Forming method of semiconductor device and grid electrode

A semiconductor and device technology, applied in the field of semiconductor preparation, can solve the problems affecting the etching process of the polysilicon layer 11 of the hard mask layer, the flatness of the sidewall of the photoresist pattern, and affecting the structure of the polysilicon gate, etc., to ensure accurate degree, reduce surface roughness, optimize the effect of photoresist pattern structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

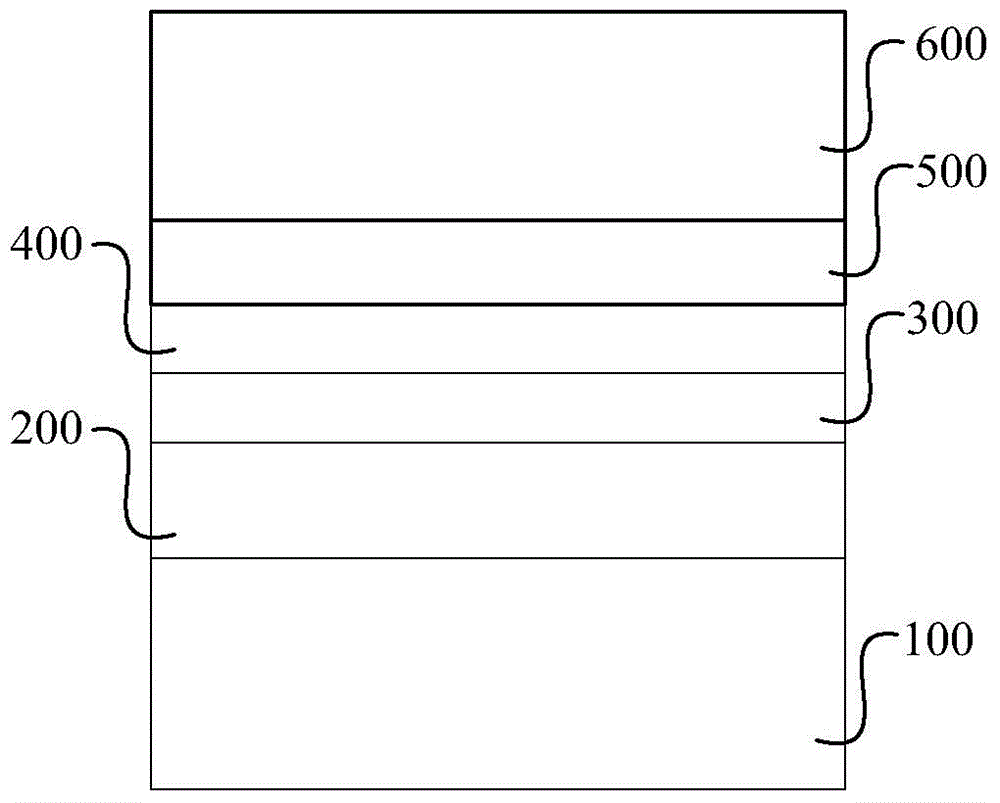

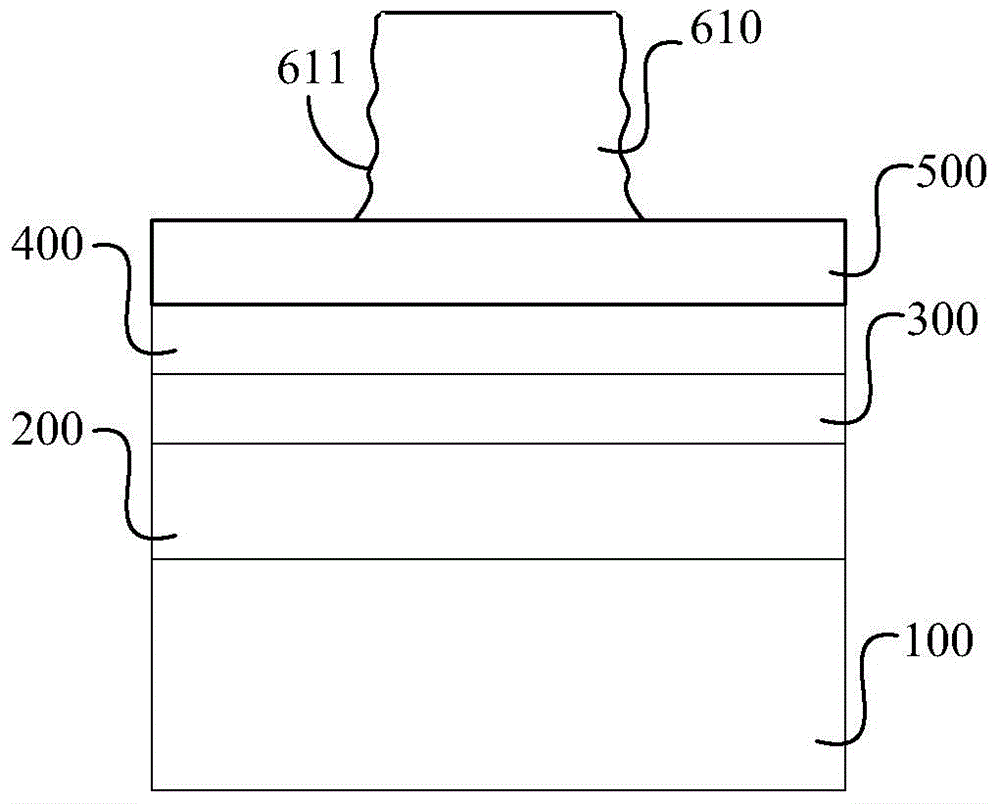

Embodiment Construction

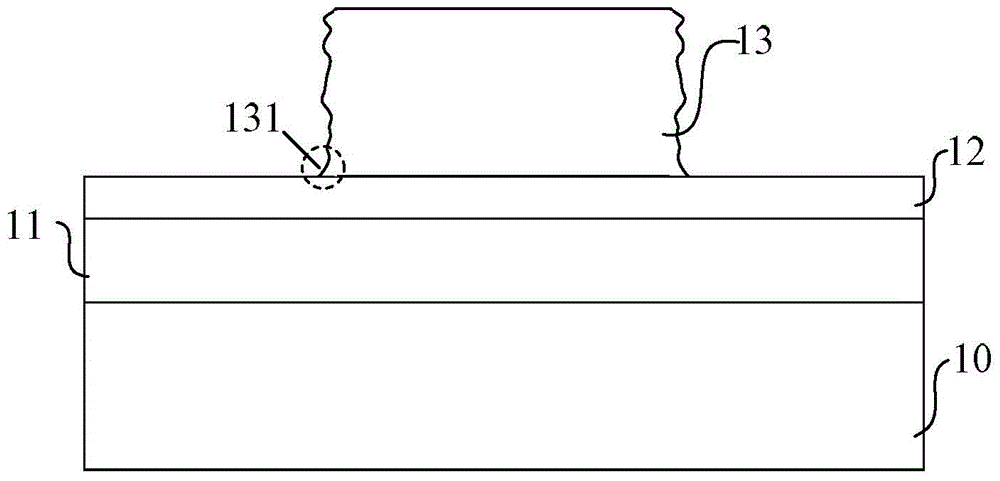

[0040] As mentioned in the background art, with the increase of the integration level of integrated circuits, the device size of integrated circuits decreases continuously, and the quality requirements for devices become more and more stringent. However, in the existing photolithography technology, the flatness of the sidewall of the photoresist pattern formed after the photoresist exposure and development process is poor, which in turn will affect the subsequent use of the photoresist pattern as a mask such as a hard mask. The etching precision of the layer affects the quality of the integrated circuit device formed by subsequent etching processes.

[0041] For this reason, after the photoresist pattern is formed, the industry will use HBr and other gases to cure the soft photoresist pattern (HBr cure), and form a polymer modification layer on the surface of the photoresist pattern to improve The flatness of the photoresist pattern surface such as sidewalls.

[0042] However...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com