Cable straightening equipment for municipal engineering

A cable and engineering technology, applied in the field of cable straightening equipment, can solve the problems of inability to clean cables and insufficient functionality, and achieve the effect of strong functionality, improved straightening effect, and not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

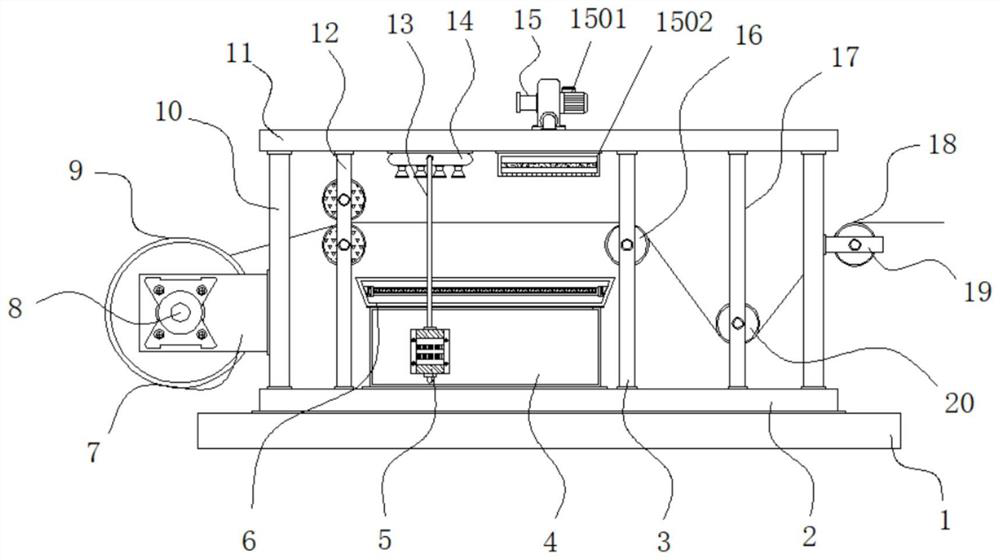

[0035] Example 1: See Figure 1-6, a cable straightening device for municipal engineering, comprising a base 1, a bottom plate 2, a pay-off roller 9 and a top plate 11, the bottom plate 2 is fixedly connected to the top of the base 1, and the two sides and two ends of the top of the bottom plate 2 are respectively fixed Connected with a support rod 10, the top plate 11 is fixedly connected to the top of the support rod 10, one side of the support rod 10 is fixedly connected with a fixed plate 7, the front end of the fixed plate 7 is fixedly connected with a drive motor 8, and the model of the drive motor 8 can be Y90L -4, the pay-off roller 9 is arranged between the fixed plates 7, the both sides of the pay-off roller 9 are provided with structures 21 for fixing, the side between the bottom plate 2 and the top plate 11 is provided with a limit guide structure 12, and the bottom of the top plate 11 A softening and drying mechanism 15 is provided at the middle position, and the ...

Embodiment 2

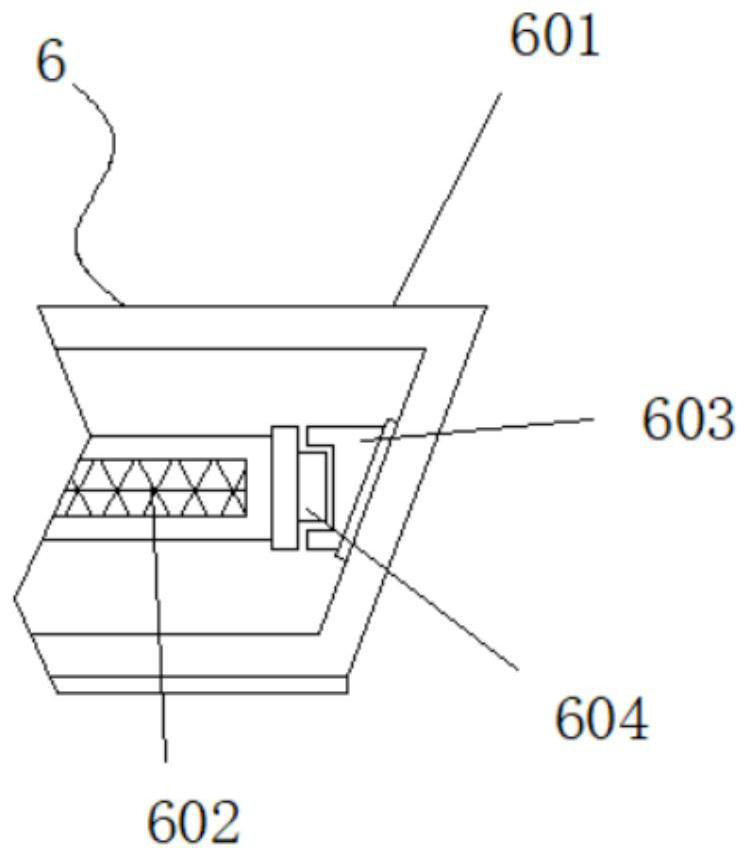

[0039] Embodiment 2: The water-saving structure 6 is composed of a water collection tank 601, a filter screen 602, a card slot 603 and a card block 604. The water collection tank 601 is fixedly connected to the top of the water tank 4, and both sides of the water collection tank 601 are respectively fixedly connected with card slots 603, the inside of the sump 601 is provided with a filter 602, and both sides of the filter 602 are respectively fixedly connected with blocks 604;

[0040] The outer diameter of the locking block 604 is smaller than the inner diameter of the locking slot 603, and an engaging structure is formed between the locking slot 603 and the locking block 604;

[0041] Specifically, such as figure 1 and image 3 As shown, when in use, the sewage generated by cleaning the cable will fall into the inside of the sump 601, and at this time, the filter screen 602 will filter the sewage, and then the clean water will flow into the inside of the water tank 4 again...

Embodiment 3

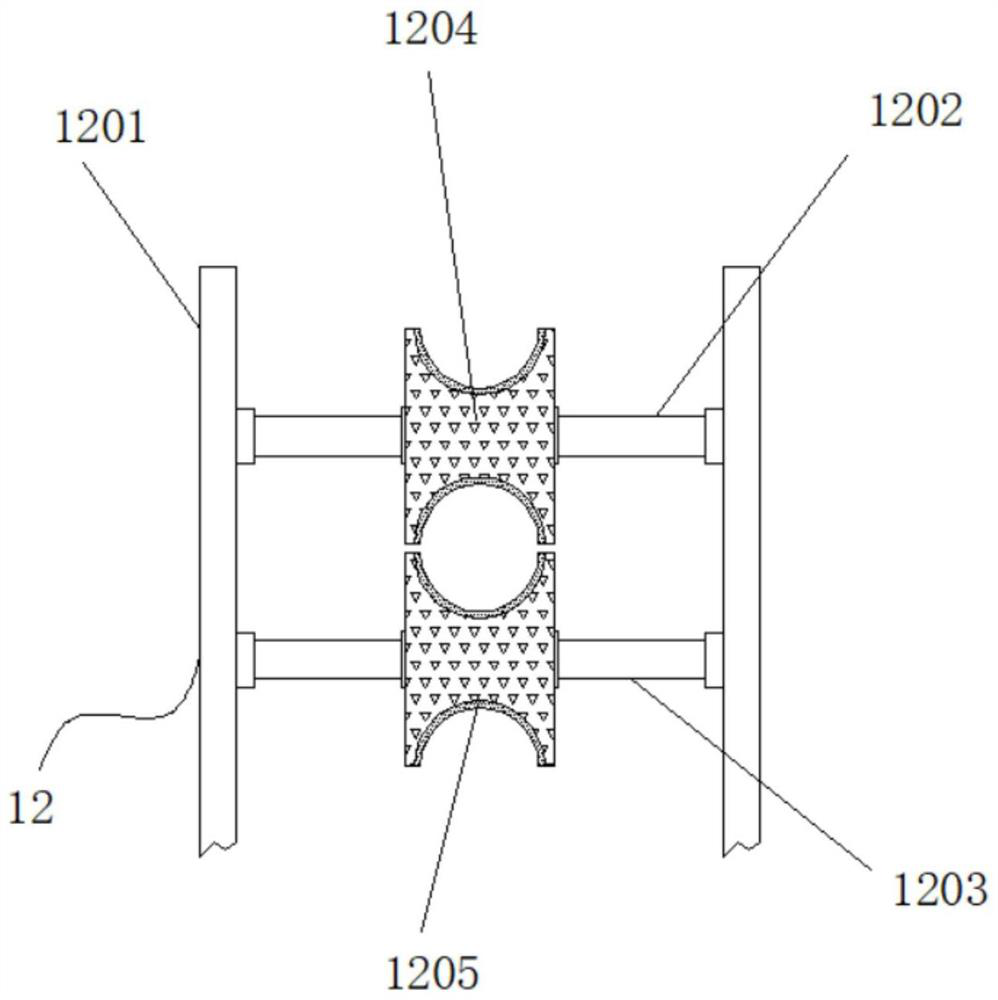

[0042] Embodiment 3: The limit guide structure 12 is composed of a vertical rod 1201, a first movable shaft 1202, a second movable shaft 1203, a limit guide roller 1204 and a protection pad 1205, and the vertical rod 1201 is respectively fixedly connected between the bottom plate 2 and the top plate 11 The first movable shaft 1202 is movably connected between the vertical rods 1201 at the position near the top, the bottom end of the first movable shaft 1202 is provided with a second movable shaft 1203, and the second movable shaft 1203 is connected to the vertical rod 1201 is movably connected, and the outsides of the middle positions of the first movable shaft 1202 and the second movable shaft 1203 are respectively fixedly connected with the limit guide roller 1204, and the inside of the limit guide roller 1204 is provided with a protective pad 1205;

[0043] A semicircular groove is arranged inside the outer end of the limit guide roller 1204;

[0044] Specifically, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com