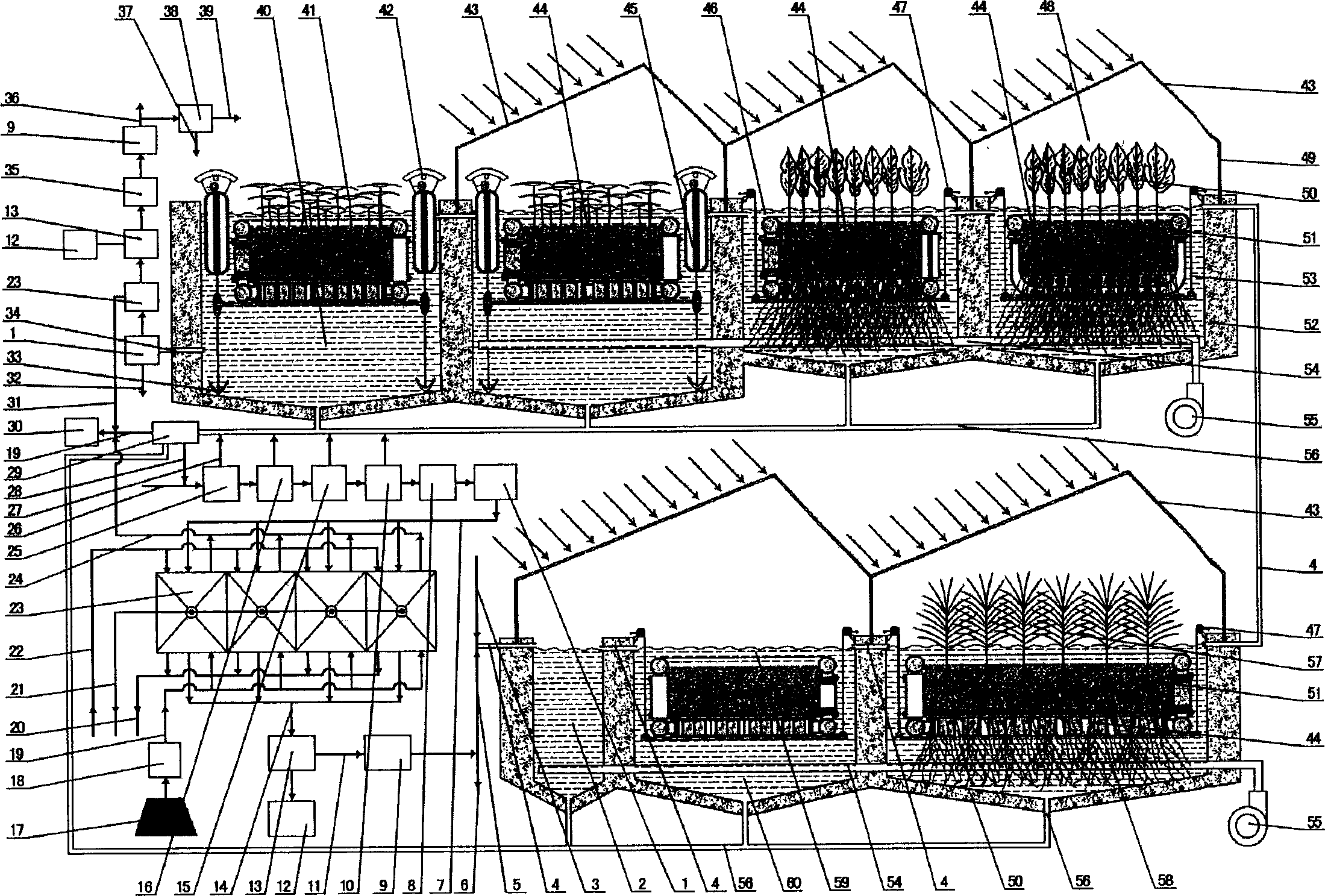

Filter-adsorption-submerged floating wet land sewage treating system and apparatus

A sewage treatment system and adsorption treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve problems such as high operating costs, poor capacity, and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the figure: the sewage enters the coarse grid 25, the fine grid 16, the sedimentation tank 15, the sedimentation tank 10, the pretreatment anaerobic storage tank 8, and the pump room 1 after being merged by the sewage area 26 and the sewage return pipe 28. After treatment, it enters the coal filter material adsorption treatment device 23 through the pretreatment sewage pipeline 7, while the sludge enters the sludge discharge pipe 56 through the sewage discharge device 27, is dried by the sludge dehydration device 29, and is output through the coal conveying device 19. The sewage entering the coal filter material adsorption treatment device 23 is confluent through 14, and is input into the electromagnetic water filter 13, and the water effluent 11 through the magnetic filtration enters the ultraviolet disinfection device 9, and the ferrous oxides are collected by the magnetic sludge collector 12, and the coal is transported The outlet water of the device 19 has two pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com