304 stainless steel strip and production method thereof

A 304 stainless steel, production method technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem that it is difficult to achieve the effect of solid solution of carbides, metallographic structure, corrosion resistance and processability of normal stainless steel materials, affect product surface gloss, roughness, formability and corrosion resistance, etc., to achieve the effect of saving natural gas consumption, reducing carbon emissions, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

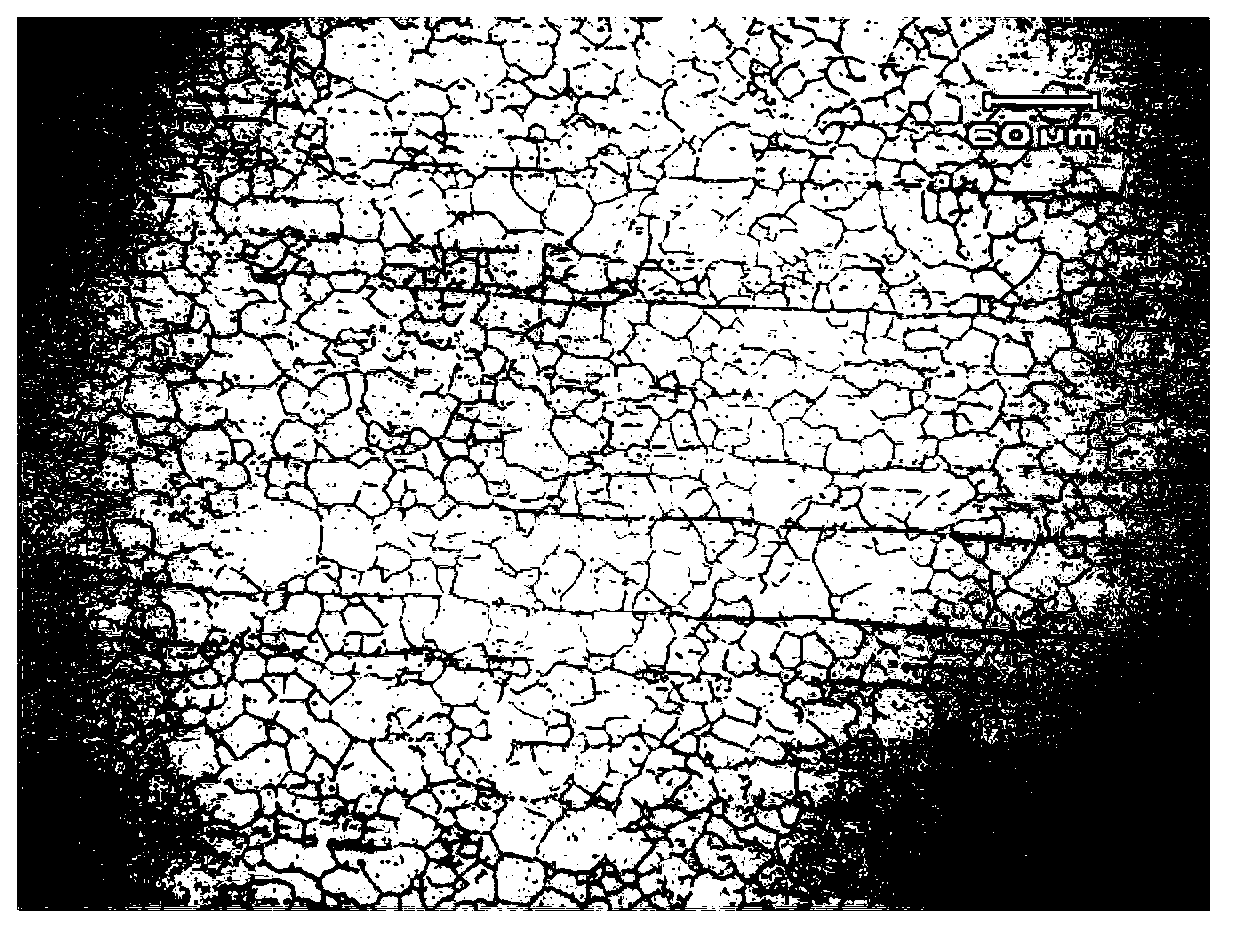

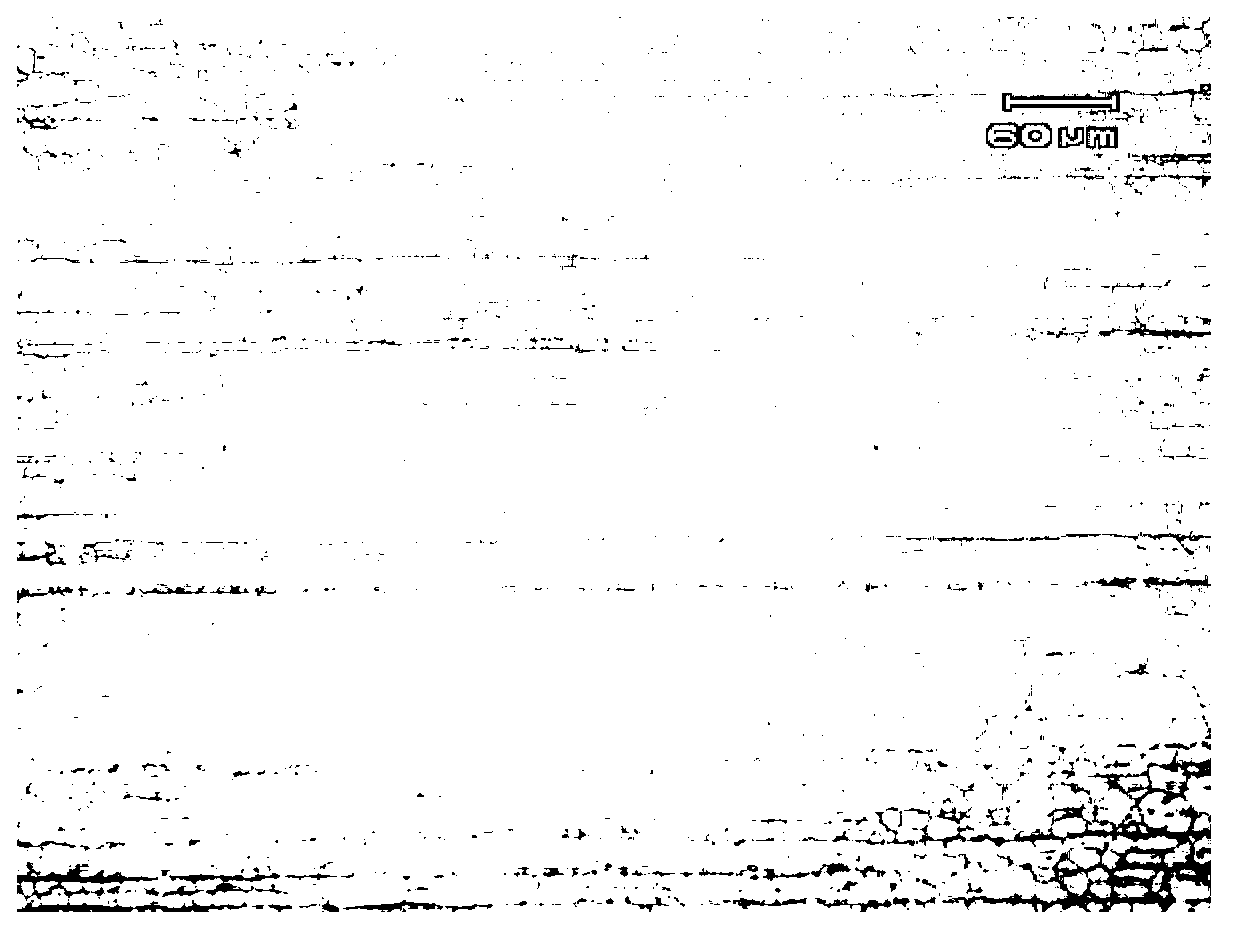

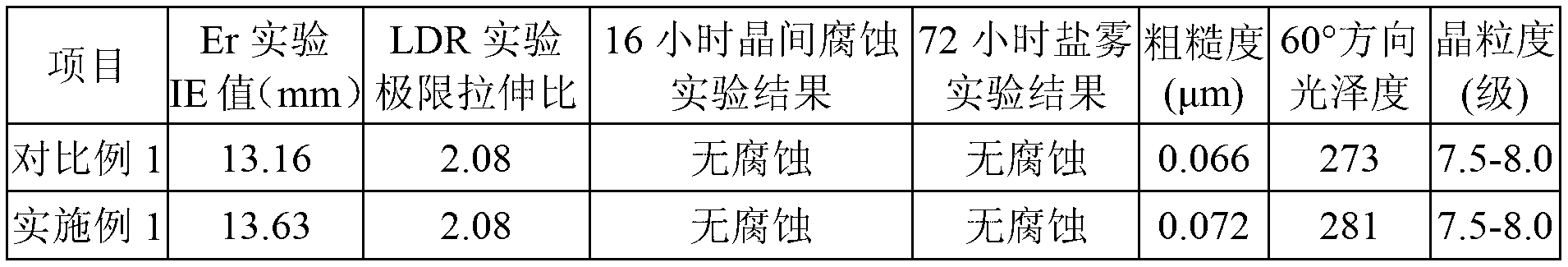

Embodiment 1

[0027] The present embodiment provides a kind of production method of 304 stainless steel strips, and it comprises the following steps:

[0028] The hot-rolled and pickled stainless steel strip (thickness 2.700mm) obtained by pickling without annealing after hot rolling is cold-rolled, and the cold-rolling is carried out by a single-stand 20-roll reversing cold-rolling unit for 7 passes Among them, 1-5 passes use 80-mesh grinding work rolls with a roughness of 0.536 μm; 6-7 passes use 120-mesh grinding rolls with a roughness of 0.275 μm to obtain cold-rolled stainless steel plates Strip, in the cold rolling process, the reduction rate of each pass is 4-16%, the rolling force is 600-850ton, the rolling speed is 150mpm-500mpm, the entrance tension of the first pass is 10ton, and the exit tension is 50ton , the entrance tension and exit tension of the remaining passes are 50ton, and the unit tension of all passes is ≤32kg / mm 2 ;

[0029] The cold-rolled stainless steel strip is...

Embodiment 2

[0034] The present embodiment provides a kind of production method of 304 stainless steel strips, and it comprises the following steps:

[0035]The hot-rolled and pickled stainless steel strip (thickness 4.000mm) obtained by direct pickling without annealing after hot-rolling is cold-rolled, and the cold-rolling is carried out 9 passes by a single-stand twenty-roller reversing cold-rolling unit Among them, 80-mesh grinding work rolls are used for 1-7 passes, and the roughness is 0.564 μm; 120-mesh grinding rolls are used for 8-9 passes, and the roughness is 0.233 μm, and the cold-rolled stainless steel plate is obtained Strip, in the cold rolling process, the reduction rate of each pass is 4-16%, the rolling force is 600-850ton, the rolling speed is 150mpm-500mpm, the entrance tension of the first pass is 10ton, and the exit tension is 50ton , the entrance tension and exit tension of the remaining passes are 50ton, and the unit tension of all passes is ≤32kg / mm 2 ;

[0036] ...

Embodiment 3

[0041] The present embodiment provides a kind of production method of 304 stainless steel strips, and it comprises the following steps:

[0042] The hot-rolled and pickled stainless steel strip (thickness 5.0mm) obtained by direct pickling without annealing after hot rolling is cold-rolled, and the cold-rolling is carried out 7 passes by a single-stand 20-roller reversing cold-rolling unit Among them, 1-5 passes use 80-mesh grinding work rolls with a roughness of 0.552 μm; 6-7 passes use 120-mesh grinding rolls with a roughness of 0.212 μm to obtain cold-rolled stainless steel plates Strip, in the cold rolling process, the reduction rate of each pass is 4-16%, the rolling force is 600-850ton, the rolling speed is 150mpm-500mpm, the entrance tension of the first pass is 10ton, and the exit tension is 50ton , the entrance tension and exit tension of the remaining passes are 50ton, and the unit tension of all passes is ≤32kg / mm 2 ;

[0043] The cold-rolled stainless steel strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com