Aftertreatment process of waterborne flyleather base cloth

A cow leather and base fabric technology, applied in textiles and papermaking, etc., can solve the problems that affect the appearance quality of the adhesive coating layer on the base fabric surface, affect the performance and quality of simulated cow leather products, and the surface flatness of the base fabric is not high, etc. To achieve the effect of improving the appearance quality, improving the hand feeling and the soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

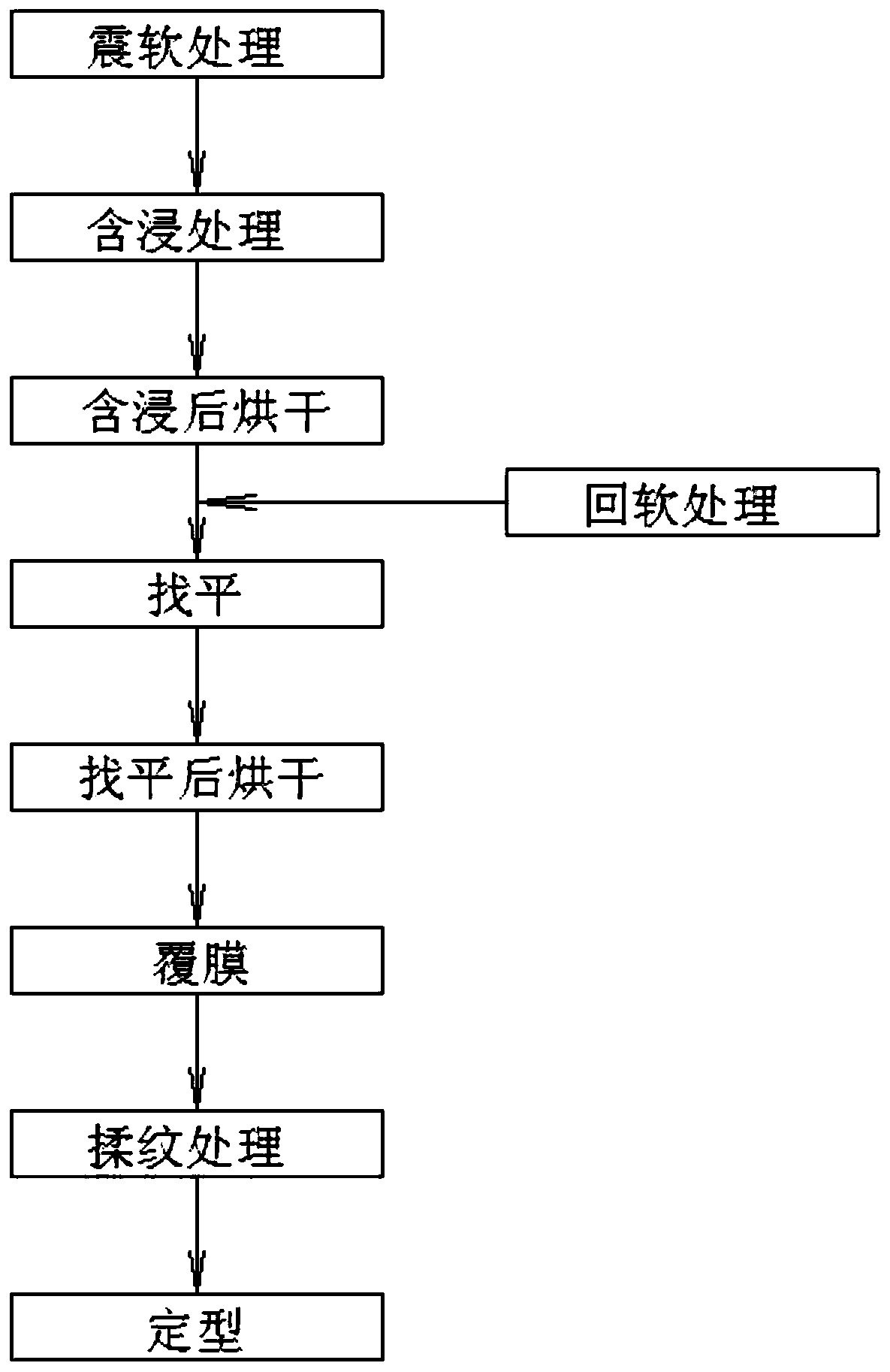

[0053] Such as Figures 1 to 2 Shown is the embodiment of the aftertreatment process of a kind of water-based kraft leather base cloth of the present invention, comprises following processing steps:

[0054] Step 10, softening treatment: using the bovine fiber leather base cloth as a raw material, adopting a through-type shock softening production line, performing a shock softening treatment on the bovine fiber leather base cloth, so that the bovine fiber leather base cloth is softened;

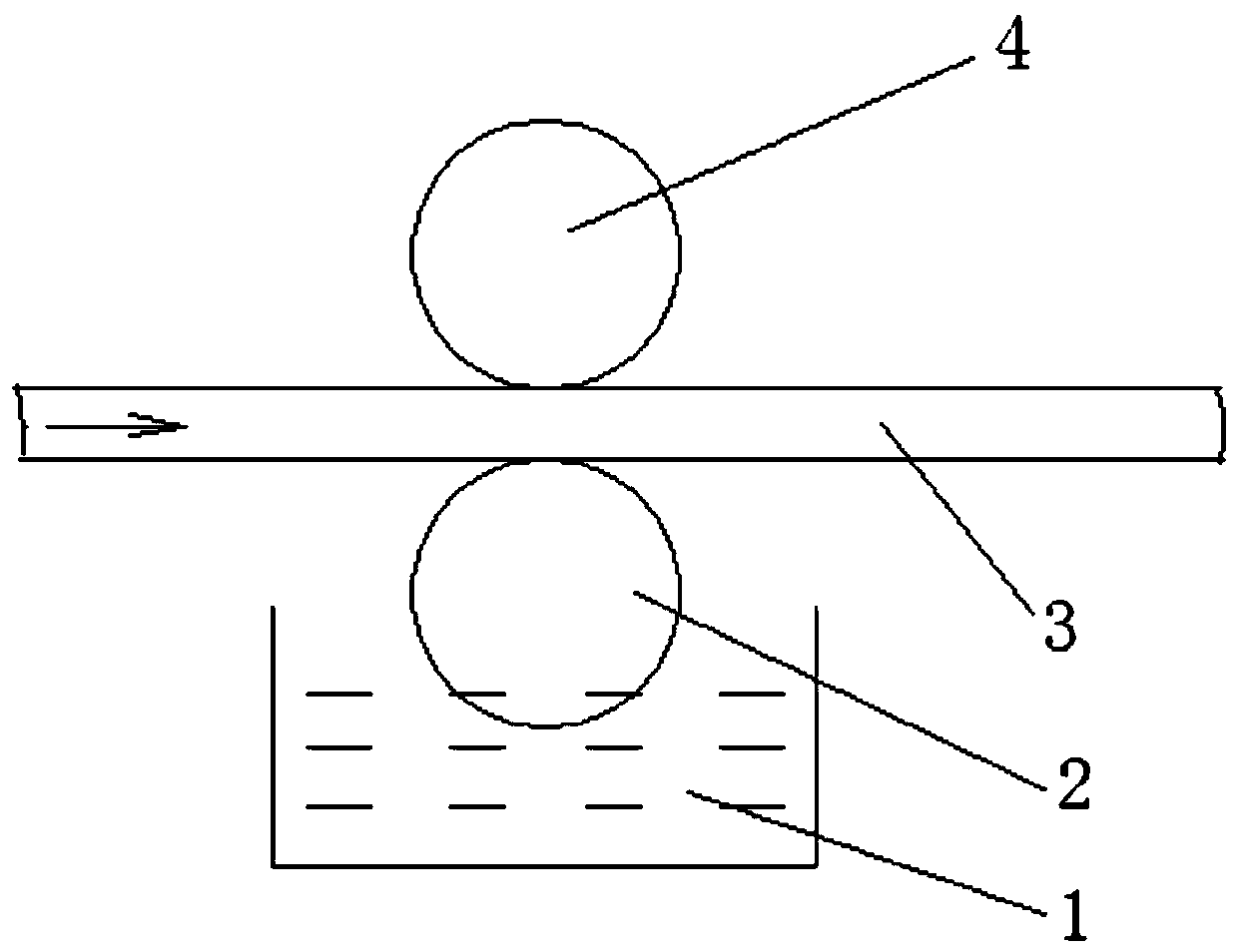

[0055] Step 20. Impregnation treatment: use water-based PU material and roller coating equipment to infiltrate the front of the cow fiber leather base cloth after shock t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com