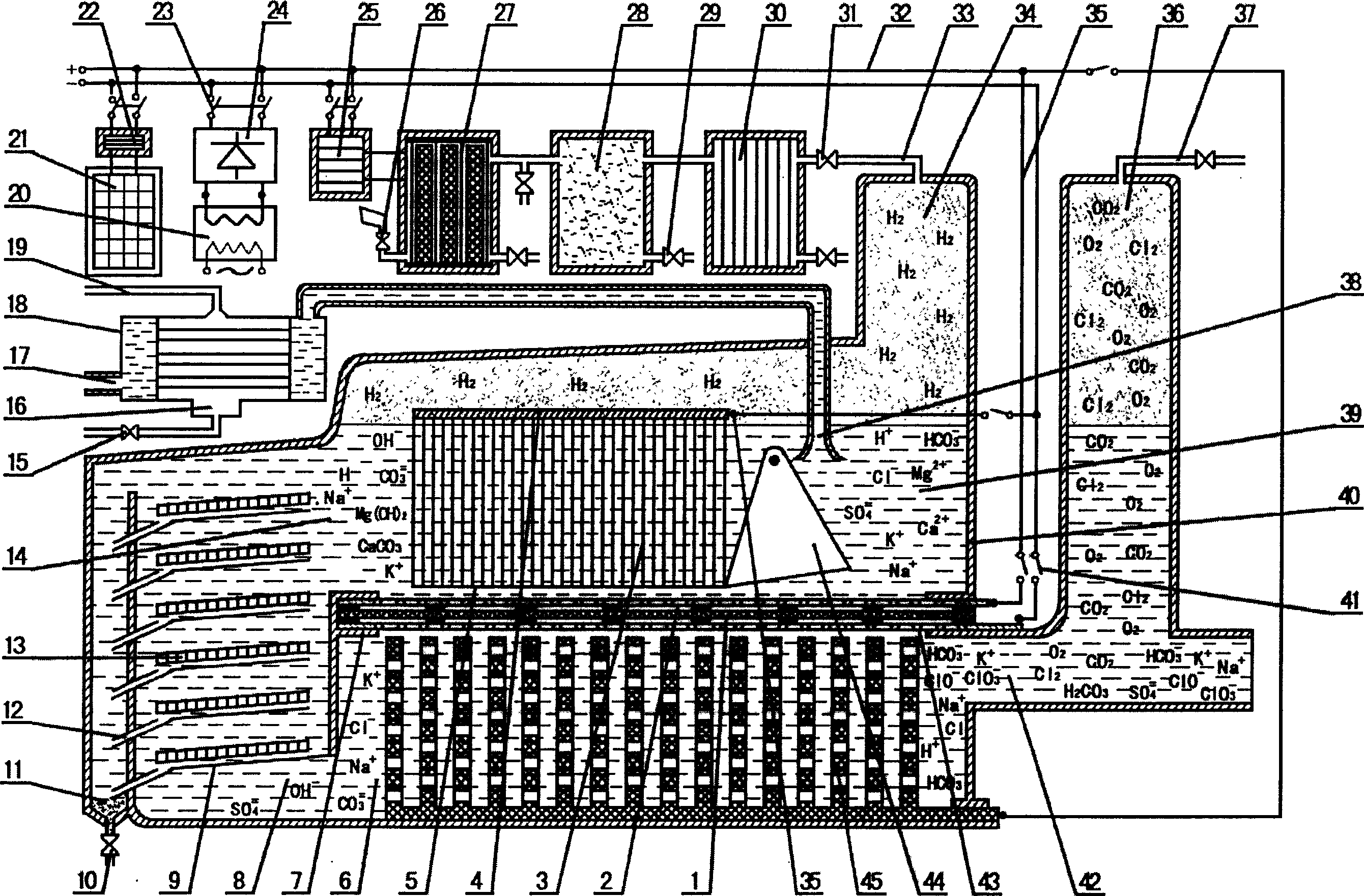

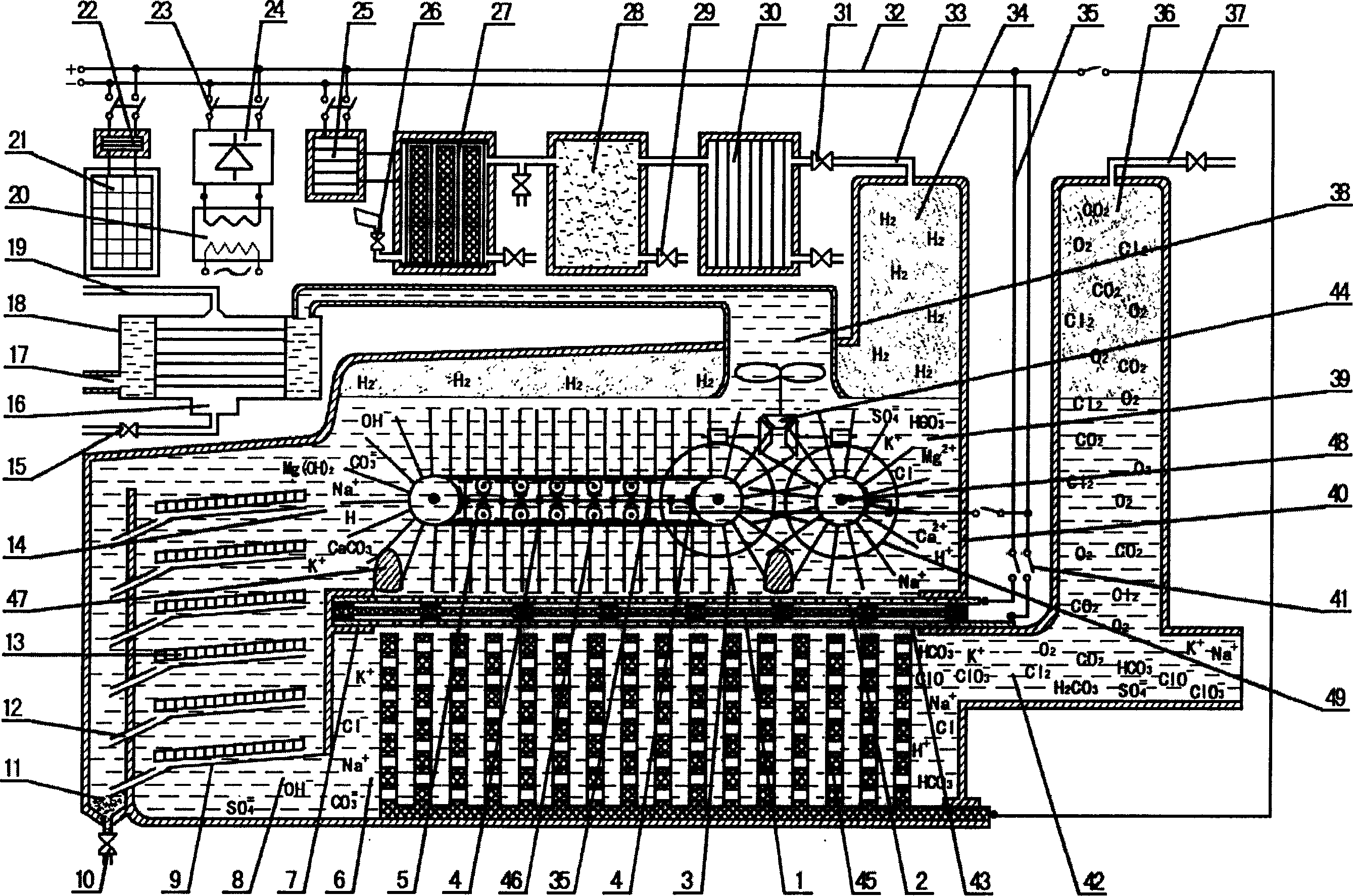

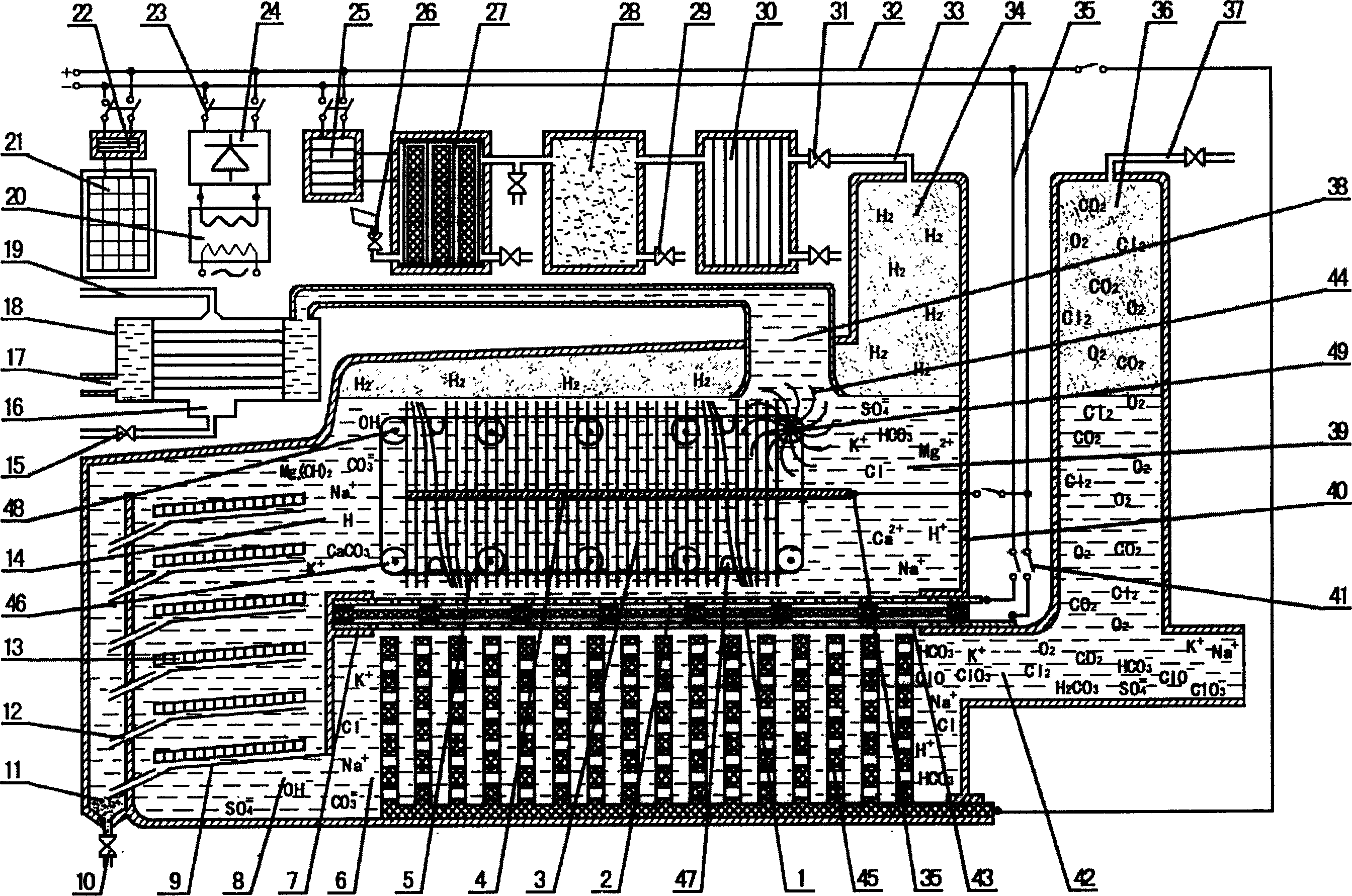

Apparatus for water treatment by electrolysis method

InactiveCN1623918AAchieve softeningRealize disinfectionDispersed particle separationScale removal and water softeningElectrolysisHypochlorous acid

An apparatus for treating water by electrolysis method is composed of DC power supply controller, water supply-discharge unit, two electrolyzing cathode bathes, electrically isolating plate unit, water scale depositing unit, and two electrolyzing anode bathes. The electrolytic reaction of water can make the calcium carbonate and the hydroxide of heavy metals to be deposited in anode bathes and the Cl2, O2, the radicals of hypochlorous acid and chloric acid, and ozone to be generated in cathode bathes.

Owner:BEIJING HIKEEN TECH +1

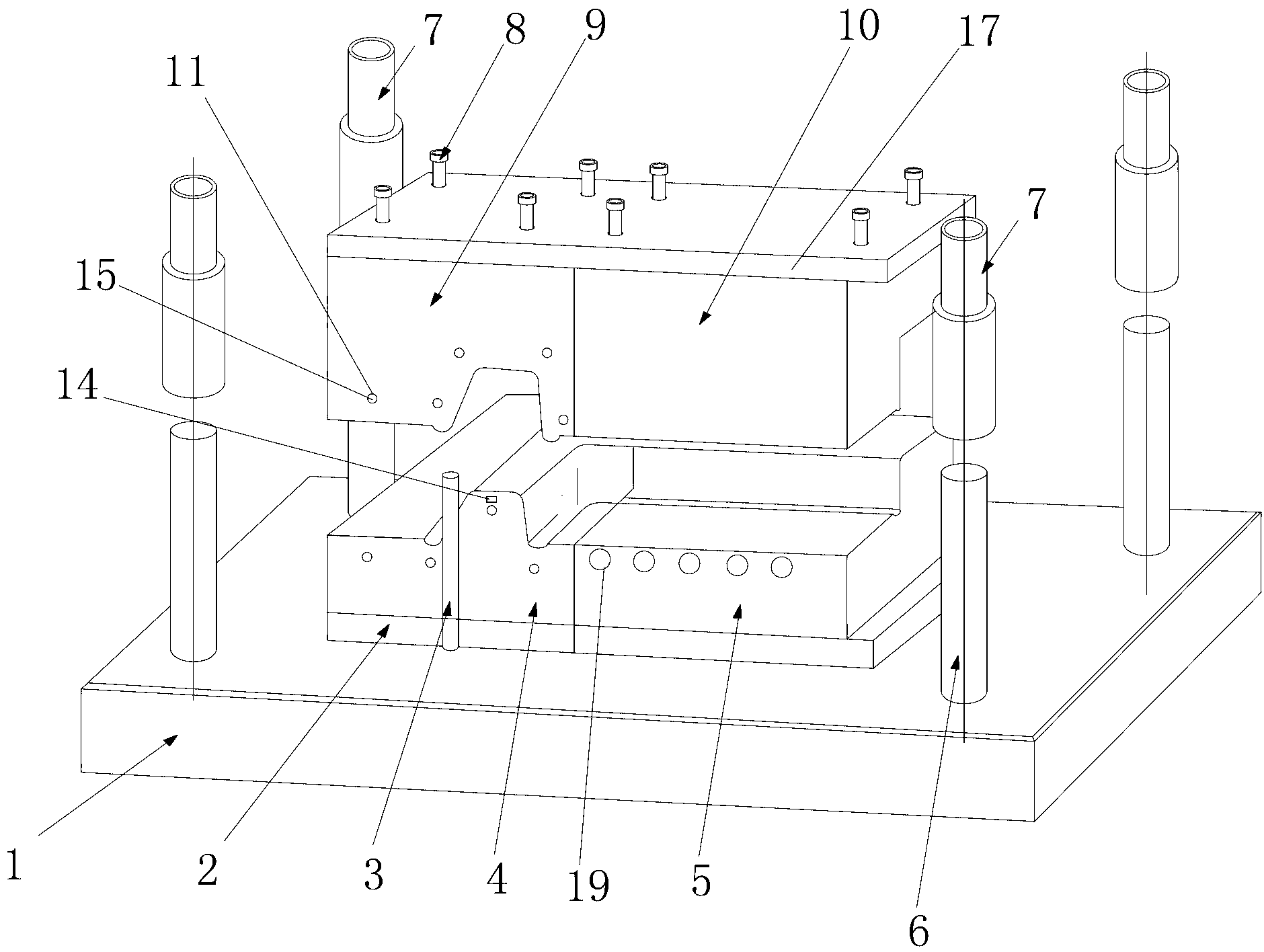

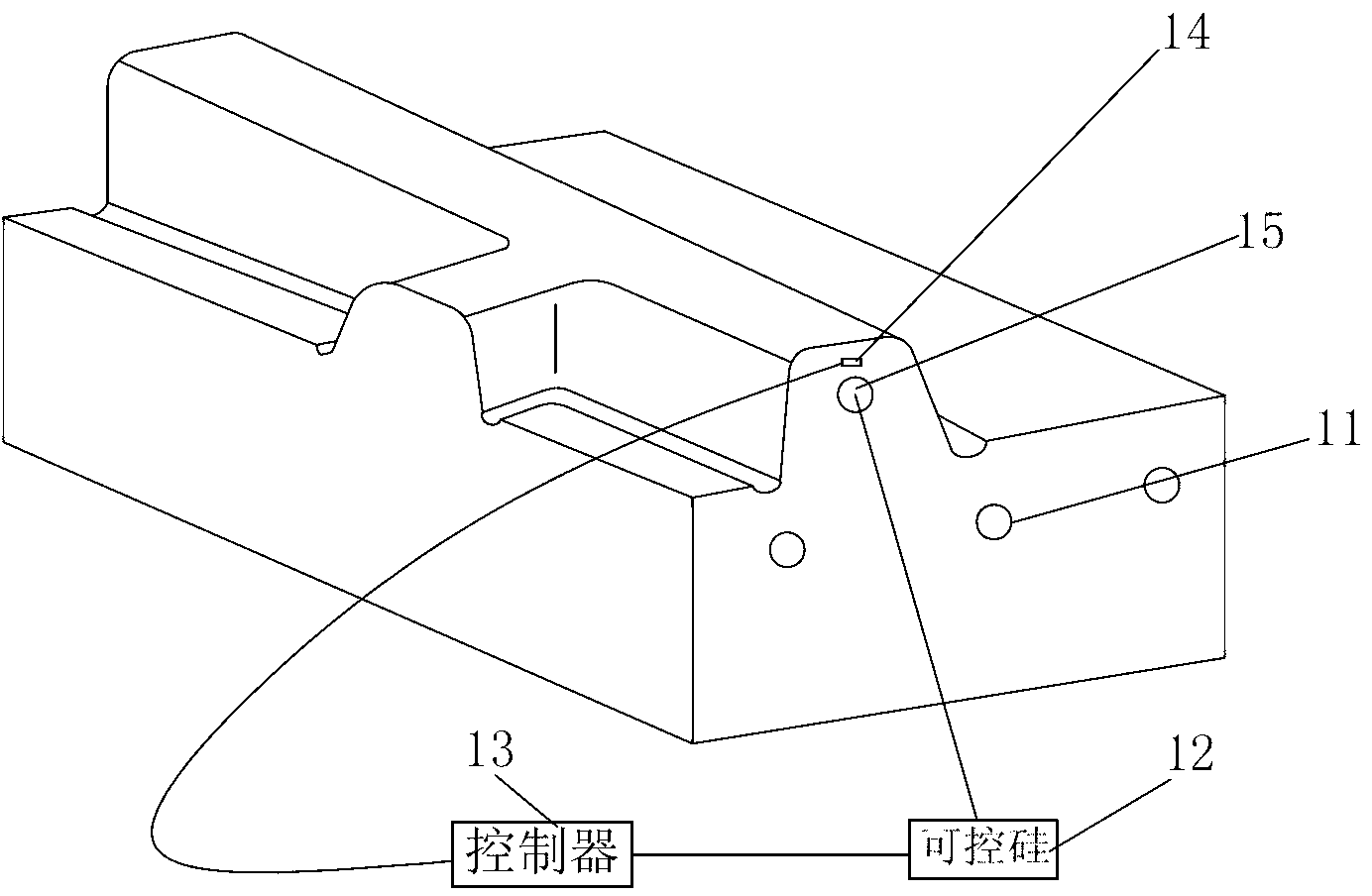

Control method and device for hot-forming plasticity distribution of high-strength steel

InactiveCN103233109AAchieve softeningReduce temperature differenceHeat treatment process controlSilicon-controlled rectifierLow voltage

The invention provides a control method and device for hot-forming plasticity distribution of high-strength steel. The control method comprises the following steps of: step one, heating a heating region of a mold to an appointed temperature; step two, placing and heating a blank in a heating furnace, so that the blank is austenized; step three, taking out the blank from the heating furnace, placing a part of blank in the heating region of the mold according to actual requirements, and placing the another part of blank in a cooling region of the mold; and step four, moving a press machine downwards so as to drive the mold to be closed, so that the blank in the mold is molded. The control device comprises a low mold seat board, a lower voltage withstanding heat insulation plate, a lower mold heating region insert, a lower mold cooling region insert, an upper mold heating region insert, an upper mold cooling region insert, a heating rod hole, a silicon controlled rectifier, a controller, a thermocouple and a heating rod. The control method and device can ensure that a high-strength steel sheet has different strength and plasticity in different regions.

Owner:武汉钢铁有限公司 +1

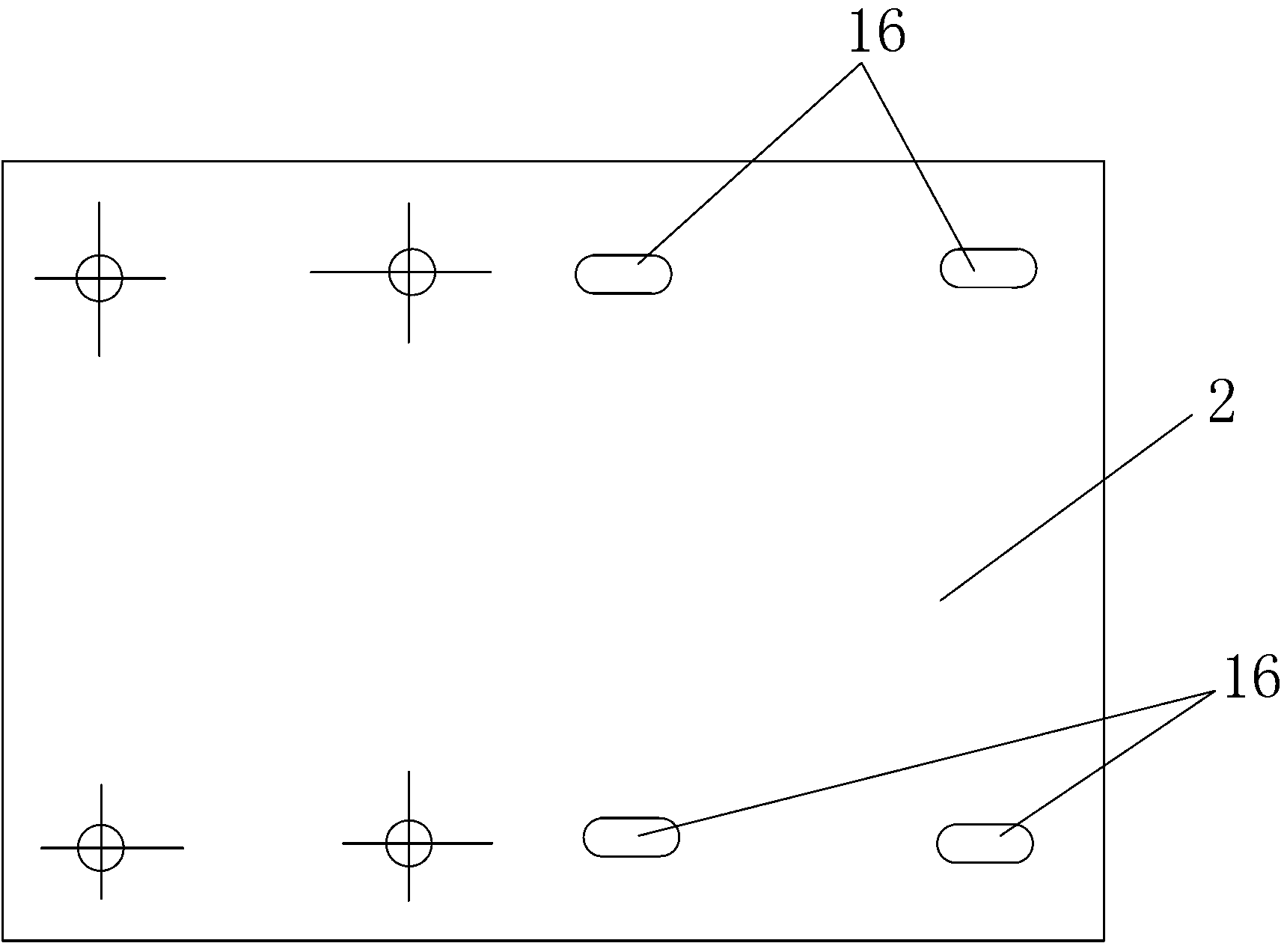

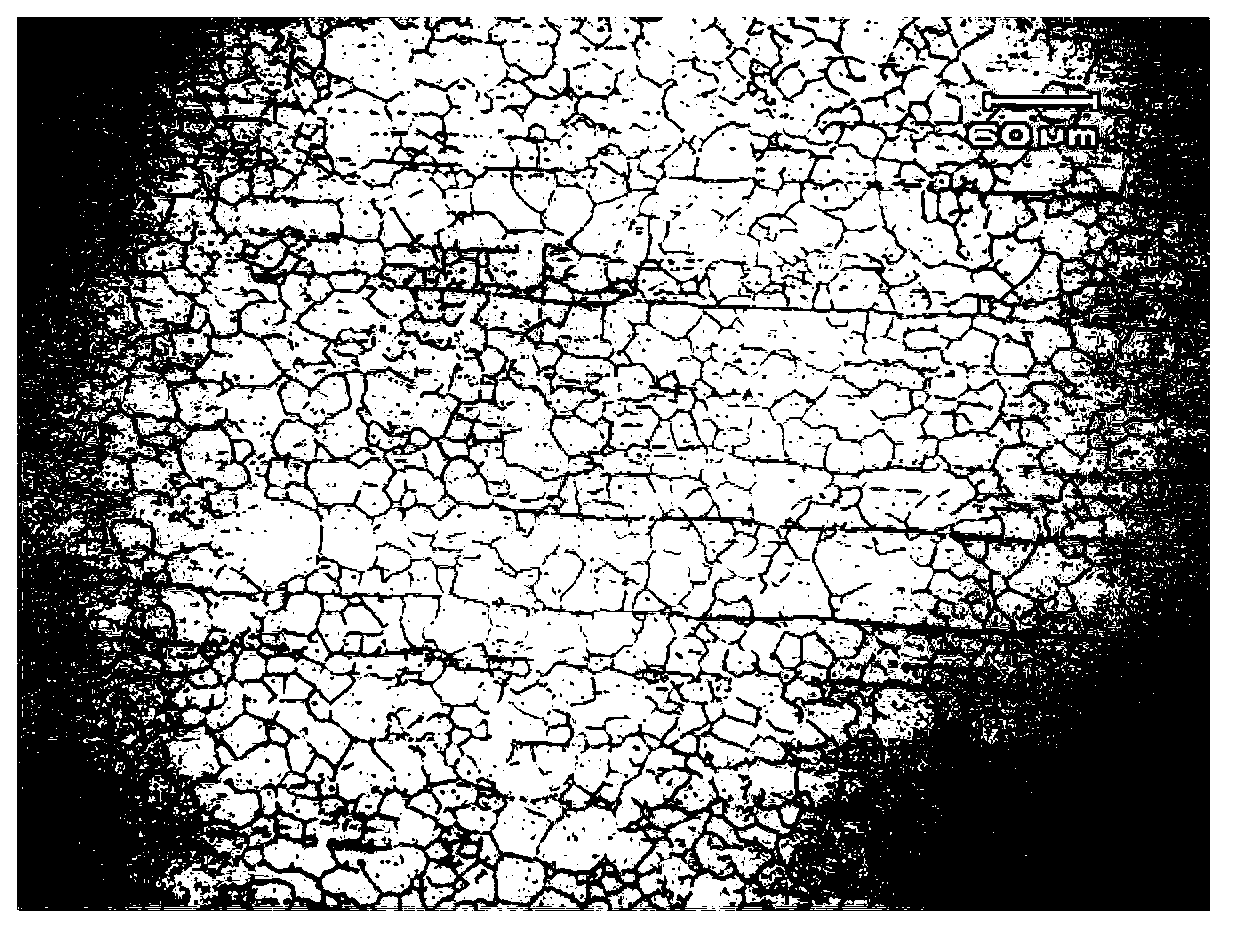

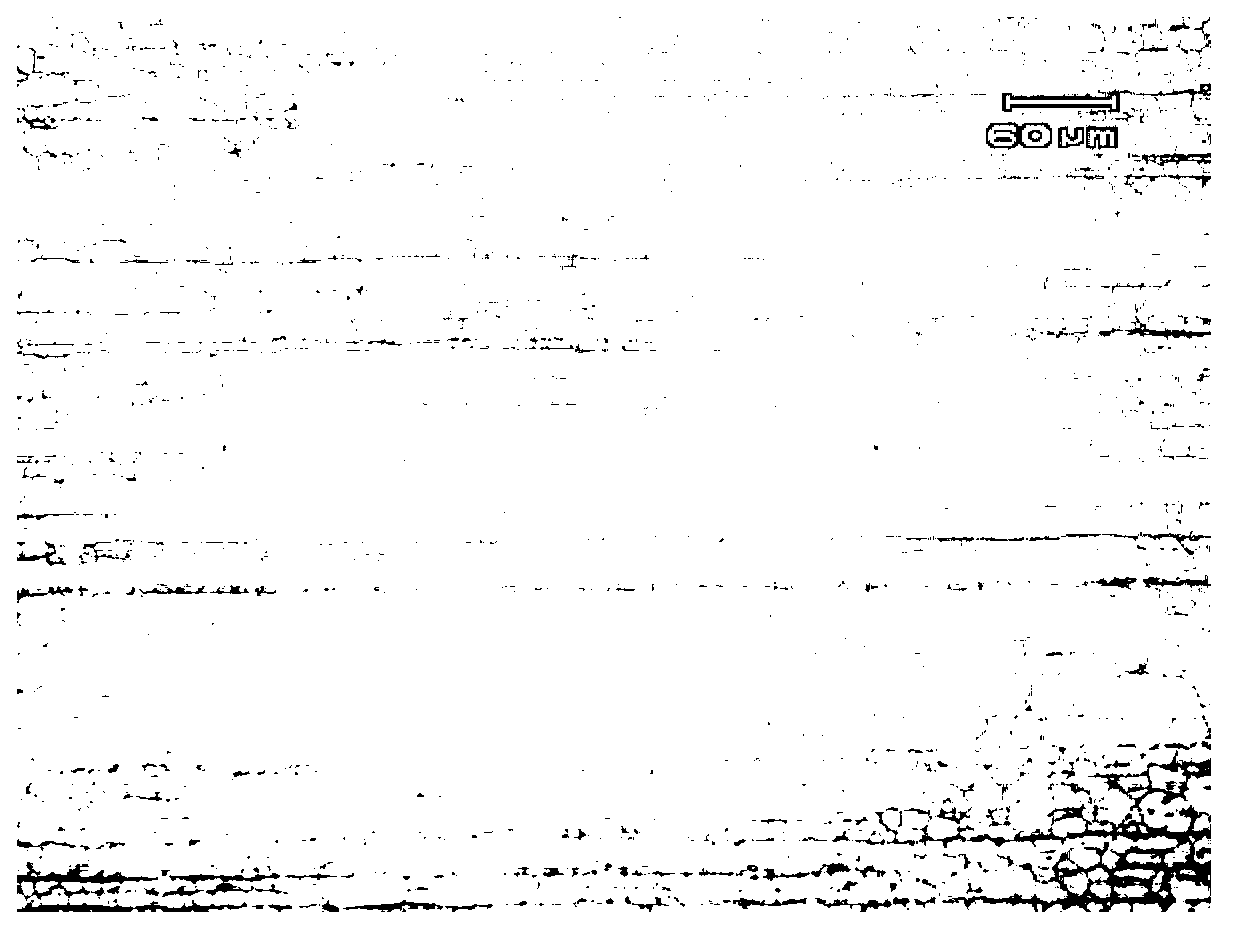

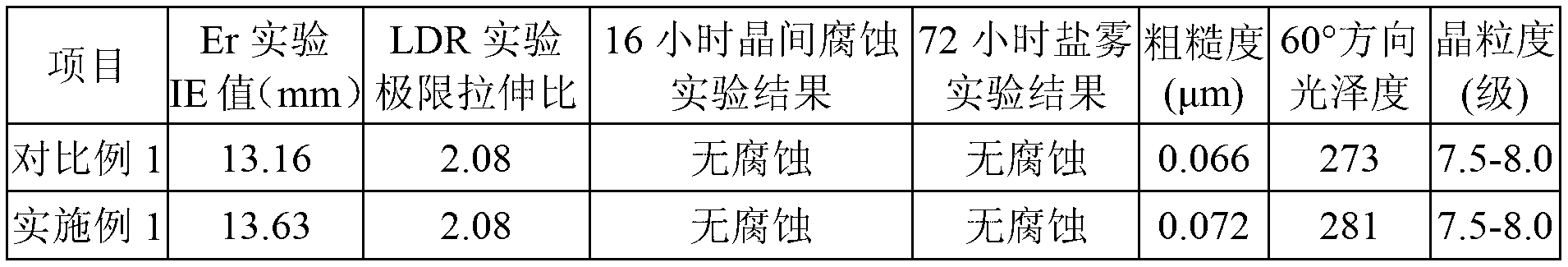

304 stainless steel strip and production method thereof

ActiveCN103191928AImprove performanceAchieve softeningRoll mill control devicesRollsHydrogen fluorideSalt solution

The invention provides a 304 stainless steel strip and a production method thereof. The production method includes performing cold rolling on a hot-rolled and pickled stainless steel strip which is directly pickled without anneal after hot rolling for 7 to 9 passes by a single-frame twenty-roller reversible cold rolling unit; continuously annealing the cold-rolled stainless steel strip at the temperature of 1150-1160 DEG C for 1 to 3 minutes; placing the cold-rolled and annealed stainless steel strip into a neutral salt solution to electrolyze; then placing the stainless steel strip into a mixed solution of HNO3 (nitric acid) and HF (hydrogen fluoride) to mix and pickle; and performing finishing on the cold-rolled, annealed and pickled stainless steel strip to obtain the 304 stainless steel strip. The 304 stainless steel strip is produced by the production method. In the production method, a hot annealing process is omitted, and the techniques of the cold rolling and the cold annealing are optimized, so that the produced 304 stainless steel strip can have all properties of stainless steel strips produced by conventional methods.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

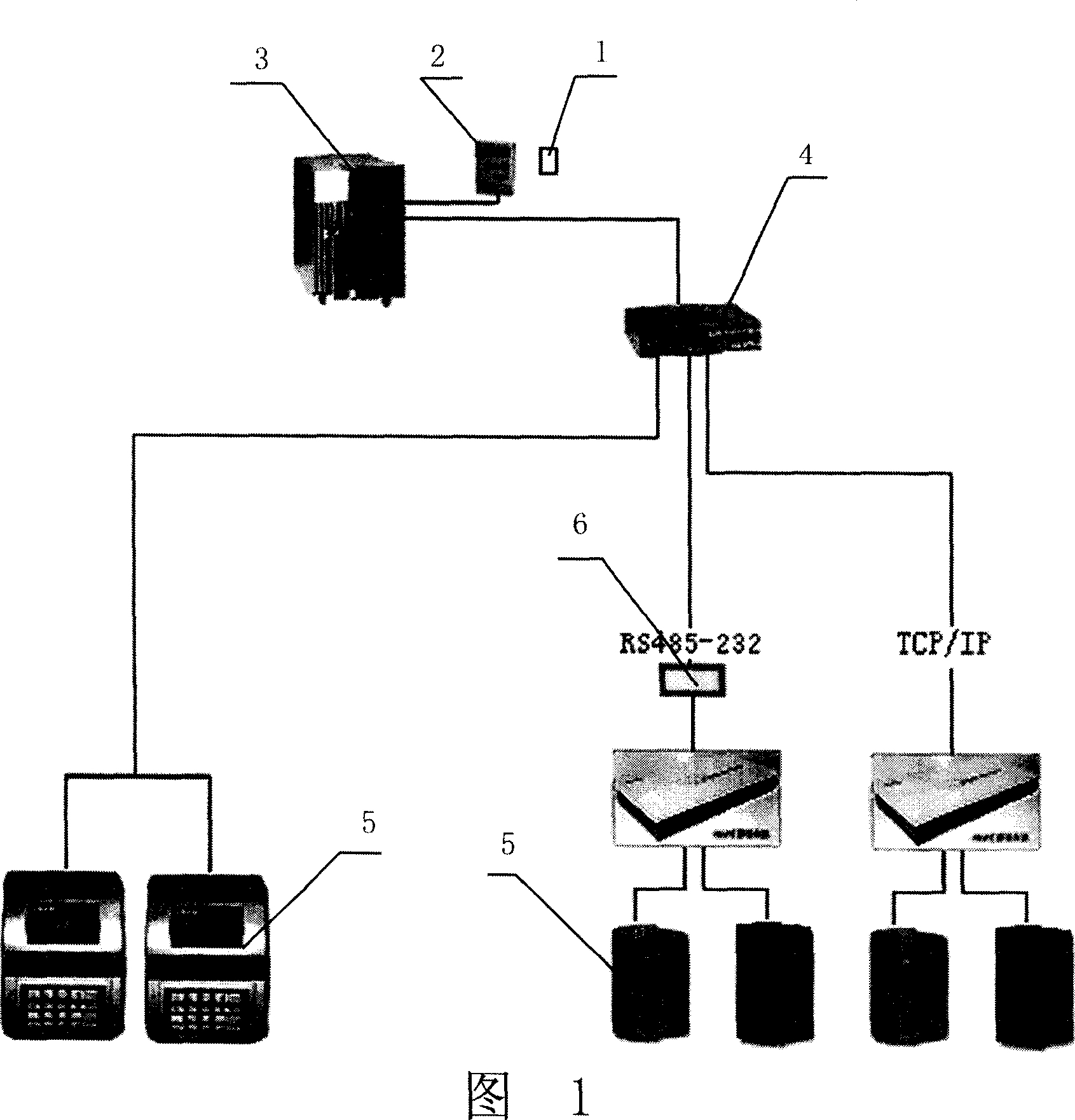

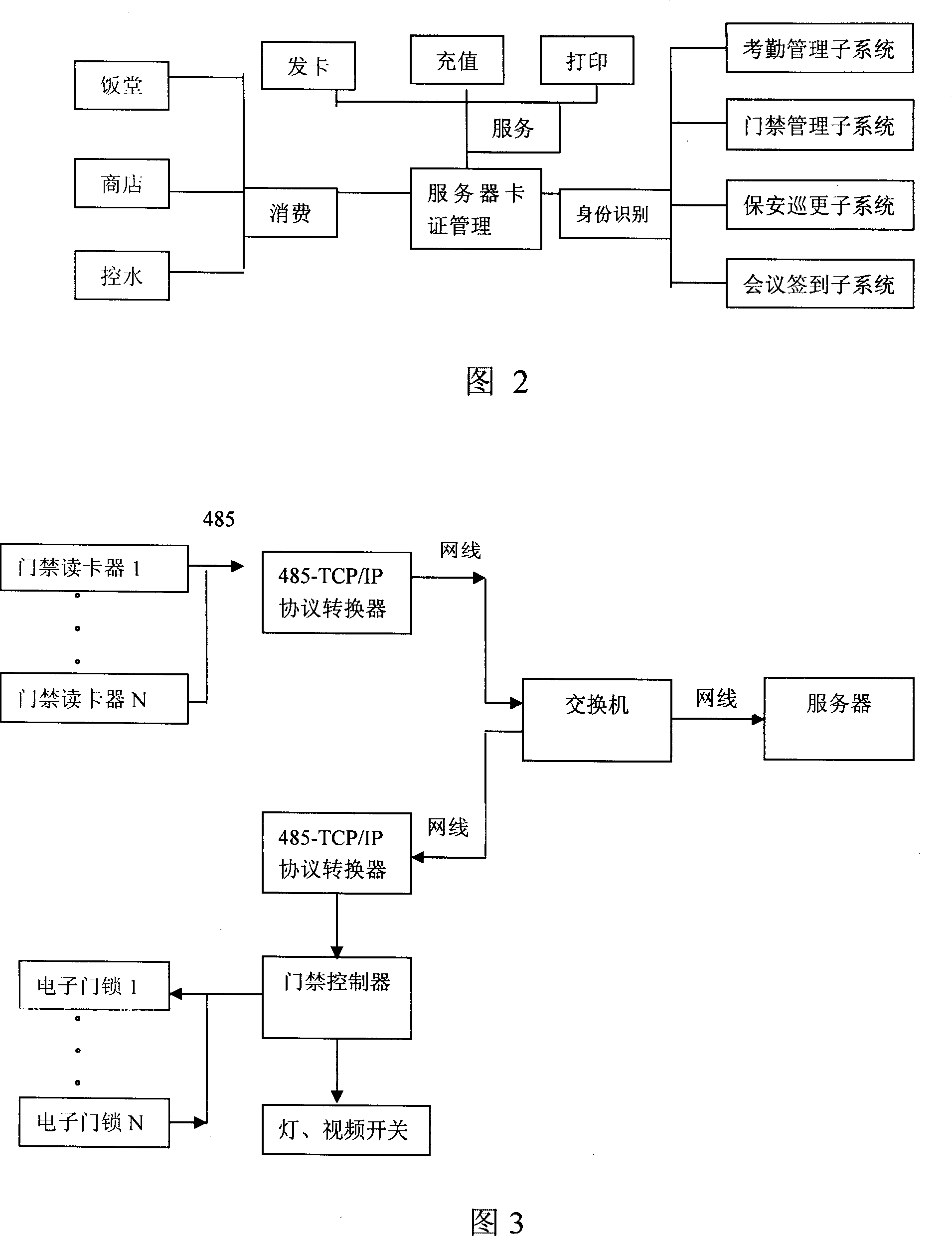

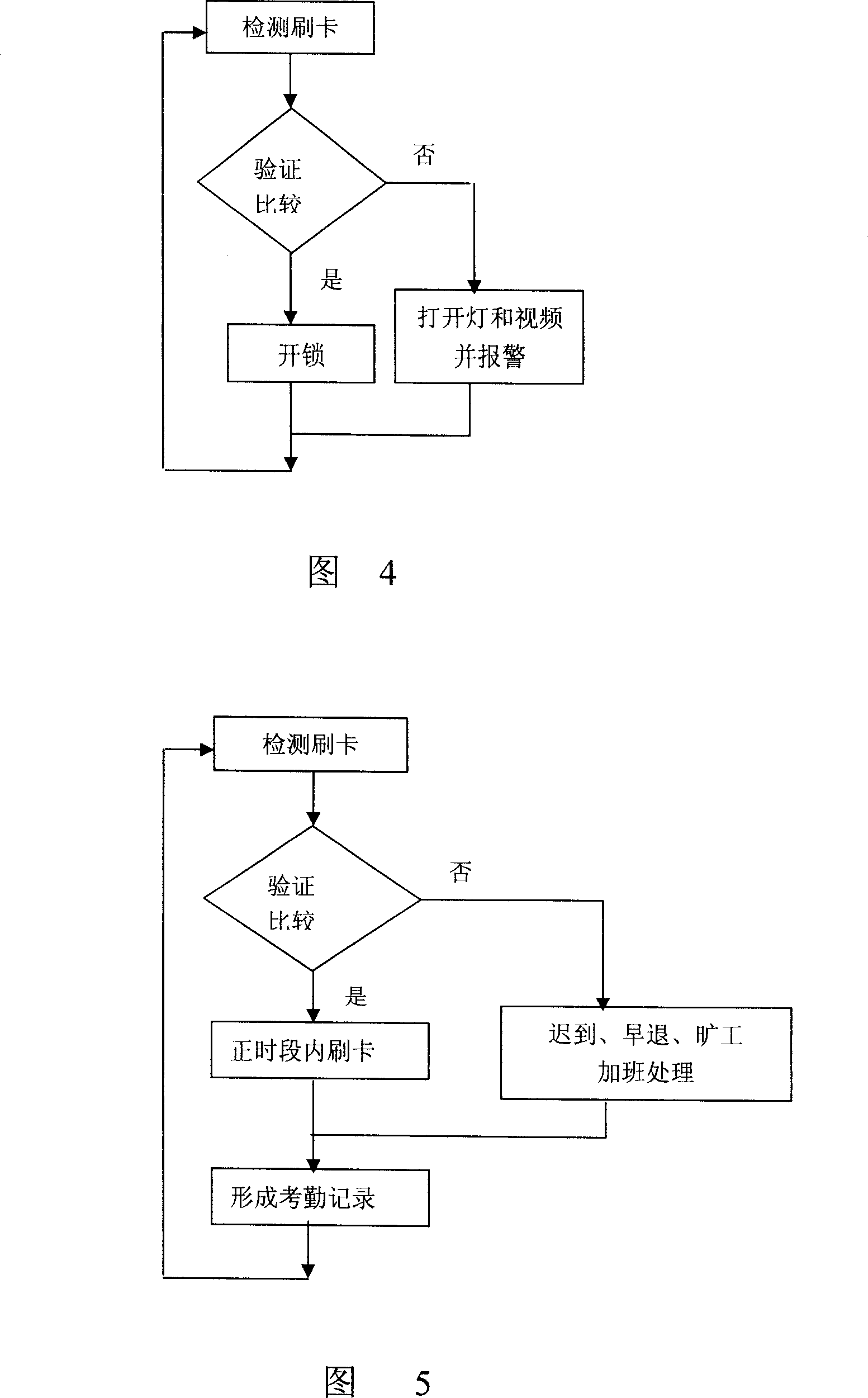

A multi-function intelligent card network management system and method

InactiveCN101106564AReduce investmentNo risk of misappropriationSensing record carriersIndividual entry/exit registersSmart cardNetwork management

The invention discloses a network management system and a management method of a multifunctional smart card, wherein, the intelligent card (1) is an information carrier and a smart card sensor (5) is an information interchange device and includes at least two sensors with different functions. The input of the smart card sensor (5) uploads the information on the smart card to a server (3) by data wire and switch (4). The server (3) judges the authority and function of the smart card according to the information and controls background processing program for proper processing, in order to realize two or more than two management functions. The invention integrates with all punch card systems as an organic whole by means of computer and communication technology and can realize the function of ID identification, access control, attendance management, conference signing in, and consumption management by a smart card.

Owner:JIANGSU ANFANG ELECTRIC POWER TECH

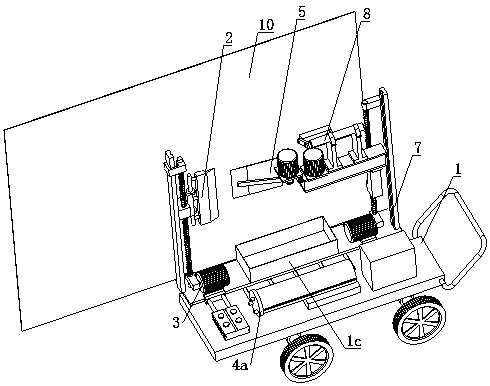

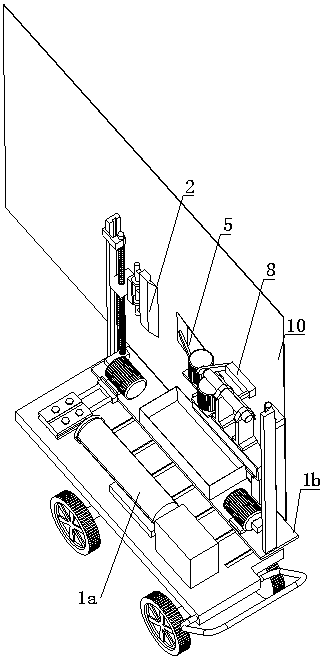

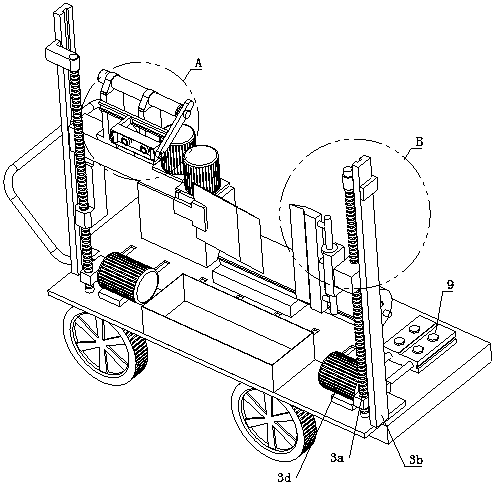

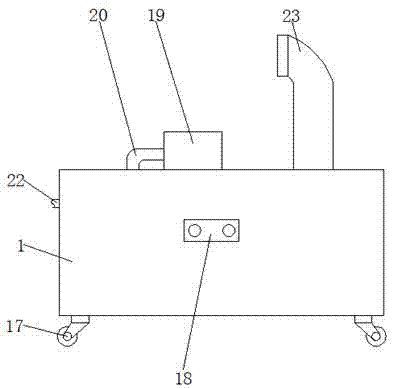

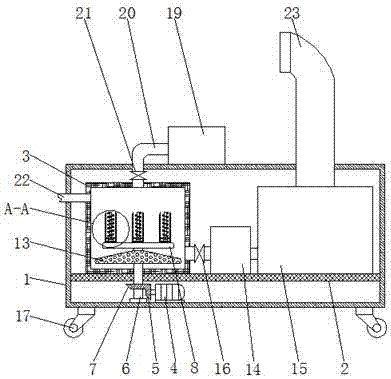

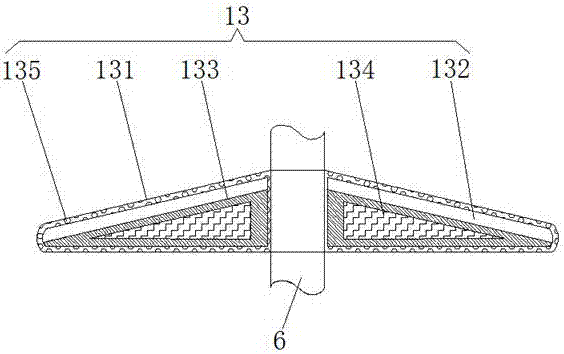

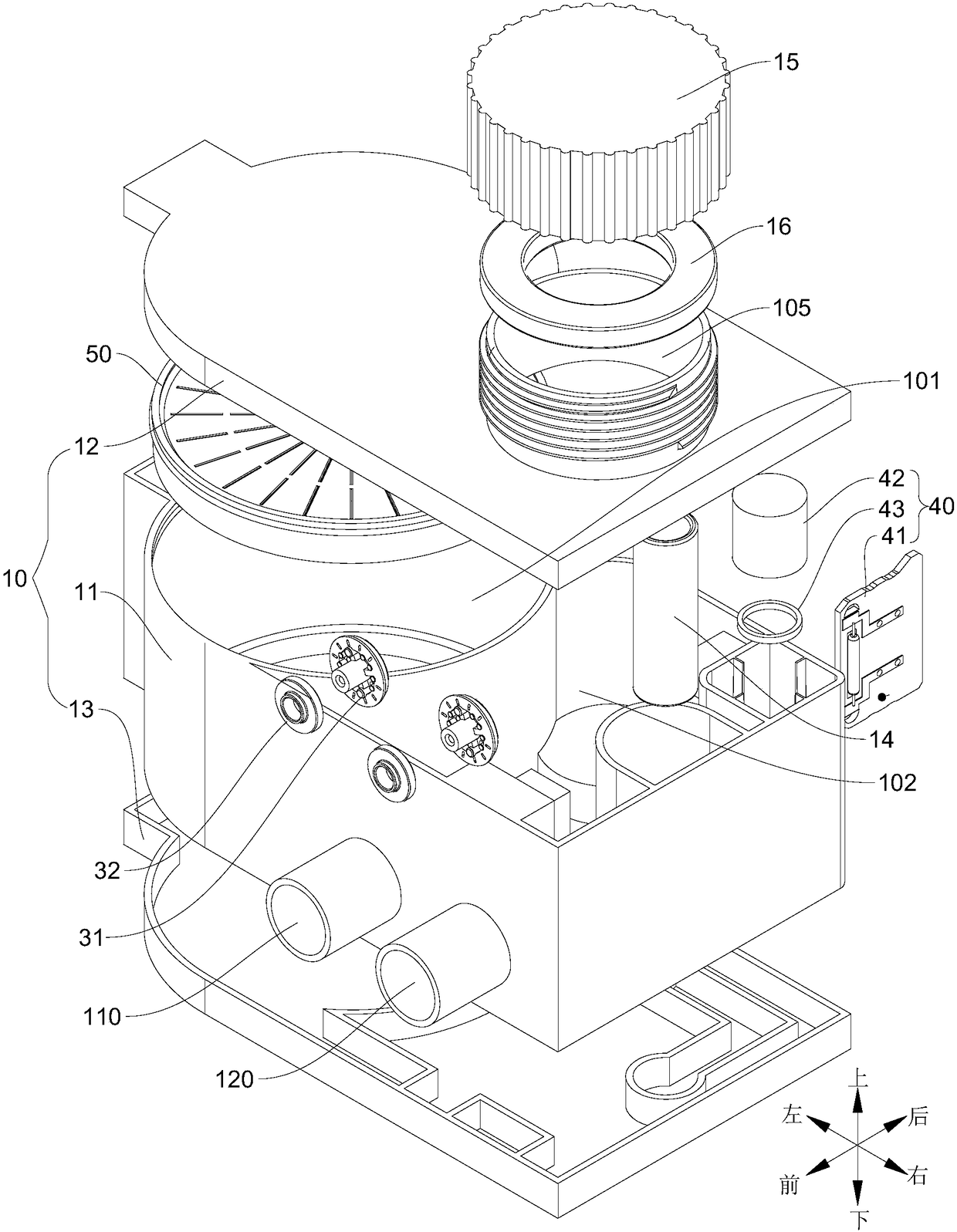

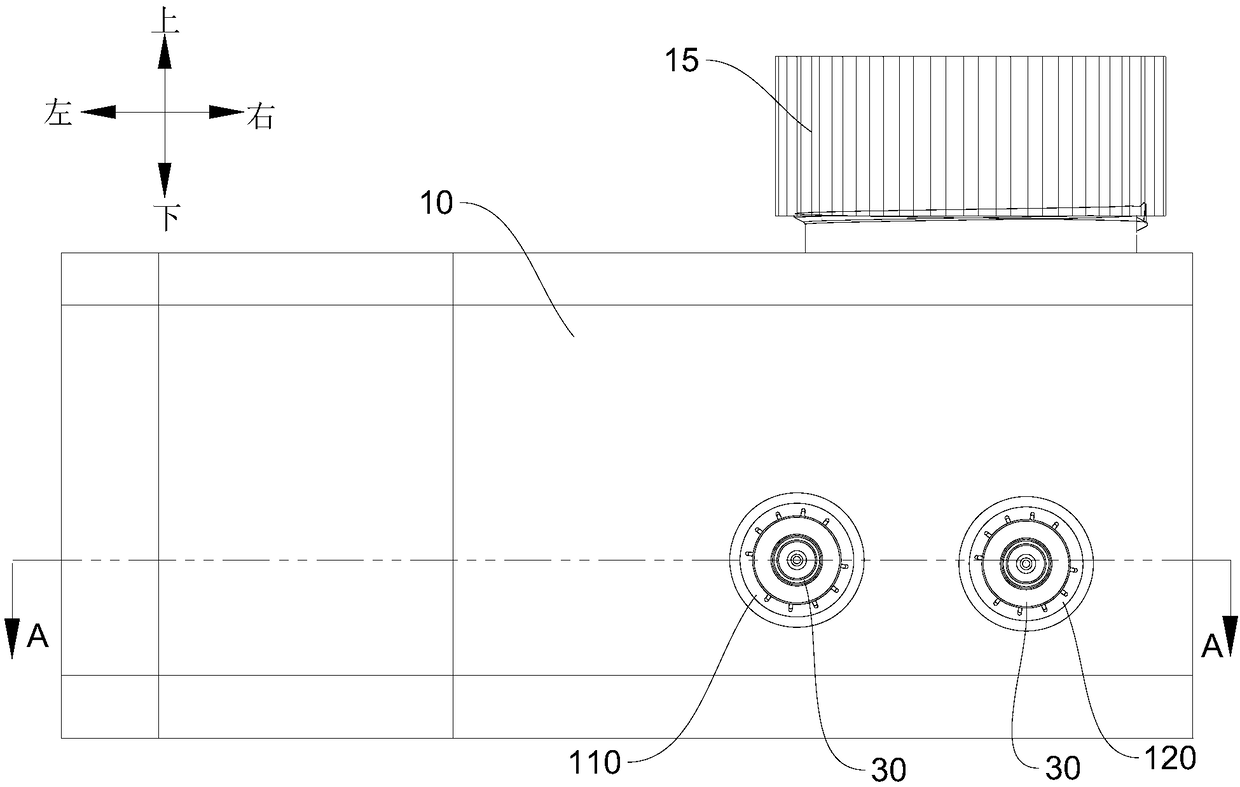

Cleaning machine for cleaning wall adlet

InactiveCN108787521AReach levelPlay a softening roleCleaning using toolsCleaning using liquidsEngineeringWork status

The invention relates to the field of municipal administration, in particular to a cleaning machine for cleaning wall adlet. The cleaning machine comprises a vehicle-mounted main body, an air warmer,an exhaust module, a shoveling module and a spraying agent module; the air warmer is mounted at the top of the vehicle-mounted main body; the exhaust module and the shoveling module are symmetricallymounted on one side of the vehicle-mounted main body, and can be vertically and movably mounted above the vehicle-mounted main body through a first lifting module and a second lifting module; the exhaust module communicates with an output end of the air warmer through an air guide module; the spraying agent module is mounted beside the shoveling module, and can vertically move with the shoveling module at the same time; and an approaching module for driving the first lifting module and the second lifting module to move to the wall direction at the same time in a working state is arranged at the top of the vehicle-mounted main body. The cleaning machine can automatically treat large-area adlet on the wall without remaining marks, and improves the cleaning efficiency when the manpower is saved.

Owner:梁波

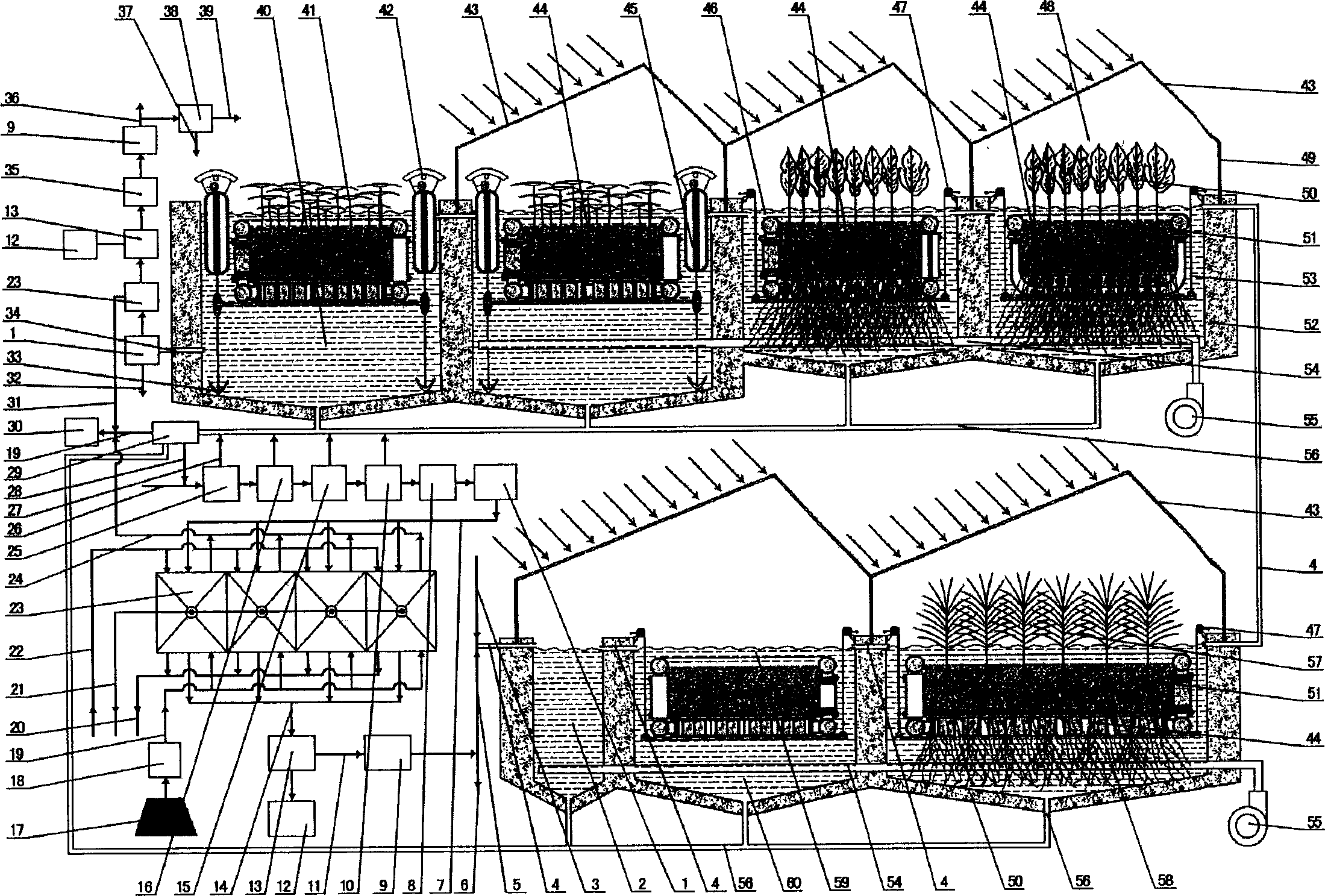

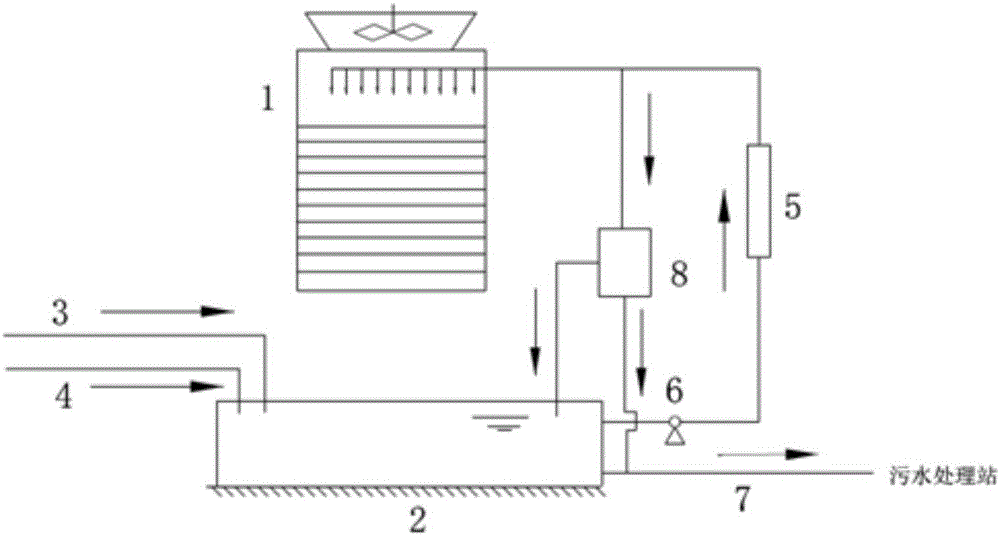

Filter-adsorption-submerged floating wet land sewage treating system and apparatus

InactiveCN1743283AAchieve softeningReduce evaporationEnergy based wastewater treatmentMultistage water/sewage treatmentFiltrationUltraviolet

This sewage treatment system of filtration-absorption submerging-surfacing wetland comprises 4 different levels of sewage disposal subsystem. The primary sewage treatment system comprises a filtration-absorption coal filter sewage treatment device, magnetic water strainer, ultraviolet sterilization device, etc. The secondary sewage treatment system comprises aeration distributing gutter placed in solar room, distributing channel for confluence, facultative aeration pond of submerging-surfacing wetland which are connected in sequence. The tertiary sewage treatment system comprises filtration-absorption coal filter sewage treatment device, magnetic water strainer, ozone sterilization device and ultraviolet sterilization device. The quarternary sewage treatment system comprises electrolytic water treatment device. The sewage is dewatered by a dewatering device, delivered by a delivering device, fed into a boiler to burn. After treated by the said sewage treatment system the exhaust gas fed to boiler to aid combustion, and the coal failing in treatment by the filtration-absorption coal filter sewage treatment device is fed to the combustor to burn after being dried.

Owner:BEIJING HIKEEN TECH +1

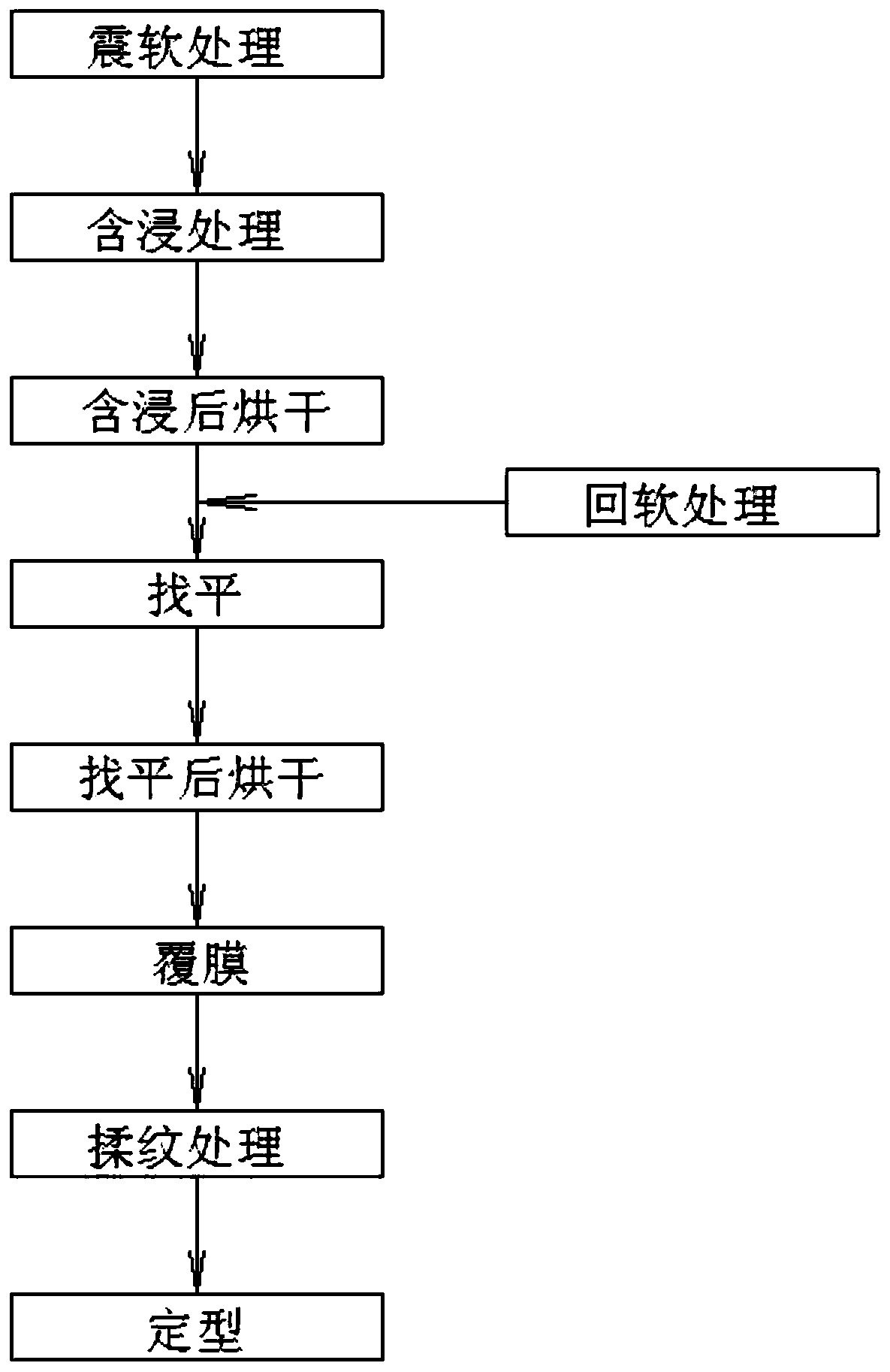

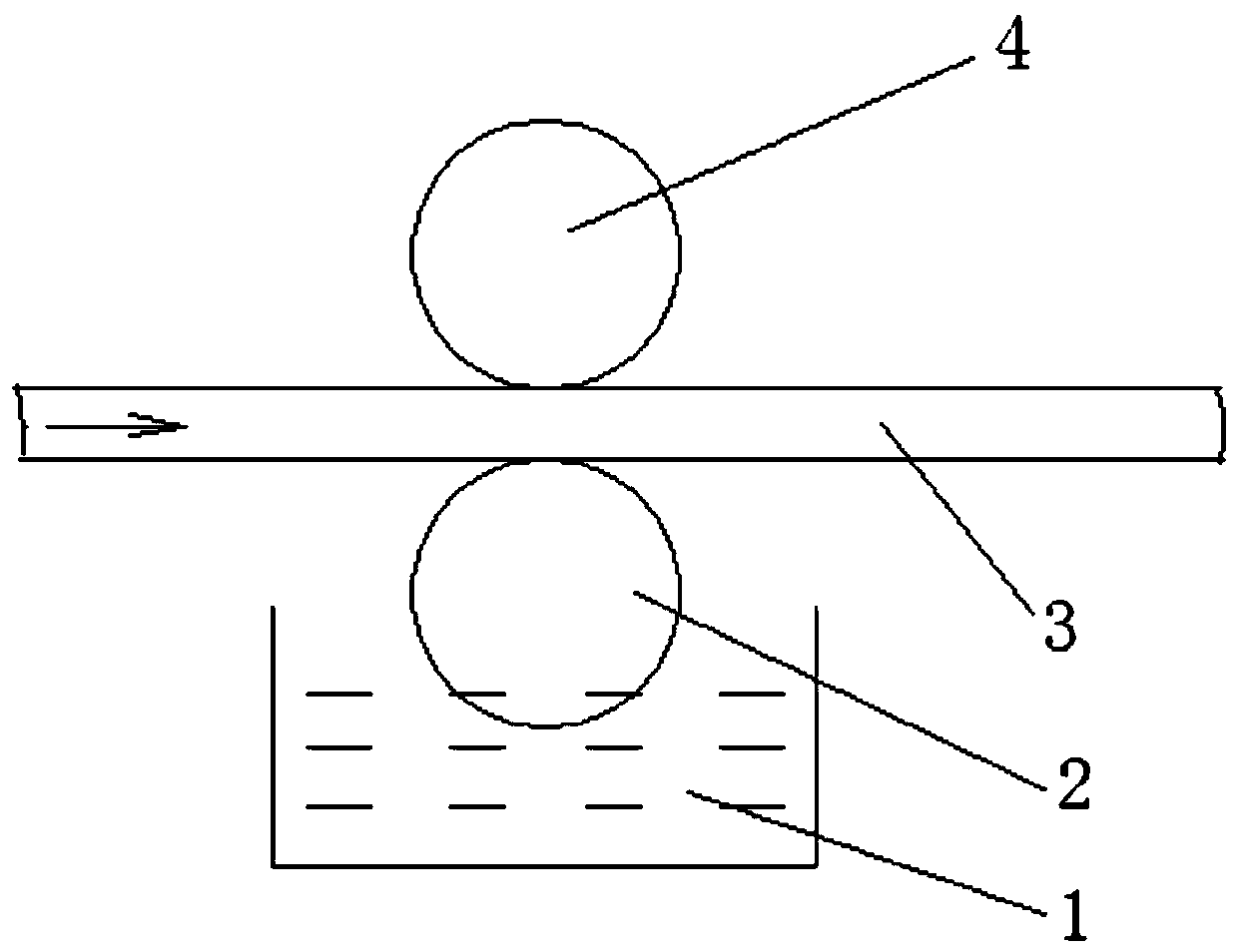

Aftertreatment process of waterborne flyleather base cloth

ActiveCN110205829AAchieve softeningFeel goodTextiles and paperAfter treatmentManufacturing technology

The invention relates to the technical field of leather manufacturing and discloses an aftertreatment process of waterborne flyleather base cloth. The process includes steps: vibration softening treatment, impregnating treatment, drying after impregnating, leveling and drying after leveling, wherein the step of impregnating treatment includes adopting a waterborne PU material and roller coating equipment to perform single-side feeding permeation on the front of flyleather base cloth after going through vibration softening treatment and controlling the depth at which the waterborne PU materialpermeates into the flyleather base cloth to be 1 / 4-3 / 4 of the thickness of the flyleather base cloth. Through two times of treatment on the flyleather base cloth, bonding strength of the flyleather base cloth is further improved while good performance of the same is maintained, so that flyleather gray cloth formed by after treatment can be used for subsequently making intermediate products of high-performance simulated cowhide, and final performance and quality of simulated cowhide leather products are improved.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Preparation method of long raw bamboo fiber

ActiveCN107937993AAchieve softeningEasy to soakMechanical fibre separationFibre treatment to obtain bast fibreChemical treatmentWastewater

The invention discloses a preparation method of long raw bamboo fiber, which belongs to the technical field of vegetable fiber production, and solves the problems of low production efficiency, low yield and serious waste water pollution of the current preparation methods. The method comprises the following steps: bamboo wood slicing, high-temperature high-pressure treatment, tearing processing, enzyme processing, chemical treatment, drying, and carding processing. The obtained long raw bamboo fiber has the following characteristics that an average fiber length is 4-5 cm, fineness is no less than 100 Nm, and the yield is no less than 60%. In addition, the long raw bamboo fiber has the beneficial effects that high production efficiency (annual output of a production line is no less than 50,000 tons), waste water pollution is light, and fiber is soft.

Owner:FUJIAN AGRI & FORESTRY UNIV

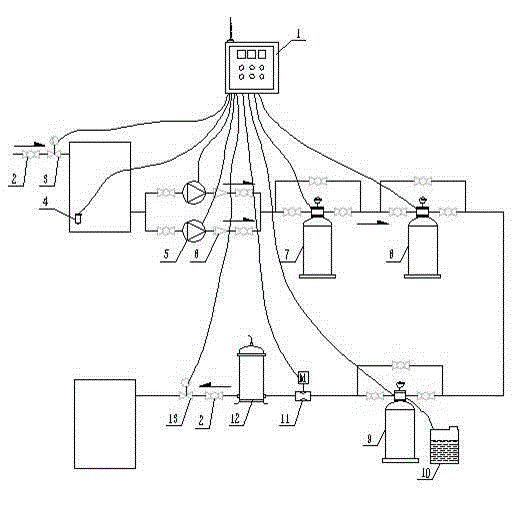

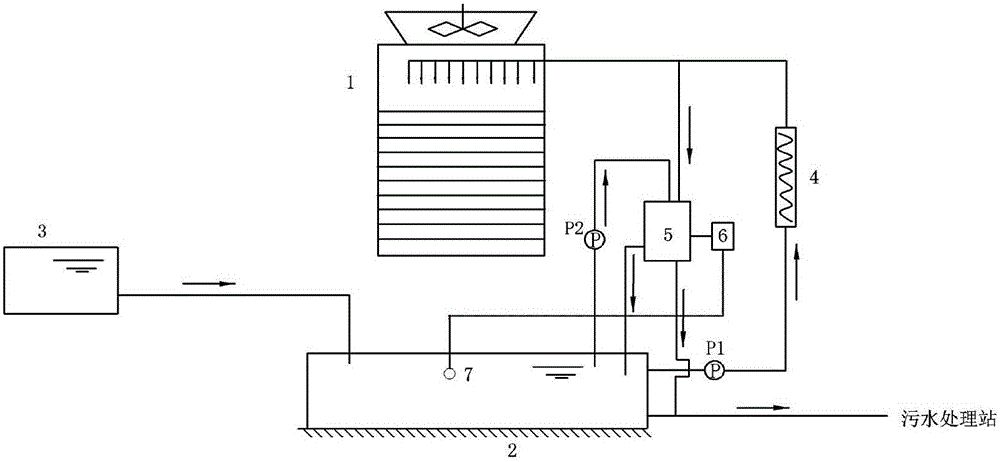

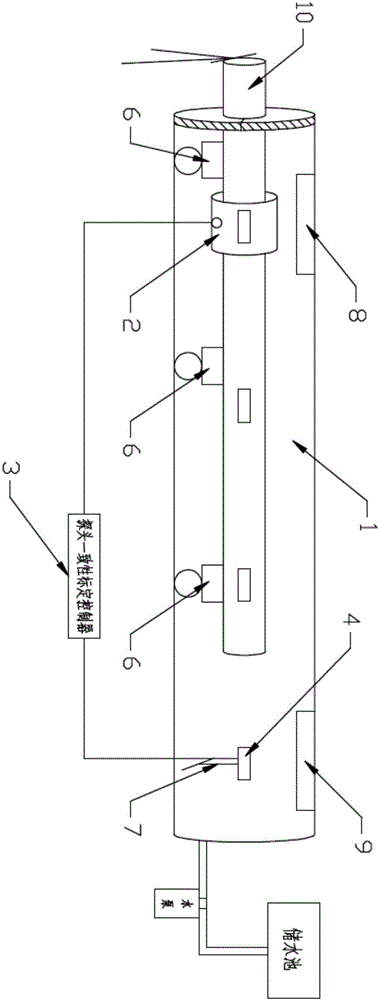

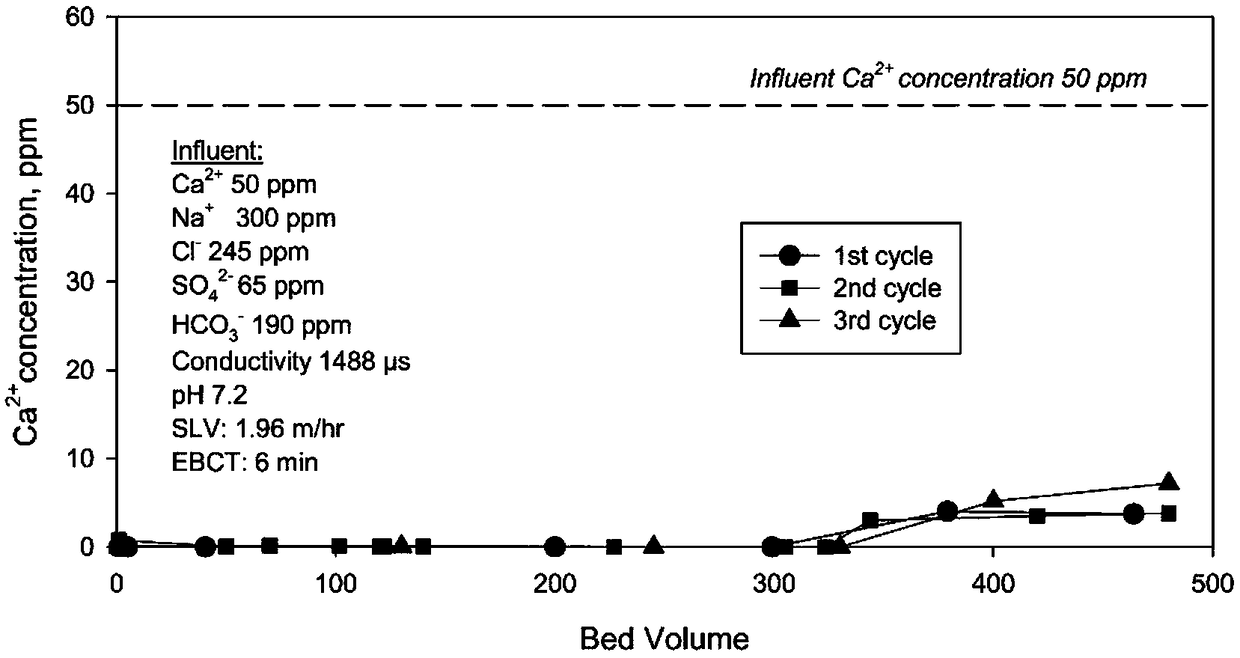

Water softening treatment apparatus

InactiveCN105461101AAchieve softeningRealize automatic controlMultistage water/sewage treatmentWater softeningSoftened water

A water softening treatment apparatus is mainly composed of a control box, a ball valve, a solenoid valve, a liquid level sensor, booster water pumps, non-return valves, a multi-medium filter, an activated carbon filter, a water softener, a salt box, a flow meter, a precise filter and an electric regulating valve, the control box controls a whole water softening system, and the solenoid valve automatically opens or closes according to information provided by the liquid sensor. The booster water pumps draw water in a water tank, provides power for realization of the softening treatment of water through the multi-medium filter and the water softener, softened water goes through the precise filter, and the softened water is conveyed to a softened water tank through the electric regulating valve.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

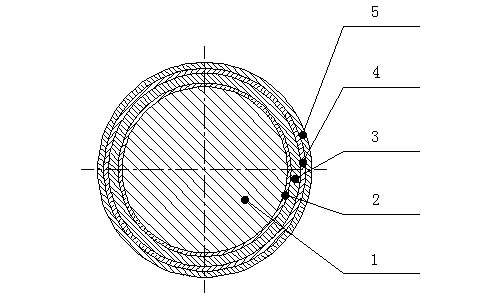

Method for producing self-adhesion compound type enameled aluminium round wire

ActiveCN103000303ASave resourcesLow costMetal/alloy conductorsInsulating conductors/cablesPolyamide-imidePolyamide

A method for producing a self-adhesion compound type enameled aluminium round wire is characterized by comprising the steps of conducting continuous wire-drawing, cleaning and softening on a round aluminum rod, applying primer, an intermediate layer, a finish layer and an self-adhesion layer on a coating of the aluminium round wire after 25-33 times of fine painting and drying, and conducting automatic disc changing and winding up after on-line monitoring and surface lubricating, wherein the primer adopts aromatic polyamide imide paint, the intermediate layer adopts polyesterimide paint, the finish layer adopts polyamide imide paint, and the self-adhesion layer adopts aromatic polyamide self-adhesion paint. The self-adhesion compound type enameled aluminium round wire is wide in temperature-resisting range, resistant to low temperature and resistant to quick temperature variation.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

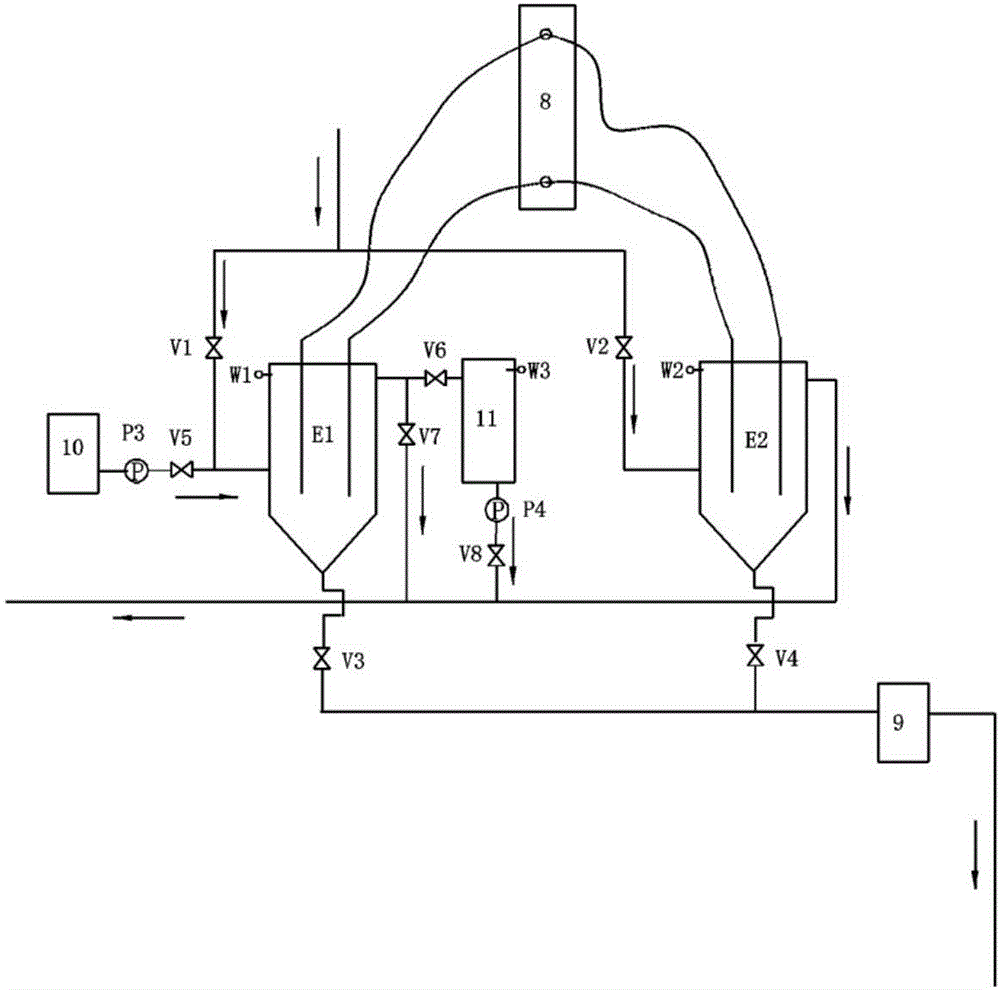

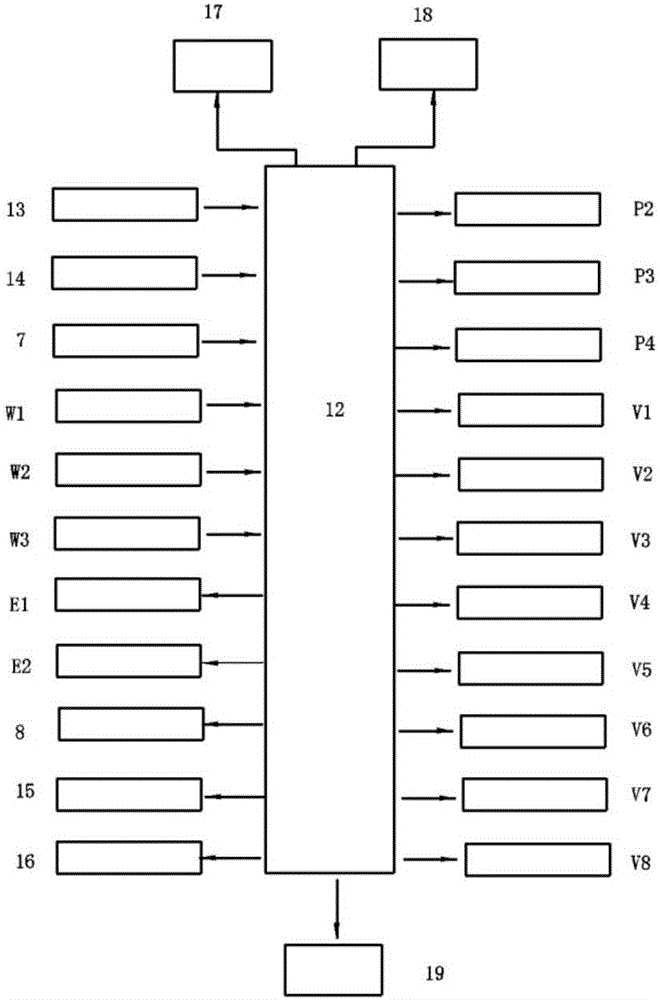

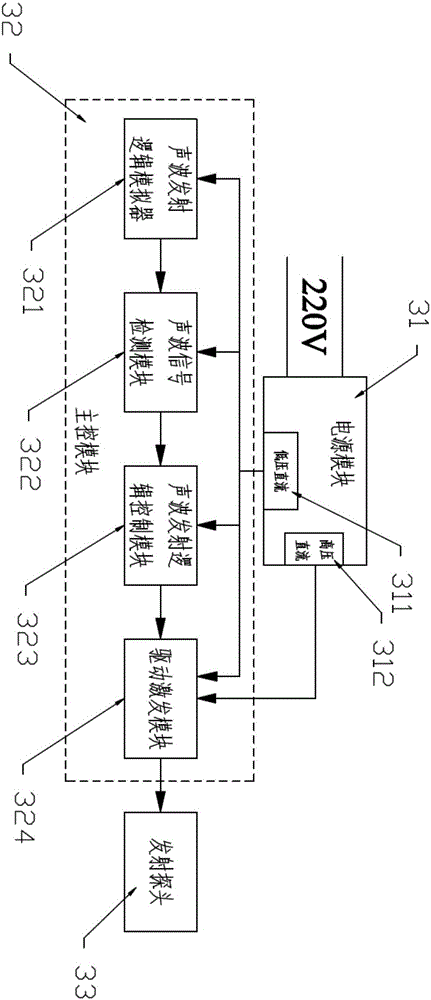

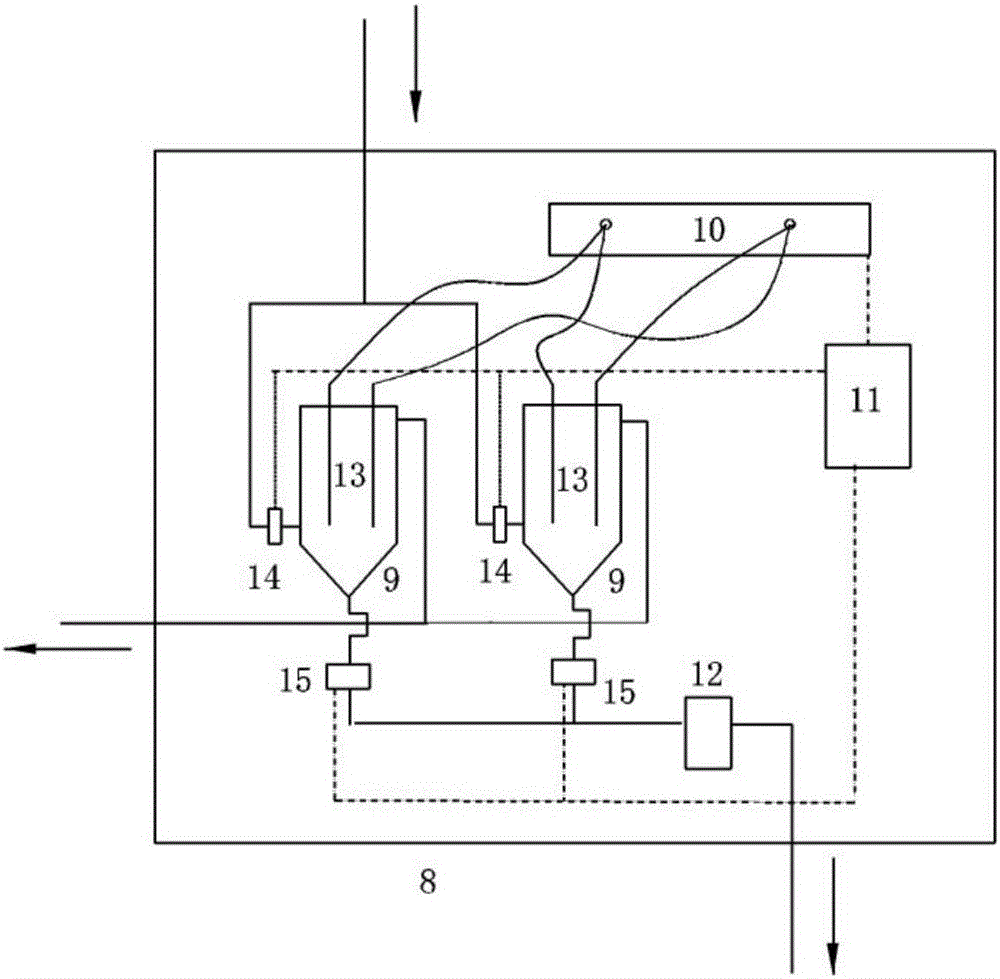

Intelligent electrochemical water treatment device with strengthened sterilization function

InactiveCN106477676AAchieve softeningRealize the sterilization functionWater/sewage treatment by electrochemical methodsWater/sewage treatment using germicide/oligodynamic-processIntelligent control systemOxidation reduction

The invention relates to an intelligent electrochemical water treatment device with cyclically strengthened sterilization and alga killing functions. The device comprises an electrochemical water treatment device and an intelligent control system and is mounted in a circulating water system in a bypass pipeline form, wherein the electrochemical water treatment device can switch a circulating water treatment mode and a cyclical strengthened sterilization treatment mode through the intelligent control system according to feedback data of an ORP (oxidation-reduction potential) sensor mounted in a cold water tank of the circulating water system. The device can effectively remove Ca<2+>, Mg<2+> and other scale forming substances in water and reduce water hardness, also has sterilization and alga killing functions and can realize cyclical strengthened sterilization, automatic scale-removal washing and intelligent operation parameter adjustment.

Owner:CHINA NAT OFFSHORE OIL CORP +2

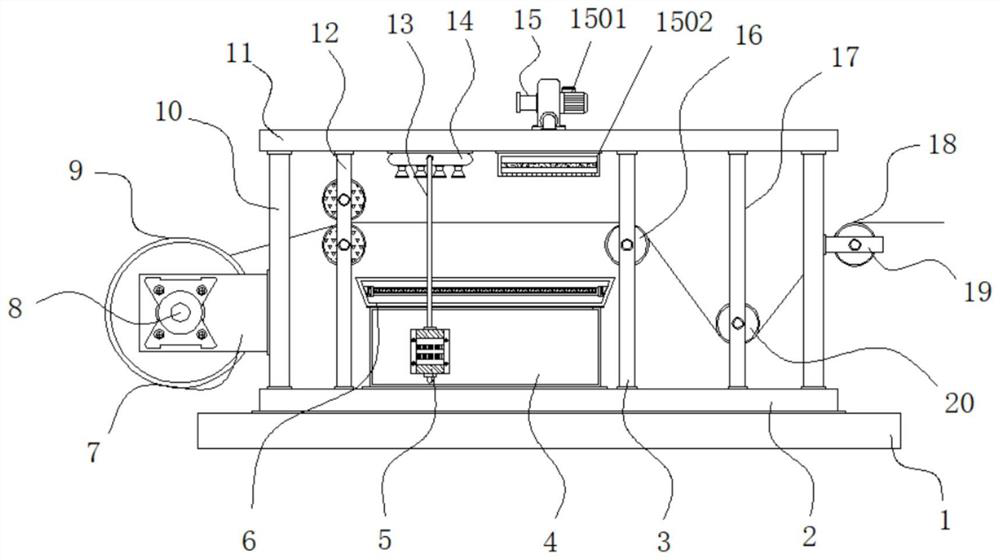

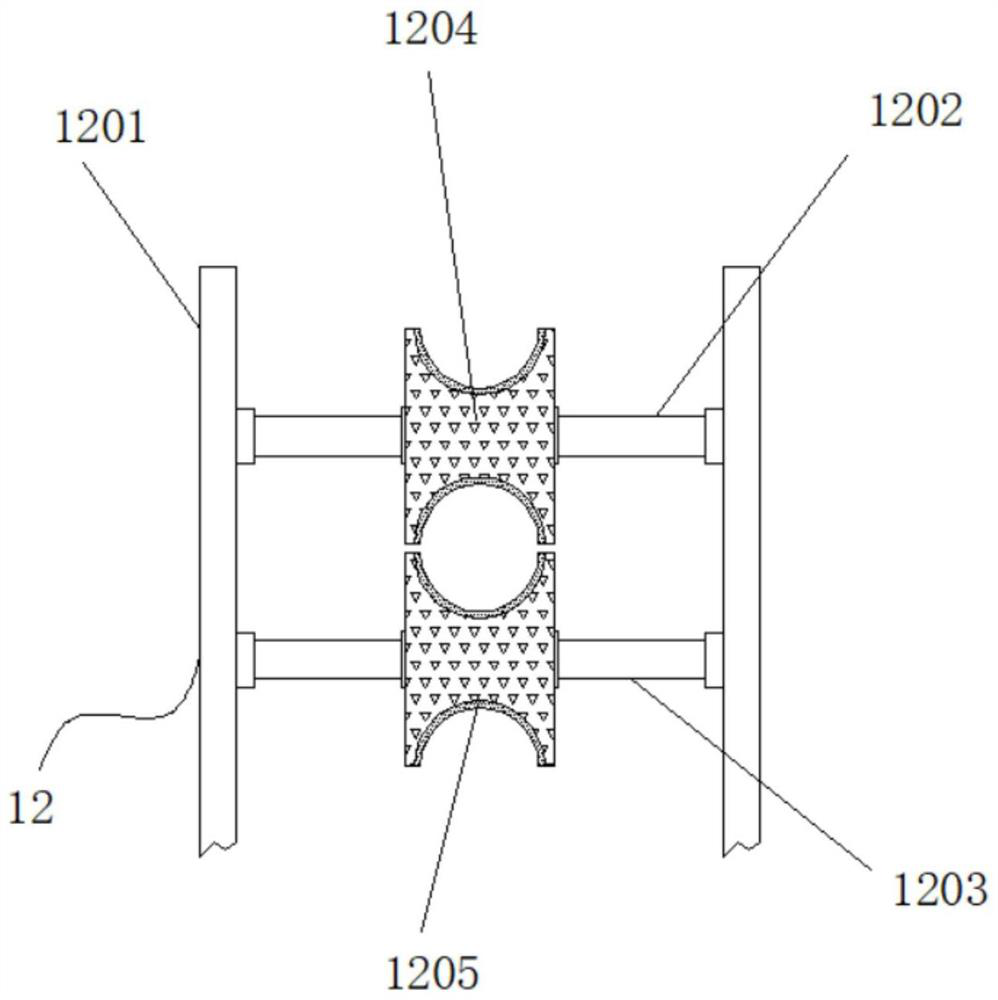

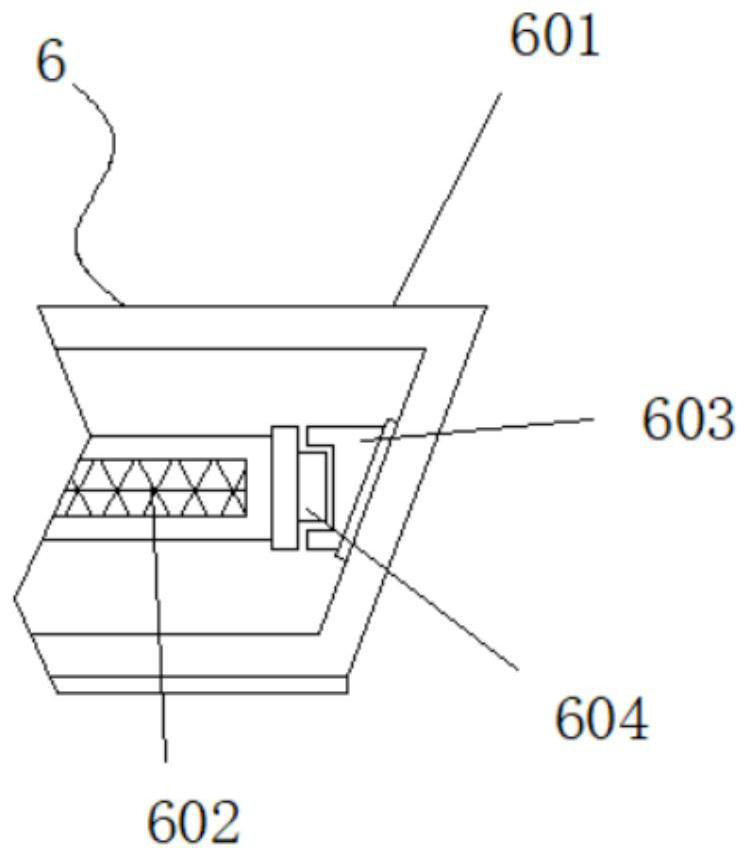

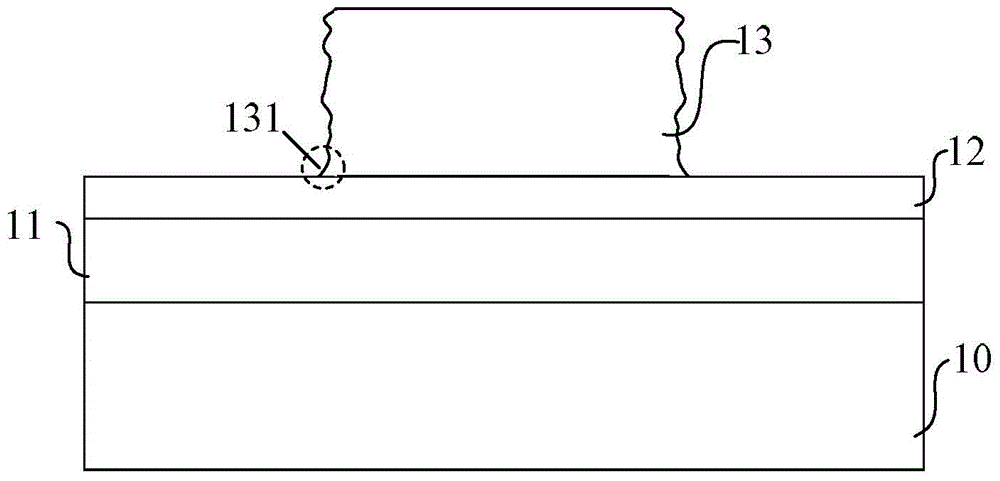

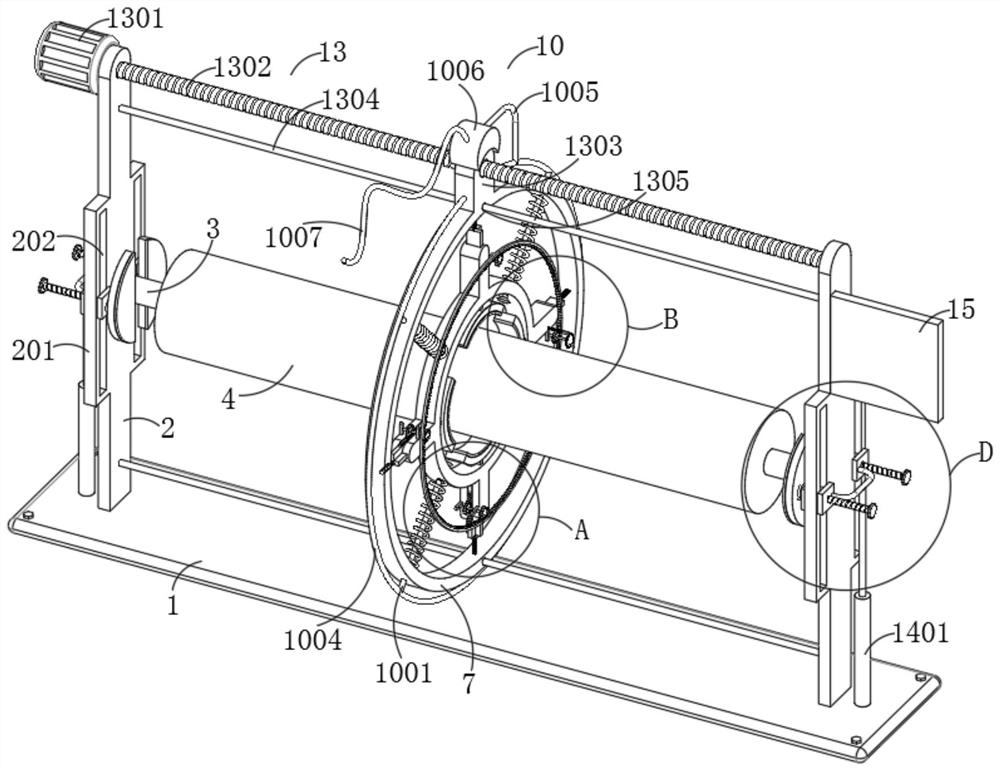

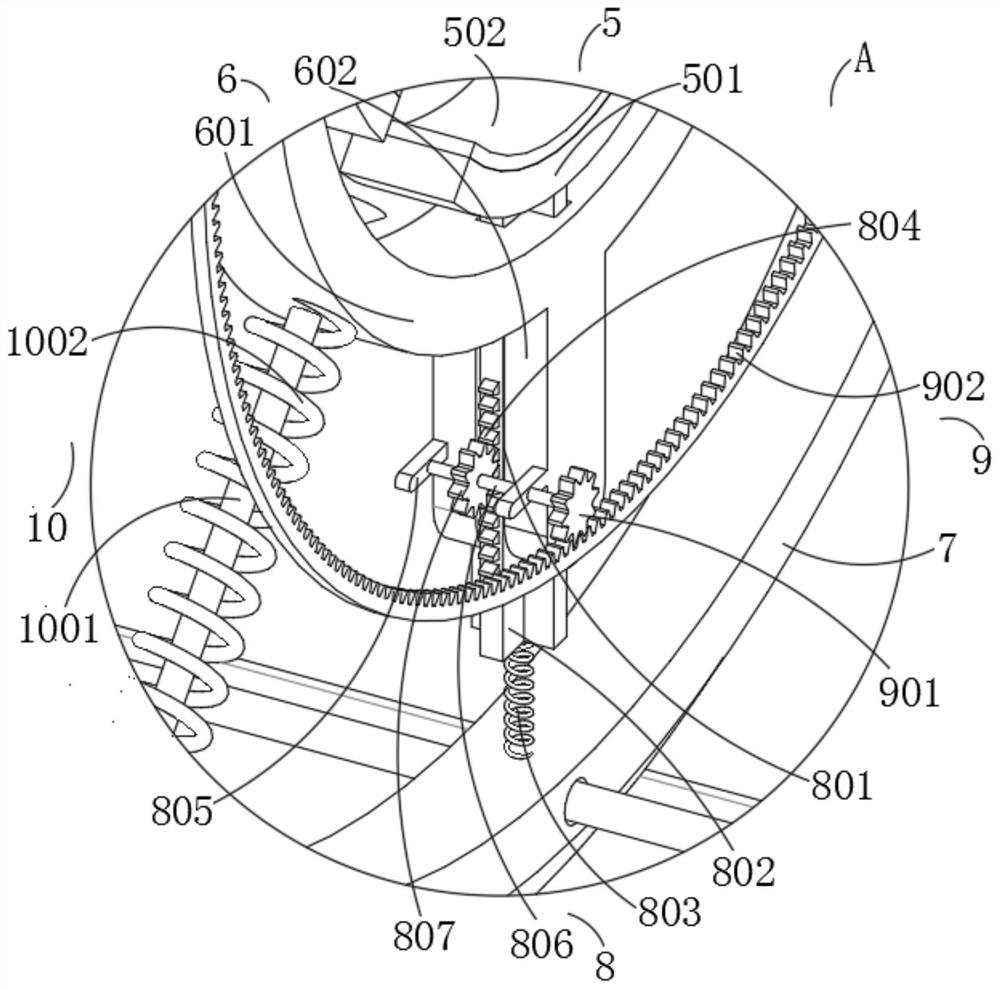

Cable straightening equipment for municipal engineering

InactiveCN112591546ANot easy to shiftAchieve softeningFilament handlingDrying gas arrangementsArchitectural engineeringMechanical engineering

The invention discloses cable straightening equipment for municipal engineering, and particularly relates to the technical field of municipal engineering. The cable straightening equipment comprises abase, a bottom plate, a pay-off roller and a top plate, the bottom plate is fixedly connected to the top end of the base, supporting rods are fixedly connected to the two sides and the two ends of the top of the bottom plate correspondingly, the top plate is fixedly connected to the top ends of the supporting rods, and a fixing plate is fixedly connected to one sides of the supporting rods. By arranging a fan, a heating box, an air outlet and an electric heating wire, when the cable straightening equipment is used, after a cable is cleaned, the electric heating wire is powered on, the fan isstarted, the fan can blow air into the heating box, the electric heating wire can heat the air, and finally the air is exhausted through the air outlet, so that the cleaned cable can be dried and softened, the softened cable can easily pass through the top end of a first straightening roller, the bottom end of a second straightening roller and the top end of a wire outlet roller in sequence to bestraightened, and the straightening effect of the cable is greatly improved.

Owner:耿建军

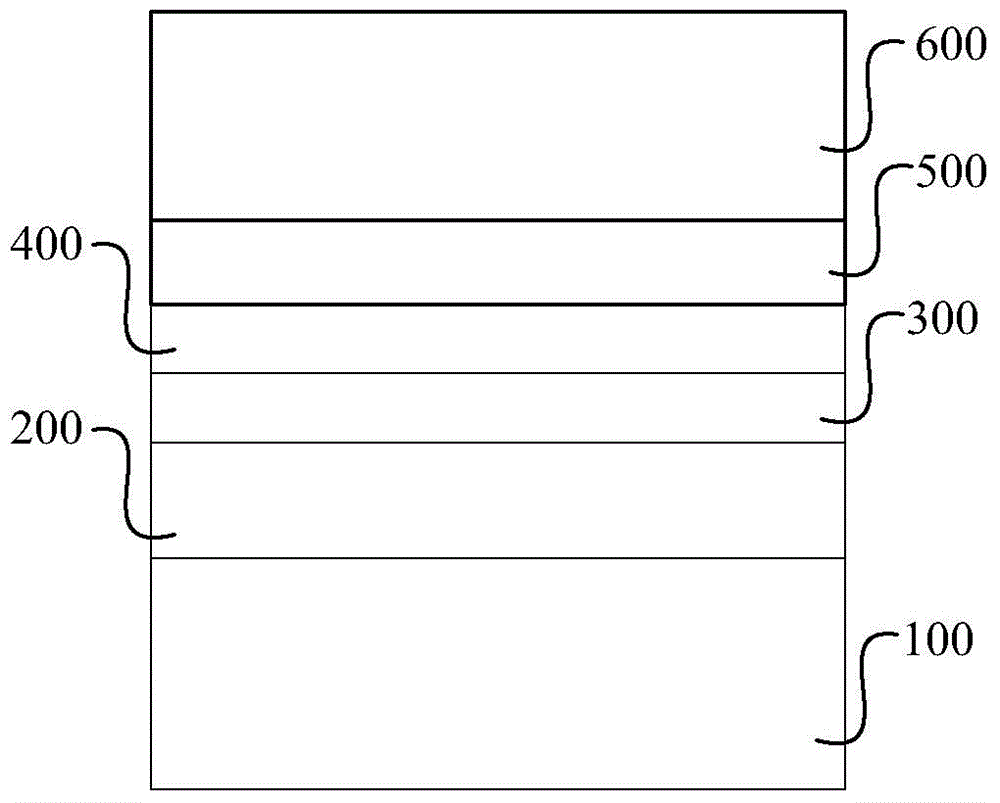

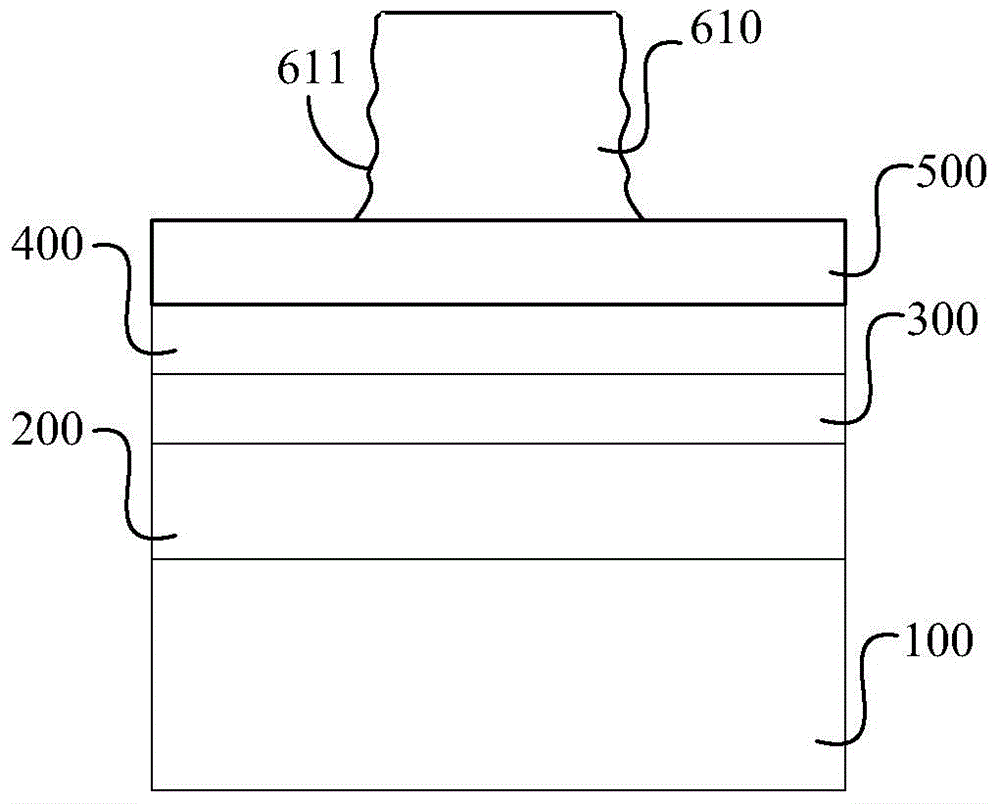

Forming method of semiconductor device and grid electrode

ActiveCN104681417AReduce surface roughnessSimple structureSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessPhotoresist

The invention provides a forming method of a semiconductor device and a grid electrode. In the forming method of the semiconductor device, a photoresist layer arranged above a hard mask layer is subjected to patterning, and after photoresist patterns are formed, the photoresist patterns are subjected to softening processing process, so that the surface roughness degree of the photoresist patterns is effectively reduced, then, the photoresist patterns are used as marks for etching the partial hard mask layer, the remained photoresist at the bottom of the side wall of the photoresist patterns is removed, then, the photoresist patterns are subjected to tightening processing process, the photoresist patterns are cured, meanwhile, a decoration layer is formed on the surfaces of the photoresist patterns, the smoothness of the side wall surface of the photoresist patterns is improved, the quality of the hard mask patterns subsequently obtained by using the photoresist patterns as the marks for etching the hard mask layer can be improved, and further, the structure precision of the semiconductor device obtained after the hard mask patterns are used as the masks for etching the materials to be etched in the subsequent steps can be improved, so that the performance of the semiconductor device is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Excessive glue scraping equipment for protective film laminating rubber roller and using method of excessive glue scraping equipment

ActiveCN112756184AAchieve softeningEasy to scrape offLiquid surface applicatorsCoatingsAdhesive glueEngineering

Owner:河源昆腾电子科技有限公司

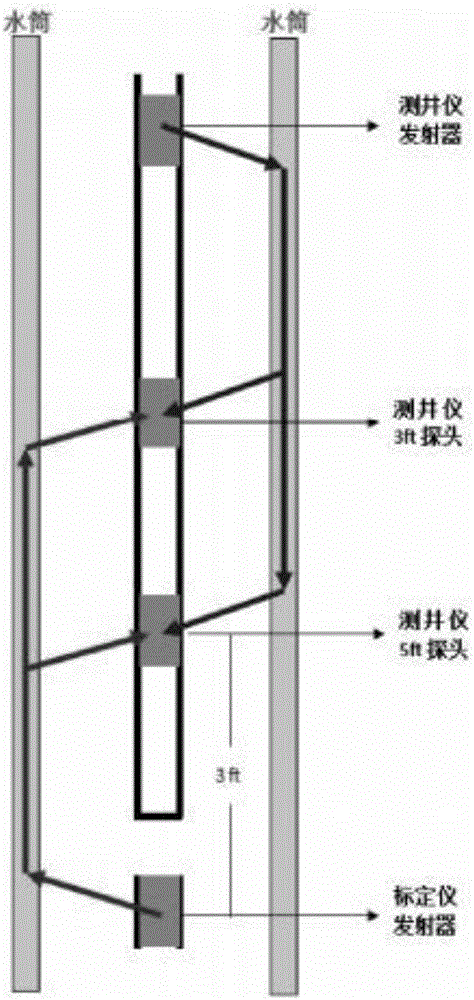

Calibration method and device of acoustic variable density logging instrument

ActiveCN105888647AEasy to operate on siteImproving the Quality of Cementing EvaluationConstructionsVariable densityUltrasound attenuation

The invention provides a probe consistency calibration method of an acoustic variable density logging instrument according to the attenuation rate related calibration principle. A calibration device is designed; through the probe consistency calibration device of the acoustic variable density logging instrument, all acoustic variable density logging instruments can be calibrated in a workshop to obtain the calibration coefficient of each acoustic variable density instrument; and the acoustic amplitude responses are unified to the same scale, thus the problem of acoustic amplitude scale caused in the logging site without a free casing is solved, the influence on the casing size, well fluid and pipe column is eliminated, the site operation is greatly facilitated, and the well cementation assessment quality is improved.

Owner:YANGTZE UNIVERSITY

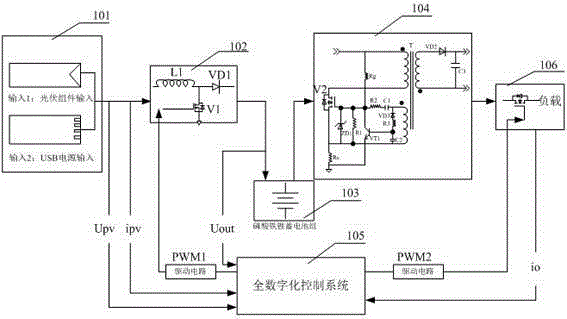

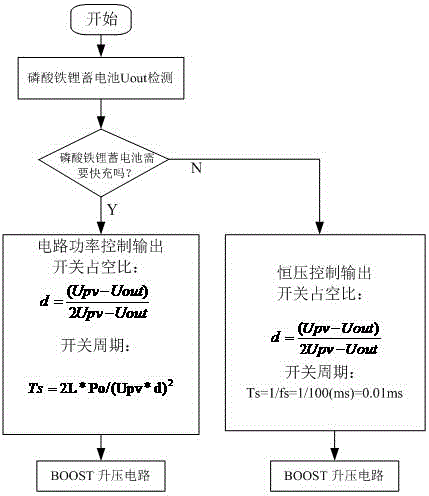

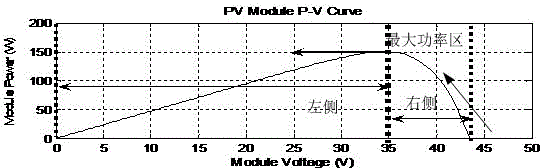

Lithium battery charging device and method thereof

ActiveCN104600808AAchieve softeningImprove conversion efficiencyDifferent batteries chargingSecondary cellsLoad circuitSoft switching

The invention relates to a lithium battery charging device and a method thereof. The lithium battery charging device comprises an input circuit component, a boost circuit, a charging control system, a battery pack, a self-oscillating reverse excitation circuit and a load circuit. The boost circuit and the charging control circuit are connected with the input circuit component, the battery pack and the self-oscillating reverse excitation circuit are connected with the boost circuit, and the load circuit is connected with the self-oscillating reverse excitation circuit. The charging control system is connected with the load circuit and controls the load circuit. The lithium battery charging device and the method thereof have the advantages that two modes including high-power charging and constant-voltage charging are achieved through the boost circuit and the charging control system, and thus, a lithium battery is charged with electricity generated by a low-voltage photovoltaic module; through output and an RCC quasi-resonance soft-switching technology of the self-oscillating reverse excitation circuit, softening of a power switch is achieved, so that conversion efficiency is improved and electromagnetic interference is reduced; multiple voltage output can be realized conveniently by the reverse excitation circuit, so that application range of the lithium battery is widened.

Owner:曹春荣

Method for processing freshwater fish in non-fried way

InactiveCN103211248ASolve the problem of corruptionRealize high-volume industrial productionFood preparationHigh pressureNutrients substances

The invention relates to a method for processing freshwater fish in a non-fried way. The method comprises the following steps of pretreating fish, seasoning, marinating, sterilizing and curing. The method has the advantages as below: harmful bacterium can be killed completely by a high-temperature high-pressure sterilization technology; the quality guarantee period of the product can reach 12 months without adding preservatives; the damage to the health of a human body caused by cancerogen in the frying process is completely avoided by using the non-fried process; the nutrient substance of the fish is remained; large-batch industrial production of aquatic products is realized; the efficiency is improved, and sanitation, safety and convenience in food taking are realized; delicious and nutrient-rich leisure food which can be easily absorbed by the human body is obtained without adding any preservative; and particularly, the taste and the economic value of low-value fish such as chub or bighead are improved.

Owner:武汉华新达食品有限公司

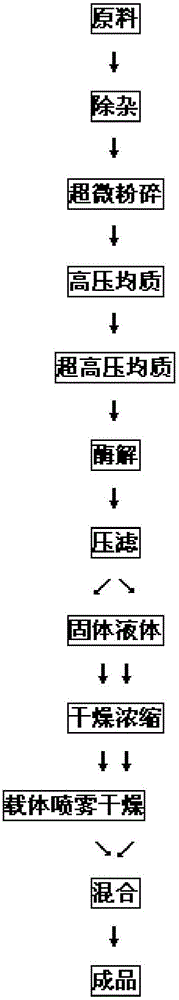

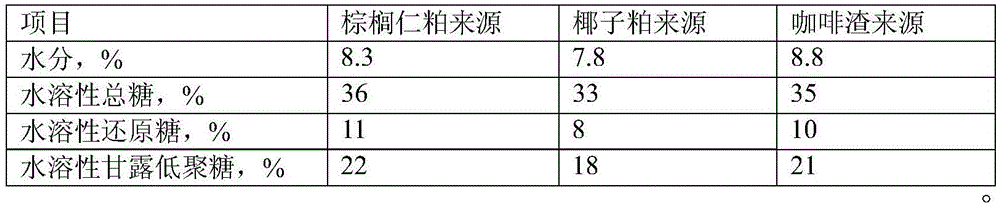

Production method of forage-use mannose oligomer

InactiveCN106173277AImprove comprehensive utilization valueImprove degradation rate and utilization rateFood processingAnimal feeding stuffMannoseChemistry

The invention relates to a production method of a forage-use mannose oligomer. Raw materials adopt materials rich in the mannose oligomer. The production method comprises the following steps: a, removing impurities; b, carrying out ultramicro pulverization, wherein fineness requirement of the pulverized material is that 95% of the pulverized material can pass 0.15mm; c, carrying out high pressure homogenizing at a pressure lower than 20000psi; d, carrying out ultrahigh pressure homogenizing at the pressure of 20000-60000psi, so that the material is uniform and floccular; e, carrying out enzymatic hydrolysis by utilizing beta-mannase and other non-starch polysaccharide enzymes under the conditions that the temperature is 40-70 DEG C, pH is 3-5, addition amount of the beta-mannase accounts for 0.05-1% of the amount of the material and enzymatic hydrolysis time is 4-48 hours; f, carrying out filter pressing for separating solid and liquid; g, directly drying the solid to obtain dry residue; h, carrying out spray drying on the liquid, so that dry powder is obtained; and i, uniformly mixing the dry residue with the dry powder, and then smashing, so that the finished product is obtained. The production method of the forage-use mannose oligomer has the advantage that the raw material from which mannose is difficult to extract can become a material from which the mannose is easy to extract.

Owner:SHANGHAI LAMP BIOLOGICAL SCI & TECH

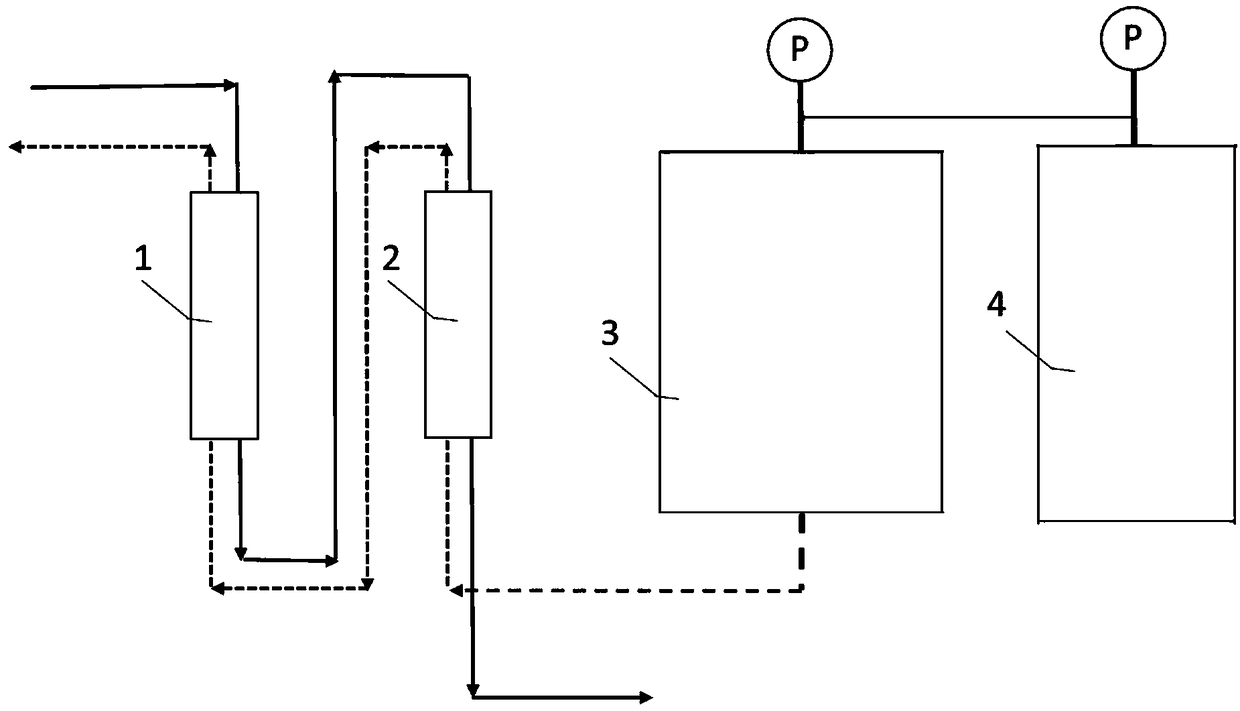

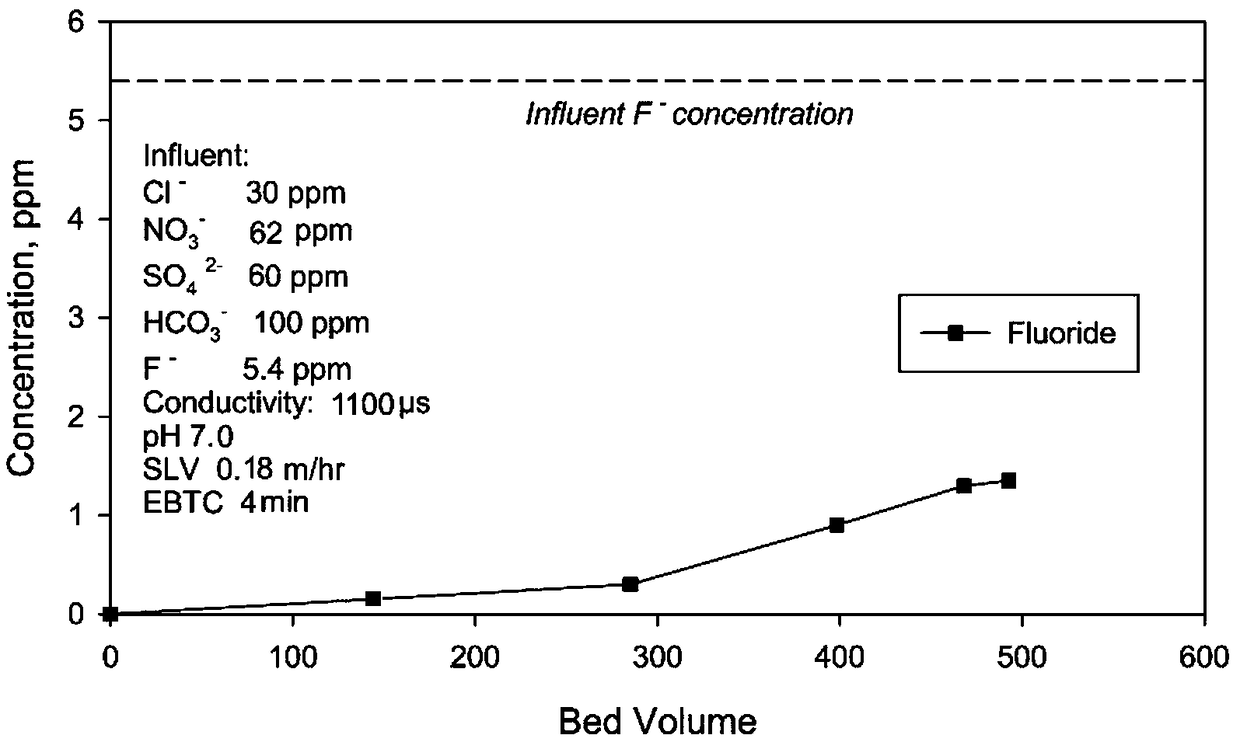

Water treatment technology for regenerating filter material by carbon dioxide

InactiveCN108928885AAchieve softeningAvoid disposition problemsIon-exchange process apparatusIon-exchanger regenerationChemistryCarbon dioxide

The invention discloses a water treatment technology for regenerating a filter material by carbon dioxide. The technology comprises the operation steps: pretreating raw materials, filling a treatmentcontainer, treating influent water, regenerating a material and reusing the material. 50% of the TDS content in earth surface water, groundwater or tap water can be reduced, and calcium and magnesiumions in water are removed, the water is softened, chloride ions and sulfate ions are adsorbed, and fluorine and other harmful ions in the water are selectively adsorbed; when the material is regenerated, two kinds of resins are regenerated by carbon dioxide at one time without production of high-concentration salt waste liquor or strong acid and alkali waste liquor. Compared with the prior art, the consumption of chemical drugs is greatly reduced, the cost is reduced, and the high-concentration or dangerous strong acid and alkali waste liquor is not produced and the discharge of wastewater isreduced.

Owner:芜湖沃泰环保科技有限公司

Biological softening method of areca seeds

ActiveCN107801938AReduce manufacturing costKeep the inherent characteristicsFungiMicroorganism based processesMicroorganismMass ratio

The invention discloses a biological softening method of areca seeds. The biological softening method comprises the following steps of deeply processing the areca seeds, placing the areca seeds afterfermentation and cleaning in fermentation liquid containing microorganisms, performing stirring and fermentation, and softening the areca seeds with complex enzymes generated by the microorganisms, sothat softened areca seeds are obtained, wherein the microorganisms are eurotium cristatum bacterial strains, the mass ratio of the areca seeds after fermentation and cleaning to the fermentation liquid containing the microorganisms is (1.0-25) to 100, the stirring speed is 10rpm-80rpm, the fermentation temperature is 25-40 DEG C, and the fermentation time is 12-48h. The biological softening method has the advantages of being high in softening effect, high in safety, capable of improving the biological activity of polyphenols of the areca seeds, high in eating quality and the like.

Owner:长沙市一诺生物科技有限责任公司

Ultrasonic humidifier for edible fungus culture

PendingCN107120768AEasy to useConvenient humidification workLighting and heating apparatusEfficient regulation technologiesDrive shaftWater quality

The invention discloses an ultrasonic humidifier for edible fungus culture. The ultrasonic humidifier comprises a case; a supporting plate is fixedly connected between the two sides of the inner wall of the case; a water tank is fixedly connected on one side of the top of the supporting plate; the bottom of the inner wall of the case is fixedly connected with a motor through a connecting block; the outer surface of a motor output shaft is sleeved with a first bevel gear; the bottom of the inner wall of the case is rotatably connected with a transmission shaft through a bearing; and the top end of the transmission shaft penetrates through the supporting plate and the water tank to extend to the interior of the water tank. The invention relates to the technical field of edible fungus culture equipment. According to the ultrasonic humidifier for the edible fungus culture, the purpose of softening to-be-atomized water is achieved; the situation that a water pipe inside the ultrasonic humidifier is blocked because the water quality is hard, and white powdery impurities are generated is well avoided; normal using of the ultrasonic humidifier is guaranteed; and humidifying work of culture personnel to edible fungi is facilitated.

Owner:江苏福利达农业科技有限公司

Sputum scab removal equipment for respiratory medicine department

InactiveCN111249548APromote softeningAchieve softeningSurgeryMedical devicesBiologyBiomedical engineering

The invention discloses sputum scab removal equipment for the respiratory medicine department, and particularly relates to the technical field of medical treatment tools. The sputum scab removal equipment comprises an equipment gun body, wherein one side of the bottom of the equipment gun body is fixedly provided with a sputum suction pump; the input end of the sputum suction pump is fixedly connected with a removal suction pipe; the outer side of one end of the removal suction pipe is fixedly provided with a fixed pipe body; a movable pipe body is movably arranged in the fixed pipe body; thetop end of the movable pipe body is fixedly provided with a first movable cover; and the bottom end of the movable pipe body is fixedly provided with a second movable cover. According to the sputum scab removal equipment, the movable pipe body moves to drive a sputum removal bag bubble, softening massage balls and removal salient points carry out sputum scab scraping and rubbing to quicken a sputum scab to be softened, the softened sputum scab is scraped, sputum liquid downwards flows into a sputum suction cover, a sputum suction pump extracts the sputum liquid through the removal suction pipe, sputum scab softening and sputum liquid suction are synchronously operated, softening efficiency is high, a sputum suction effect is good, operation is convenient, and a sputum scab removal effect is improved.

Owner:THE SECOND HOSPITAL OF HEBEI MEDICAL UNIV

Machining process of stainless steel material special for faucets

InactiveCN108950417AImprove mechanical propertiesThinning the pickling passivation layerCorrosionThermal treatment

The invention discloses a machining process of a stainless steel material special for faucets. The machining process comprises the following steps that (1) a steel blank raw material is smelted; (2) coarse-smelted molten steel is subjected to refining; (3) pouring is carried out to obtain a steel blank; (4) the steel blank is subjected to first annealing treatment; (5) the steel blank is subjectedto thermal treatment and then hot rolling; (6) hot-rolled stainless steel is subjected to first acid pickling; (7) the stainless steel is cold-rolled; (8) the stainless steel is subjected to secondary annealing treatment; (9) the stainless steel is subjected to electrolysis and secondary acid pickling; and (10) the surface of the stainless steel is subjected to polishing and burr removal, and thus the stainless steel material special for the faucets is obtained. The prepared stainless steel is dense in material structure, smooth in surface, good in corrosion resistance, excellent in mechanical performance and easy to machine.

Owner:合肥久新不锈钢厨具有限公司

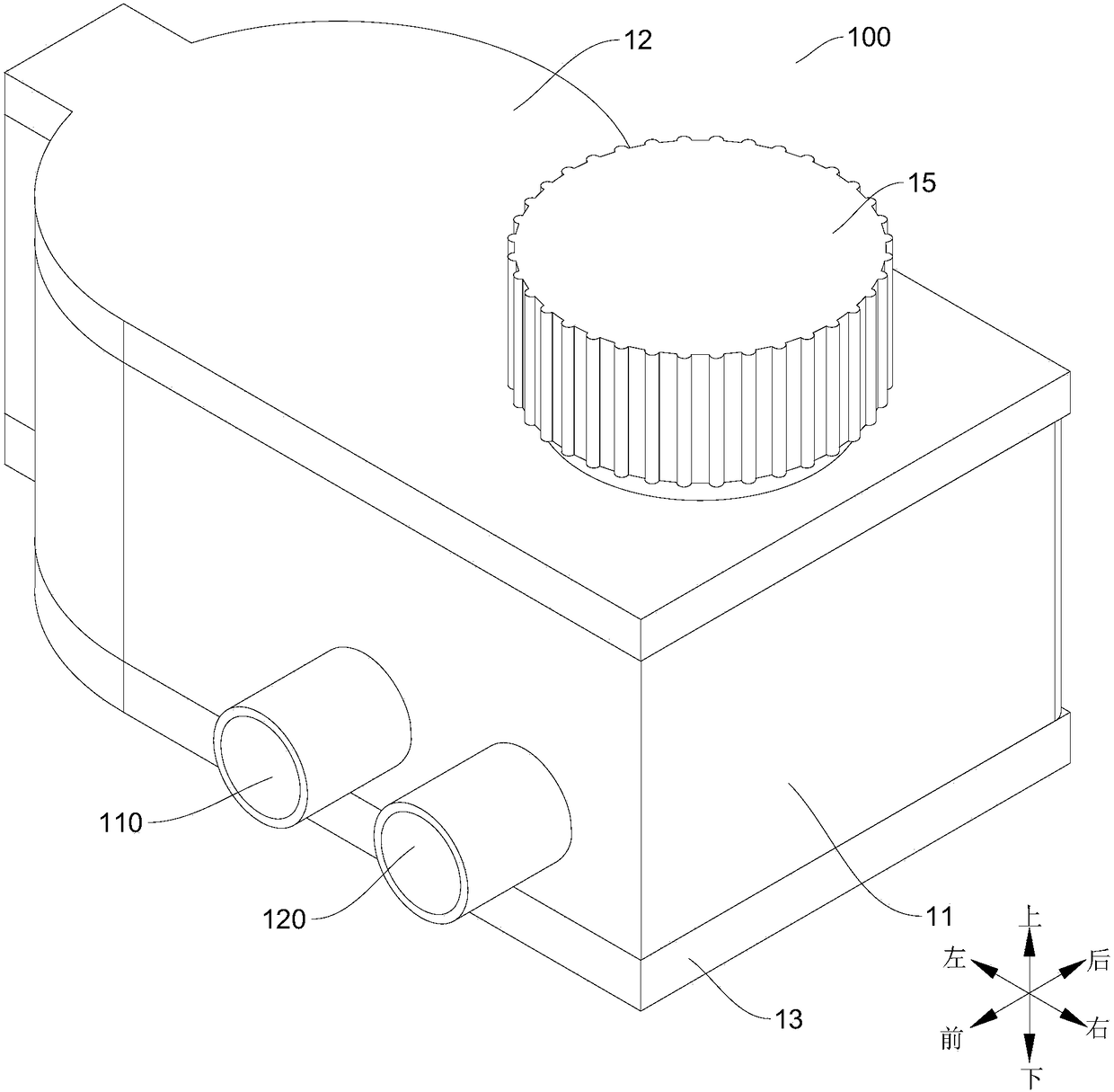

Water softening device and washing equipment having water softening device

InactiveCN109384280AAchieve softeningAchieve regenerationWater treatment parameter controlTableware washing/rinsing machine detailsSoftened waterEngineering

The invention discloses a water softening device and washing equipment having the water softening device. The water softening device comprises: an outer shell, wherein a salt chamber and a resin chamber are defined in the outer shell, and the outer shell is provided with a softened water inlet and a softened water outlet communicated to the resin chamber, and a regenerated water inlet communicatedto the salt chamber; and a single-way conduction device arranged at the communicating position of the salt chamber and the resin chamber and capable of moving between the single-way conduction position for conducting the salt chamber to the resin chamber and the isolating position for isolating the salt chamber from the resin chamber. With the water softening device of the embodiments of the present invention, the water softening and the water regenerating can be achieved, the regeneration operation is simple, and the service life is long.

Owner:SANHUA AWECO APPLIANCE SYST WUHU CO LTD

Recycling method for high-hardness high-salinity recycled paper paper-making wastewater

ActiveCN108483761AReduce the pressure of purificationEmission reductionTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsSulfate radicalsSulfate radical

The invention discloses a recycling method for high-hardness high-salinity recycled paper paper-making wastewater. Firstly, pre-softening treatment is carried out on high-hardness wastewater by usinglime powder, and efficient interception is carried out on divalent ions and multivalent ions in the wastewater by using a membrane separation method to remove calcium, magnesium, silicon, sulfate radical and other ions. In the process of using the membrane separation method, the characteristics of the ions in the wastewater are changed by using an electromagnetic method, thereby changing deposition speed of calcium carbonate and physical characteristics of deposition to prevent the formation of hard scale so as to greatly reduce the possibility of the scale formation, the separation effect isgood, the inner treated sewage is recycled, the purification treatment pressure of the sewage is reduced, the out-emission of the sewage is reduced, and the production process is cleaner and more environmentally-friendly.

Owner:DONGGUAN TAICHANG PAPER CO LTD

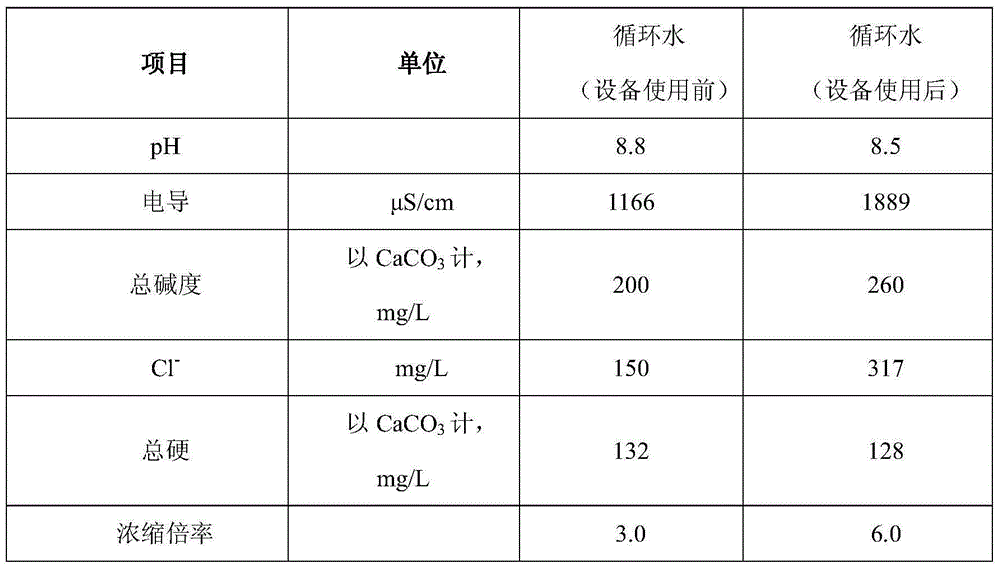

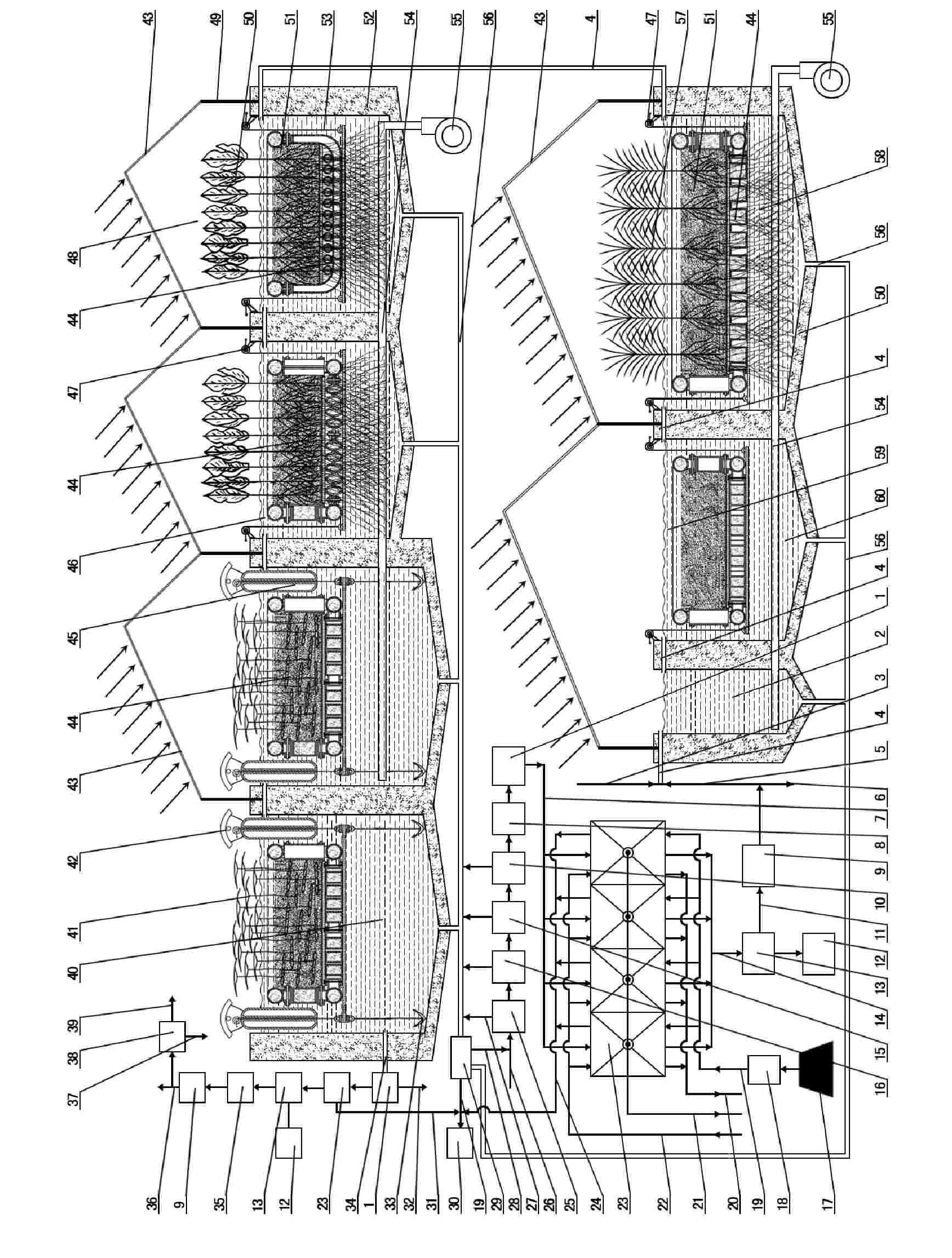

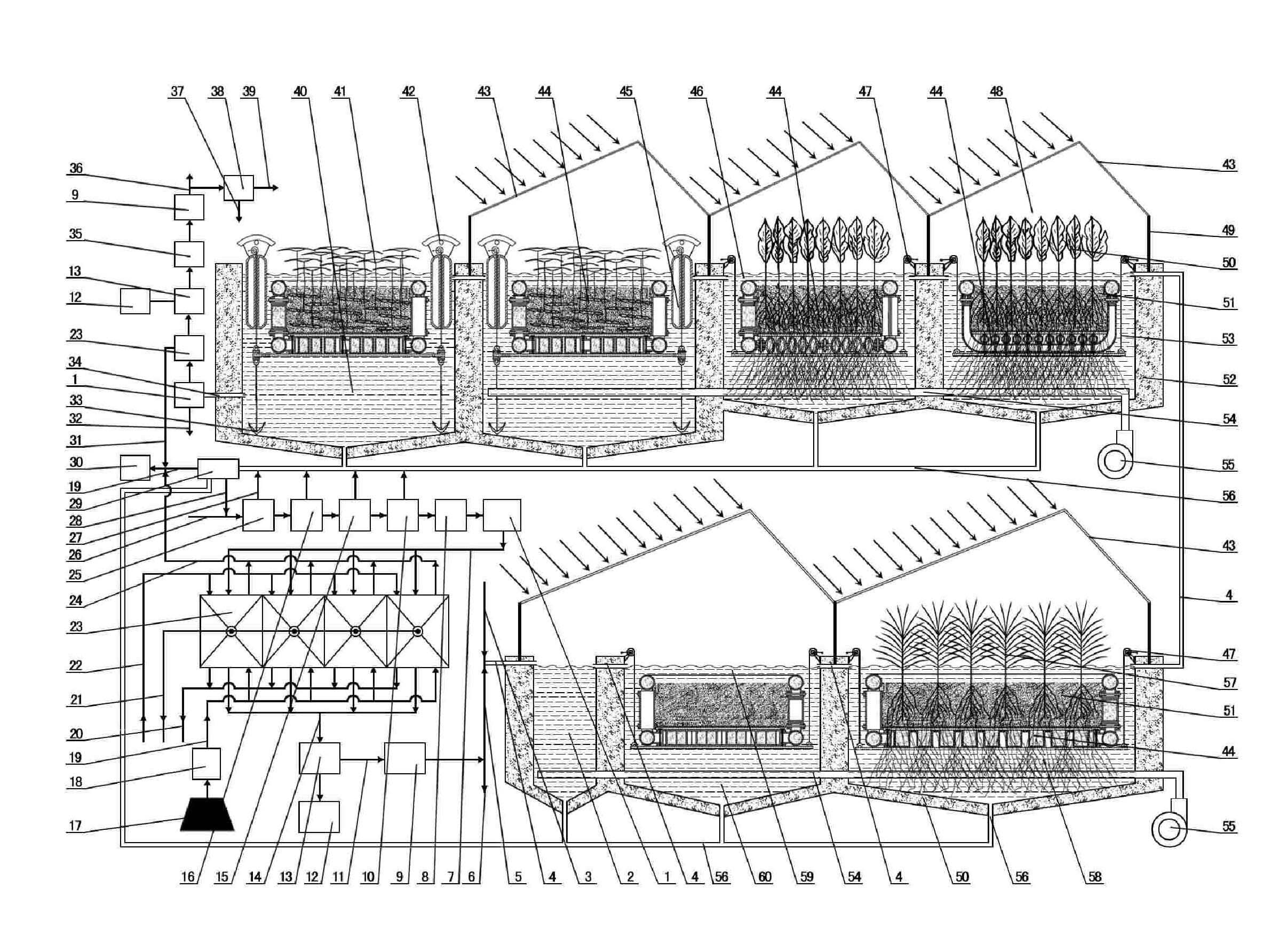

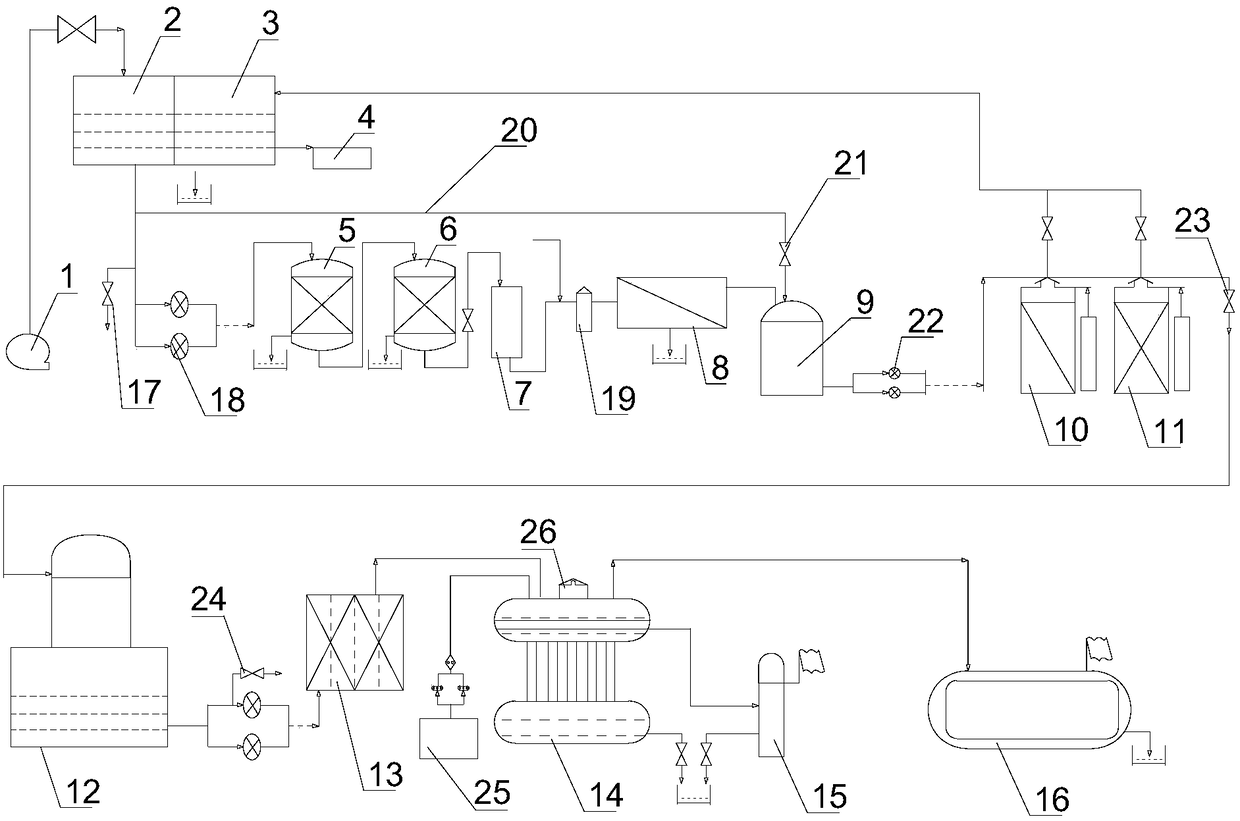

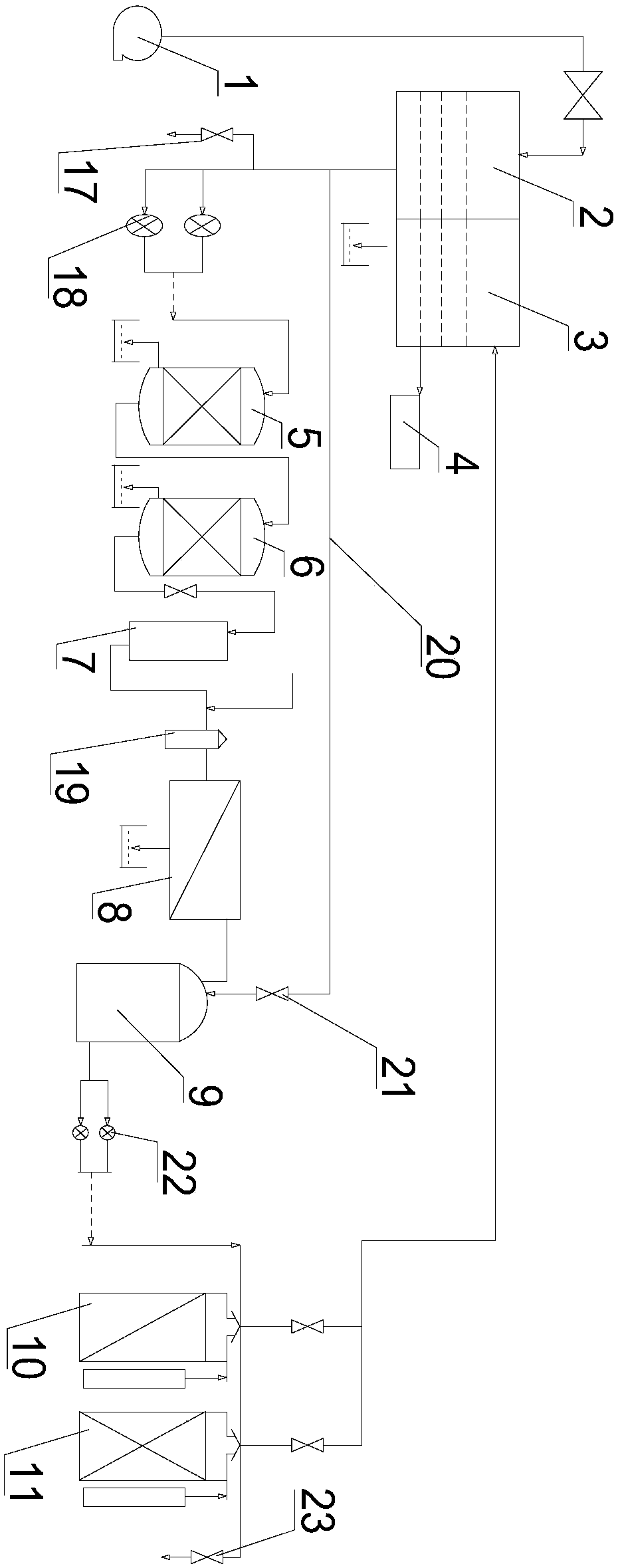

Oil refining reclaimed water reuse high-concentration-ratio circulating water treatment method and device

InactiveCN105016432AImprove sewage reuse rateReduce consumptionWater/sewage treatment using germicide/oligodynamic-processHigh concentrationElectrolysis

The invention relates to an oil refining reclaimed water reuse high-concentration-ratio circulating water treatment method and device. The method and device are characterized in that electrochemical water treatment complete equipment is connected to a water return main pipeline of a circulating cooling system in parallel for water quality treatment of circulating water, wherein reclaimed water obtained after deeply processing oil refining waste water serves as supplemented water. The electrochemical water treatment complete equipment carries out circulating taking and using treatment on the circulating water through circulating water return residual pressure. Softening and sterilization of water quality of the circulating system are achieved in an electrolysis mode, and the concentration ratio of the circulating water is effectively increased. The method can increase the sewage recycle rate of refining enterprises, consumption of fresh water is reduced, pollution of drained water to the environment is reduced, and meanwhile the method and the device have the advantages of being low in energy consumption, low in cost, environmentally friendly, free of pollution and high in automation degree.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Filter-adsorption-submerged floating wet land sewage treating system and apparatus

InactiveCN1743283BAchieve softeningReduce evaporationMultistage water/sewage treatmentEnergy based wastewater treatmentFiltrationUltraviolet

This sewage treatment system of filtration-absorption submerging-surfacing wetland comprises 4 different levels of sewage disposal subsystem. The primary sewage treatment system comprises a filtration-absorption coal filter sewage treatment device, magnetic water strainer, ultraviolet sterilization device, etc. The secondary sewage treatment system comprises aeration distributing gutter placed insolar room, distributing channel for confluence, facultative aeration pond of submerging-surfacing wetland which are connected in sequence. The tertiary sewage treatment system comprises filtration-absorption coal filter sewage treatment device, magnetic water strainer, ozone sterilization device and ultraviolet sterilization device. The quarternary sewage treatment system comprises electrolytic water treatment device. The sewage is dewatered by a dewatering device, delivered by a delivering device, fed into a boiler to burn. After treated by the said sewage treatment system the exhaust gas fed to boiler to aid combustion, and the coal failing in treatment by the filtration-absorption coal filter sewage treatment device is fed to the combustor to burn after being dried.

Owner:BEIJING HIKEEN TECH +1

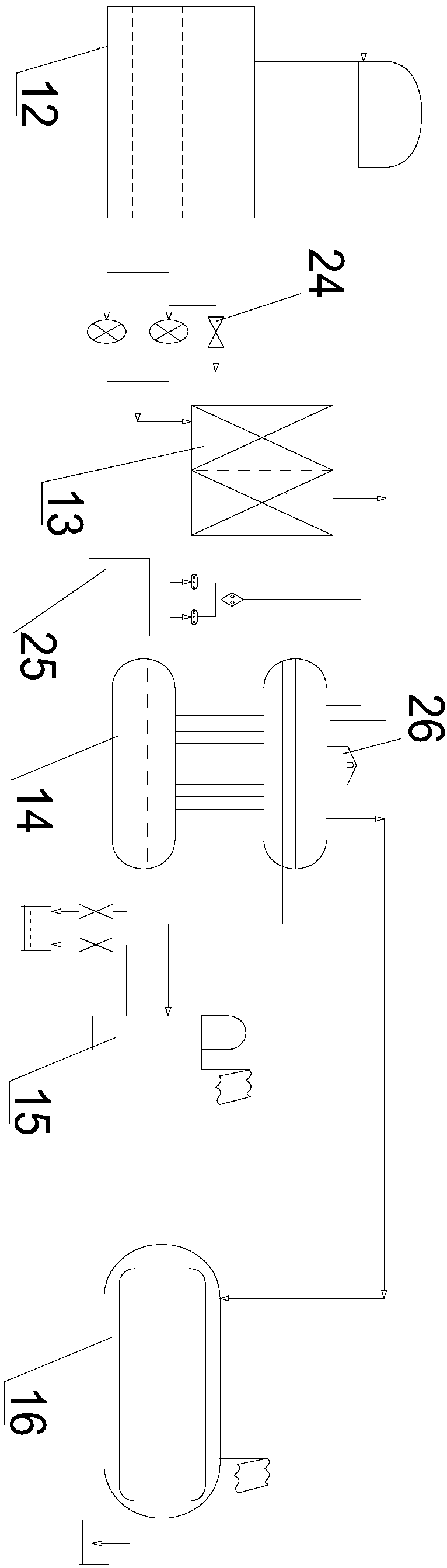

Boiler water treatment system

PendingCN108101269AAvoid corrosionPrevent scalingSpecific water treatment objectivesTreatment involving filtrationReverse osmosisWater quality

The invention discloses a boiler water treatment system. The boiler water treatment system comprises a deep well pump, a raw water tank, a soft water tank, a deaerator, a sand filter, a carbon filter,a security filter, a reverse osmosis device, a reverse osmosis water production tank, a first salt tank, a second salt tank, a deaerator, a coal economizer, a boiler steam pocket, a tandem expansionvessel and a reactor. The boiler water treatment system has a reasonable structure, comprehensive functions, remarkable water purification effects and a perfect system.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY +1

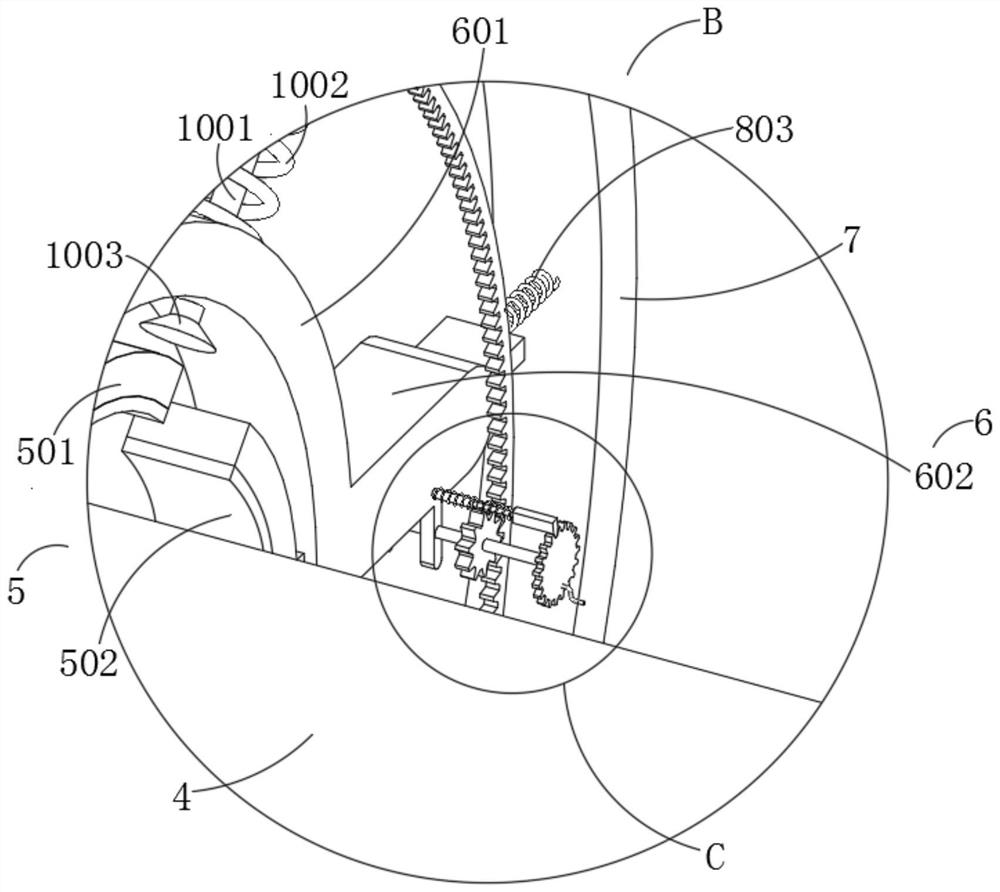

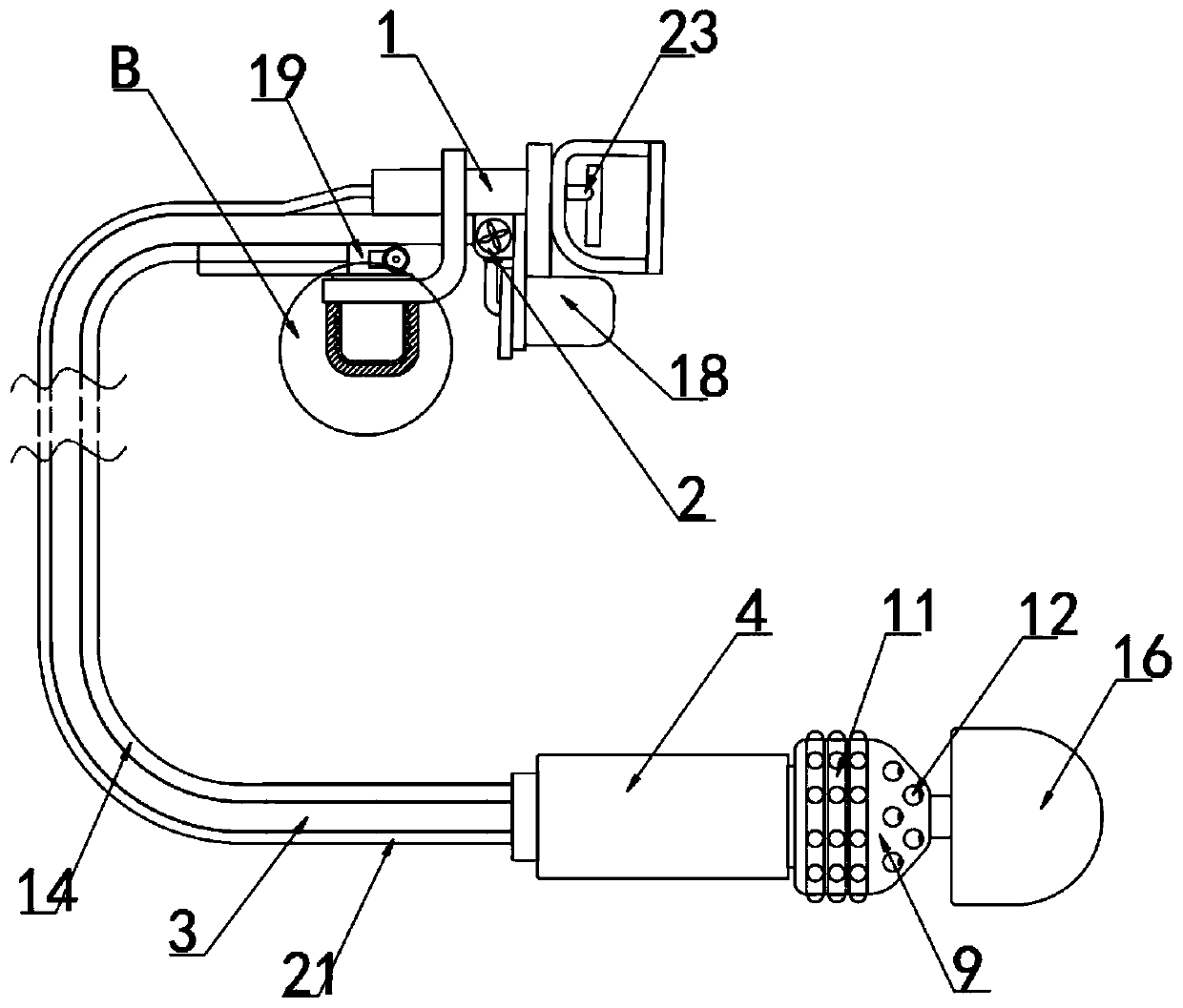

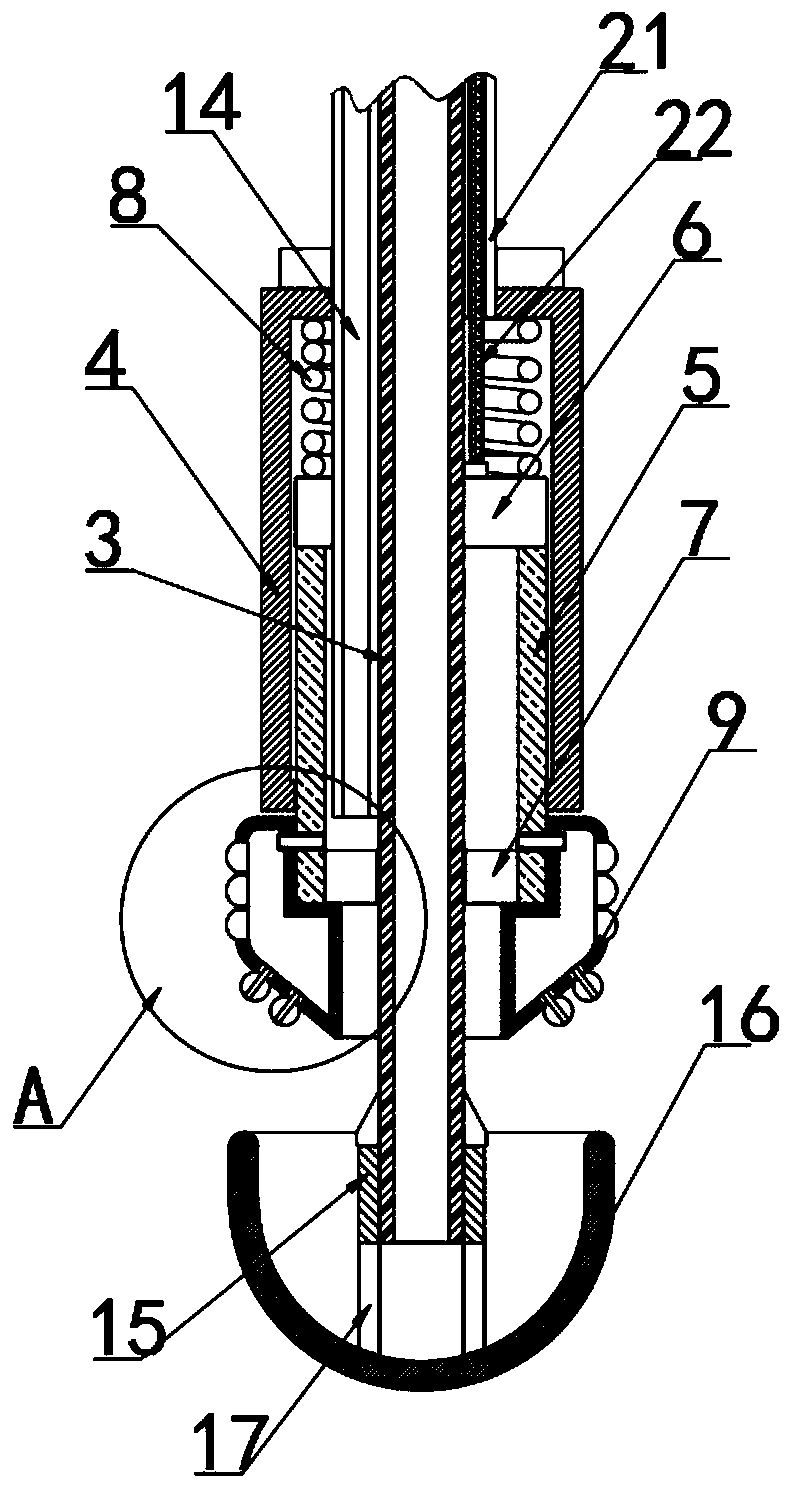

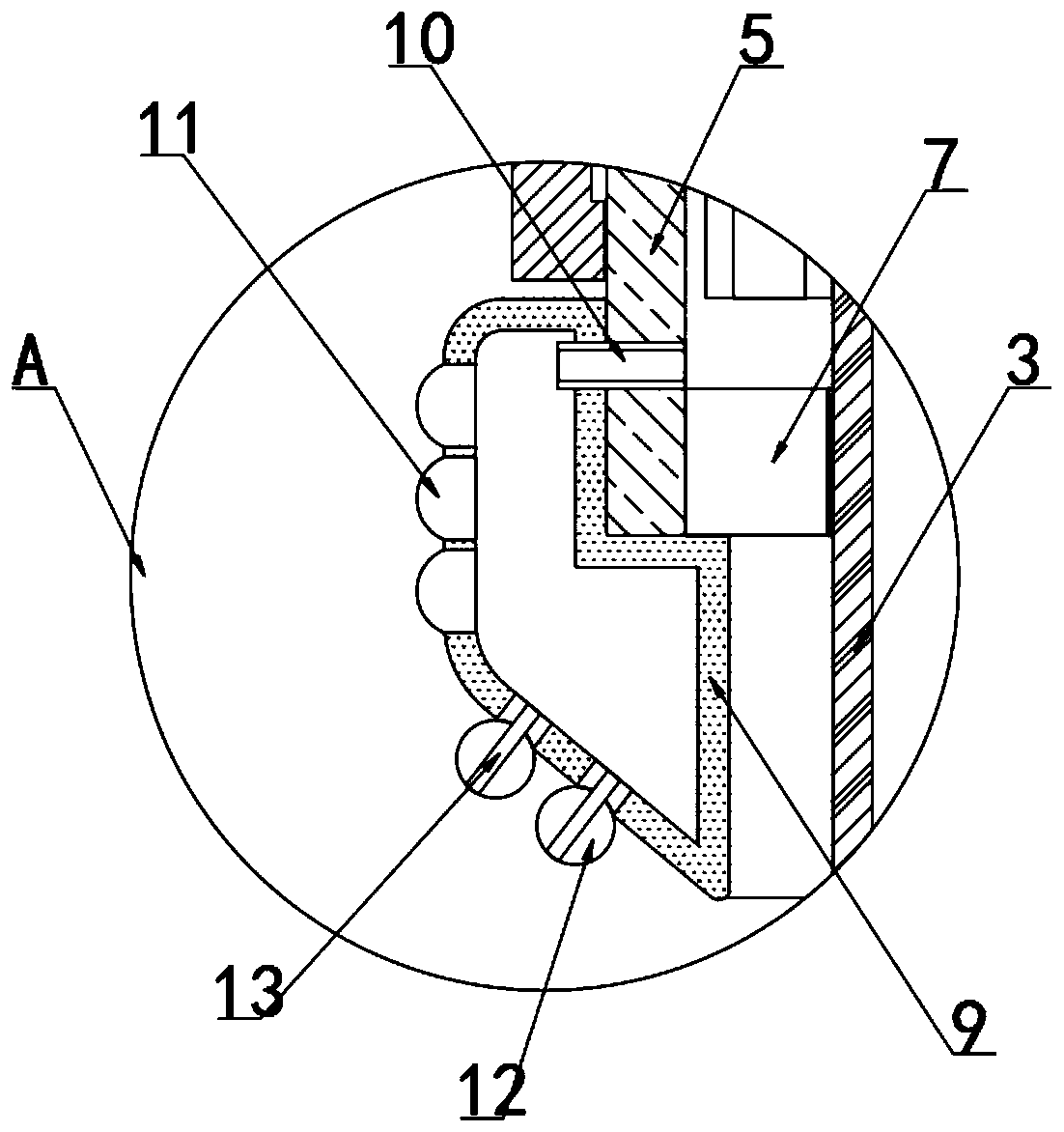

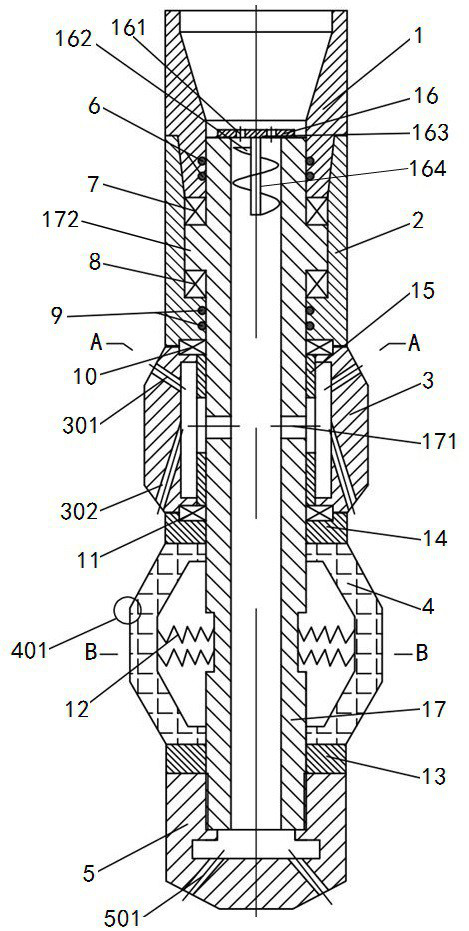

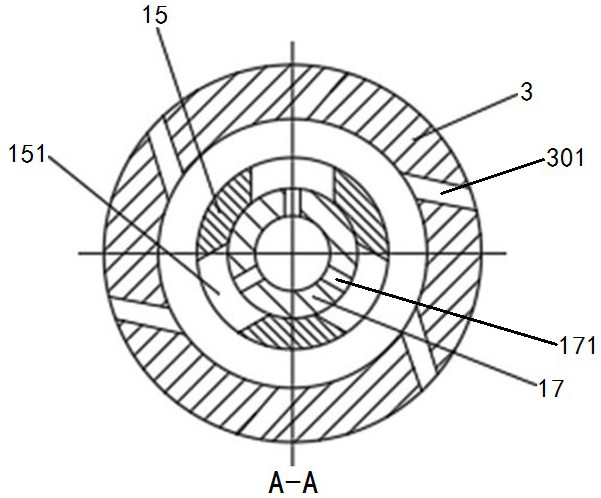

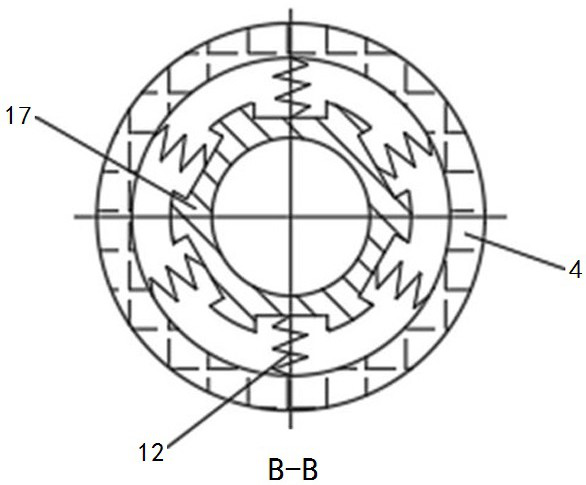

Oil pipe unblocking tool

The invention provides an oil pipe unblocking tool. The oil pipe unblocking tool comprises an upper connector and a lower connector, the core shaft is rotatably connected to the lower portion of the upper connector, the core shaft is provided with an inner cavity communicated with the upper connector, and a rotation generator used for driving the core shaft to rotate is installed on the core shaft; the rotary lower spray head is fixed on the mandrel so as to synchronously rotate along with the mandrel, the mandrel is provided with a communicating structure for communicating an inner cavity of the mandrel with an inner cavity of the rotary lower spray head, and the rotary lower spray head is provided with a liquid spraying hole for flushing blockages on the inner wall of the oil pipe; and the grinding and milling brush is arranged outside the mandrel and located above the rotary lower spray head, and the grinding and milling brush, the mandrel and the rotary lower spray head rotate together so as to grind blockages on the inner wall of the oil pipe. According to the oil pipe plug removal device, the rotary lower spray head and the milling brush are combined, plugs on the inner wall of an oil pipe can be softened firstly, loose plugs on the surface can be removed, then hard plugs are ground, the good plug removal effect can be achieved, and smooth development of follow-up production cannot be affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com