Patents

Literature

64results about How to "Avoid side force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

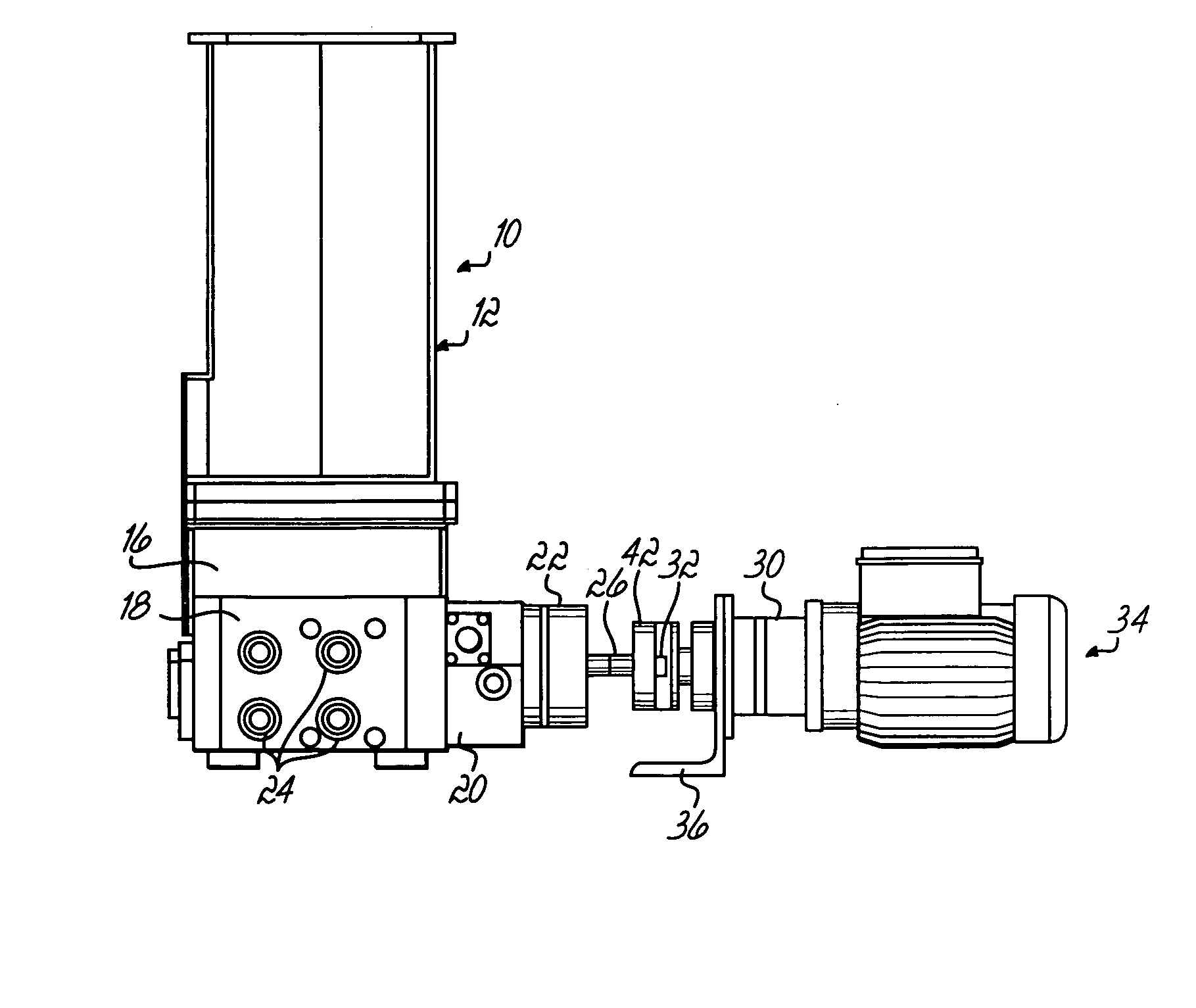

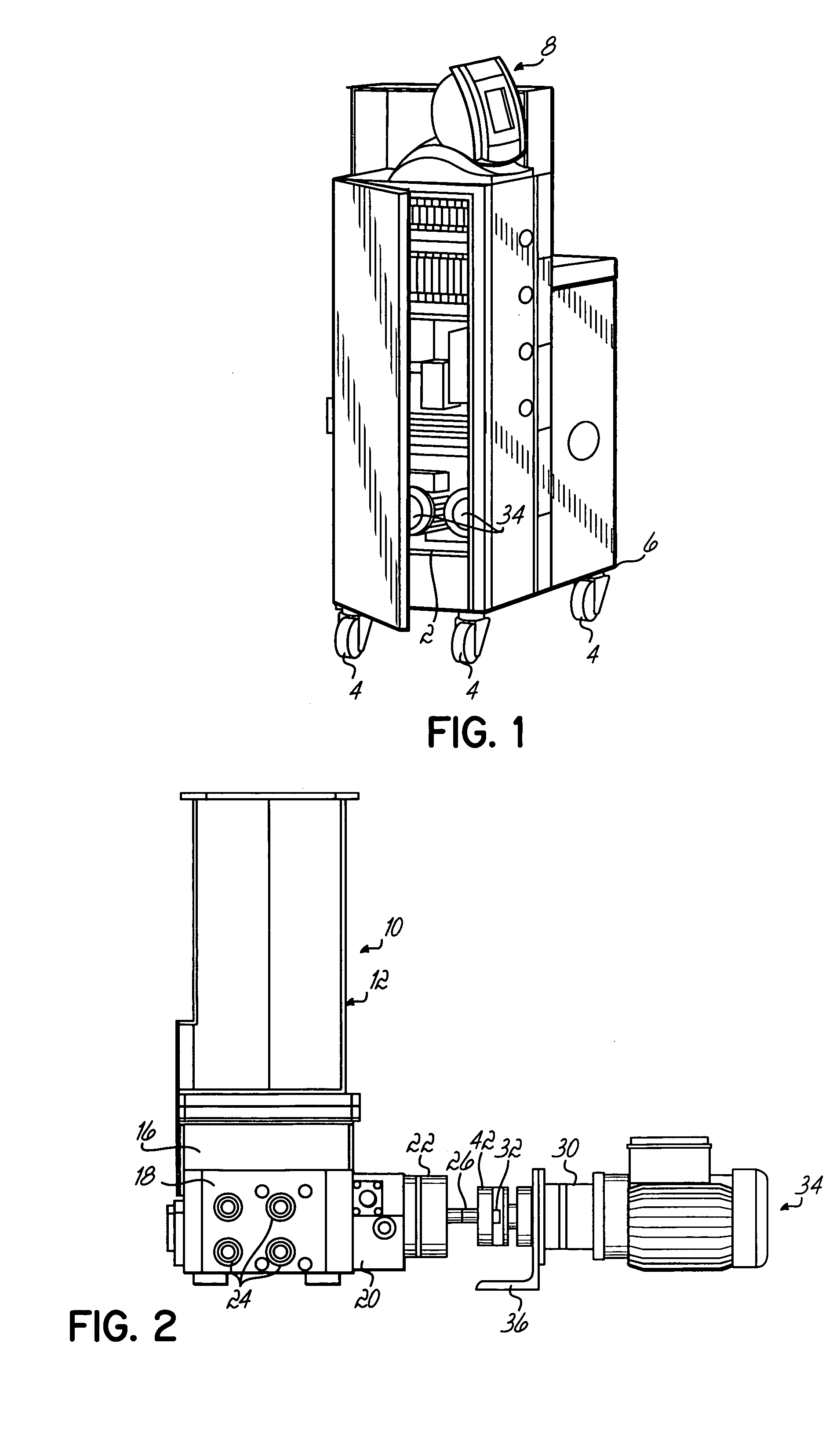

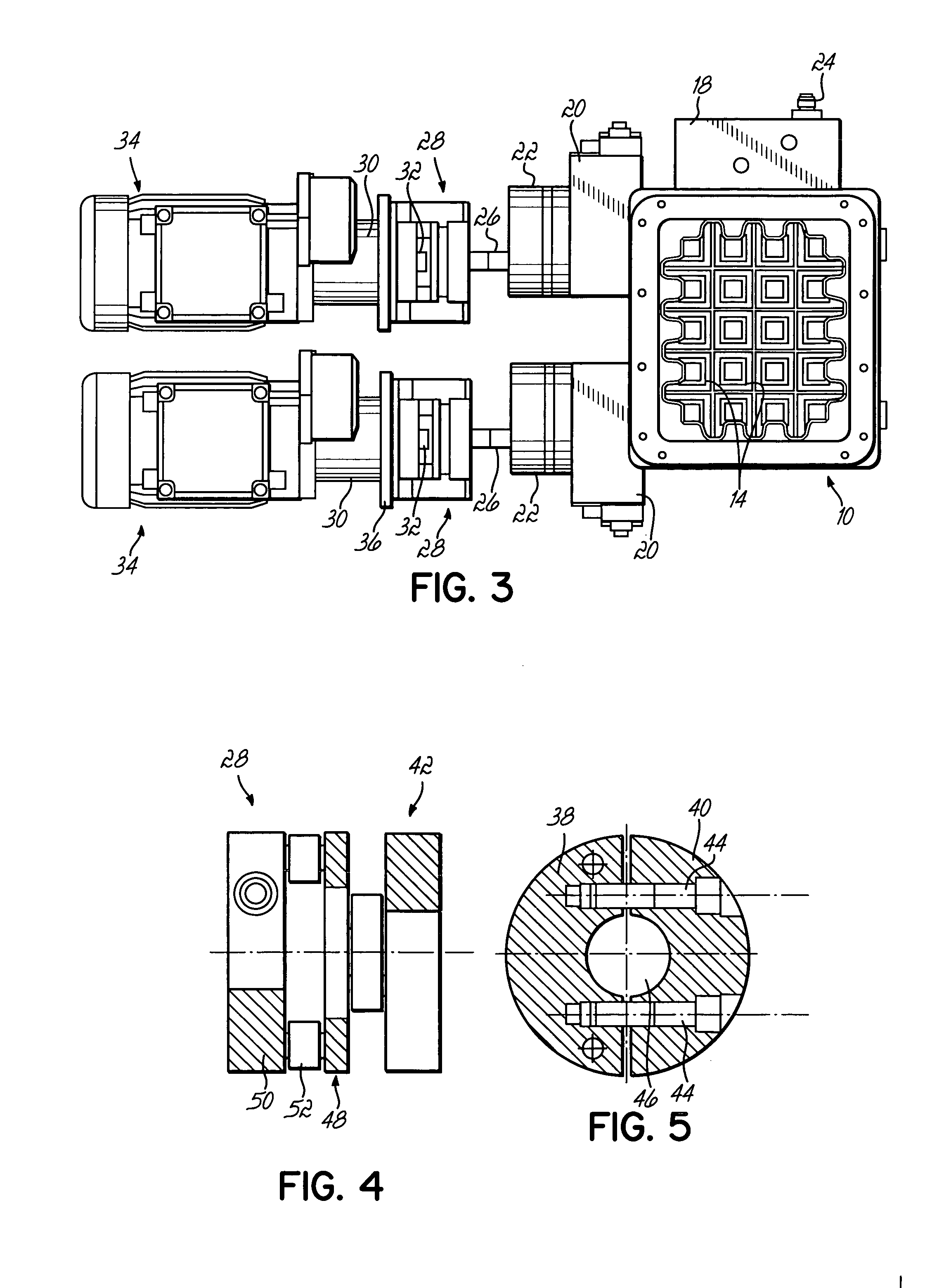

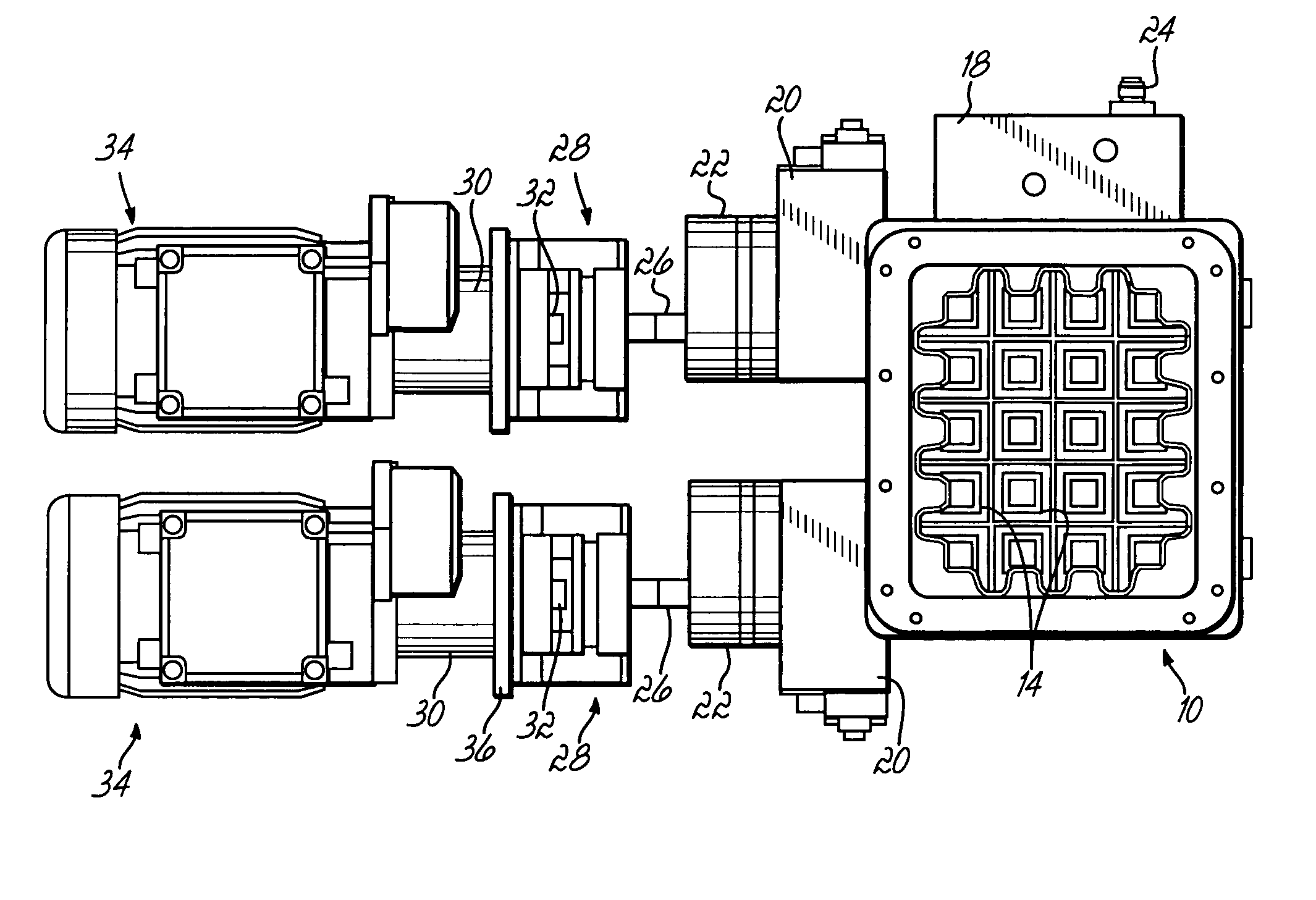

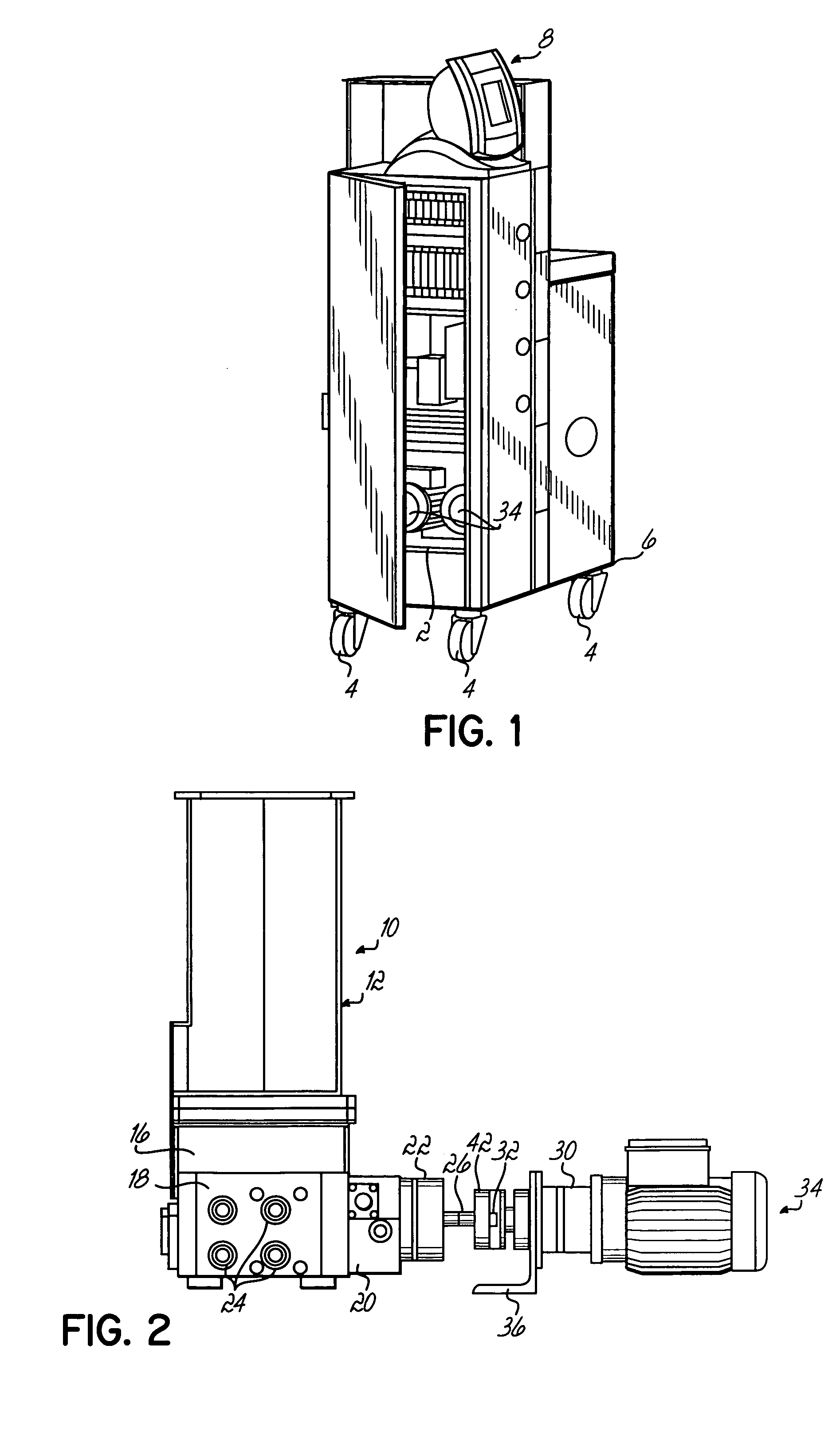

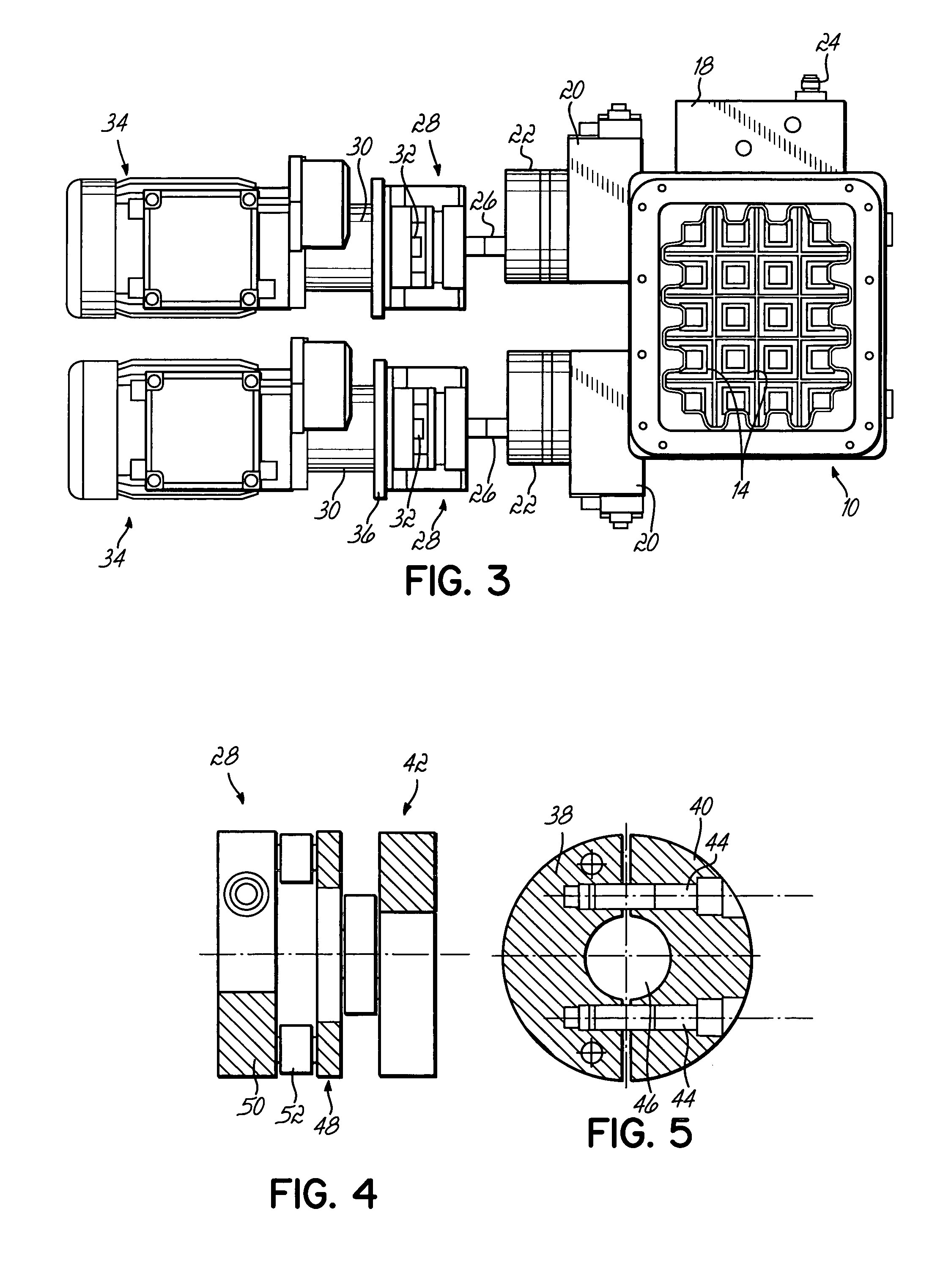

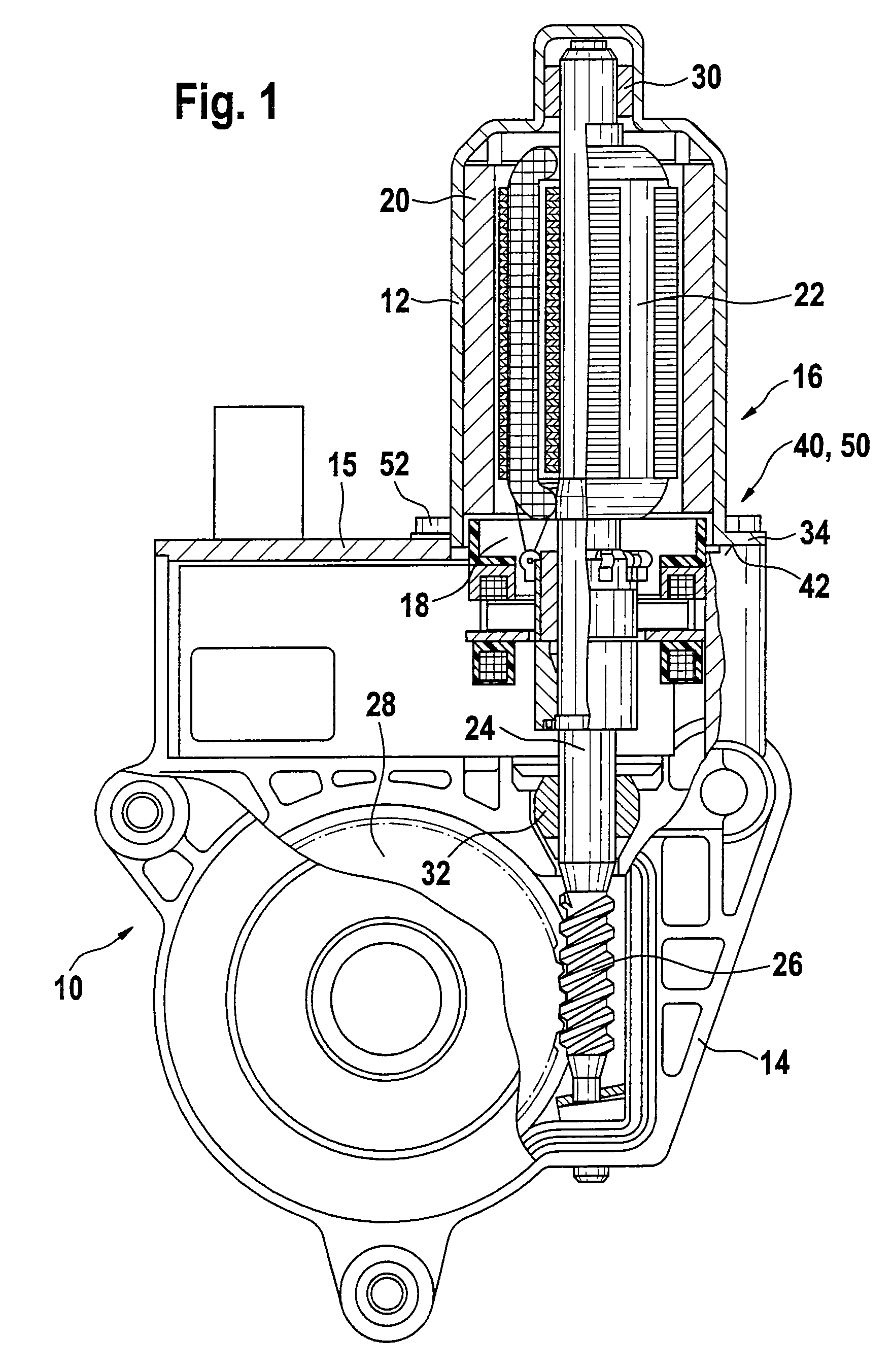

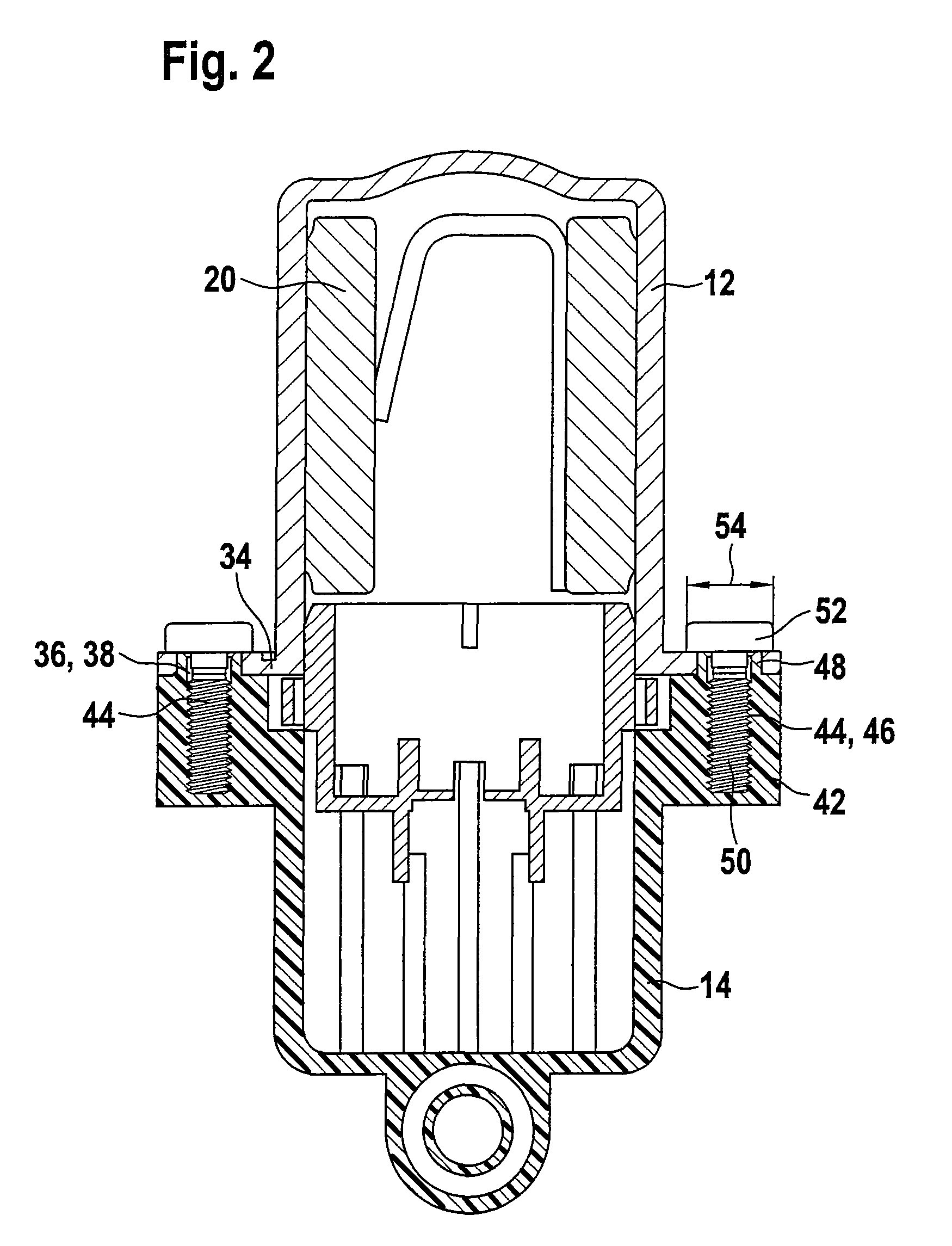

Apparatus for dispensing free-flowing material

InactiveUS20050098579A1Simplify assemblyReduce wearLiquid surface applicatorsYielding couplingDrive motorFree flow

Apparatus for dispensing a free-flowing material comprising a container for receiving the material, a pump connected to the container for conveying the material to a port from which free-flowing material can be dispensed. The pump includes at least one rotatable pump element and a rotatable drive shaft coupled to the pump element, a drive motor, and a coupling attached between the drive shaft and the drive motor. The coupling is radially detachable from the drive shaft.

Owner:NORDSON CORP

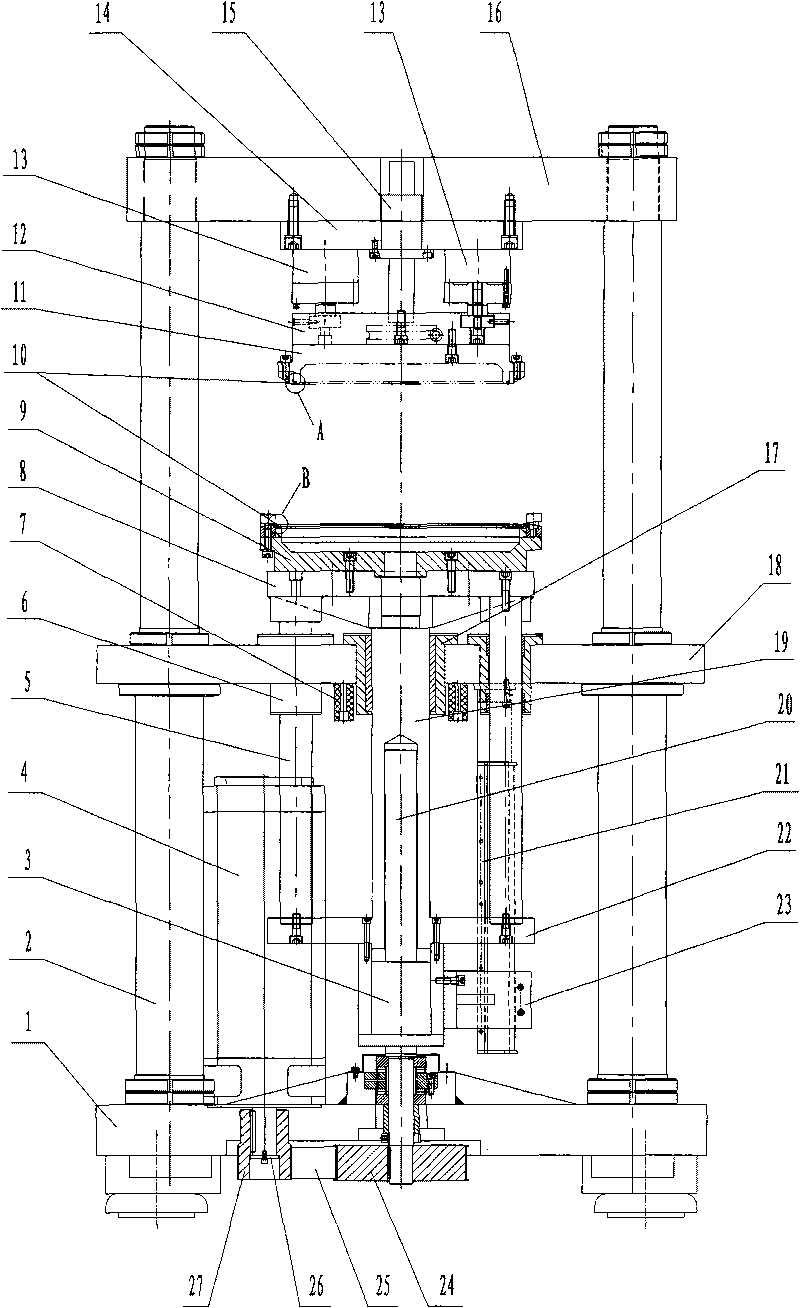

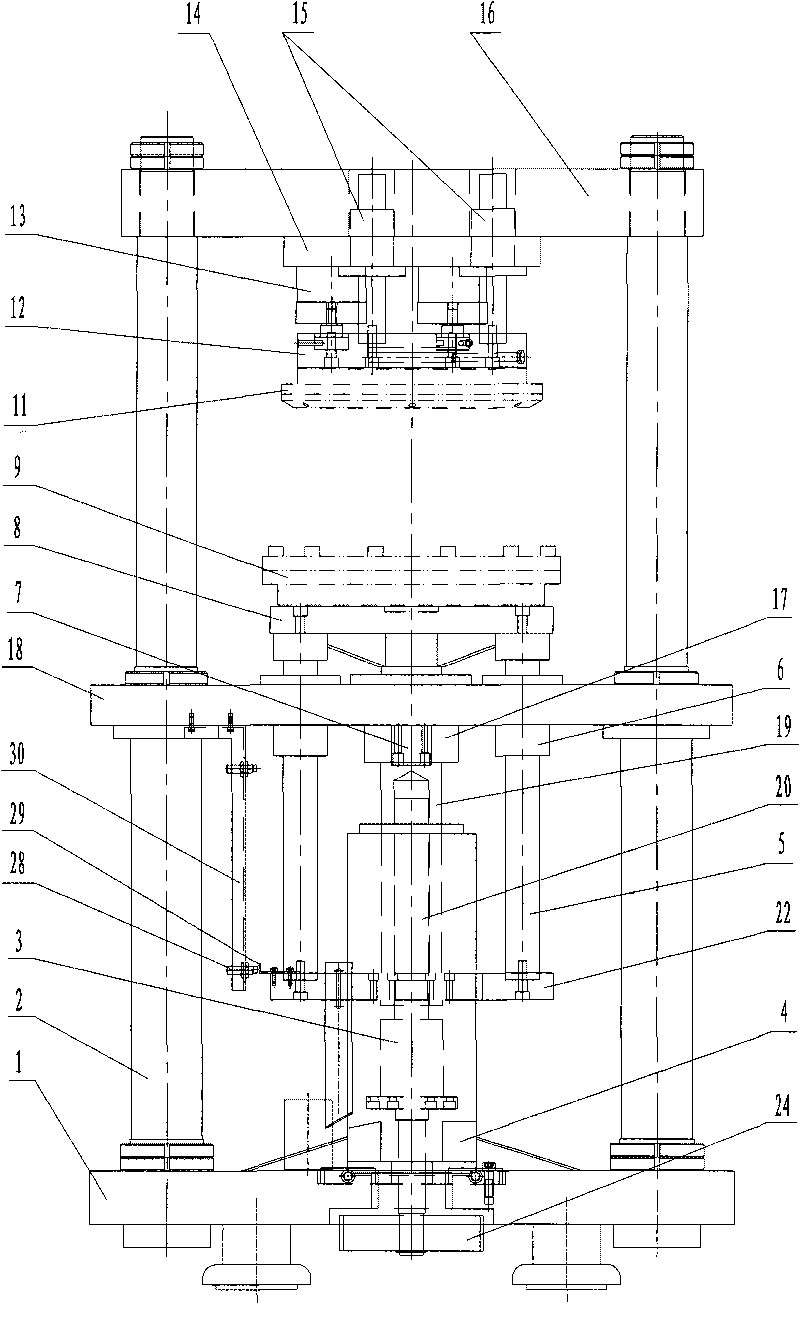

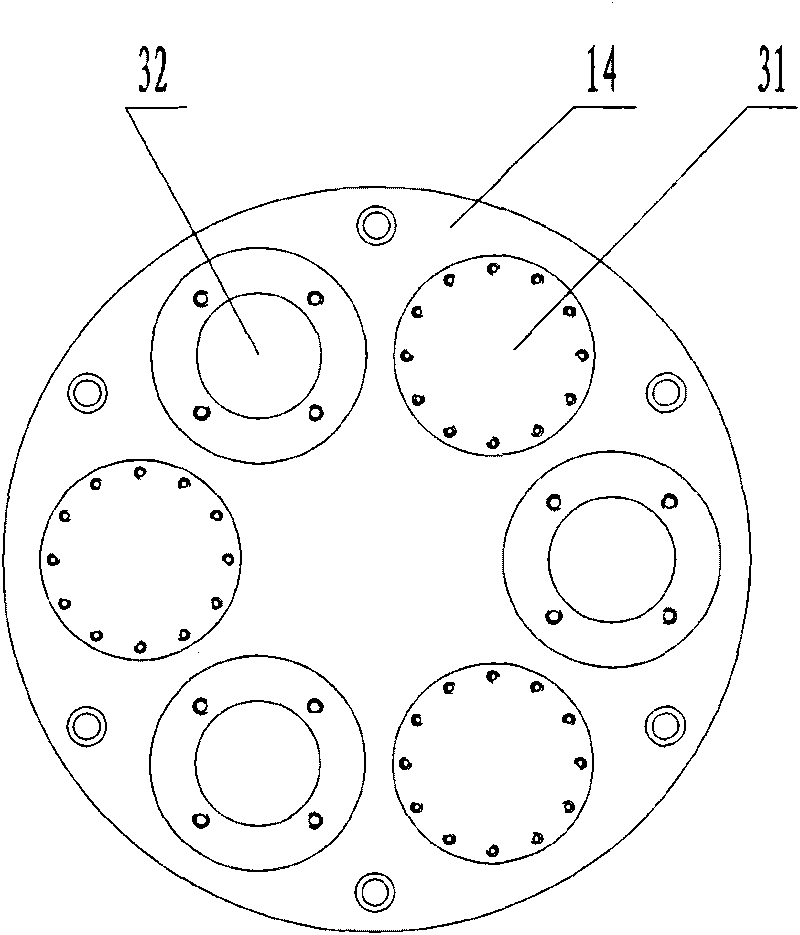

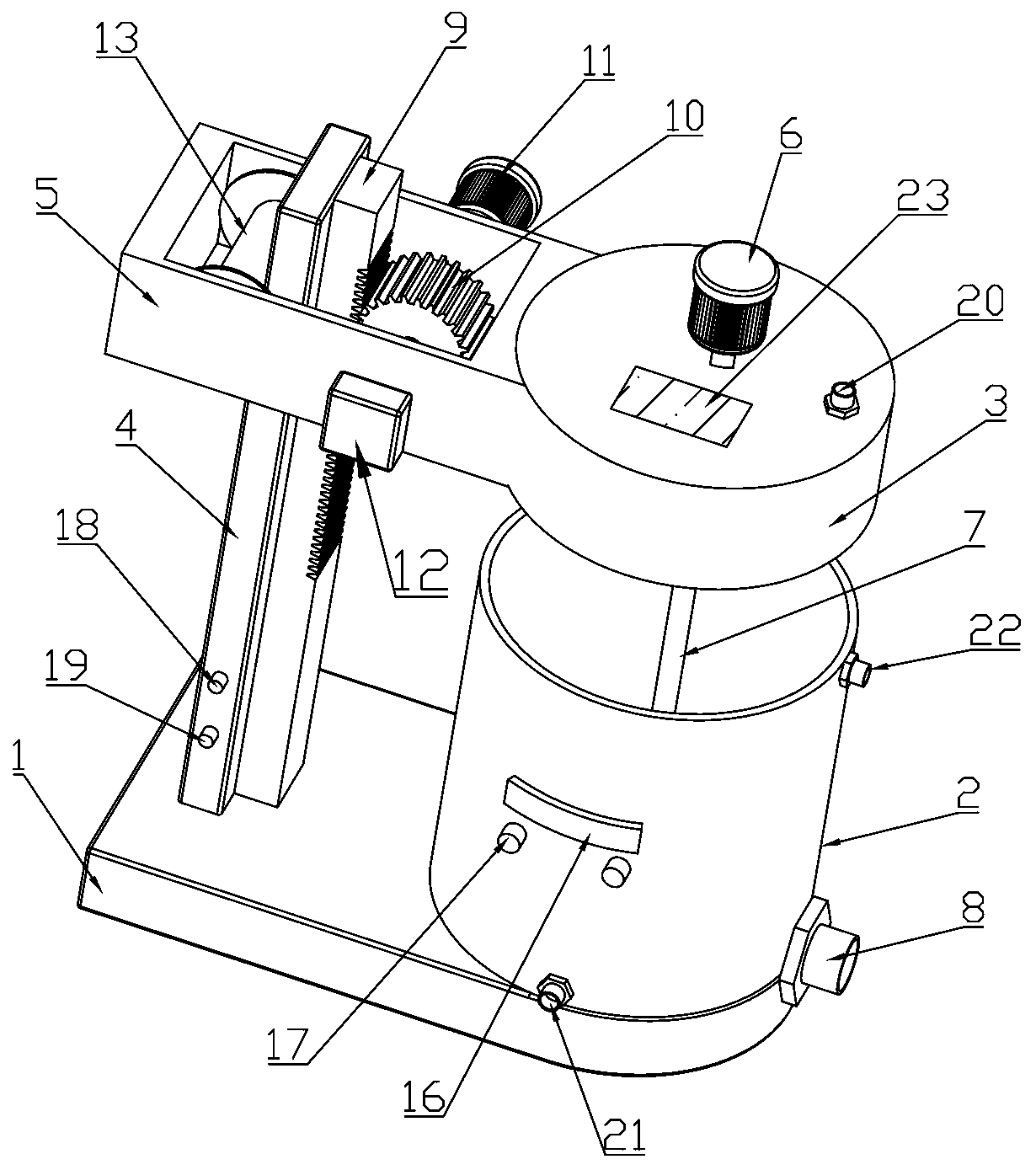

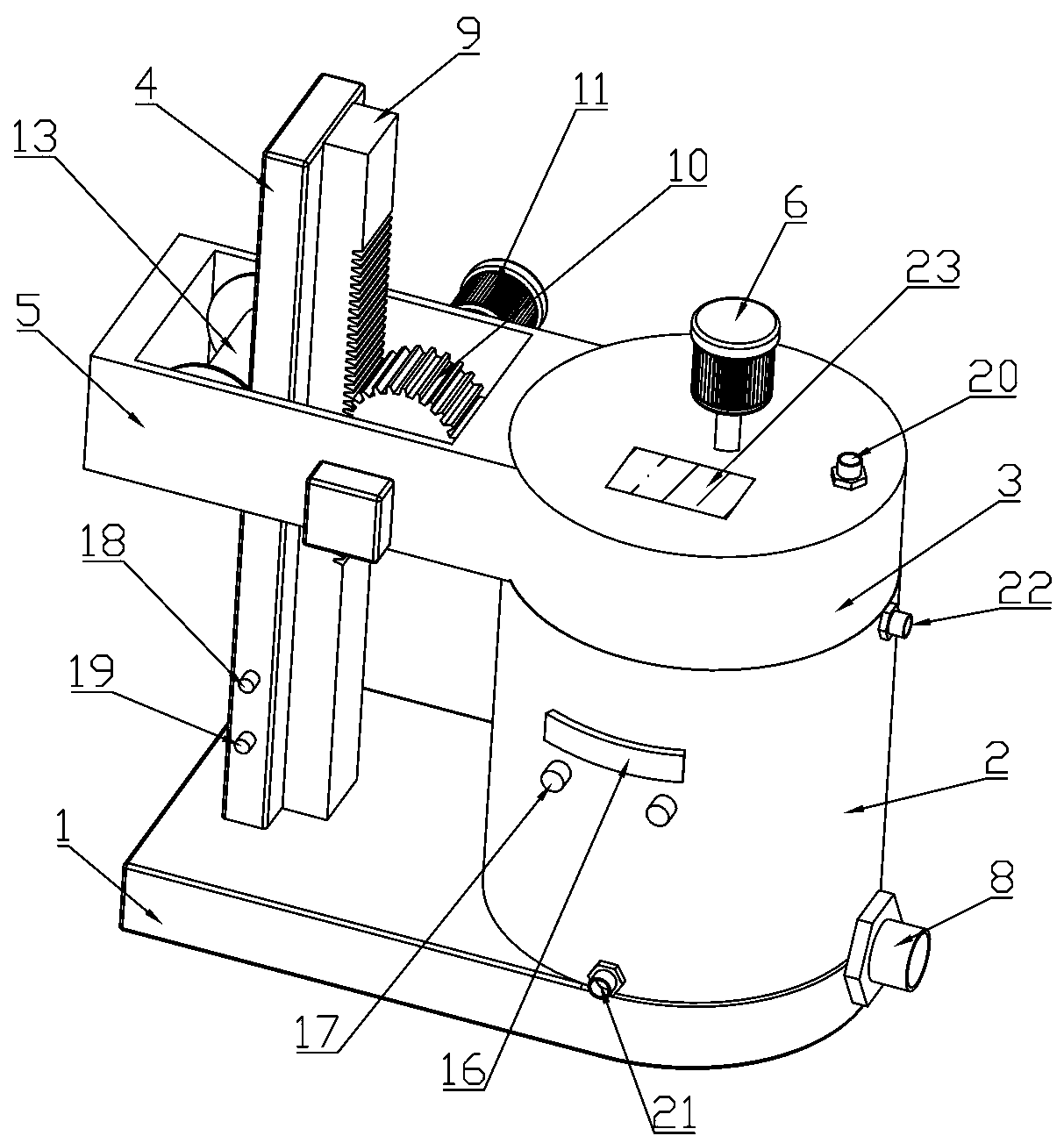

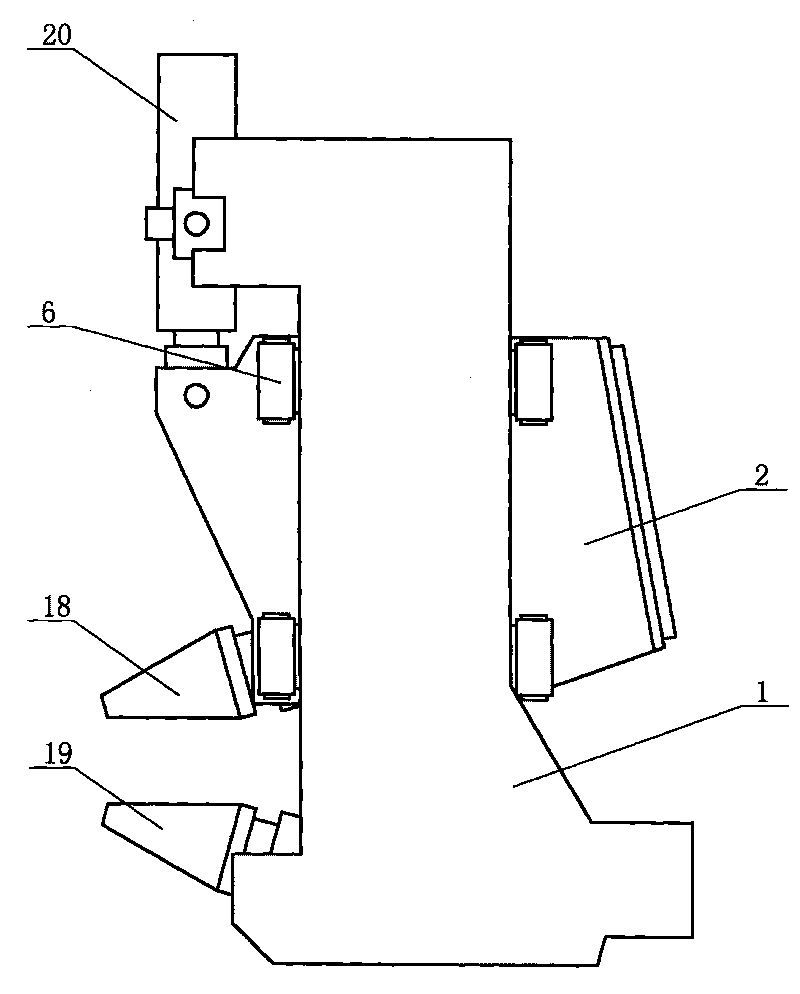

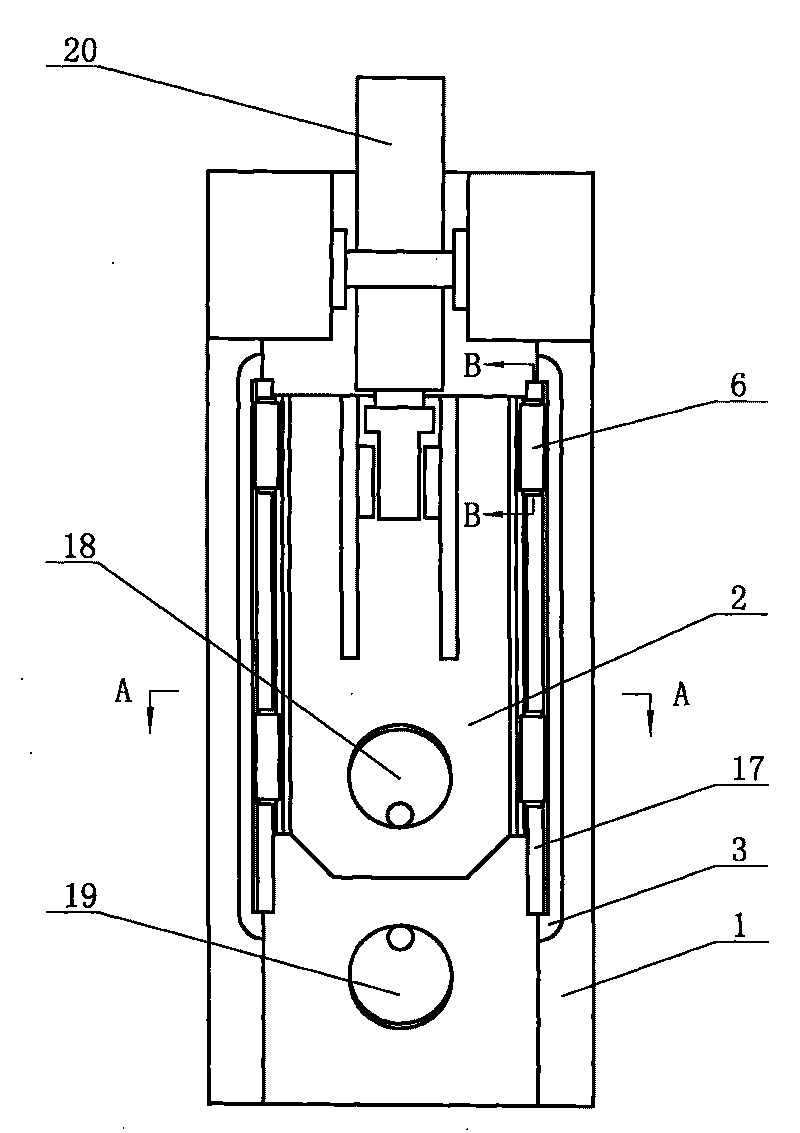

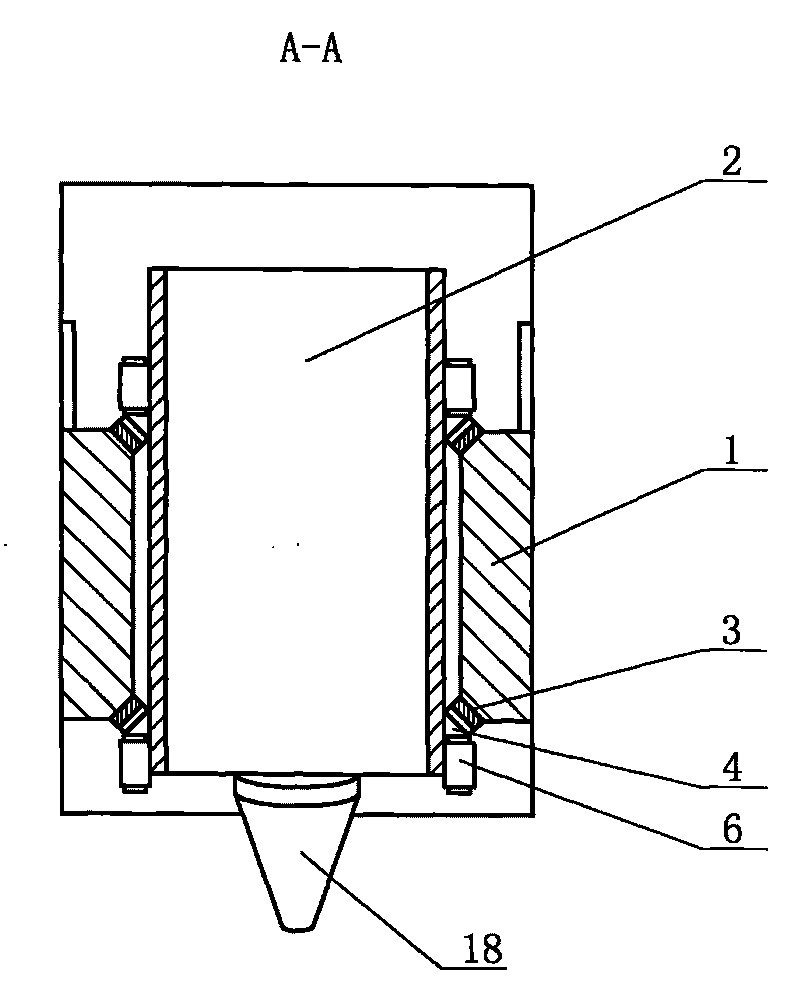

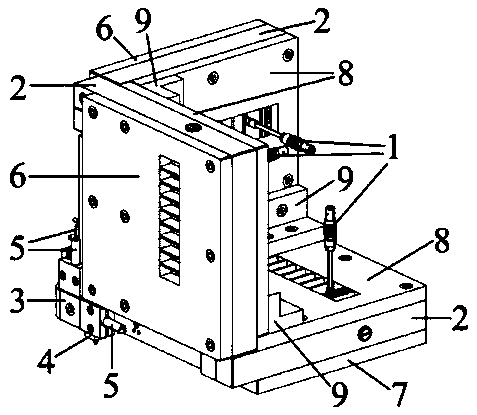

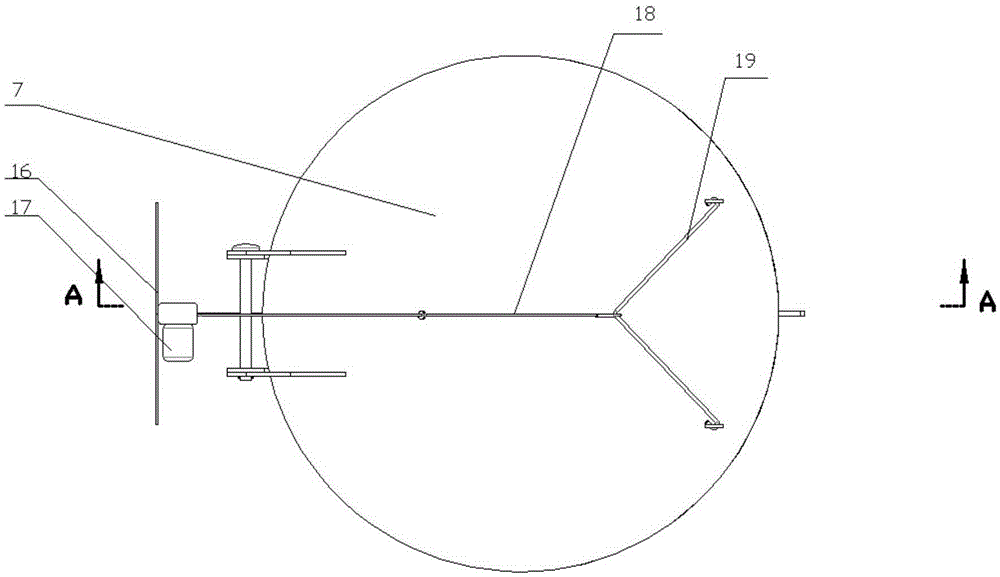

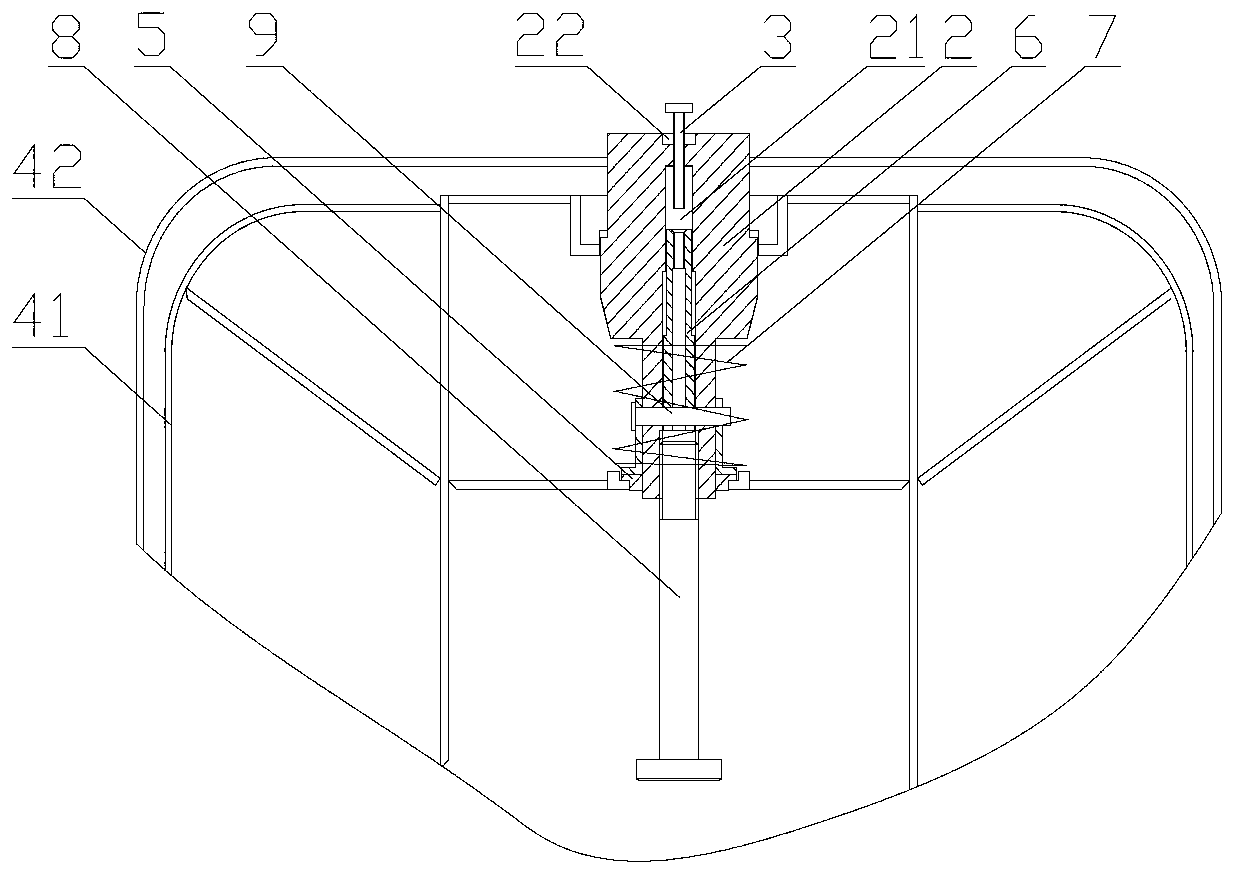

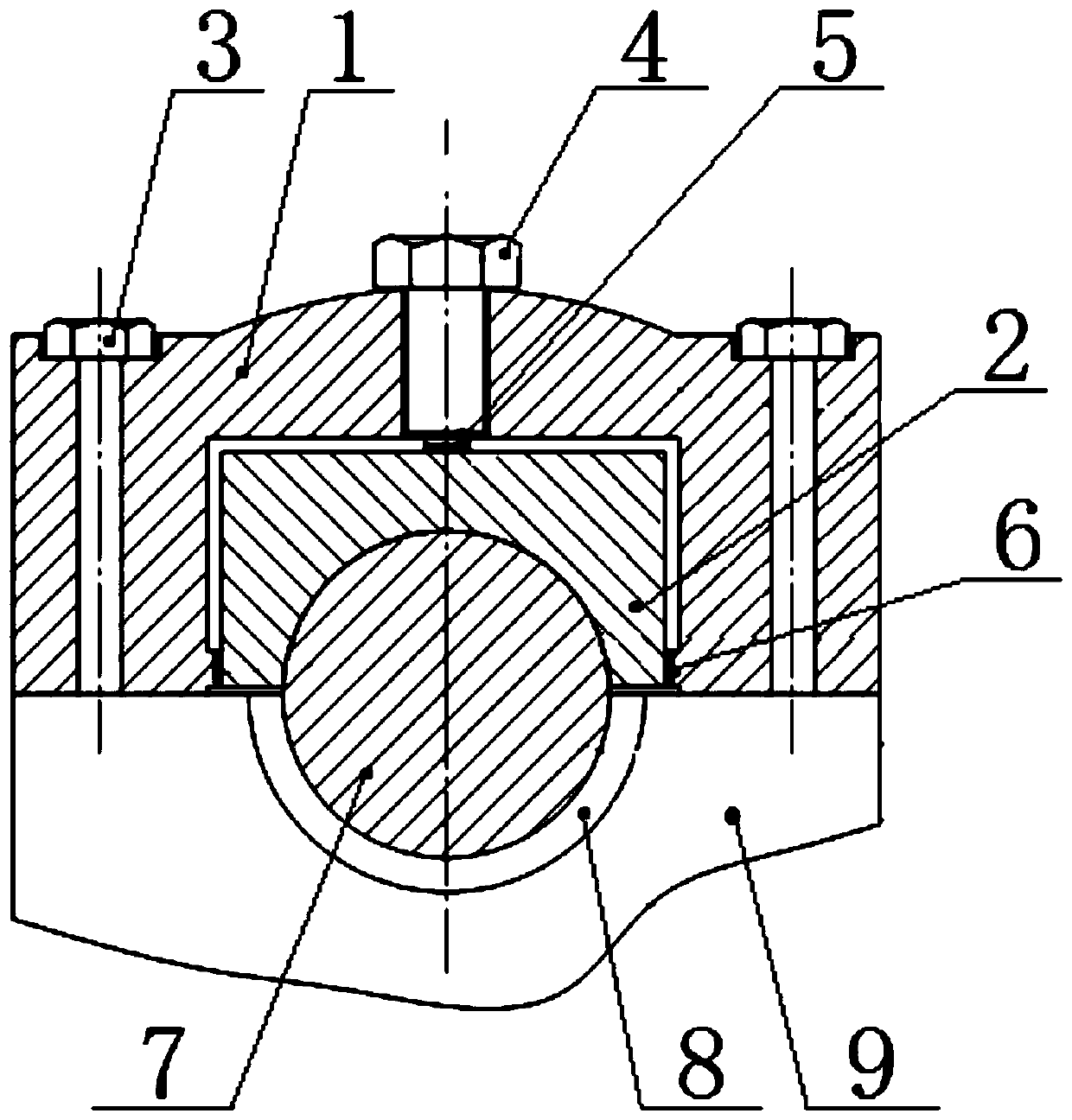

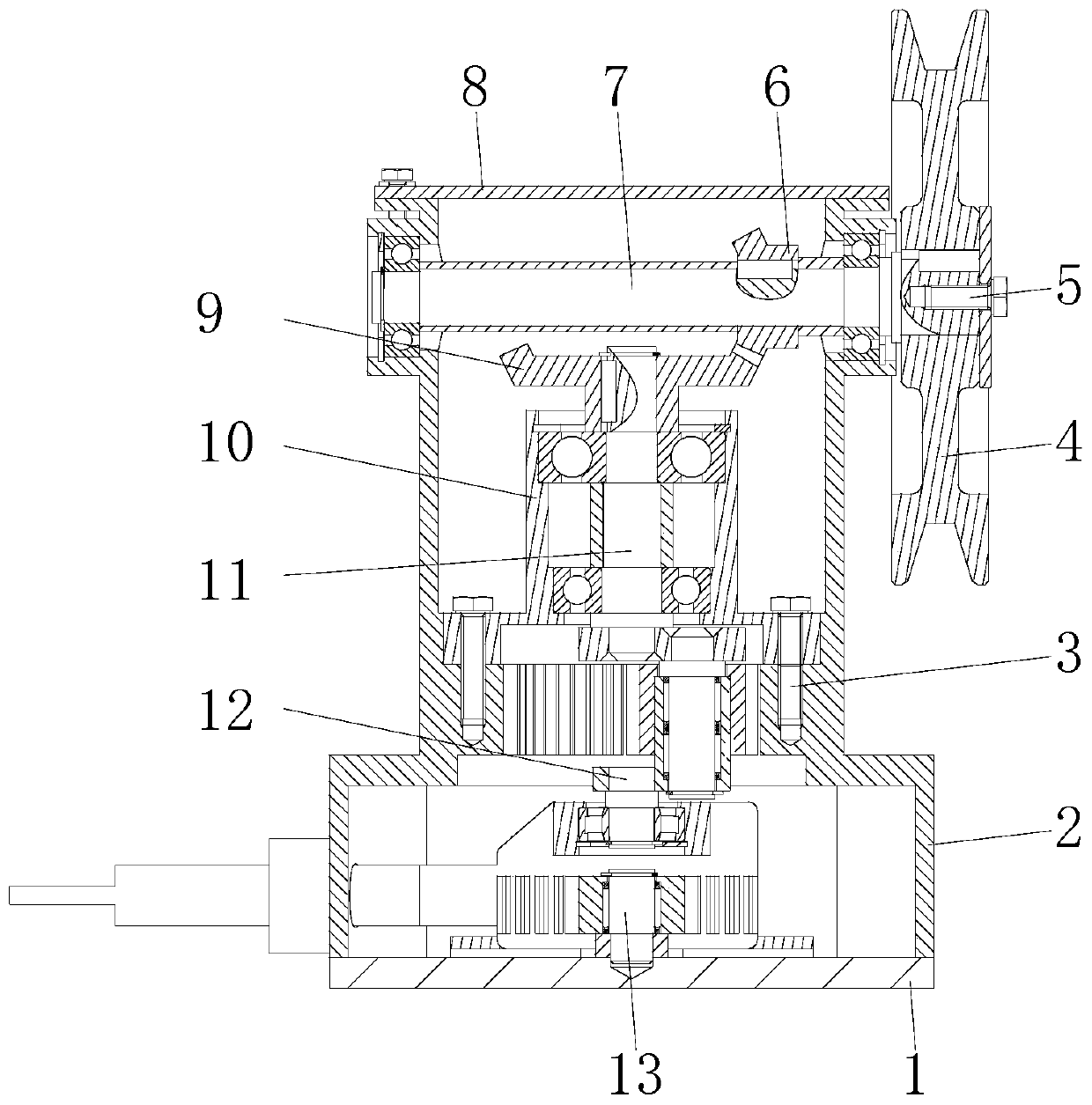

Diaphragm spring tester

InactiveCN101750208AImprove efficiencyHigh precisionMachine part testingApparatus for force/torque/work measurementBall screwEngineering

The invention relates to a test mechanism of an automobile clutch diaphragm spring, in particular to a diaphragm spring tester which can effectively measure stress and deformation and detects the load characteristics thereof. The diaphragm spring tester comprises a tester body bottom plate, a nut, a workbench, a low die, a top die, a tester body top plate, a middle lathe bed plate and a ball screw, wherein the tester body bottom plate, the middle lathe bed plate and the tester body top plate are connected by a stand column; the ball screw is installed on the tester body bottom plate and penetrates from the tester body bottom plate to be connected with an actuating device; the nut in threaded connection with the ball screw is provided with a sleeve; the revolute pair of the ball screw is in threaded connection with the nut by the ball screw to form the upper sliding pair and the lower sliding pair of the sleeve; the other end of the sleeve passes through the middle lathe bed plate to be connected with the workbench; the workbench is provided with the lower die; the top die is installed on the tester body top plate and is above the lower die; and the tester body top plate is provided with a pressure sensor contacting with the top die. The invention has the advantages of high efficiency, high precision, high rigidity, reversibility and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

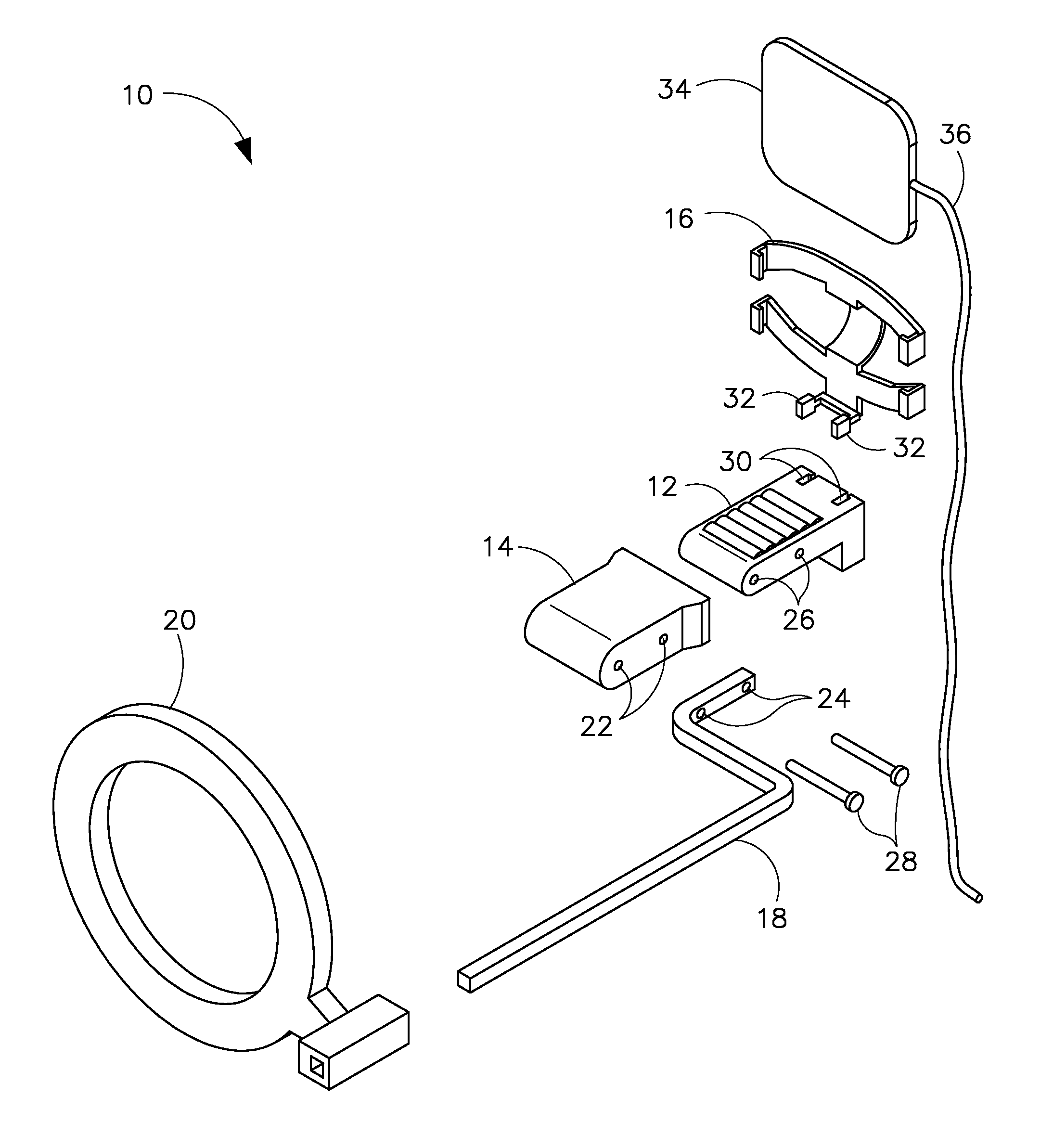

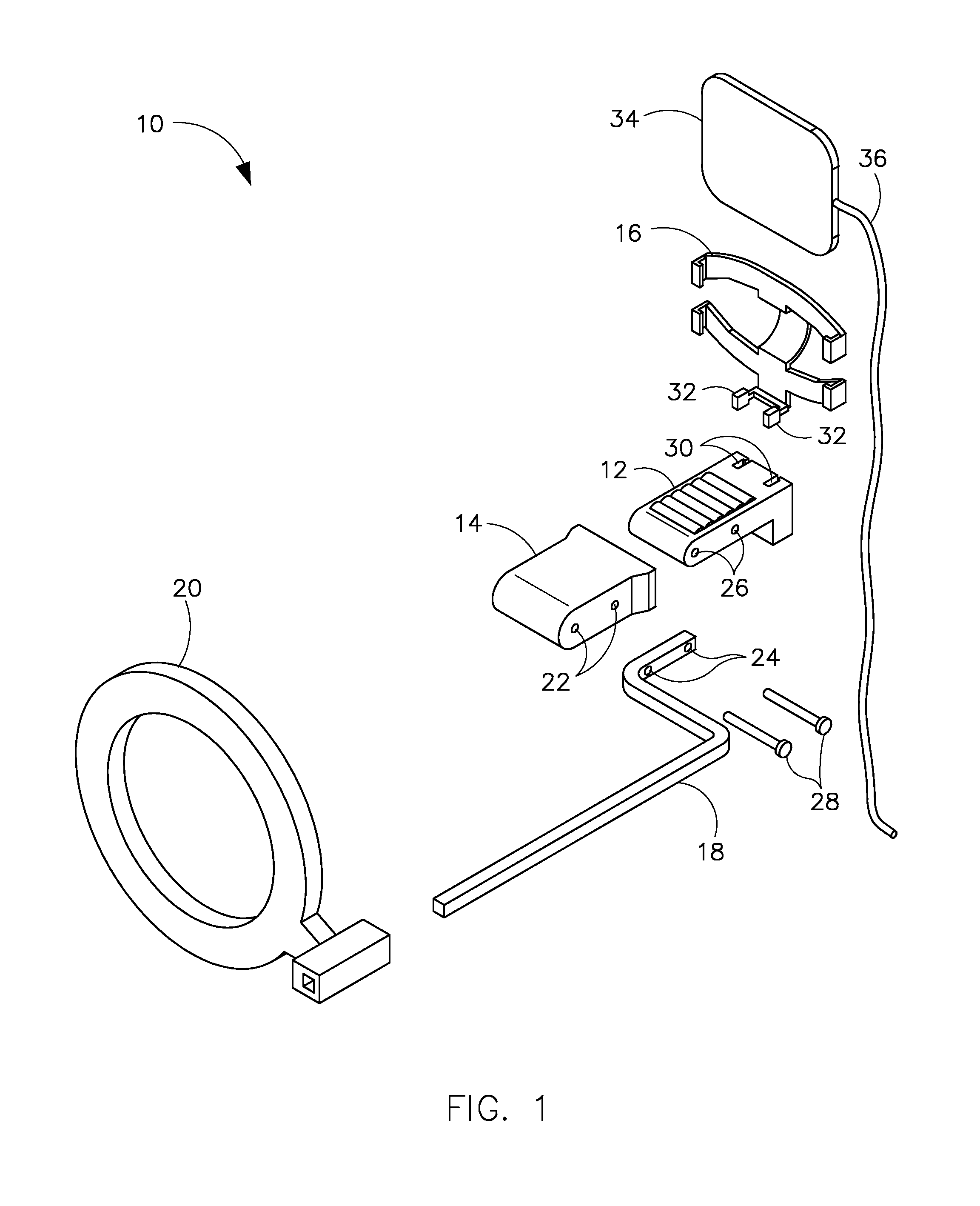

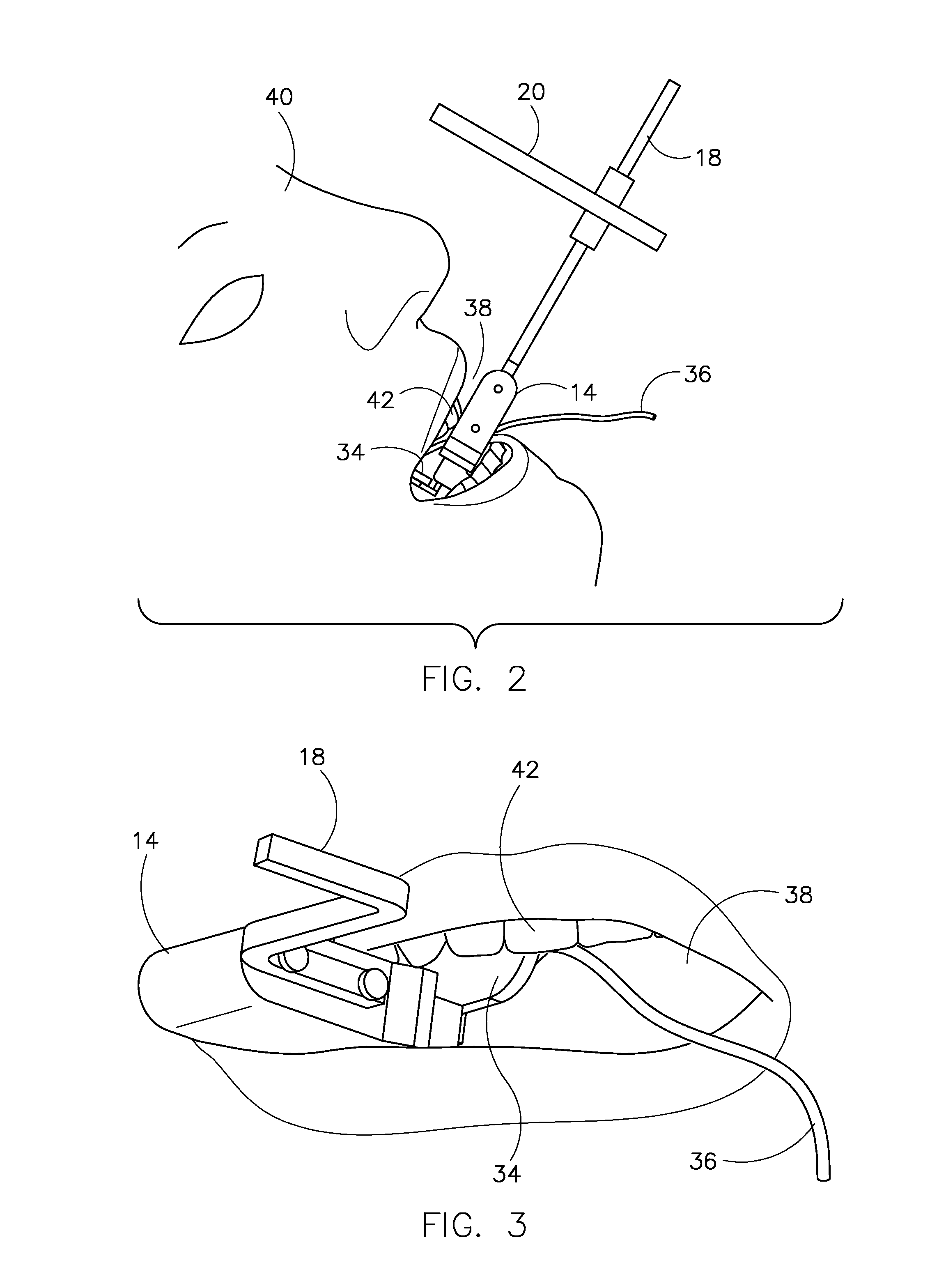

Apparatus for holding digital dental x-ray sensor and method of making same

InactiveUS20110280378A1Avoid side forceX-ray/infra-red processesMetal working apparatusDigital imagingBite force quotient

A dental x-ray sensor assembly includes a bite block used for digital imaging, wherein a surface of the bite block includes a deformable material that readily returns to an undeformed position after a biting force is removed therefrom.

Owner:INNOVATION 101

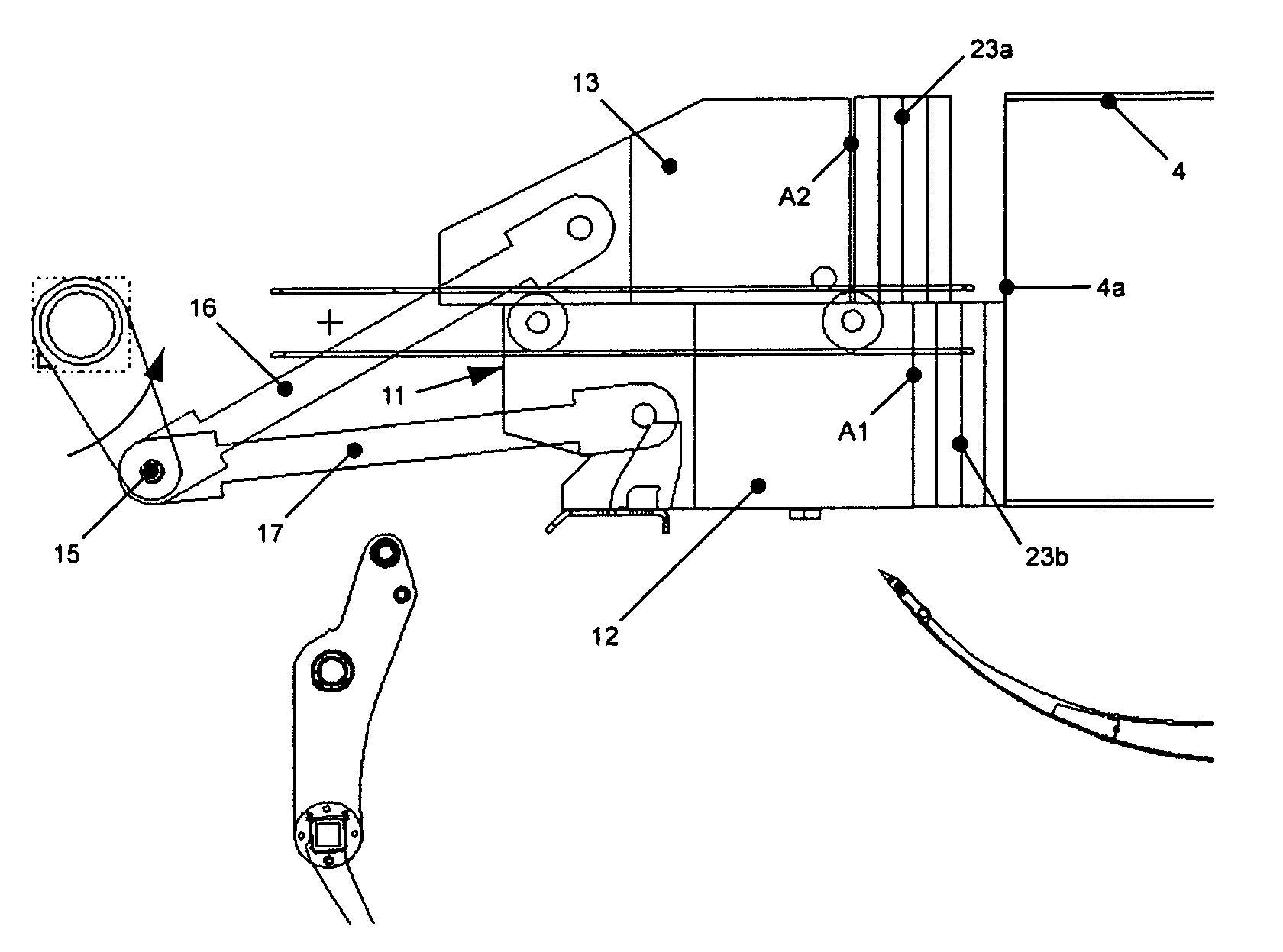

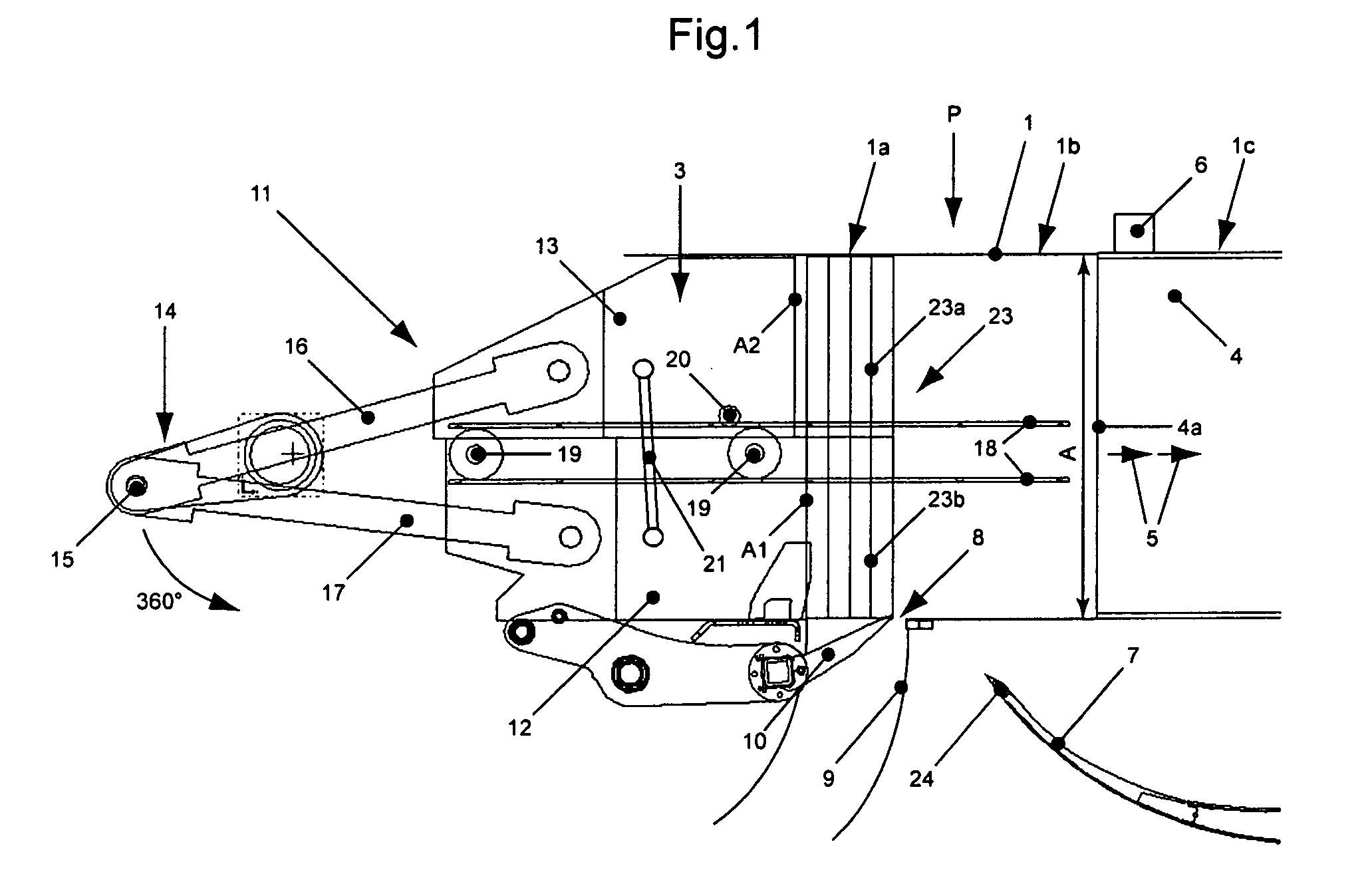

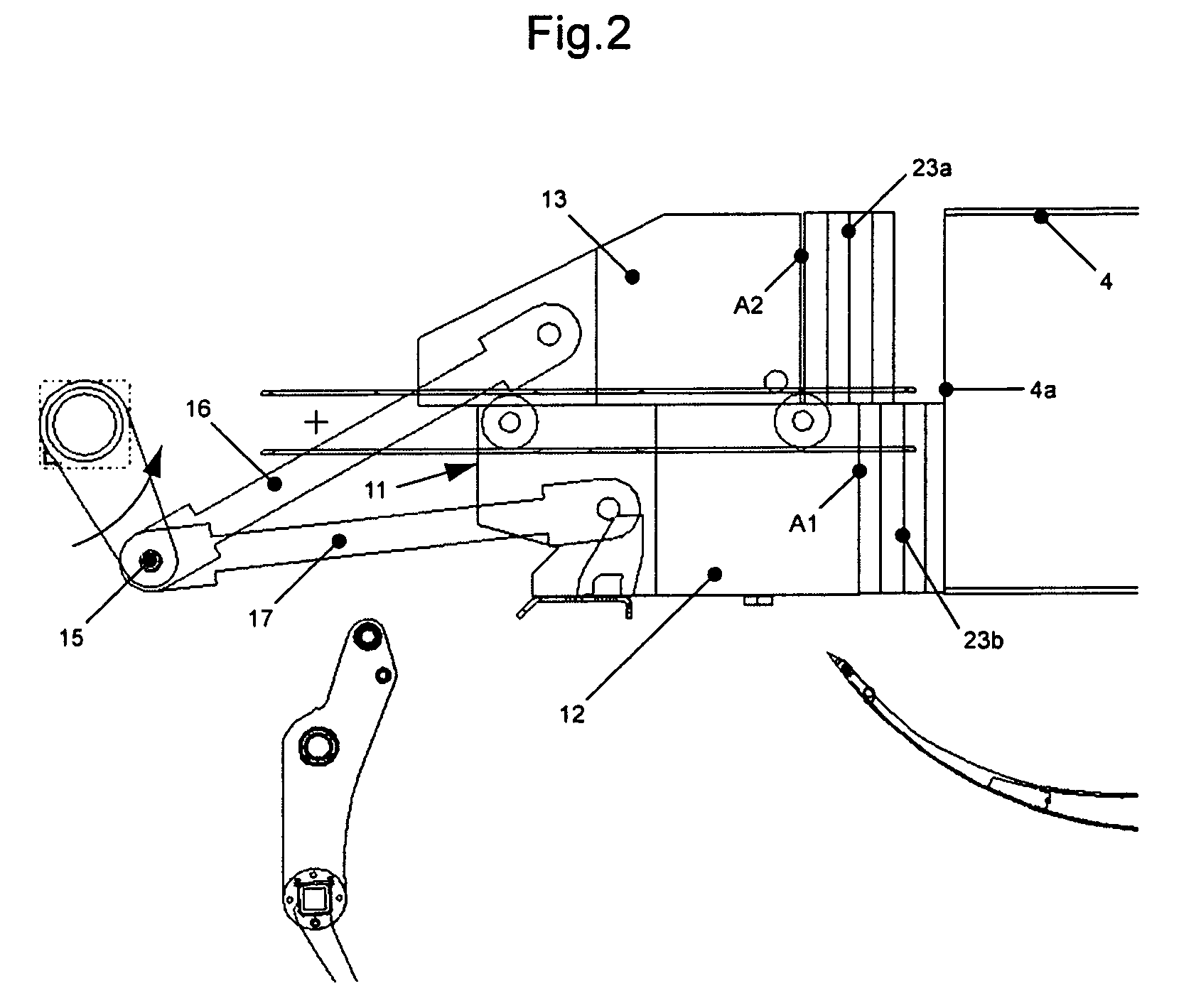

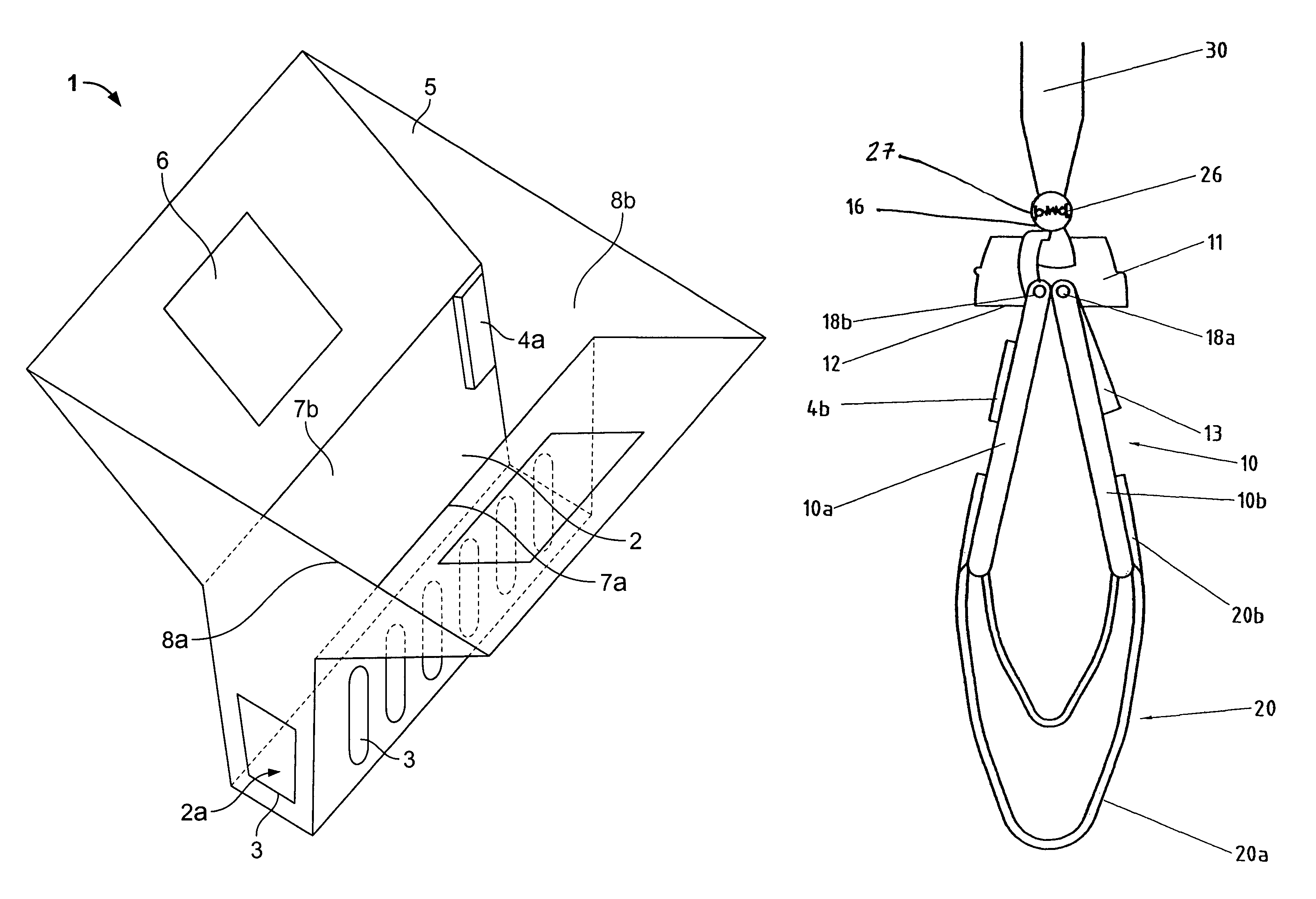

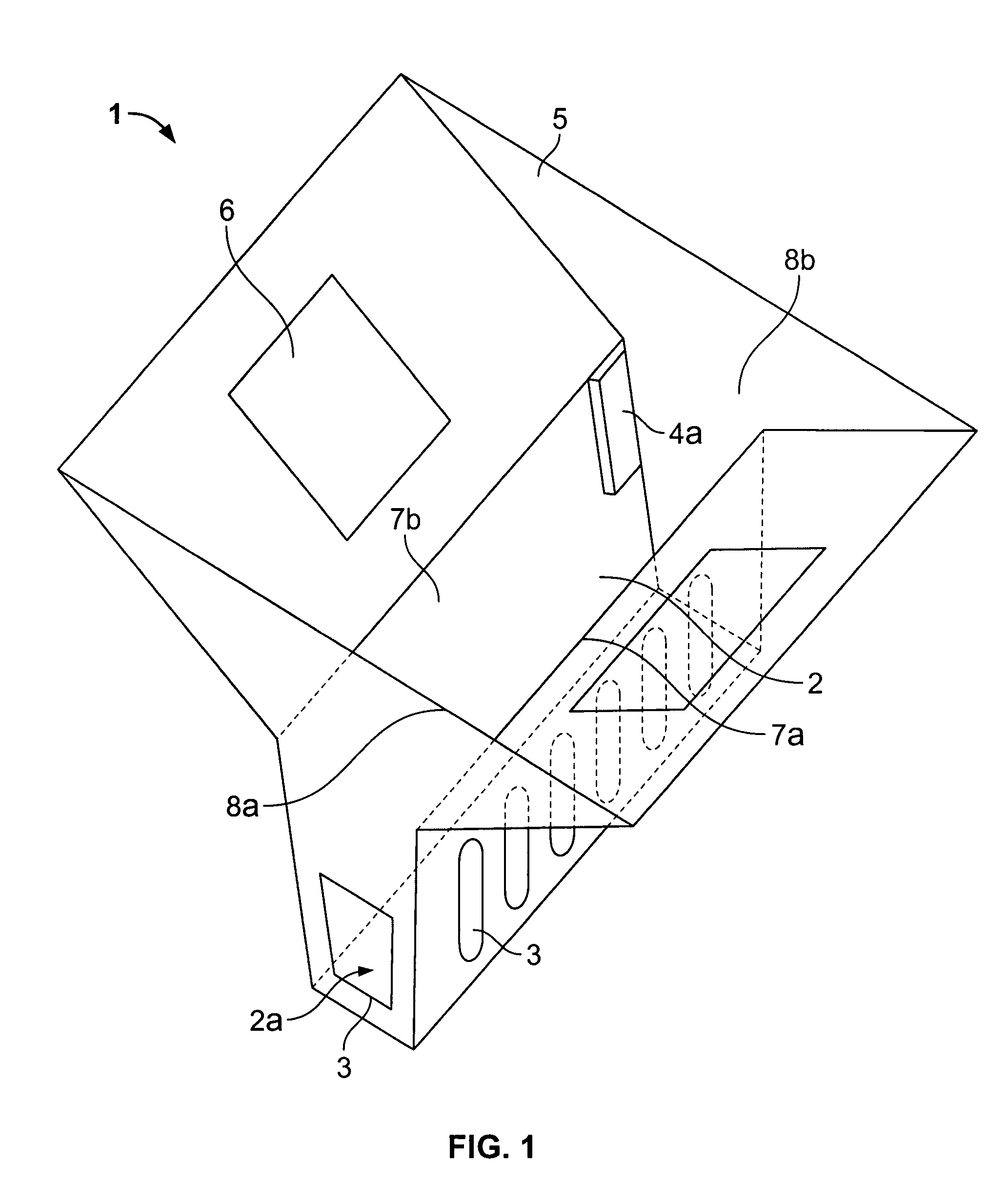

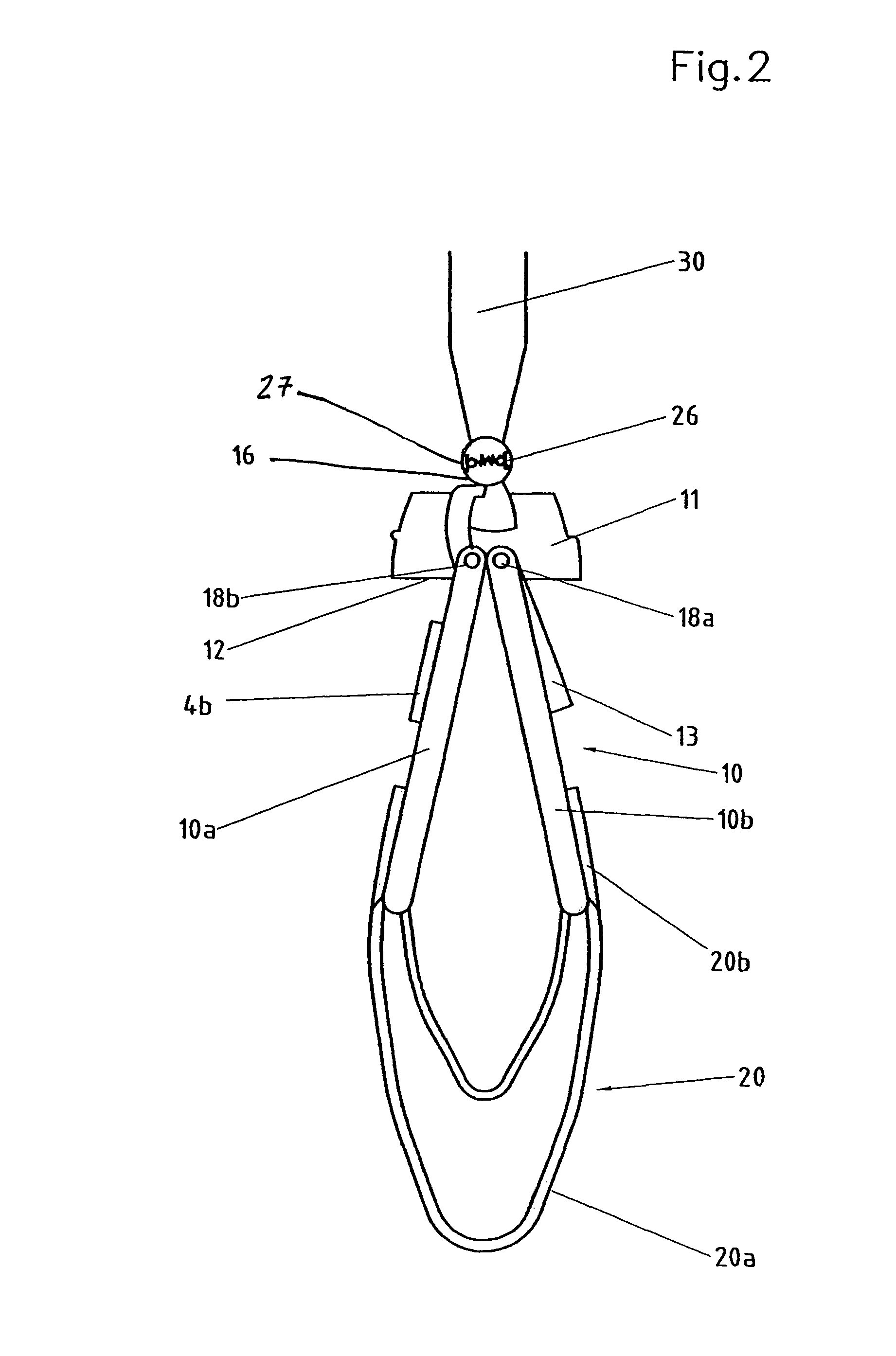

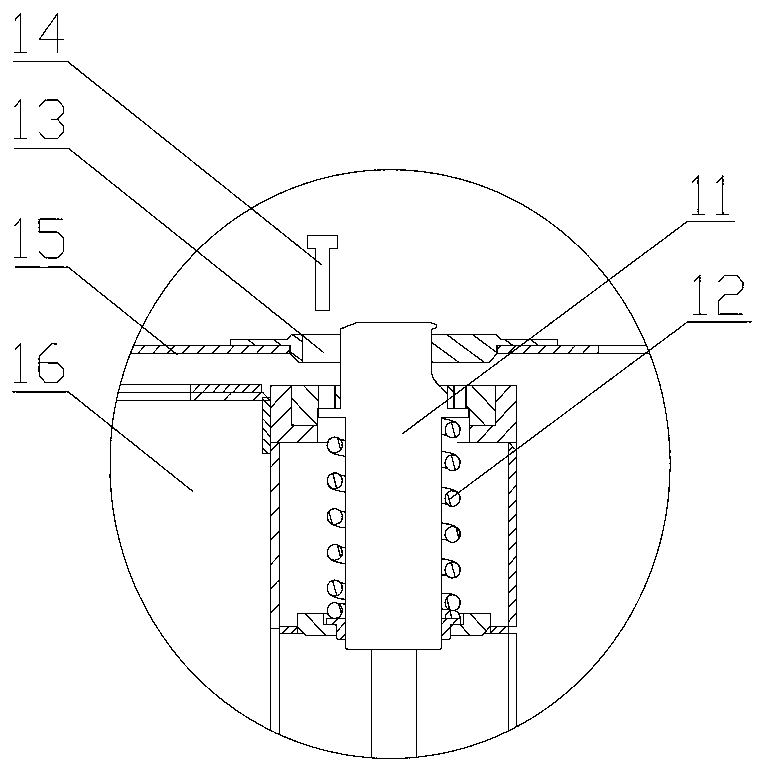

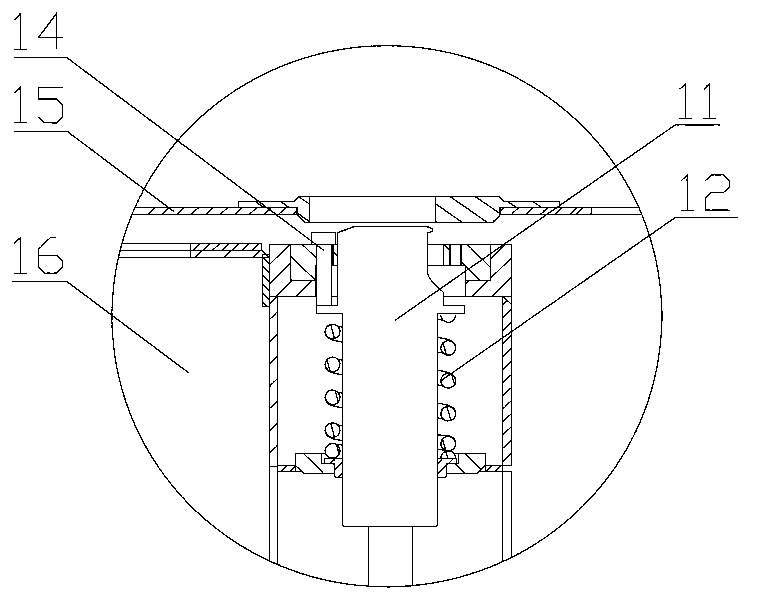

Plunger press and method for producing compressed bales

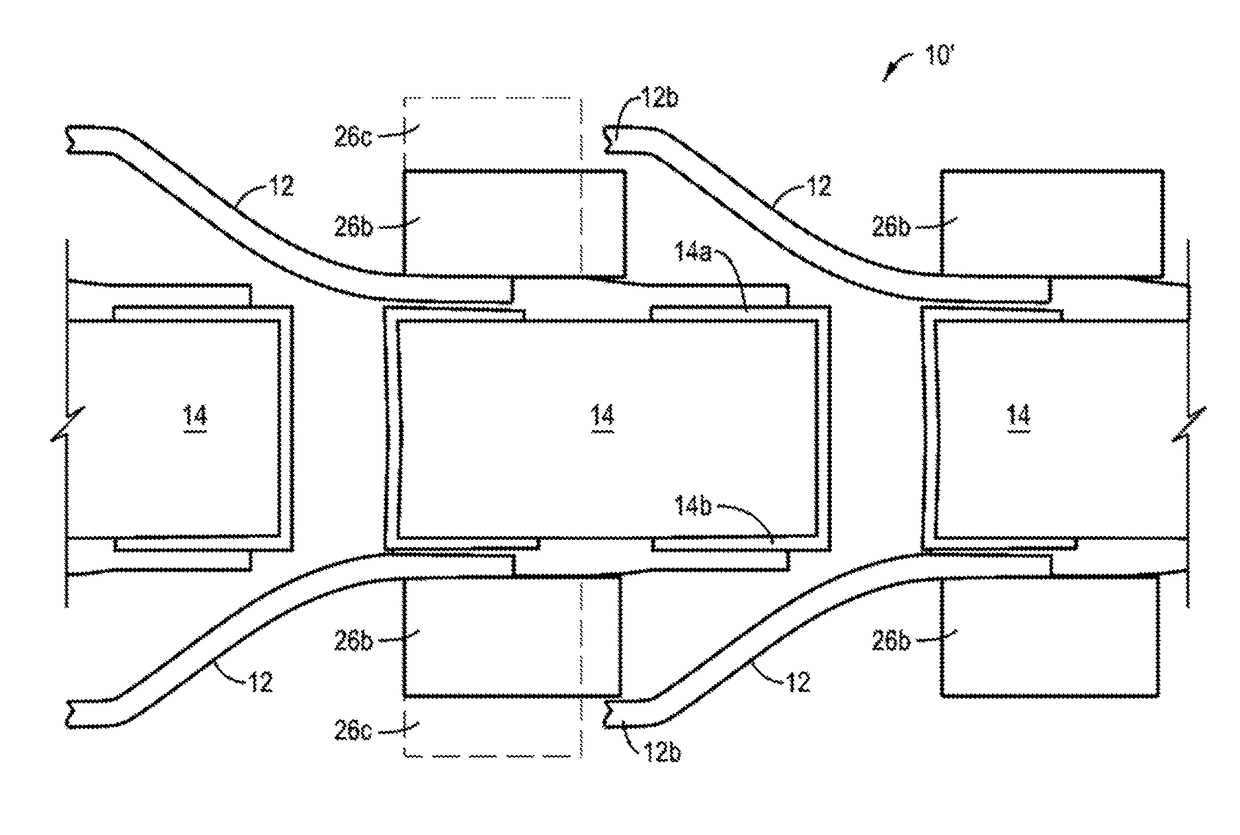

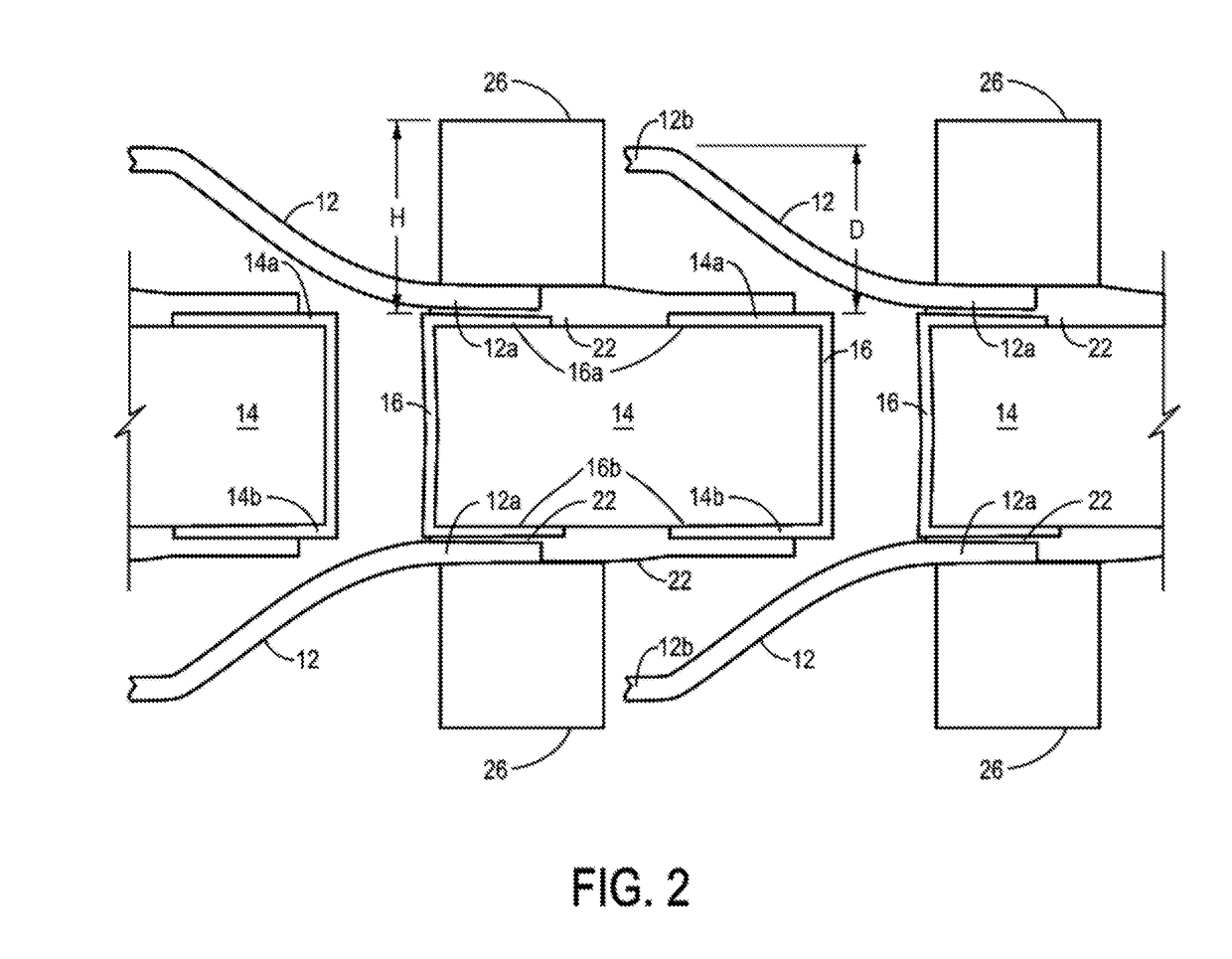

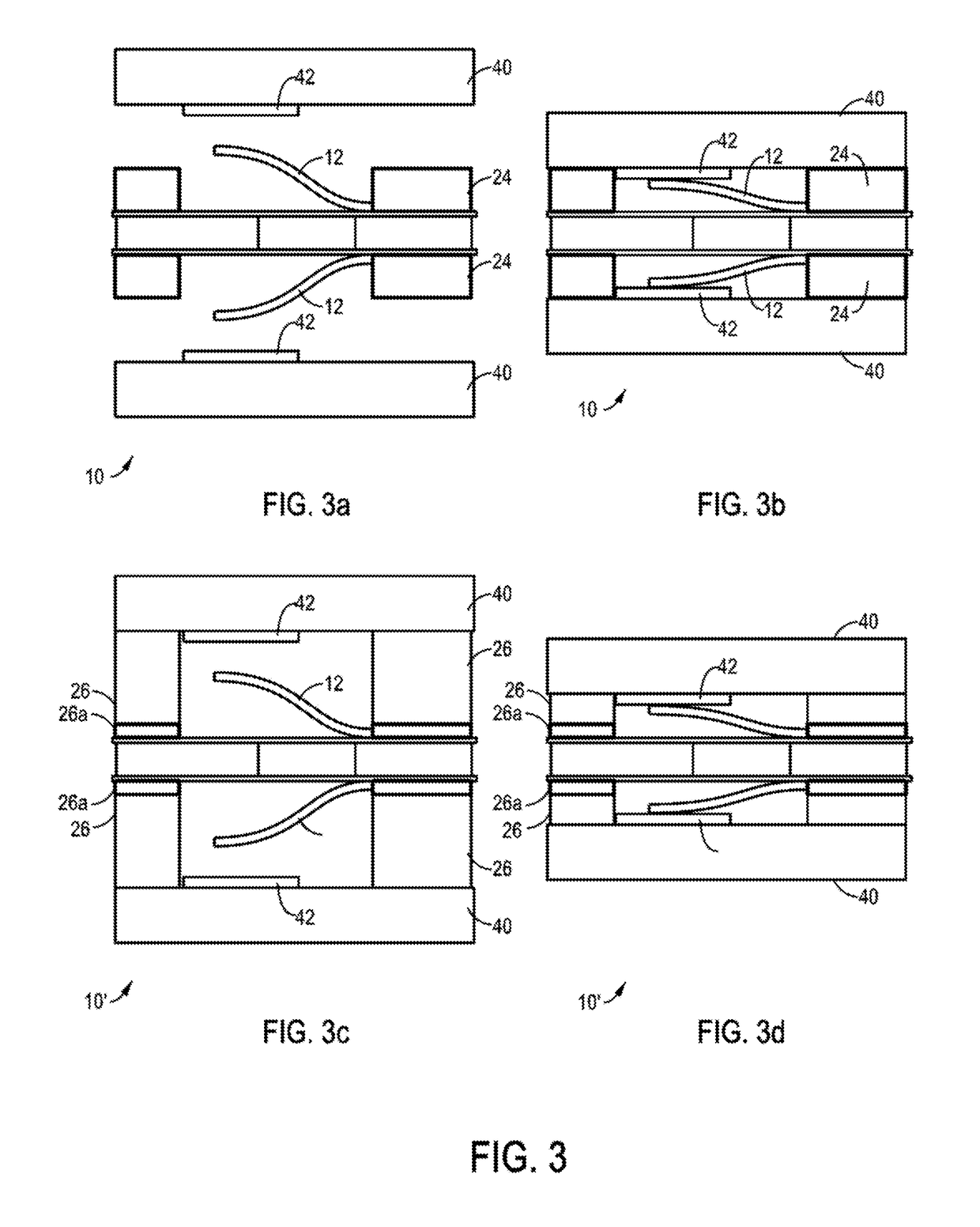

A plunger press produces compressed bales of forage, straw, biomass or fibrous mass for agricultural and / or industrial use. The press includes a bale case, a reciprocating plunger structure, at least one material feeding duct laterally leading into a material charge feeding section of the bale case, and at least one plunger structure drive mechanism. The plunger structure compresses respective material charges fed from the feeding duct into the bale case. The plunger structure is subdivided perpendicularly to a reciprocation direction of the plunger structure in the bale case into at least two structurally separated compression surfaces. Each of the compression surfaces is smaller than a cross-section area of the bale case. The compression surfaces are driven substantially parallelly in the reciprocation direction and with a time shift in relation to each other to alternatingly compress material on partial surfaces of the cross-section area.

Owner:KUHN GELDROP

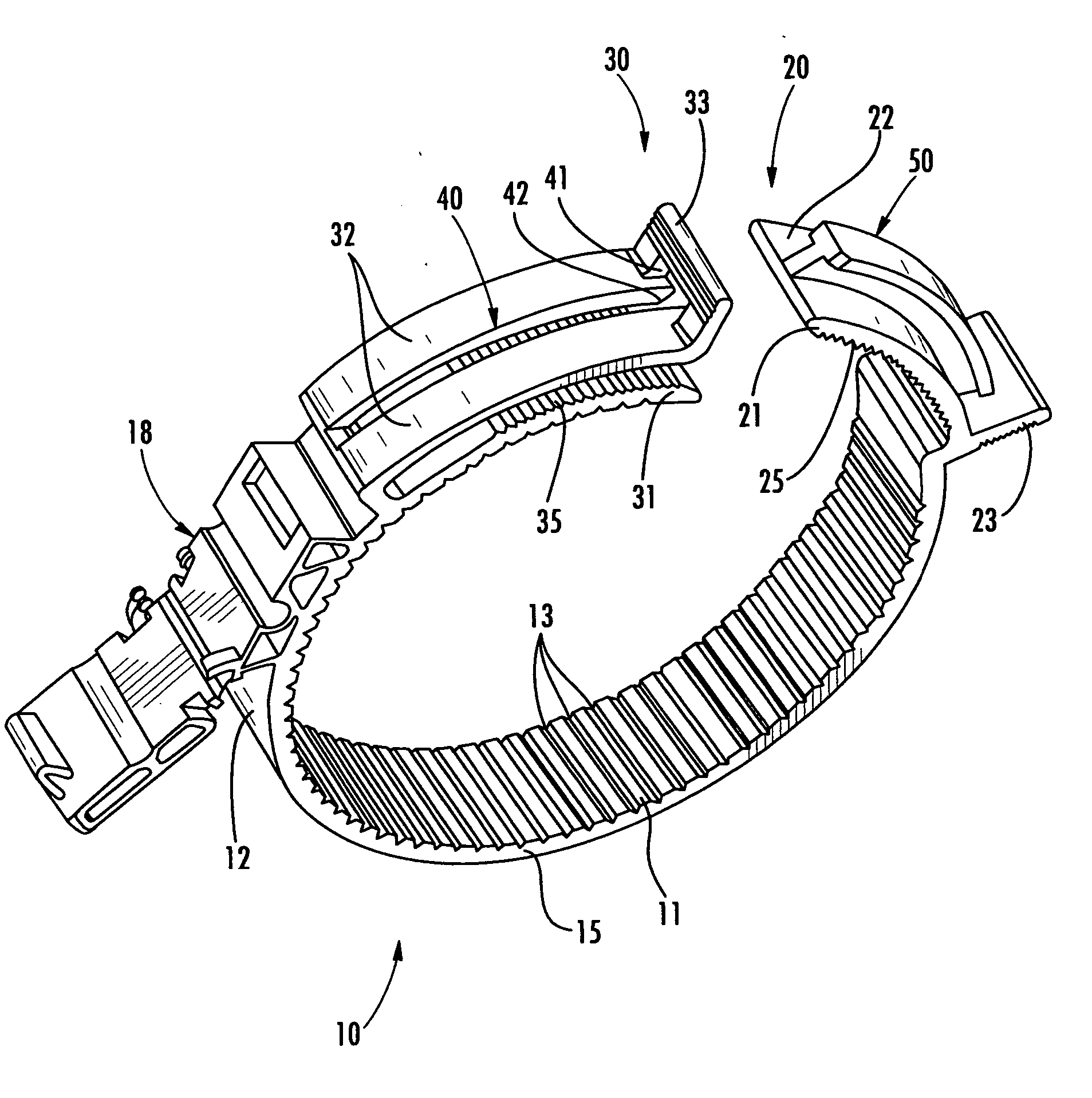

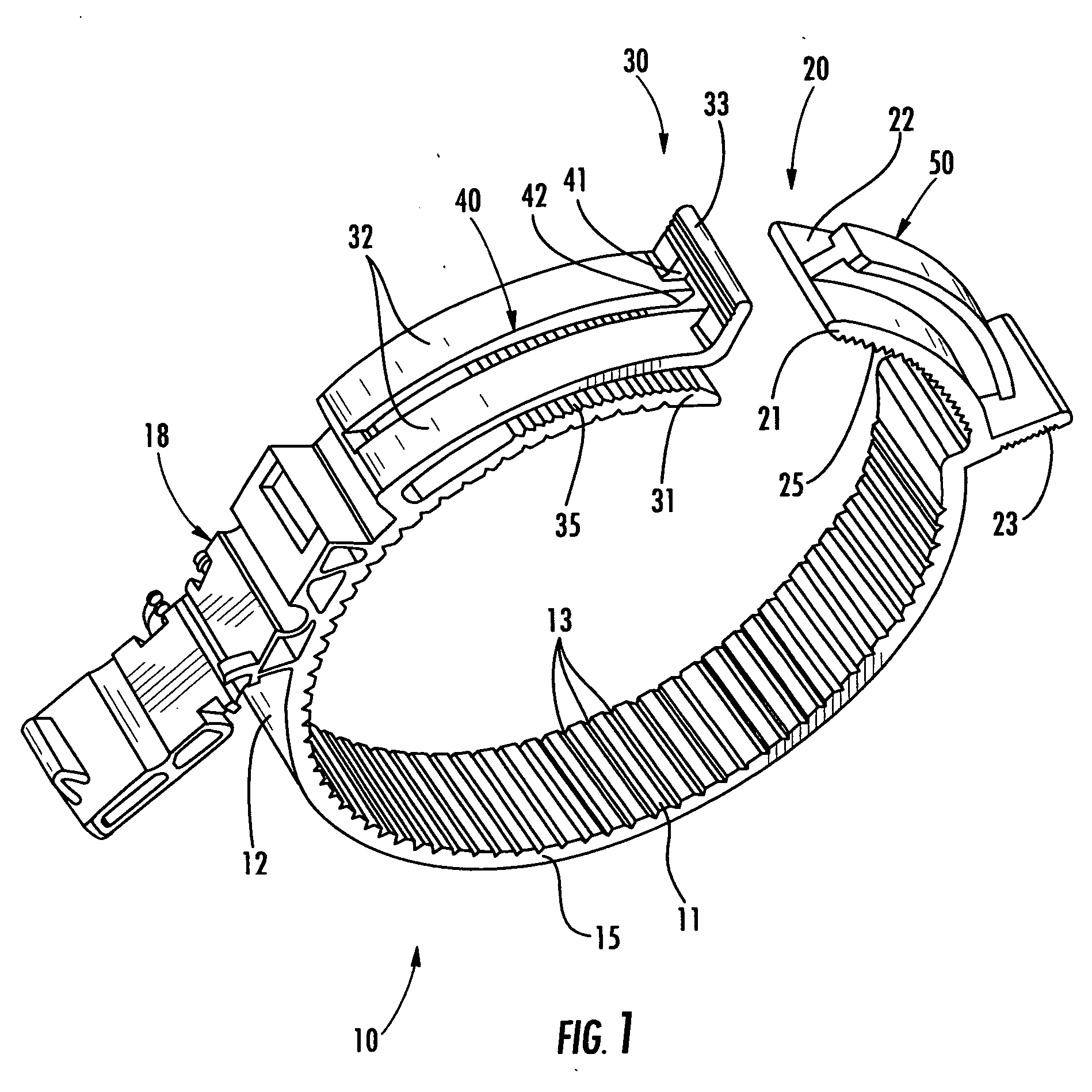

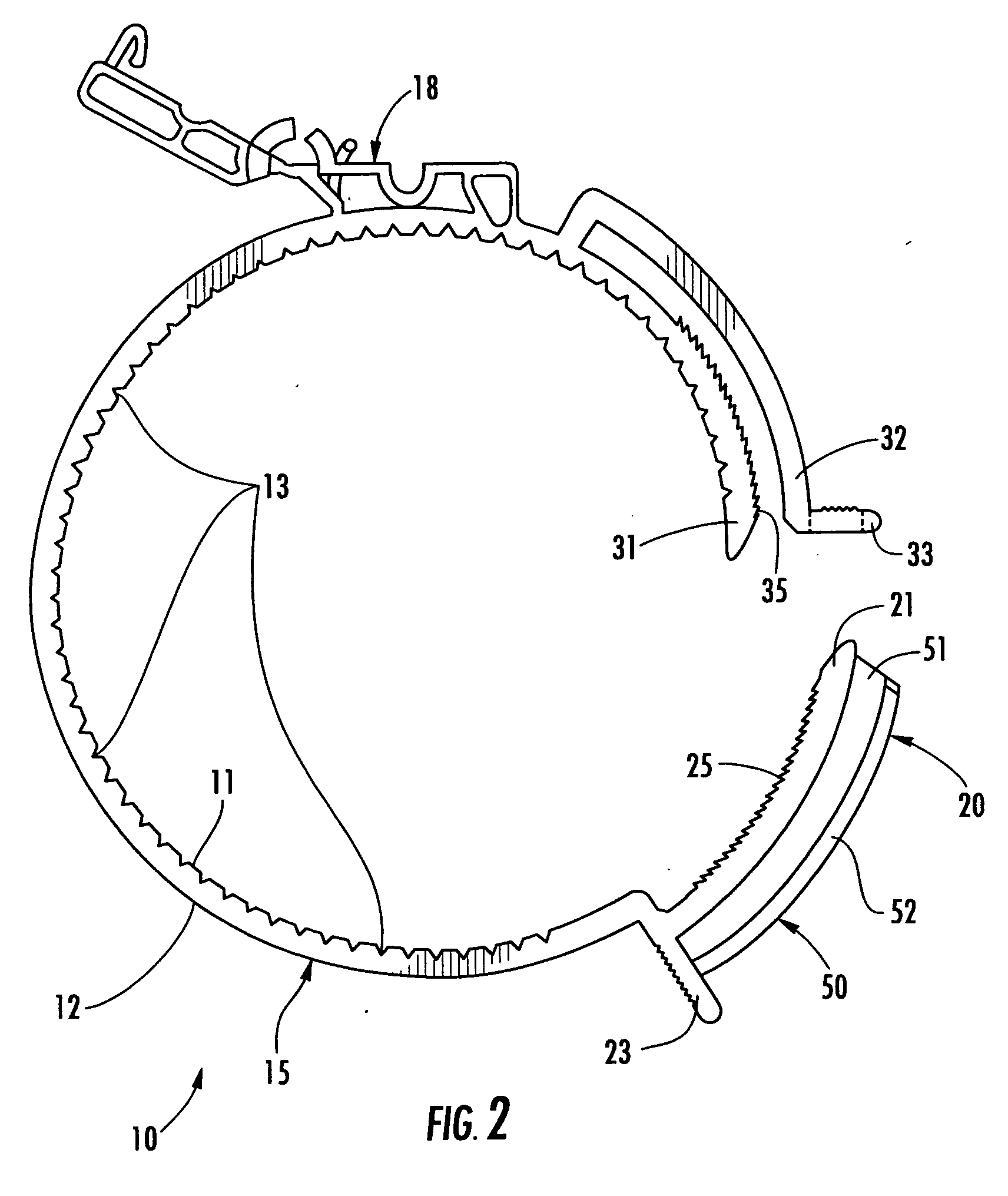

Anti-removal ratchet clip

Owner:ILLINOIS TOOL WORKS INC

Electrical connector with electrical contacts protected by a layer of compressible material and method of making it

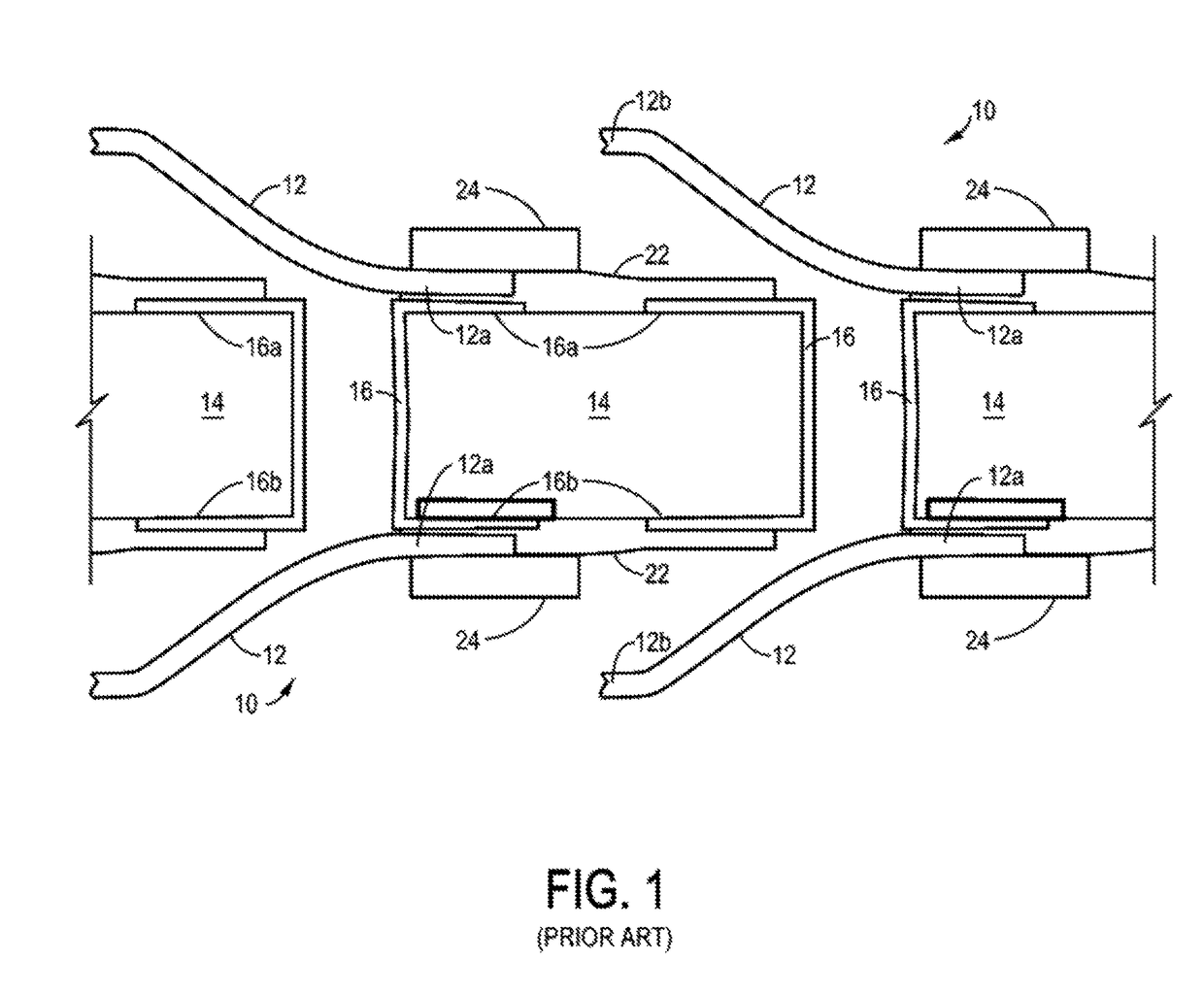

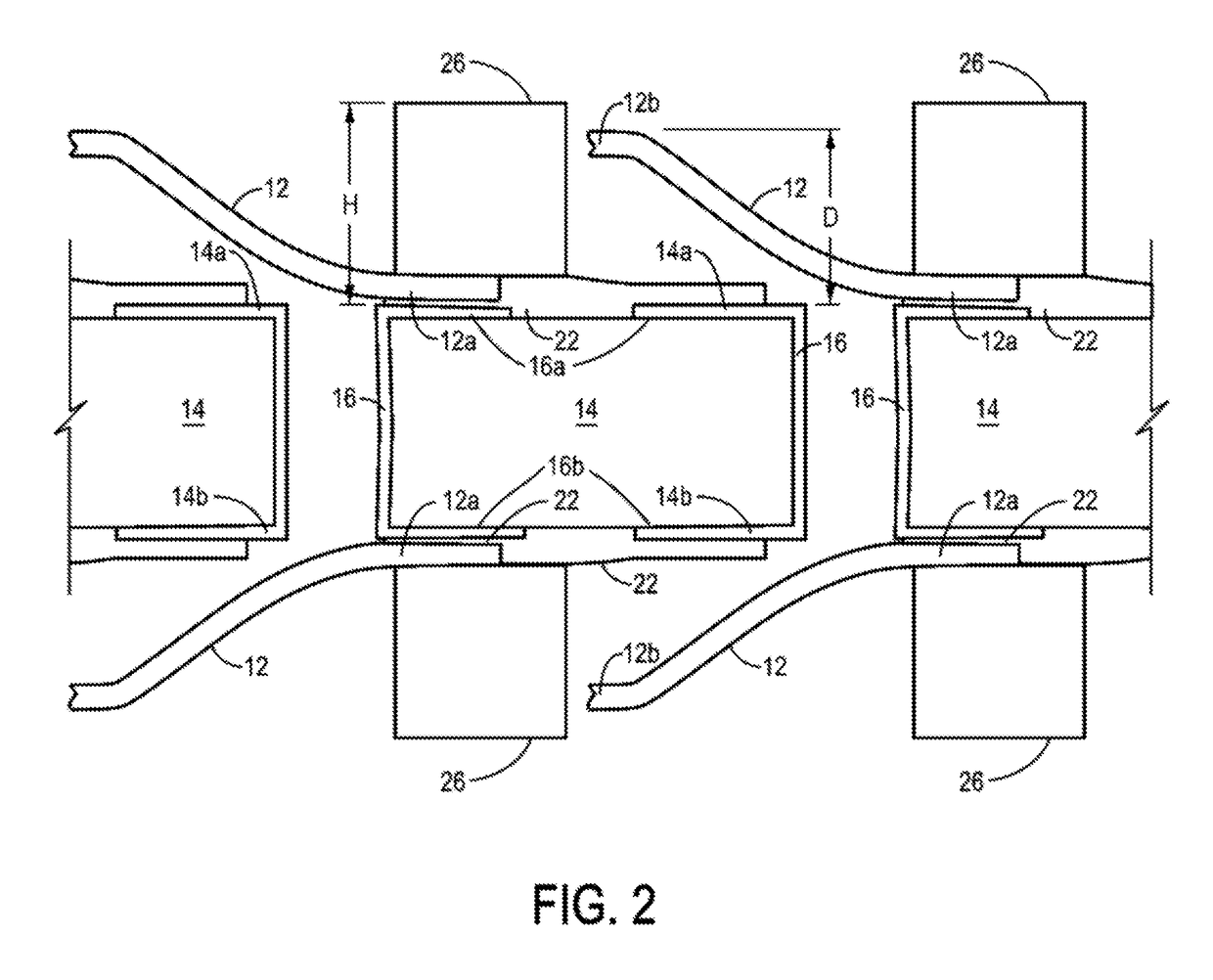

InactiveUS9680273B2Assist in their functioningMaximum protectionPorous dielectricsContact member manufacturingCompressible materialElectricity

Disclosed is an electrical connector having a substrate and movable electrical contacts which are mounted to the substrate and extend a distance D from the substrate. A layer of compressible material (such as a foam or elastomeric material) is positioned on the substrate adjacent at least some of the electrical contacts and ideally has an uncompressed thickness slightly greater than the distance D to provide for protection of the electrical contacts. When a mating electrical device such as an electrical connector or other circuit member is mated to the electrical connector with its electrical contacts and its layer of compressible material, the layer of compressible material is compressed to a thickness less than the distance D, allowing the contacts to make a suitable electrical interconnection to the mating electrical device. The compressible material may be selected which has a force-to-compression plot which includes at least one inflection, defining a first region on one side of the inflection where a given increment of force provides a larger increment of compression and a second region on the other side of the inflection where the same increment of compressive force provides a substantially smaller increment of compression. The compressible material can function to prevent damage to the movable electrical contacts from handling, packing, shipping, assembly, testing, connection and / or mating of the connector.

Owner:NEOCONIX INC

Apparatus for dispensing free-flowing material

InactiveUS7021504B2Avoid side forceReduce wearLiquid surface applicatorsYielding couplingDrive shaftCoupling

Owner:NORDSON CORP

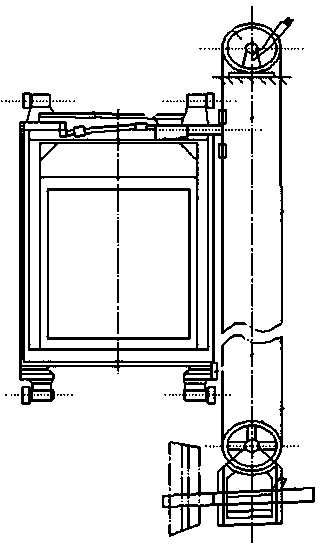

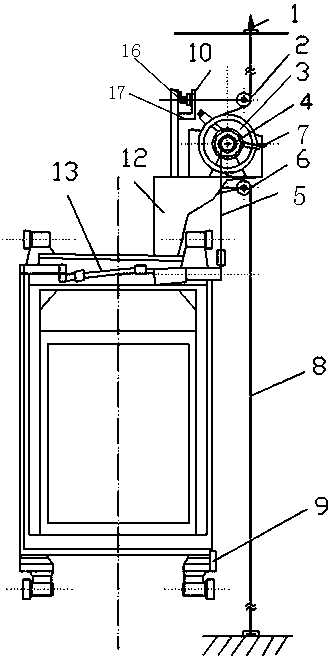

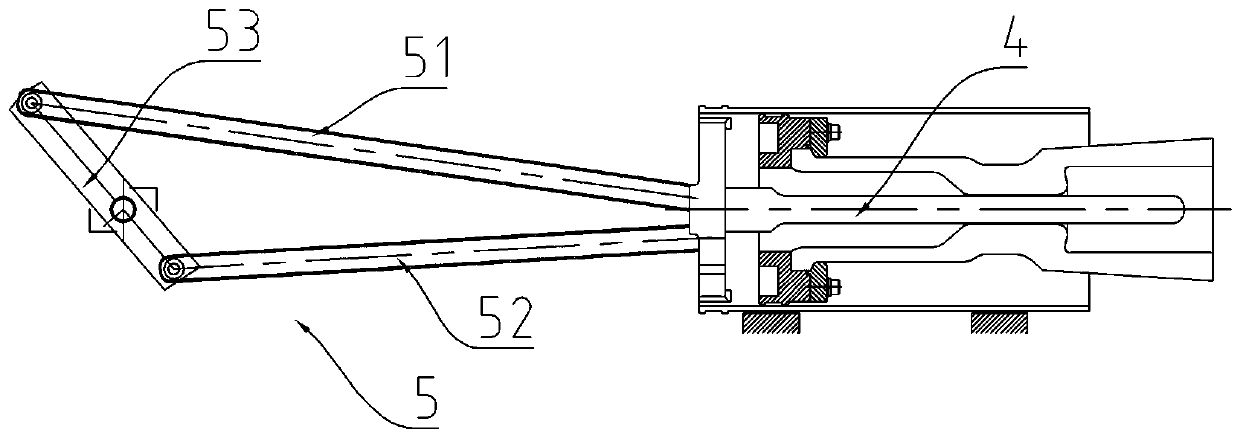

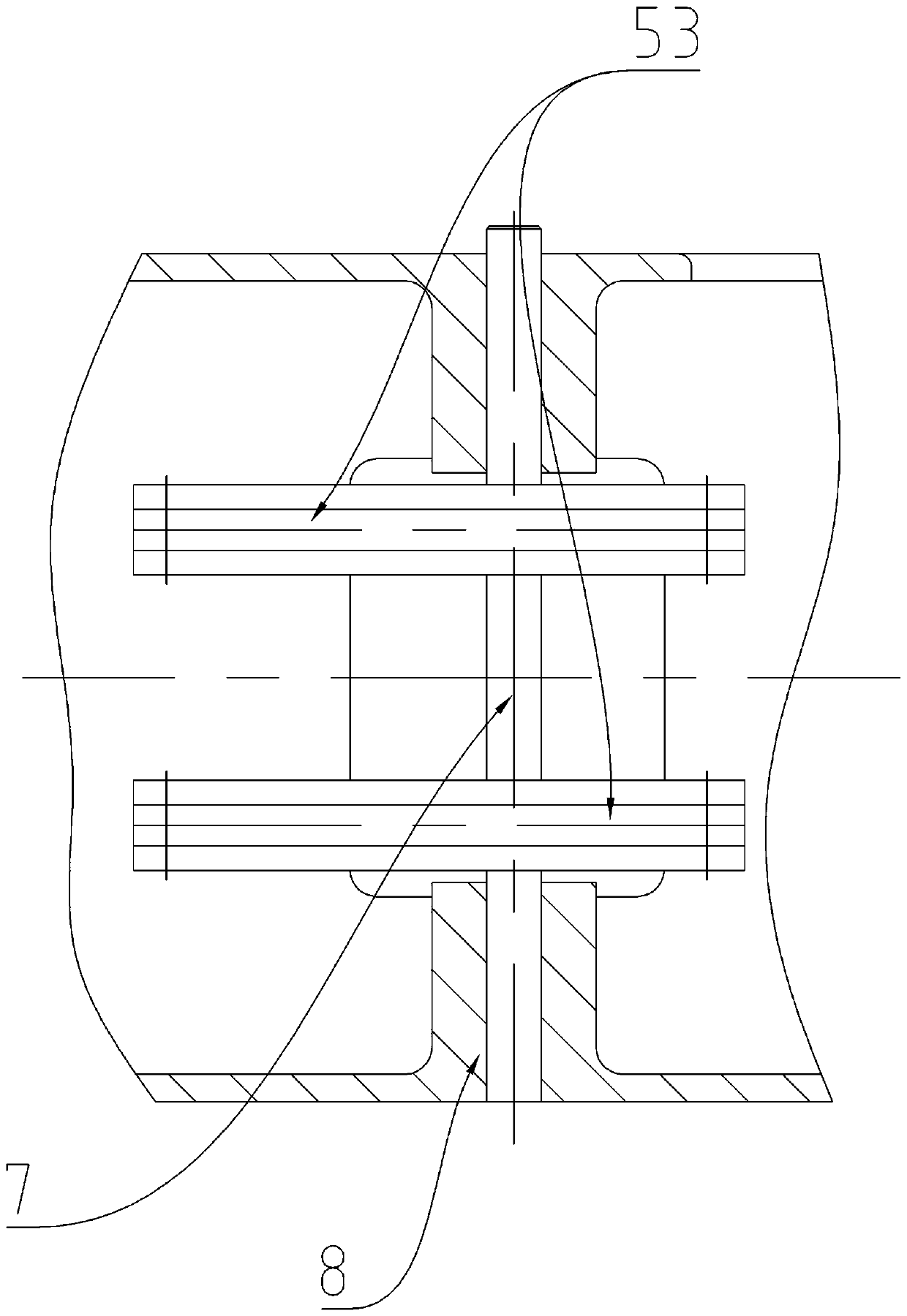

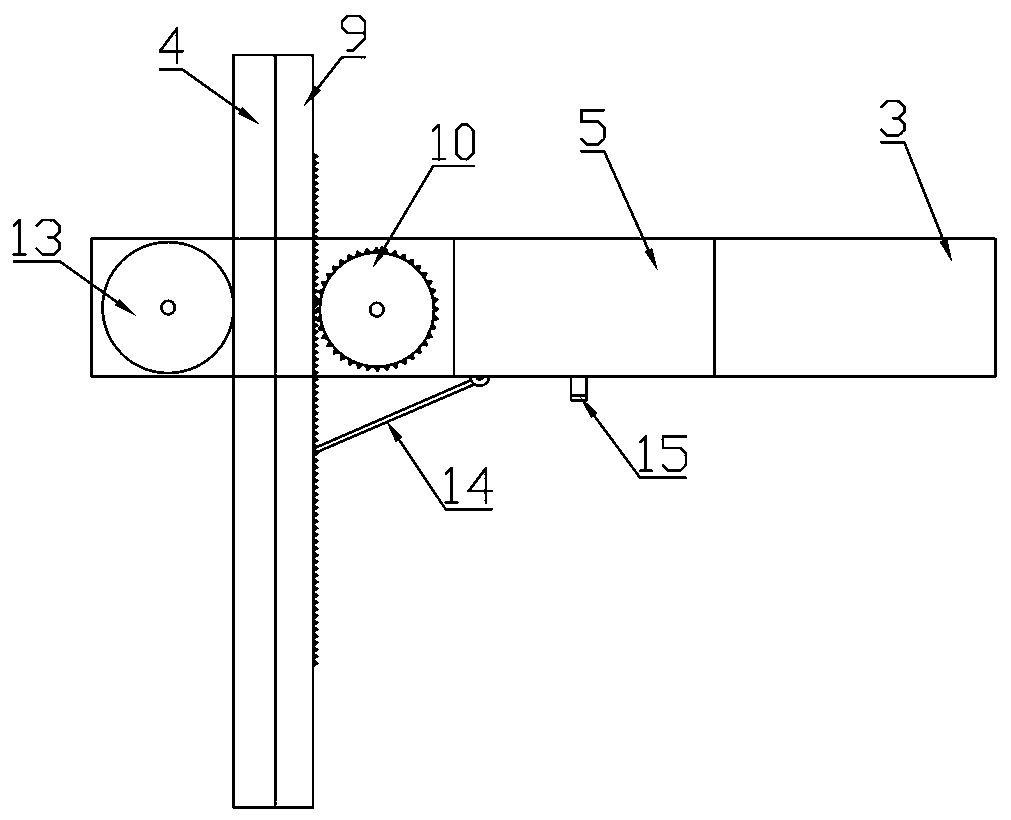

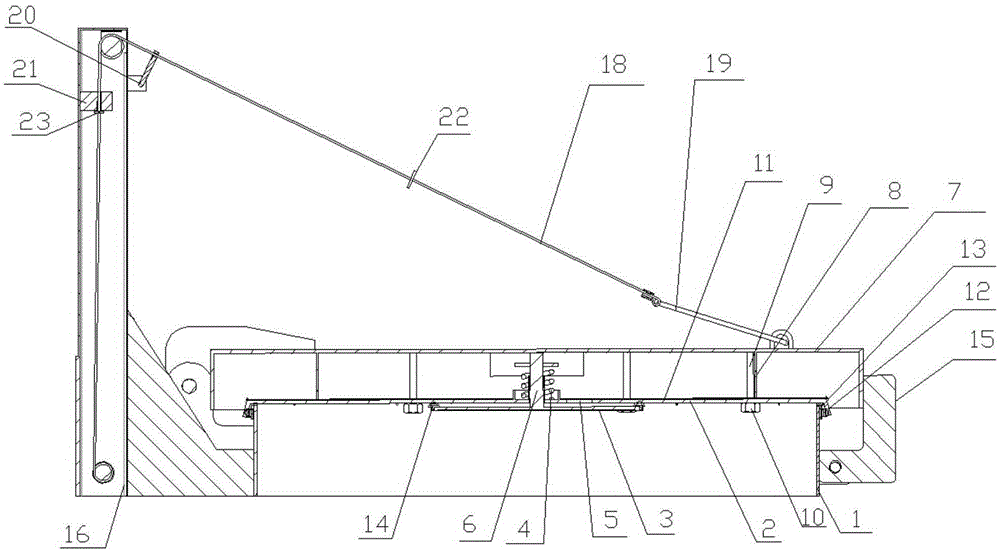

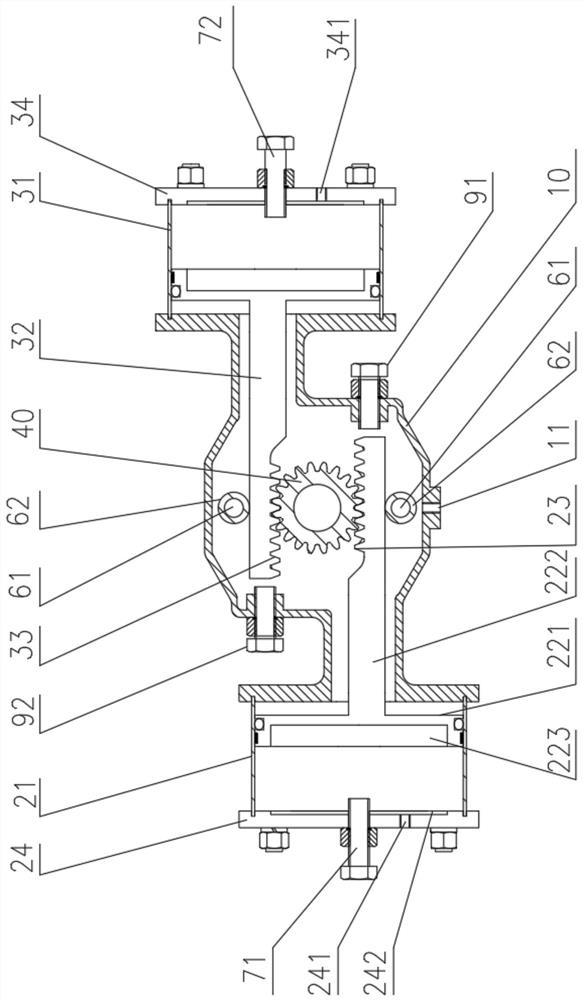

Speed limiter and safety gear linkage system based on elevator

The invention discloses a speed limiter and safety gear linkage system based on an elevator. The speed limiter and safety gear linkage system based on the elevator mainly solves the problems that in the prior art, a speed limiter and safety gear linkage system is complex in structure and high in cost, and especially a speed limiter of an elevator without a machine room is inconvenient to install, maintain, inspect and check. The speed limiter and safety gear linkage system based on the elevator comprises a speed limiter, a speed limiter rope, a guiding adjusting mechanism, a lifting winding drum, a linkage mechanism, a lifting steel rope and safety gears, wherein the speed limiter is arranged on the car roof of a lift car of the elevator, the speed limiter rope is wound around the speed limiter, the upper end of the speed limiter rope is fixedly connected with the top of a shaft of the elevator, the lower end of the speed limiter rope is fixedly connected with the bottom of the shaft of the elevator, the guiding adjusting mechanism is used for detecting whether the speed limiter rope is tensioned or not at any time, the lifting winding drum and the speed limiter are arranged in a coaxial mode, the speed limiter drives the lifting winding drum to rotate through the linkage mechanism, and the lifting steel rope is wound around the lifting winding drum. According to the speed limiter and safety gear linkage system based on the elevator, the speed limiter is arranged on the car roof of the lift car of the elevator, one longitudinal speed limiter rope is adopted, the existing speed limiter and safety gear linkage system of a lift car of the elevator is simplified, and the speed limiter and safety gear linkage system of the elevator are optimized and upgraded comprehensively.

Owner:成都市特种设备检验检测研究院(成都市特种设备应急处置中心)

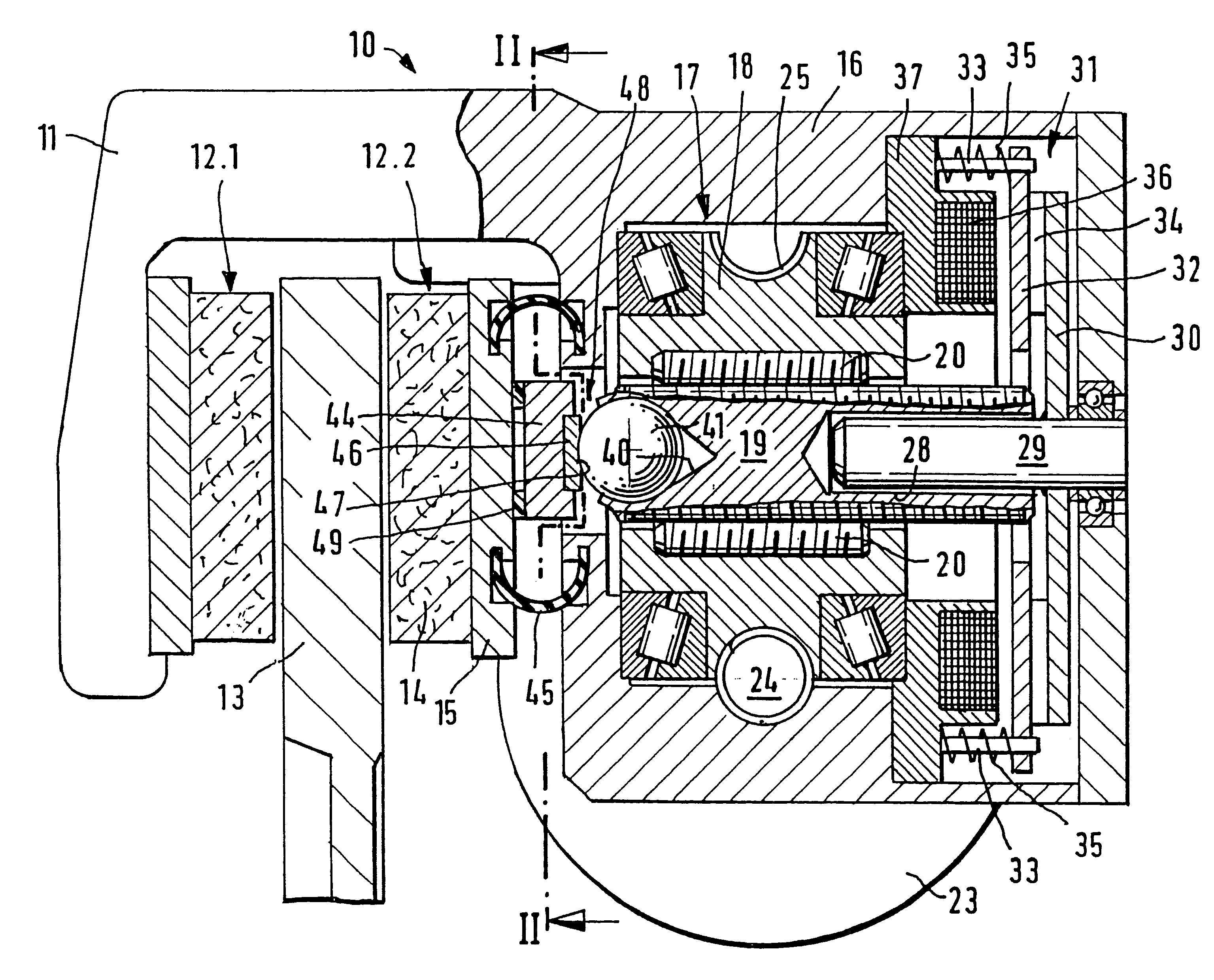

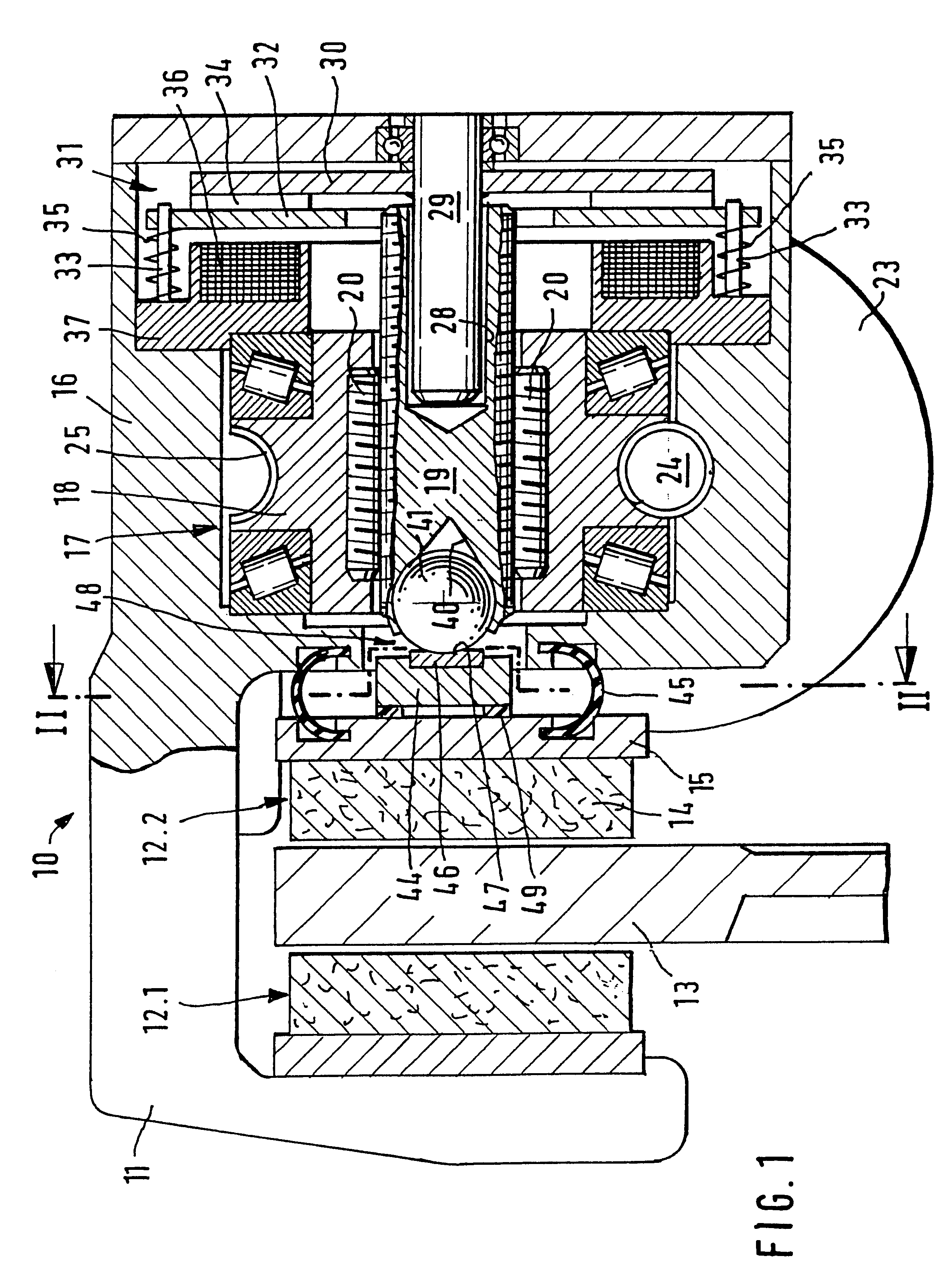

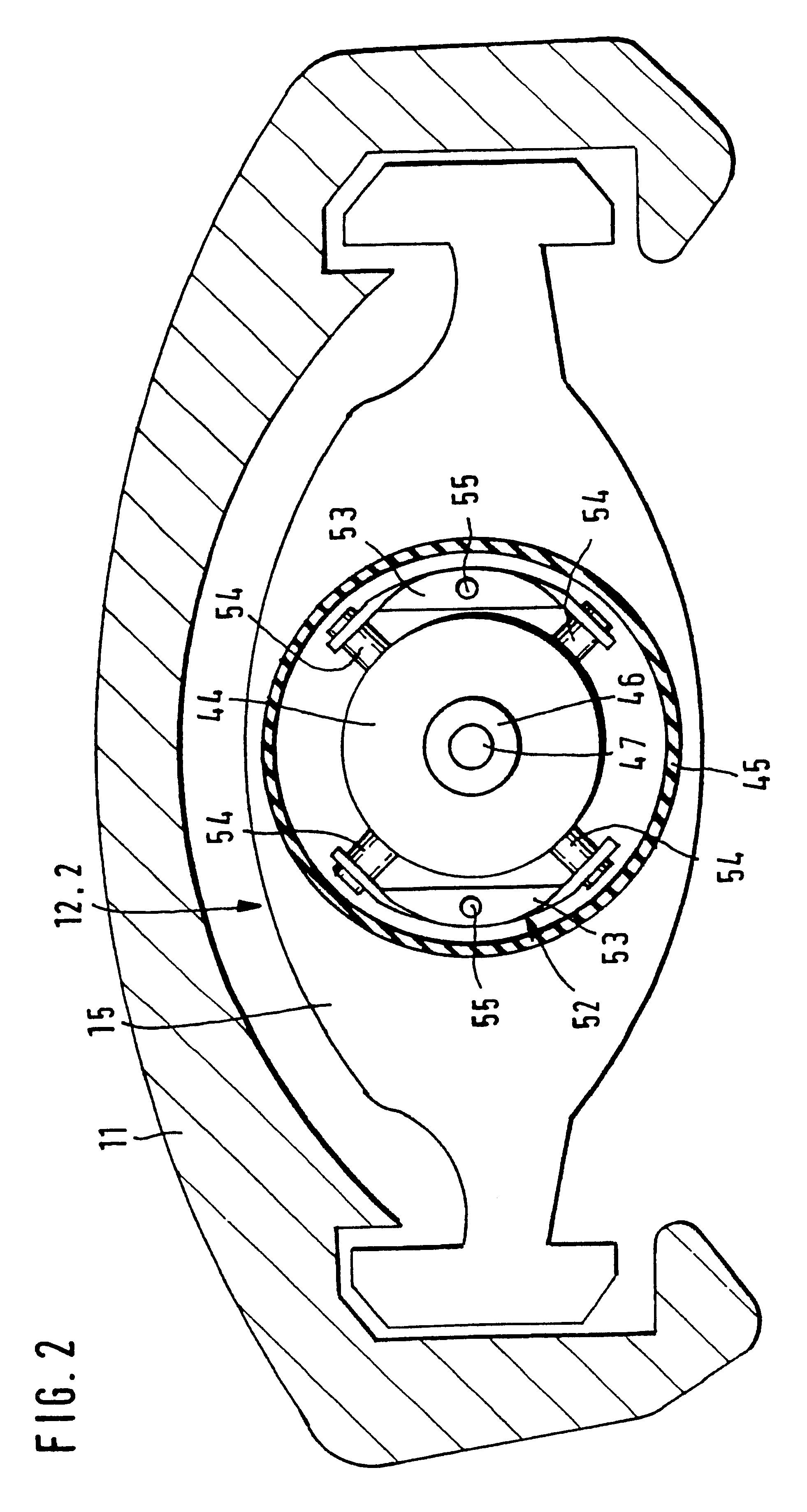

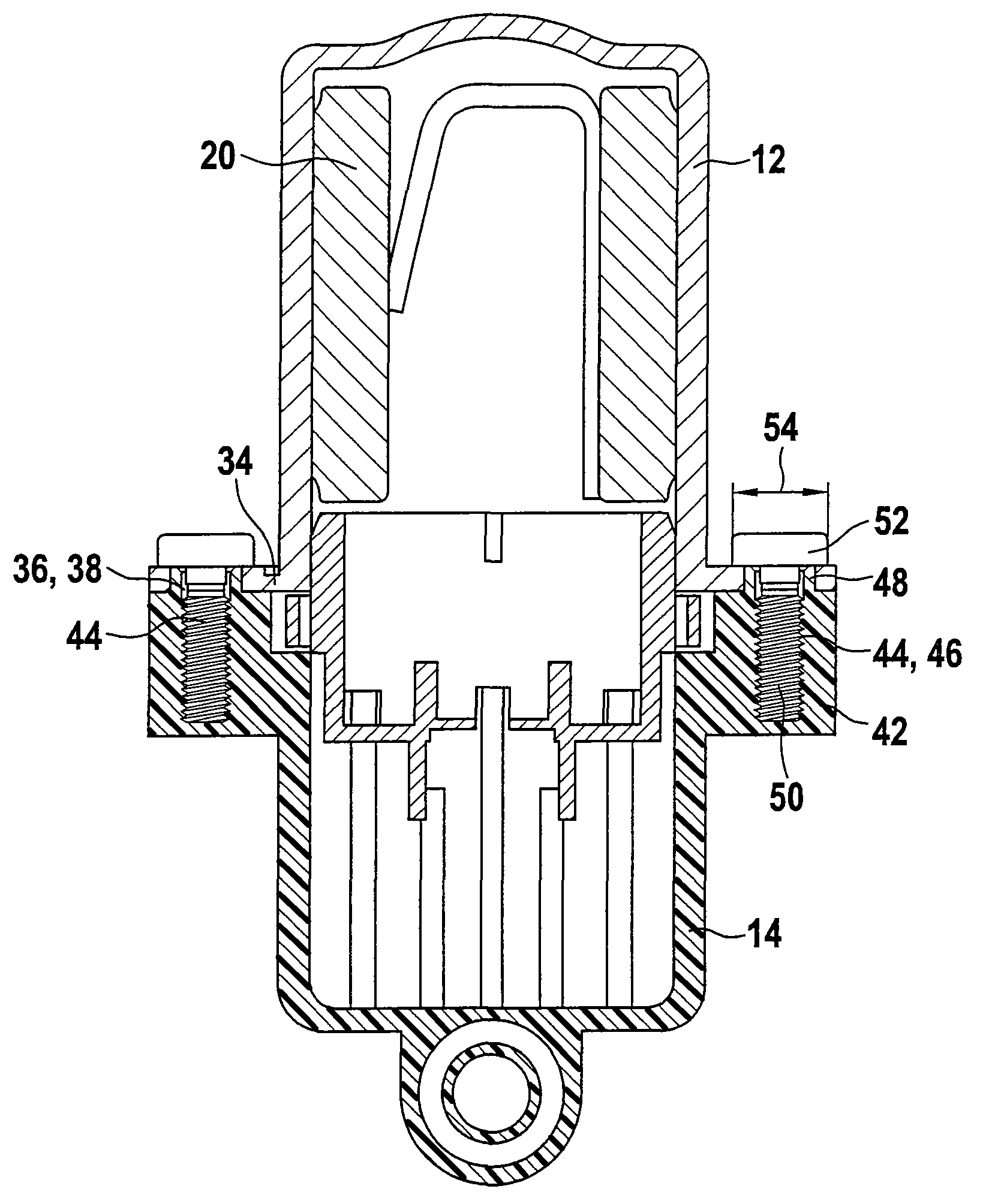

Electromechanical brake for motor vehicles

InactiveUS6336529B1Avoid side forceReduce frictionAxially engaging brakesBraking action transmissionMobile vehicleEngineering

An electromechanical brake for motor vehicles having a selflocking-free spindle that is electromotively moved bidirectionally in a longitudinal direction in order to press at least one brake lining against a rotating friction element in an advancing stroke and and in order to release the brake lining in a restoring stroke. The brake also has a plate-shaped coupling member between the spindle and the brake lining. The coupling member engages directly with the spindle and is supported against the brake lining so that the brake lining slides lateral to the longitudinal axis of the spindle. This largely prevents lateral forces, which interfere with the lack of friction of the spindle and can occur when the brake lining is against the friction element. The electromechanical brake is used in passenger motor vehicles.

Owner:ROBERT BOSCH GMBH

Double-acting arc extinguish chamber transmission structure, arc extinguish chamber adopting same and circuit break

InactiveCN109767949AGuaranteed uptimeSmall footprintContact driving mechanismsHigh-tension/heavy-dress switchesSwitchgearArc extinction

The invention relates to that field of switching equipment, in particular to a double-acting arc extinguish chamber transmission structure, an arc extinguish chamber adopting the same and a circuit break. The double-acting arc extinguish chamber transmission structure comprises connecting rod mechanisms arranged in pairs, wherein the same pair of connecting rod mechanisms are arranged in the extension direction of a rotation axis of rotating connecting rods; projections of corresponding connecting rods in the same pair of connecting rod mechanisms in a first projection plane perpendicular to the rotation axis are symmetrical with respect to a projection line of a center line of a first contact assembly; the projections of the corresponding connecting rods in the same pair of connecting rodmechanisms in a second projection plane perpendicular to the first projection plane and parallel to the center line of the first contact assembly are symmetrical with respect to the projection line of the center line of the first contact assembly; and thus occupied space of the connecting rod mechanisms is reduced, the volume of the arc extinguish chamber is further reduced, and the problem of large volume of the arc extinguish chamber caused by parallel arrangement of the two connecting rod mechanisms in the current double-acting arc extinguish chamber transmission structure is solved.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +3

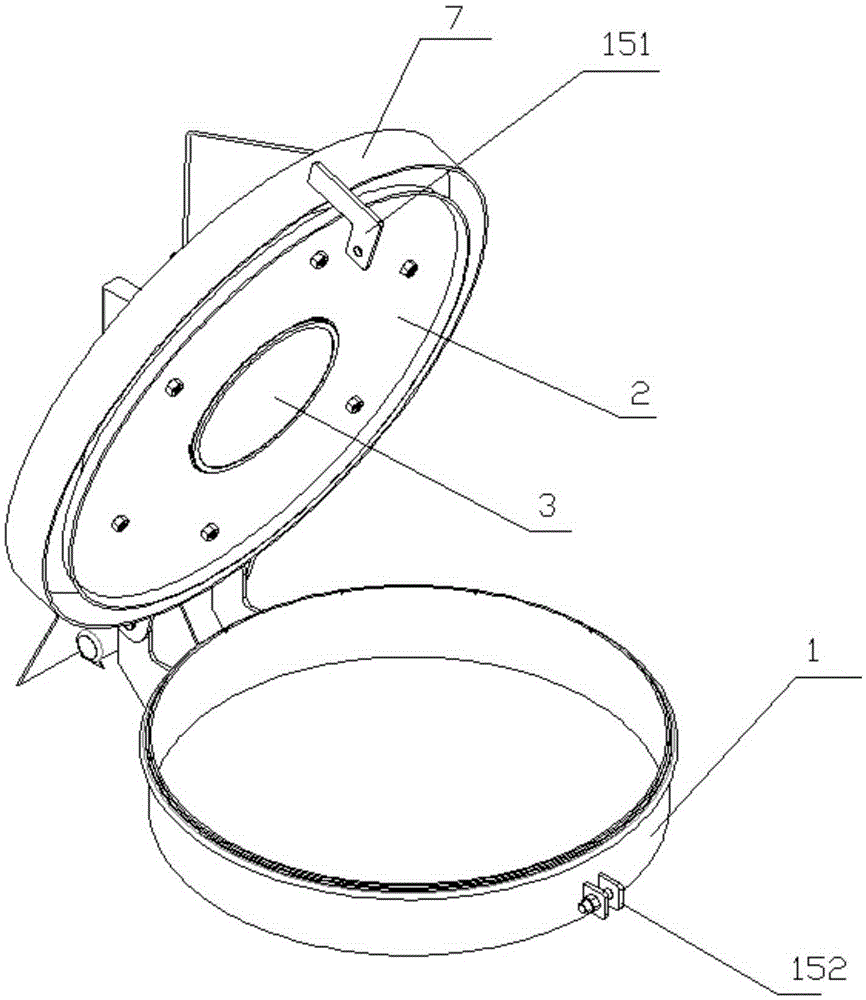

Cooking, pulping and stirring all-in-one machine

PendingCN111097317AEasy to open and refillStir wellRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention belongs to the technical field of food processing, and particularly relates to a cooking, pulping and stirring all-in-one machine which comprises a base; a tank body is fixed to the base, and a tank cover is arranged on the tank body; a lifting structure is further fixed to the base, and the tank cover is fixed to the lifting structure; the tank body is of an interlayer structure, and a heating structure and a cooling structure are arranged in an interlayer of the tank body. A stirring structure fixedly connected with a rotating shaft of the stirring motor is arranged at the lower part of the tank cover; and a slurry outlet is formed in the bottom of the tank body. According to the all-in-one machine, cooking, pulping and stirring processes are carried out in the same device,and the tank cover adopts an automatic lifting mode, so that the process is simplified, the operation convenience is improved, and meanwhile, the loss caused by the transfer of materials among different processes is avoided.

Owner:XUZHOU COLLEGE OF INDAL TECH

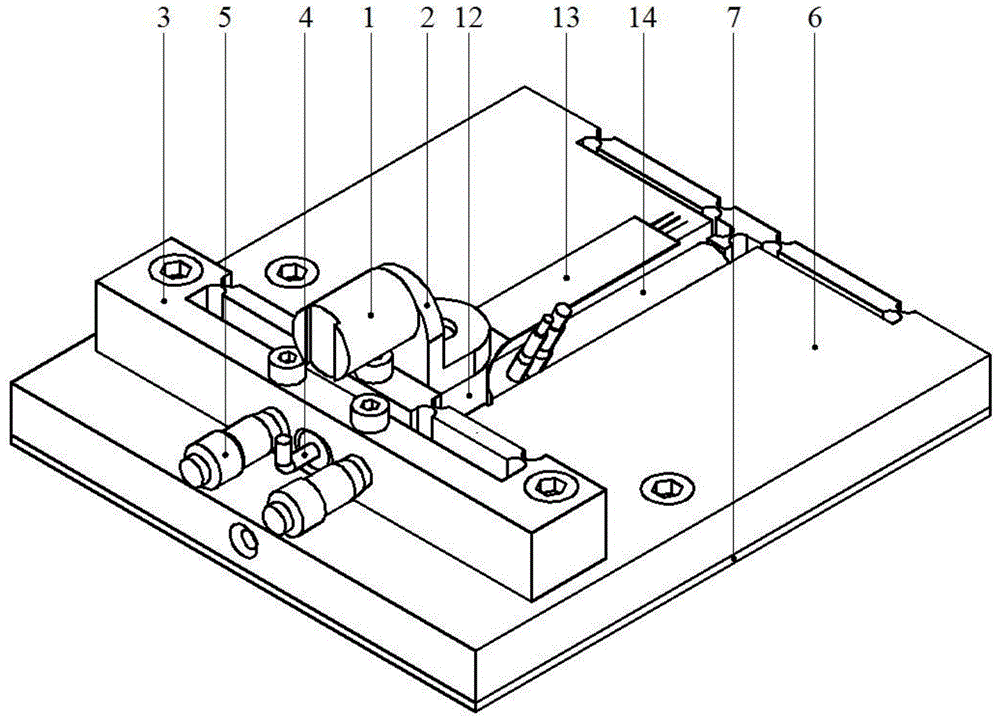

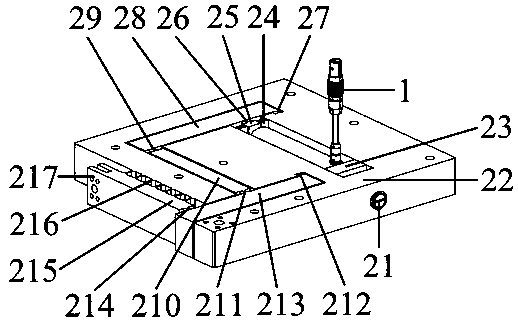

Precision positioning drive-end pre-tightening device

ActiveCN104088871AHigh precisionImprove accuracyAngles/taper measurementsElectric/magnetic position measurementsCapacitive sensingActuator

The invention discloses a precision positioning drive-end pre-tightening device. The precision positioning drive-end pre-tightening device comprises a positioning platform, an actuator, a capacitive sensor, a capacitive sensor support, a pre-tightening block and a thin-film force sensor. A sliding groove is formed in the middle of the positioning platform. The pre-tightening block, the thin-film force sensor and the actuator are sequentially arranged in the sliding groove. The capacitive sensor support is fixed to the positioning platform. Three connecting rods which are sequentially connected with one another through flexible hinges are arranged on one side of a support body of the capacitive sensor support in the axial direction. The end face of the capacitive sensor is parallel to the upper side face of the pre-tightening block, and a gap is formed between the end face of the capacitive sensor and the upper side face of the pre-tightening block. The positioning platform is further provided with a two-stage pre-tightening device for pre-tightening the pre-tightening block. The precision positioning drive-end pre-tightening device can meet the requirements for precision positioning, precision and ultra-precision machining, precision operation and precision measurement and can also meet the requirements of a micro electromechanical system and related fields. The precision positioning drive-end pre-tightening device is simple in technological means and easy to realize, and has outstanding essential characteristics and remarkable progress compared with the prior art.

Owner:SOUTH CHINA UNIV OF TECH

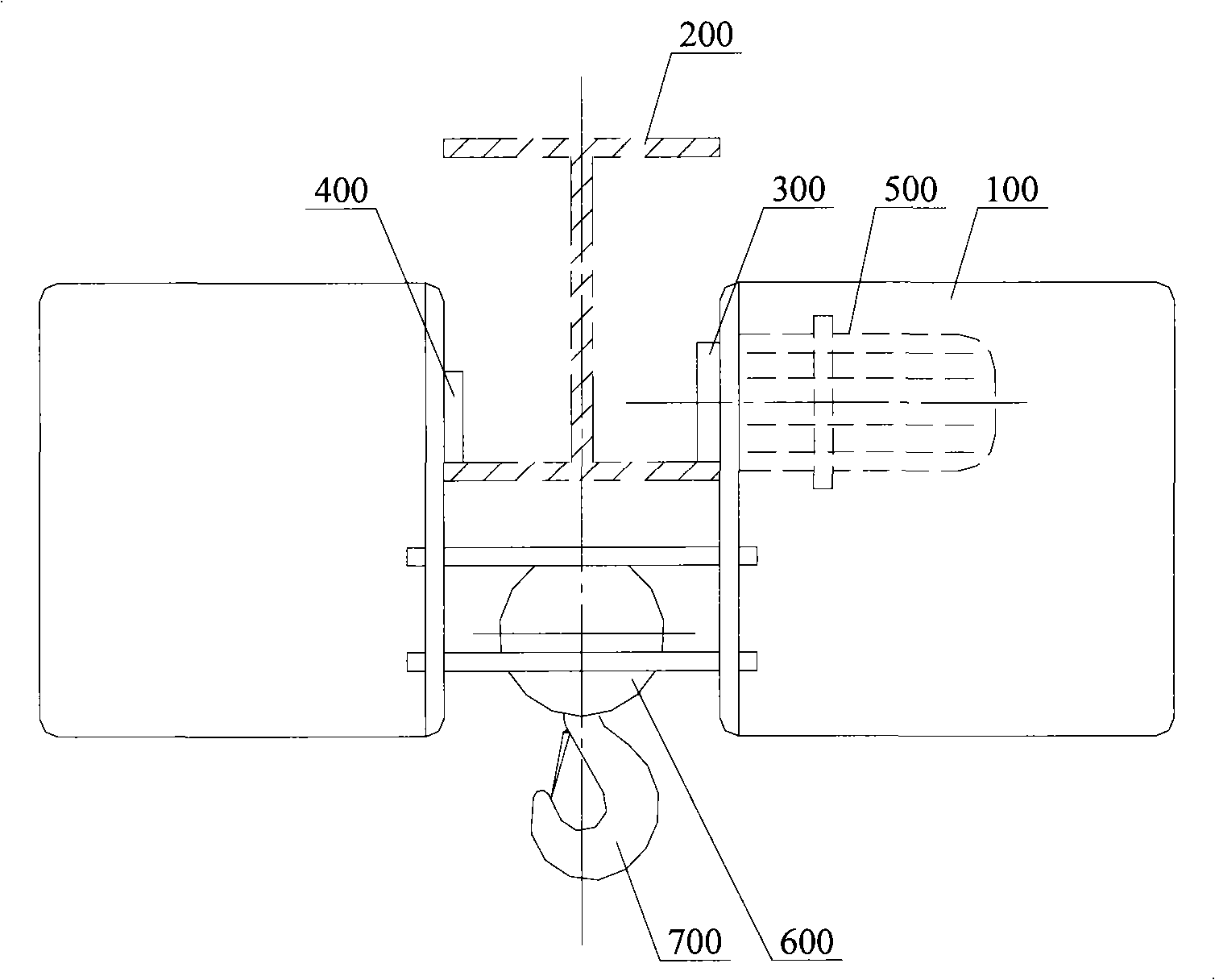

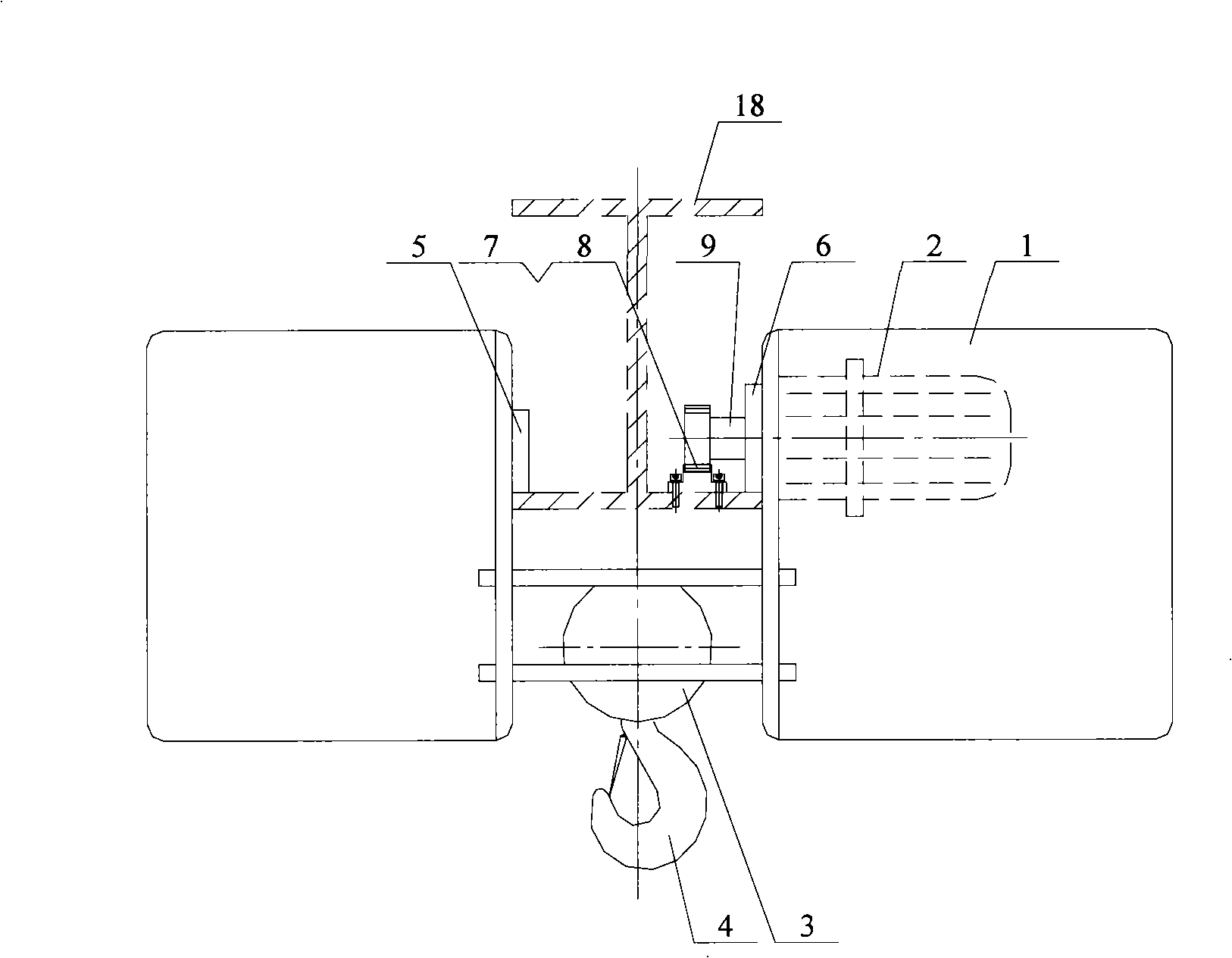

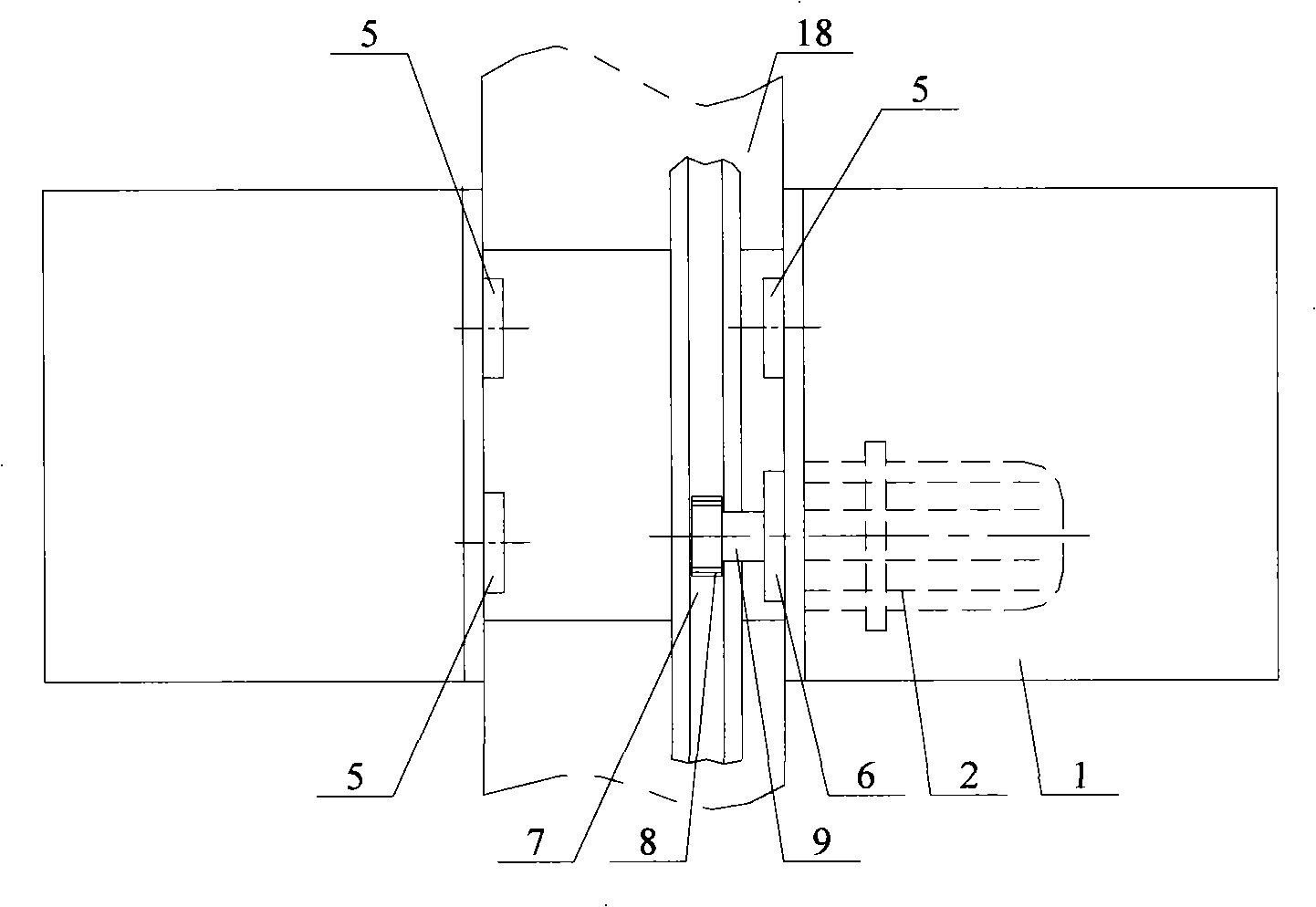

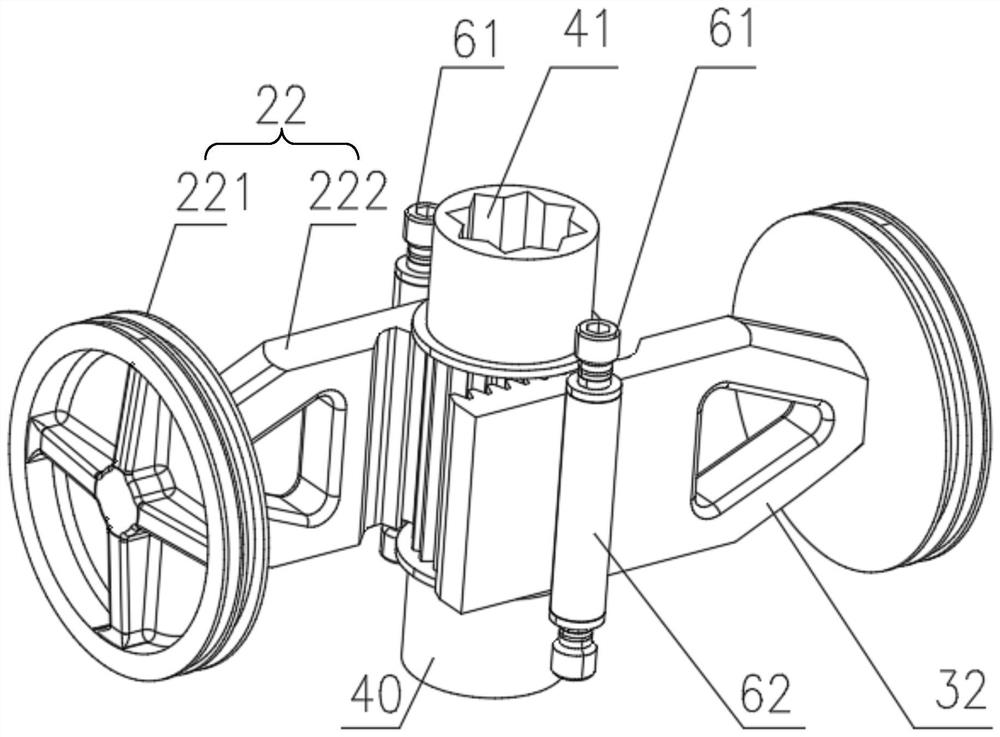

Electric gourd and lorry using the same

InactiveCN101298309ASatisfy climbing abilityAvoid side forceWinding mechanismsWagons/vansGourdGear wheel

The invention discloses an electric hoist and a railway truck that adopts the electric hoist. Aiming at the problem that the existing electric hoist has poor climbing capacity, the electric hoist of the invention includes a travel carriage, a traveling electric motor, a driving gear and a rack that engages with each other; the driving gear is fixedly connected with the wheel axle of the traveling wheel and rotates coaxially, the rack is fixedly arranged on the upper surface of the lower edge of the steel I-beam along the length direction of the steel beam. As the gear is driven by the electric motor, then the travel carriage is actuated along the steel I-beam to finish the traveling operation. During the travel of the carriage, the traveling wheel is designed to carry load, the transmission mechanism of the gear rack is designed to provide driving power, and the climbing capacity can reach 20 permillage. Preferably, a regulation electric motor and a corresponding driving mechanism are added to control the engagement and disengagement of the gear rack; the gear rack disengagement mode is adopted under the normal lifting conditions to improve the running speed; and the gear rack engagement mode is adopted when the gradient is relatively higher.

Owner:CRRC QIQIHAR ROLLING CO LTD

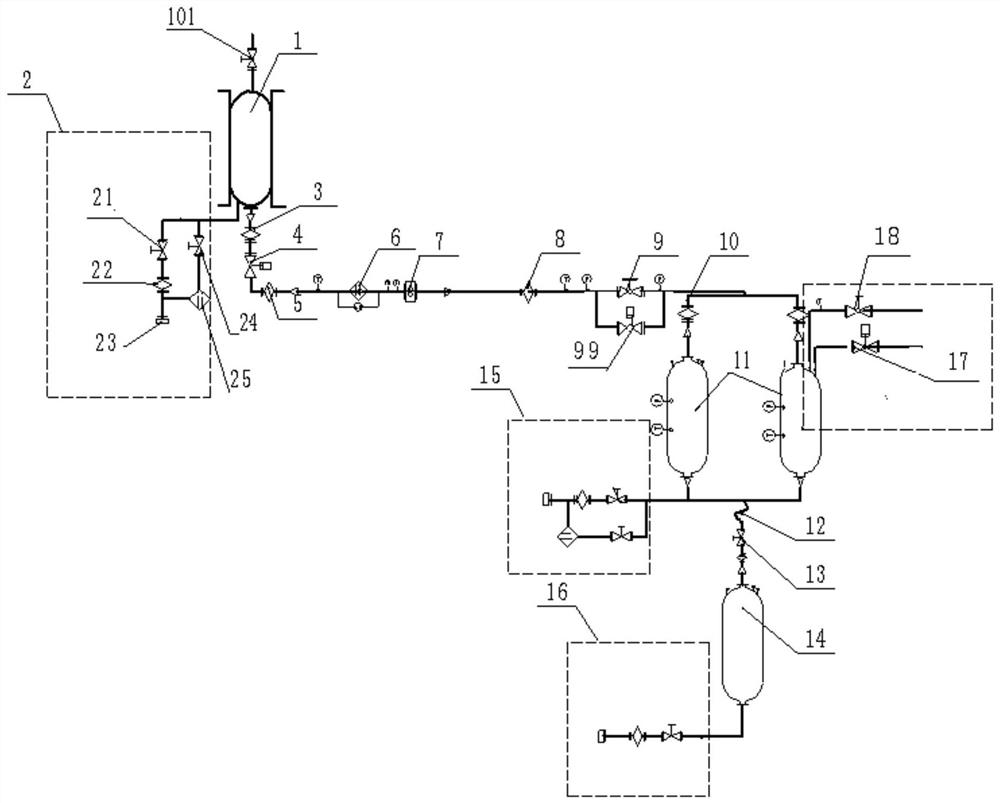

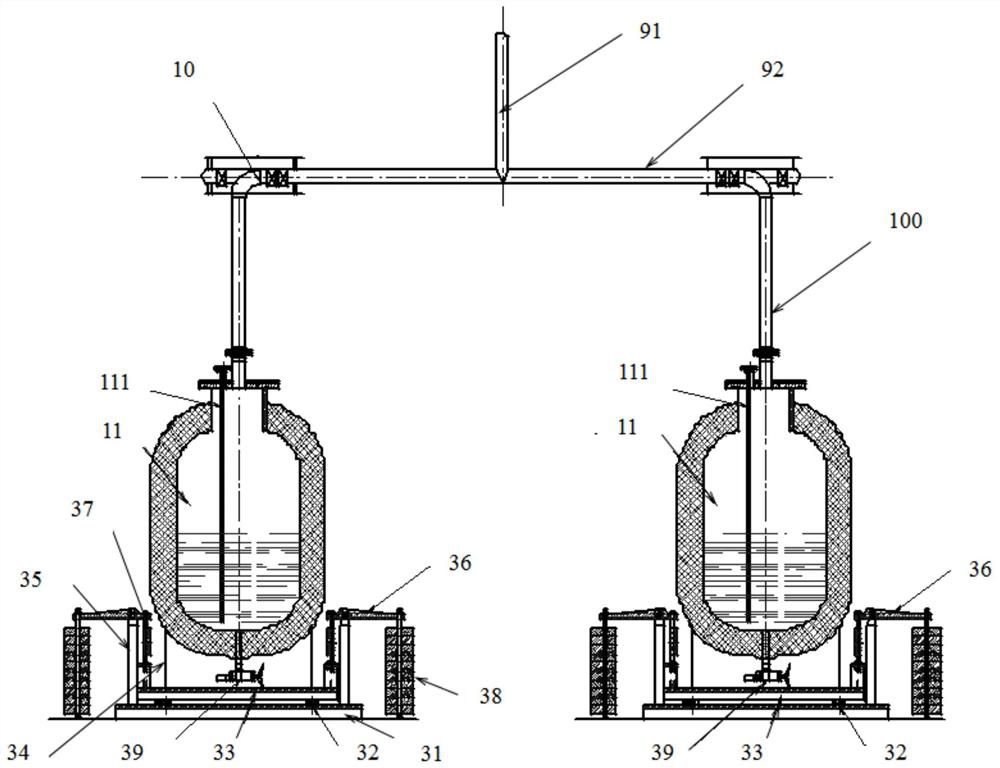

Flowmeter calibration system and method for cryogenic propellant rocket engine

ActiveCN113588047AWeighing effectAvoid side forceTesting/calibration apparatusContainer filling methodsIsolation valveStress sensors

The invention relates to a low-temperature propellant rocket engine, in particular to a flowmeter calibration system and method for the low-temperature propellant rocket engine, and aims to solve the problems that when an existing low-temperature propellant rocket engine uses a flow meter for flow measurement, the measurement accuracy of the flowmeter is low, and only reference flow meter calibration in a short time period can be carried out. According to the technical scheme, the flowmeter calibration system of the low-temperature propellant rocket engine comprises a container filling unit, a container, a supply pipeline, a weighing unit, a rapid recovery container, a weighing filling recovery unit and a recovery unit which are sequentially connected; the container filling unit is used for connecting a tank car and a container; the supply pipeline comprises a temperature sensor, a pressure sensor, and a first isolation valve, a reference flowmeter, a calibration flow adjusting hand valve, a vertical main pipe and N horizontal pipes which are sequentially connected through a pipeline, wherein the horizontal pipes are evenly distributed on the circumference. The invention further provides a flowmeter calibration method of the low-temperature propellant rocket engine.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Squeezing device for a flat-body wiper and cleaning system

ActiveUS8099824B2Performed easily and efficientlyPrecise positioningBoard cleaning devicesCarpet cleanersEngineeringFunnel shape

A squeezing device for a wiping cover of a flat-body wiper, the wiper cover hanging downward and partially detached from a wiper plate of the flat-body wiper in a vertical position of the wiper plate, the wiper plate including a downward facing pressure surface in the vertical position. The squeezing device includes a funnel-shaped squeezing shaft having a counterpressure surface in a lower region of the squeezing shaft. The squeezing shaft is configured to receive the wiper cover and at least a portion of the wiper plate in the vertical position of the wiper plate so that a squeezing pressure of the pressure surface against the counterpressure surface squeezes out the wiper cover. The squeezing shaft includes stabilizing devices configured to stabilize the wiper plate against tipping relative to a first plane from the vertical position. In addition a cleaning system including the squeezing device and a method of squeezing a wiping cover of a flat-body wiper with the squeezing device.

Owner:CARL FREUDENBERG KG

Guiding device of upper tapered roller box body of ring rolling machine

InactiveCN101695734AAvoid side forceImprove work efficiencyMetal rollingEngineeringMechanical engineering

The invention discloses a guiding device of an upper tapered roller box body of a ring rolling machine, which comprises a frame and the upper tapered roller box body. The frame is provided with four track planes. The included angles between the track planes and both lateral surfaces of the upper tapered roller box body are all 45 degrees. Each track plane is provided with two slide blocks. The slide blocks are arranged on regulation blocks respectively. One side of each regulation block is provided with a fixed block. A contact surface between the fixed block and the regulation block is a jagged surface consisting of a plurality of inclined planes. Each fixed block is provided with a regulation hole. An elastic bolt is arranged in each regulation hole. The elastic bolts are all connected with the regulation blocks. Both upper and lower ends of each fixed block are provided with an upper pressing plate and a lower pressing plate. Each upper pressing plate is provided with an upper regulation top thread. Each lower pressing plate is provided with a lower regulation top thread. The guiding device can overcome a side force generated by the upper tapered roller box body when the ring rolling machine works, effectively reduces the wear condition of the guiding device, can improve the work efficiency of the ring rolling machine, and is favorable for saving production cost for enterprises.

Owner:济南沃茨数控机械有限公司

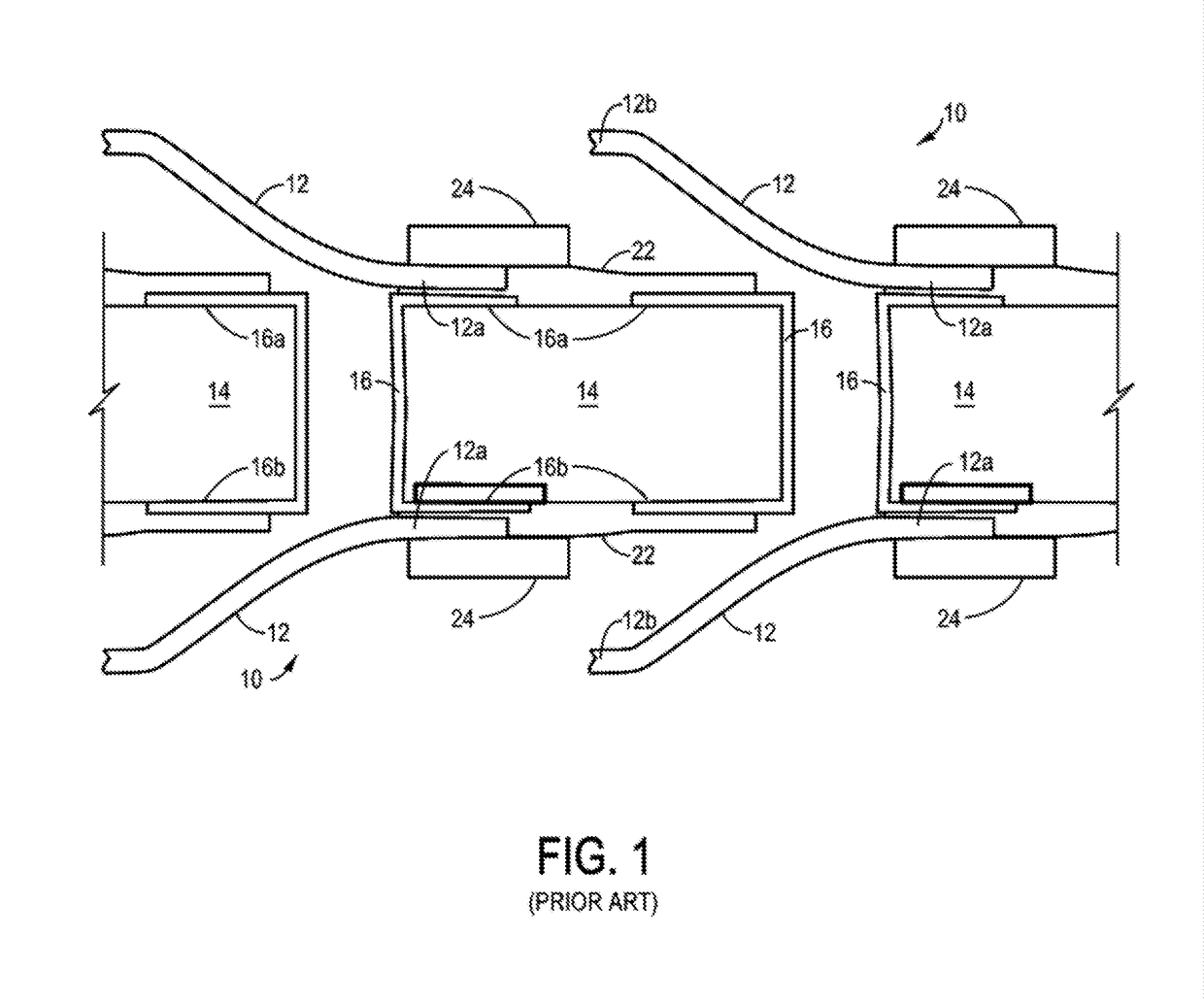

Electrical Connector with Electrical Contacts Protected by a Layer of Compressible Material and Method of Making It

InactiveUS20180358770A1Assist in their functioningMaximum protectionContact member cases/bases manufactureContact member assembly/disassemblyCompressible materialInterconnection

Disclosed is an electrical connector having a substrate and movable electrical contacts which are mounted to the substrate and extend a distance D from the substrate. A layer of compressible material (such as a foam or elastomeric material) is positioned on the substrate adjacent at least some of the electrical contacts and ideally has an uncompressed thickness slightly greater than the distance D to provide for protection of the electrical contacts. When a mating electrical device such as an electrical connector or other circuit member is mated to the electrical connector with its electrical contacts and its layer of compressible material, the layer of compressible material is compressed to a thickness less than the distance D, allowing the contacts to make a suitable electrical interconnection to the mating electrical device. The compressible material may be selected which has a force-to-compression plot which includes at least one inflection, defining a first region on one side of the inflection where a given increment of force provides a larger increment of compression and a second region on the other side of the inflection where the same increment of compressive force provides a substantially smaller increment of compression. The compressible material can function to prevent damage to the movable electrical contacts from handling, packing, shipping, assembly, testing, connection and / or mating of the connector.

Owner:NEOCONIX INC

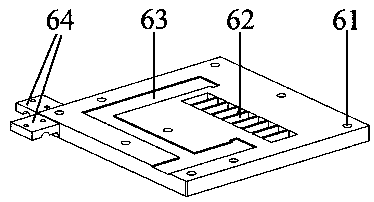

Multi-degree-of-freedom nanometer positioning platform based on flexible parallel mechanism

ActiveCN109502542AHigh precisionHigh output stiffnessMicrostructural devicesPosition/direction controlMicro nanoHigh bandwidth

The invention relates to the technical field of micro-nano machining and manufacturing devices, in particular to a multi-degree-of-freedom nanometer positioning platform based on a flexible parallel mechanism. Branch movement chains include a first branch movement chain and a second branch movement chain; one end of the first branch movement chain is connected with a first fixed base, and the other end of the first branch movement chain is connected with an end executor; and one end of the second branch movement chain is connected with the first fixed base, a supporting point is provided by asecond fixed base, and the other end of the second branch movement chain is connected with the end executor. The end executor can realize single-degree-of-freedom output through the multi-axis secondbranch movement chain in a vertical direction; through redundant driving with the nanoscale precision, high output rigidity, high acting force, large load capacity, high bandwidth and high precision in the vertical direction can be realized; and the platform can be used as a main shaft in the fields of micro-nano machining and manufacturing, and the like.

Owner:GUANGDONG UNIV OF TECH

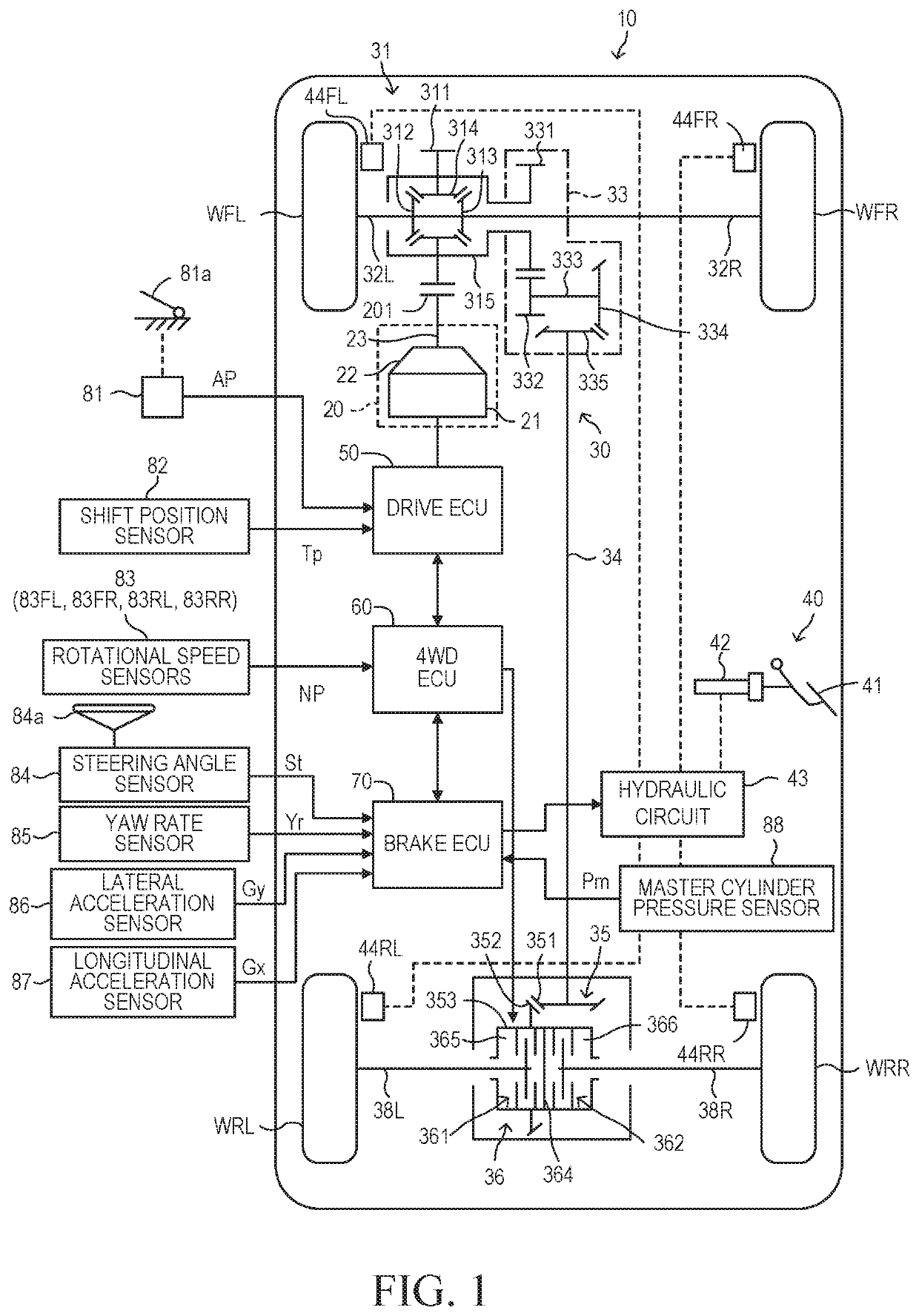

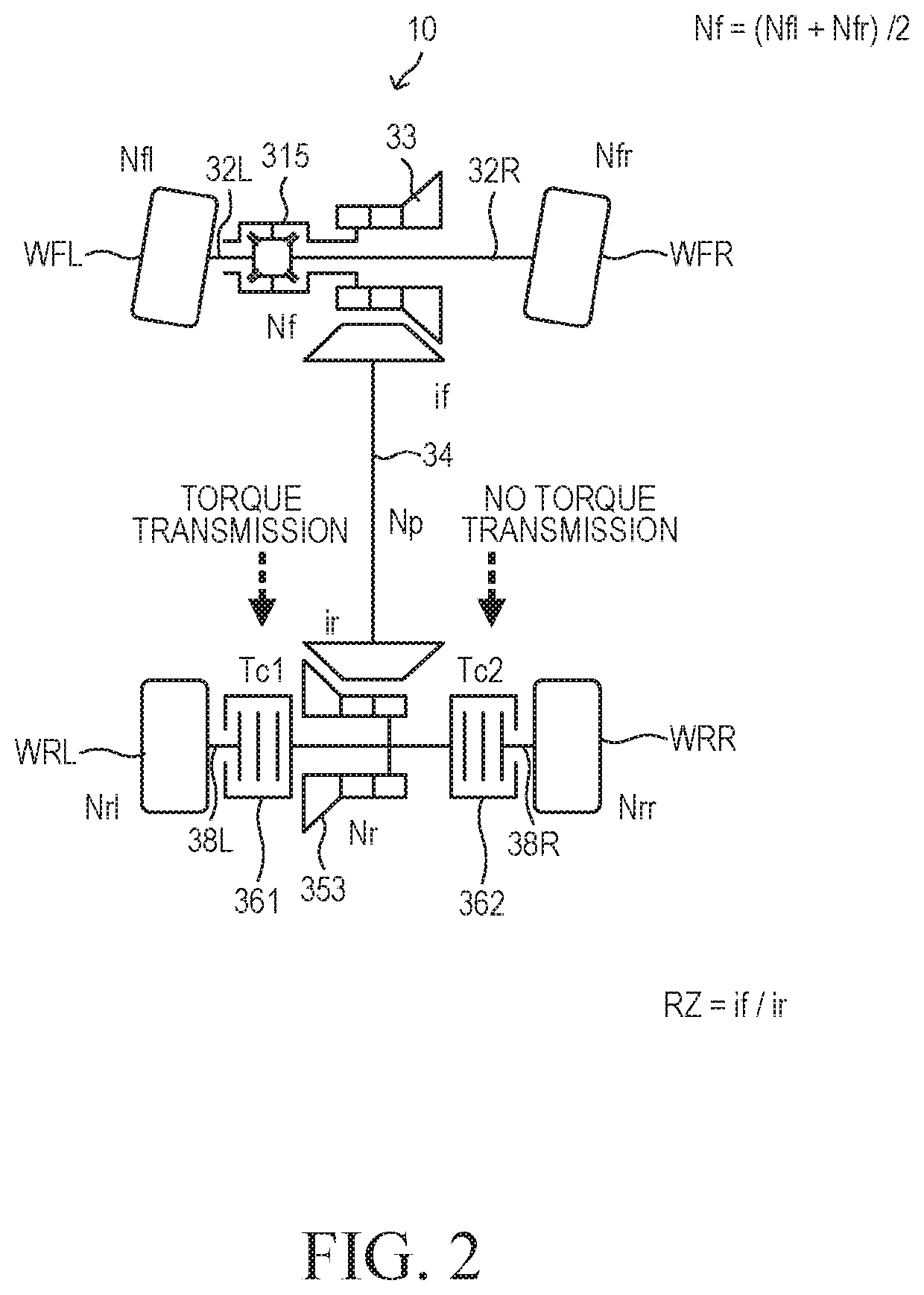

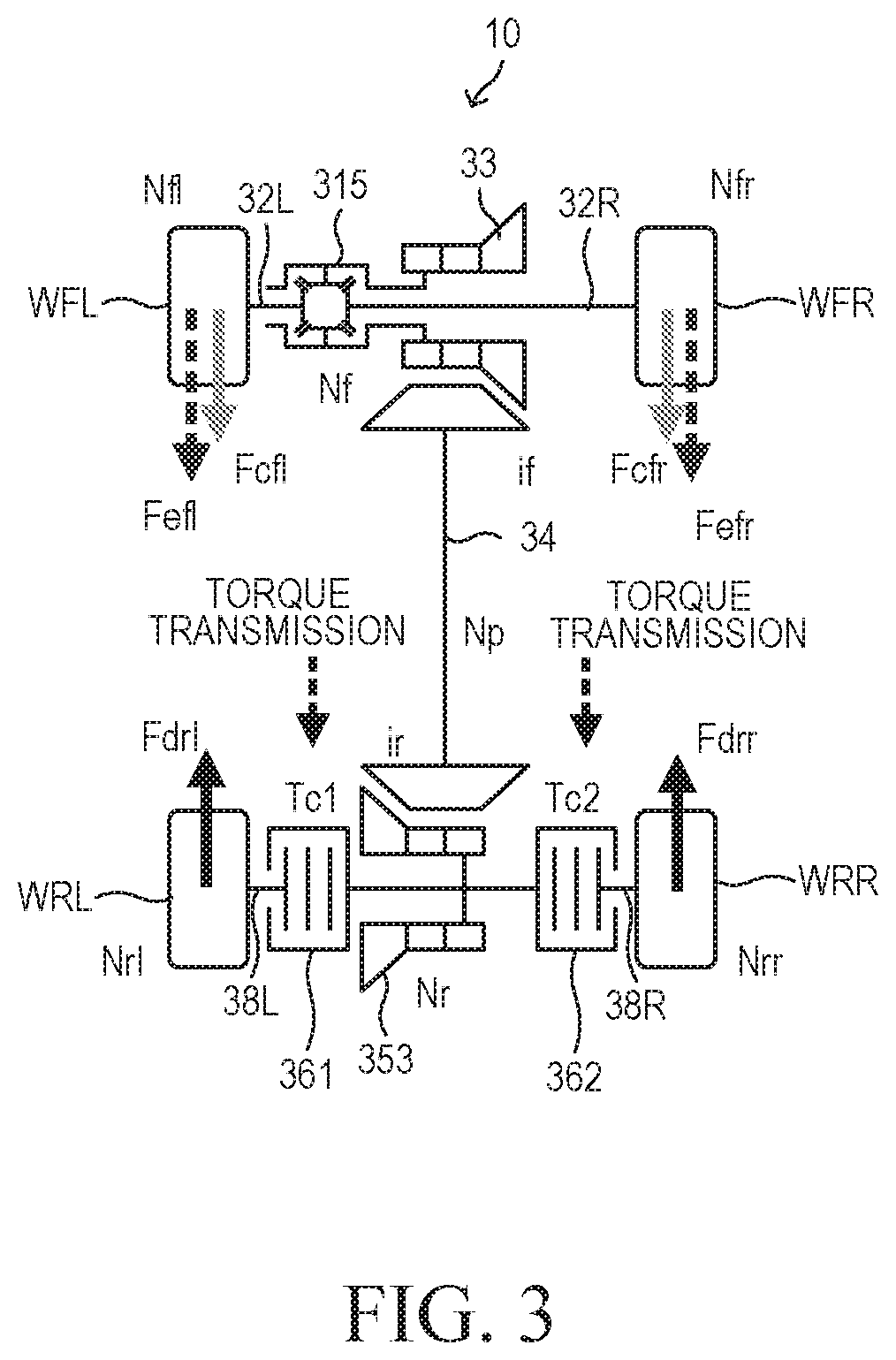

Travel control apparatus for four-wheel drive vehicle

ActiveUS20200108716A1Reduce frequency of occurrenceUndersteer behaviorVehicle sub-unit featuresDifferential gearingsFour-wheel driveWheel drive

Disclosed is a travel control apparatus for a four-wheel drive vehicle in which the states of engagements between a drive output part for secondary drive wheels and left and right secondary drive wheel axles are each changed to a torque transmission state or a torque transmission interruption state. The ratio of rotational speed of the drive output part to the average of rotational speeds of primary drive wheels is greater than 1. When the engagement states corresponding to the secondary drive wheels on the outer and inner sides of a turning locus have been set to the torque transmission state and the torque transmission interruption state, respectively, the engagement state having been set to the torque transmission state is changed to the torque transmission interruption state upon determination that an accelerator pedal is not operated and the magnitude of lateral acceleration is equal to or greater than a predetermined threshold.

Owner:TOYOTA JIDOSHA KK

Three-axis cutter servo device based on compliant parallel mechanism

ActiveCN109079552ARealize displacement outputIncrease stiffnessFeeding apparatusHigh bandwidthHigh stiffness

The invention relates to the technical field of nano-positioning, measuring and machining devices, in more particularly to a three-axis cutter servo device based on a compliant parallel mechanism. Thethree-axis cutter servo device comprises outer side fixing bases, an inner side fixing base, uniaxial nano-positioning platforms and a three-axis end actuator, wherein the uniaxial nano-positioning platforms and the three-axis end actuator transfer motion through compliant hinges and flexible rod pieces. The three-axis end actuator is connected with a cutter and provided with a capacitive sensor,and the capacitive sensor is connected with a controller. The output end of the controller is connected with a piezoelectric ceramic driver, the piezoelectric ceramic driver is connected to the inputends of the uniaxial nano-positioning platforms, and the three-axis end actuator is connected to the output ends of the three uniaxial nano-positioning platforms. According to the three-axis cutter servo device based on the compliant parallel mechanism, nanoscale linear displacement of the three-axis end actuator can be output, meanwhile, end output displacement is directly measured through the sensor, feedback control is conducted, and the three-axis cutter servo device has high stiffness, high precision, the high bandwidth, the large stroke, the high speed, high acceleration, the large bearing capacity and excellent decoupling performance.

Owner:GUANGDONG UNIV OF TECH

Intelligent pressure relief device

InactiveCN105257877ARealize two-way pressure reliefRainproofOperating means/releasing devices for valvesEqualizing valvesControl systemPositive pressure

The invention discloses an intelligent pressure relief device. The intelligent pressure relief device comprises a base, a positive-pressure valve cover, a negative-pressure valve cover and a spring, wherein the positive-pressure valve cover is rotationally connected with one side of the base; when the positive-pressure valve cover is closed, the positive-pressure valve cover and the base are in sealing fit; the negative-pressure valve cover is positioned at the inner side of the positive-pressure valve cover, and is smaller than the positive-pressure valve cover; the negative-pressure valve cover is connected with the positive-pressure valve cover through the spring; a hole is formed in the positive-pressure valve cover; and when the negative-pressure valve cover is closed under the effect of spring force, the hole is covered. The intelligent pressure relief device can realize two-way pressure relief thereof through the fit between the positive-pressure valve cover and the negative-pressure valve cover through the spring and the like, and further comprises a control system to realize such functions as remote control, ventilation and pressure re-relief.

Owner:BEIJING SFD TECH CO LTD

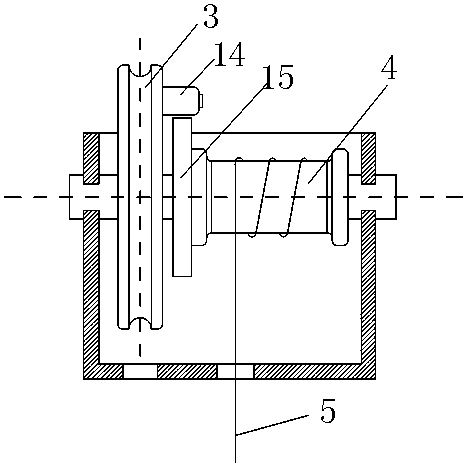

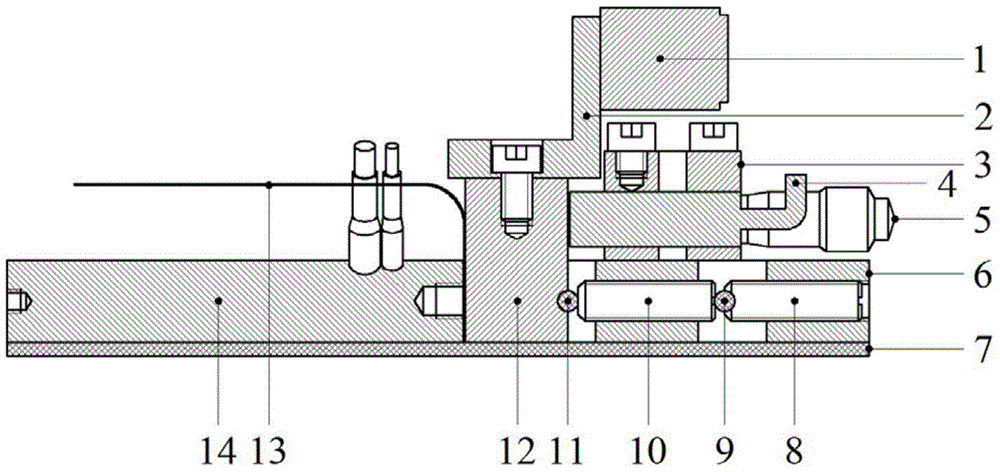

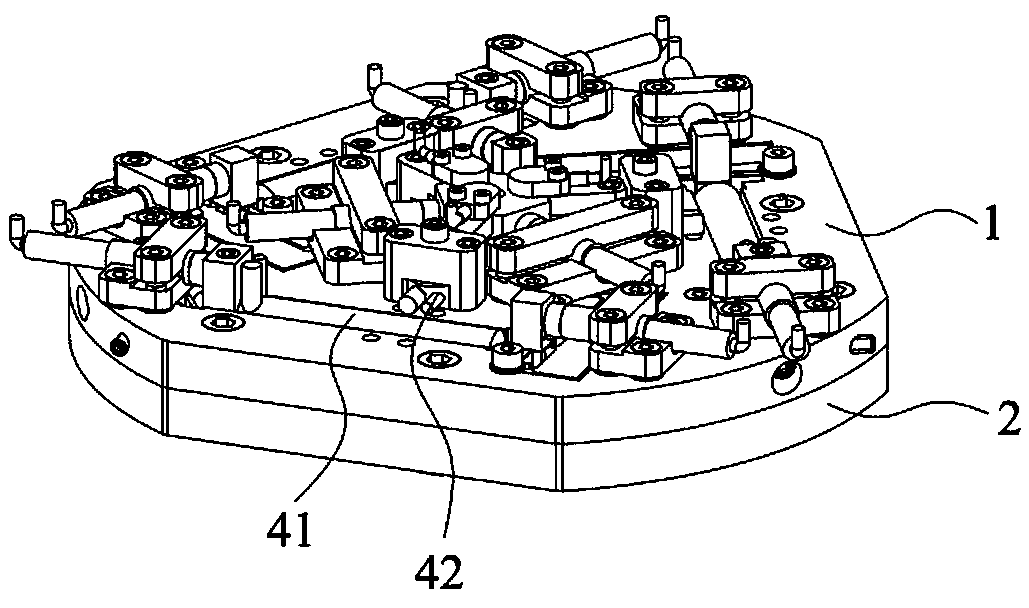

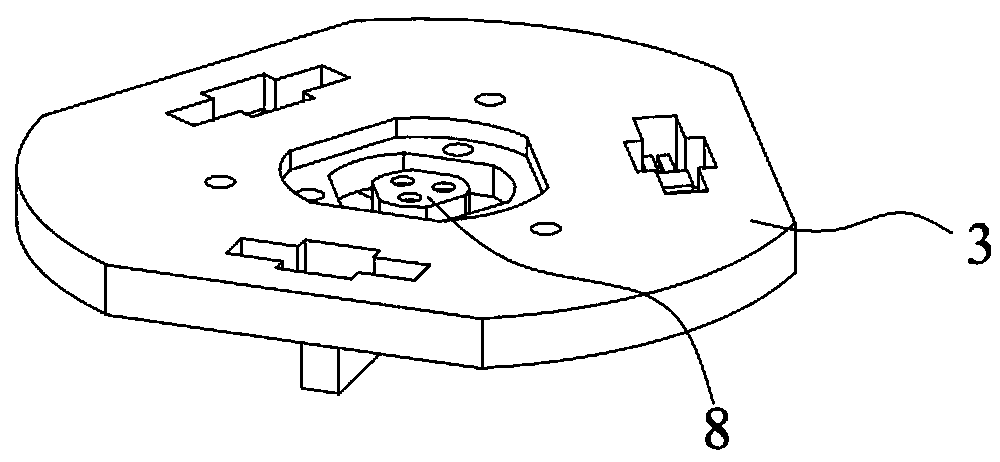

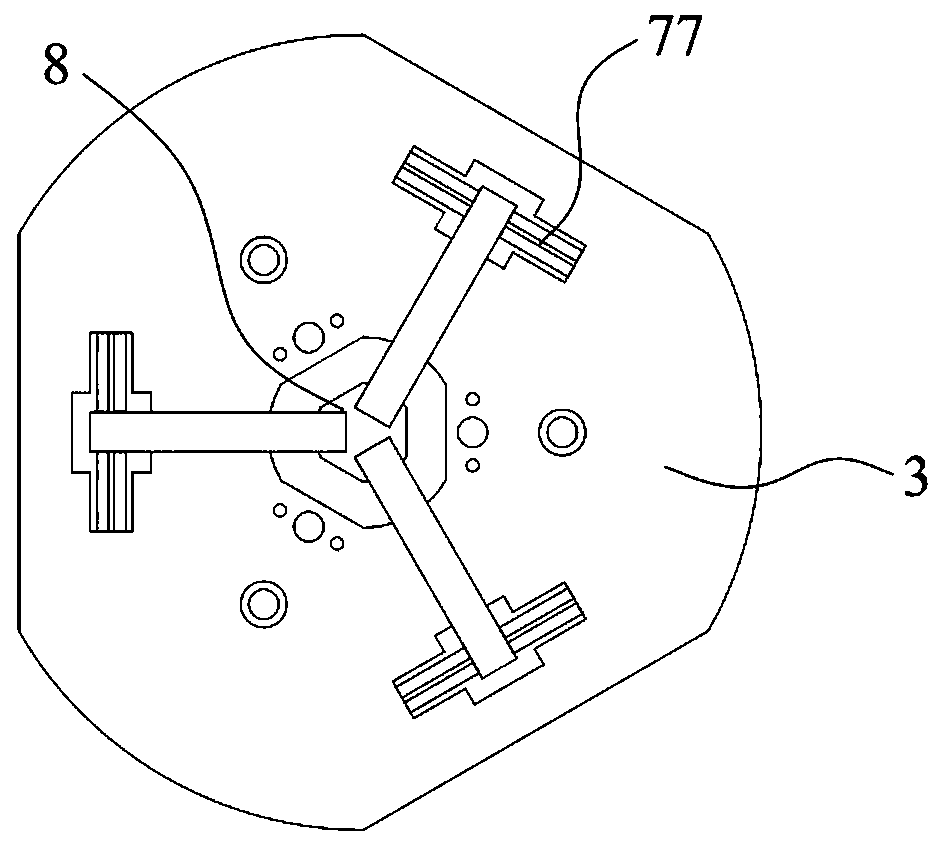

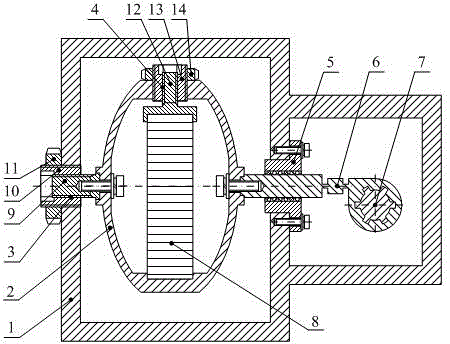

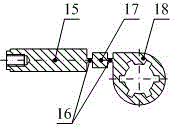

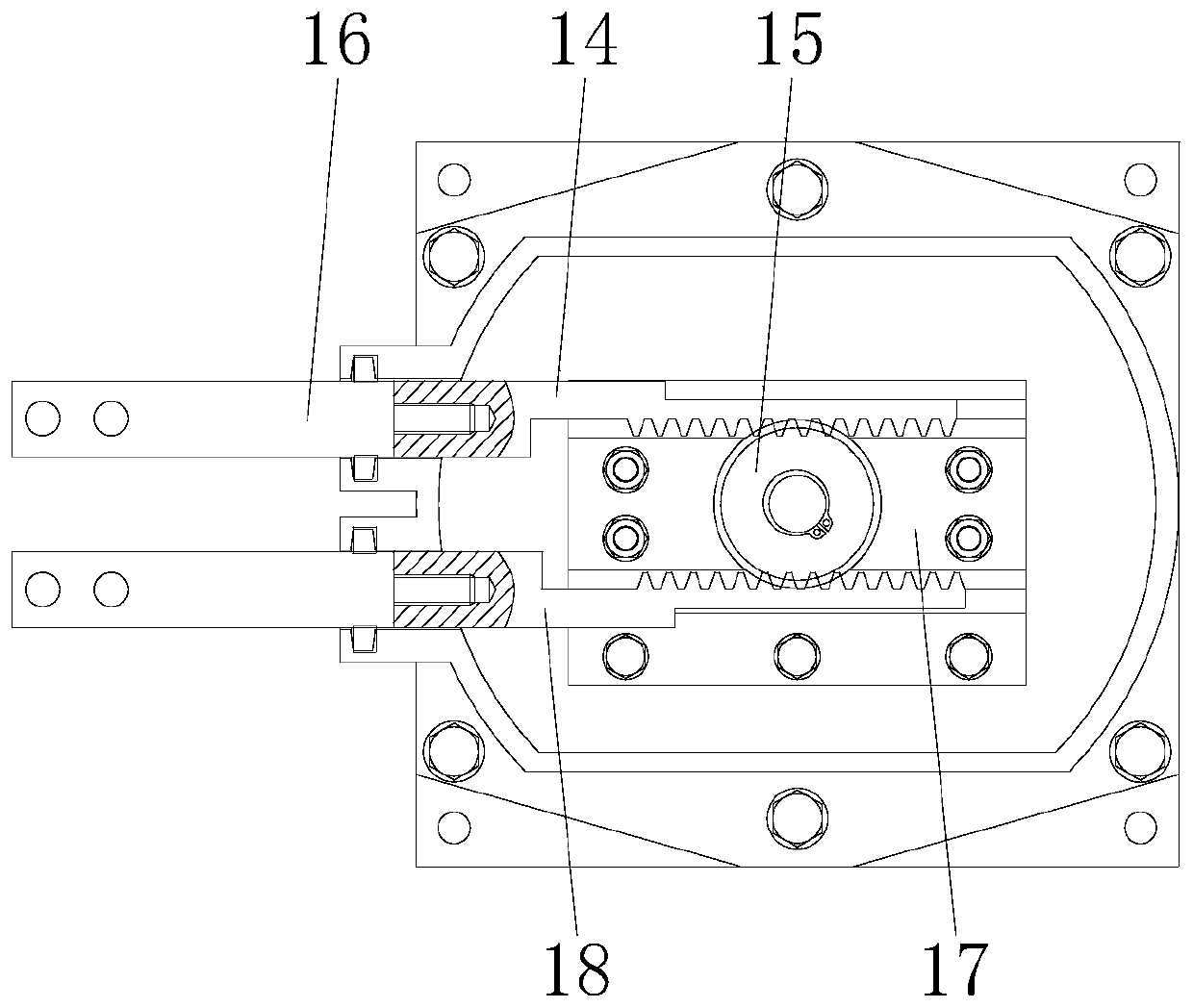

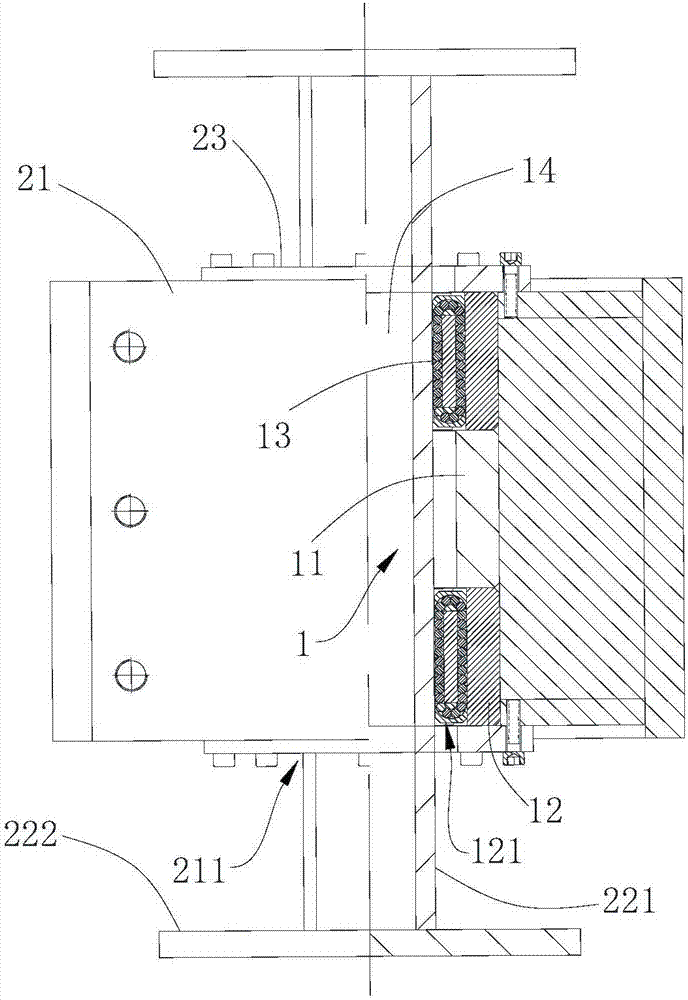

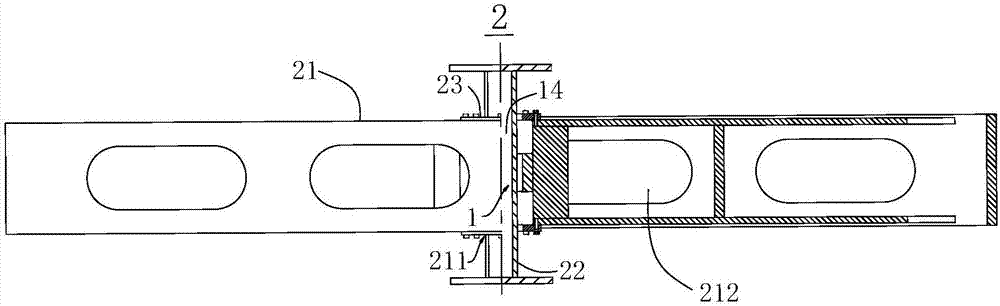

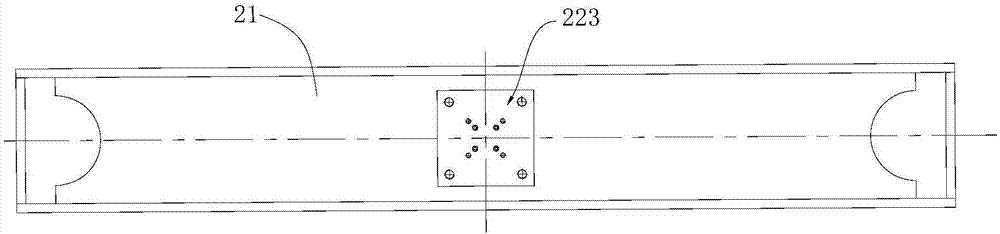

Micro-displacement amplification and conversion device

InactiveCN105489751AMeet functional requirementsHigh magnificationPiezoelectric/electrostrictive devicesIntegrated designEngineering

The invention discloses a micro-displacement amplification and conversion device. The micro-displacement amplification and conversion device comprises a base (1), a micro-displacement amplification mechanism (2) and an intelligent material driver (8) and also comprises a slight zero adjustment mechanism (3), a pre-tightening adjustment mechanism (4), a linear bearing (5), a displacement conversion mechanism (6) and an output shaft (7), wherein the micro-displacement amplification mechanism (2) is used for amplifying micro-displacement generated by the intelligent material driver (8) according to a lever principle and structural elastic deformation, the displacement conversion mechanism (6) is used for converting linear displacement output from the micro-displacement amplification mechanism (2) into angular displacement to be transferred to the output shaft (7) through a key under the joint effects of a transmission rod (15), a flexible hinge (16), a connection rod (17) and an eccentric wheel (18), and the pre-tightening adjustment mechanism (4) and the micro-displacement amplification mechanism (2) are jointly used for applying pre-tightening force onto the intelligent material driver (8). The micro-displacement amplification and conversion device adopts an integrated design and is compact and high-efficiency in structure, and the function is full and simple.

Owner:BEIJING MECHANICAL EQUIP INST

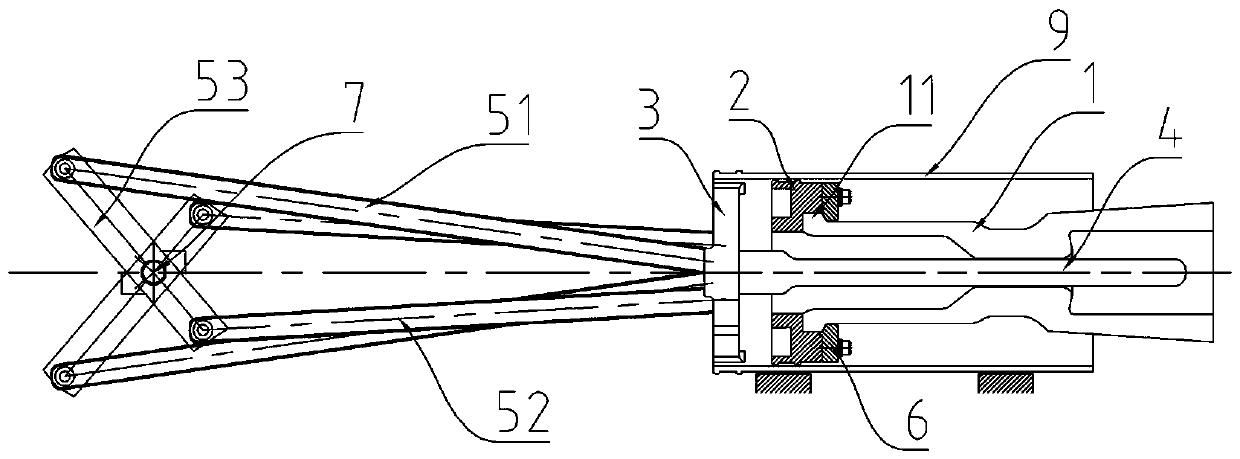

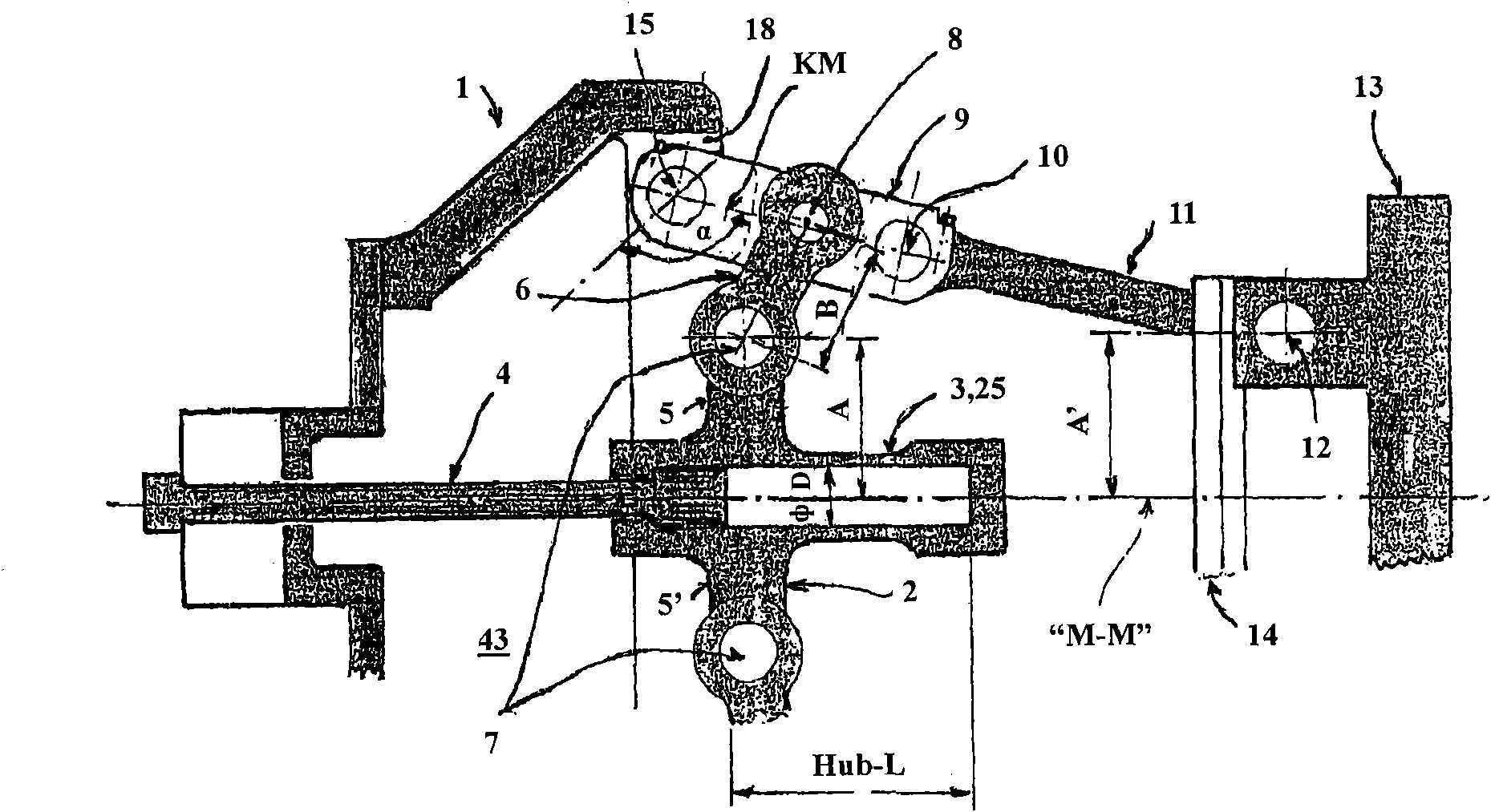

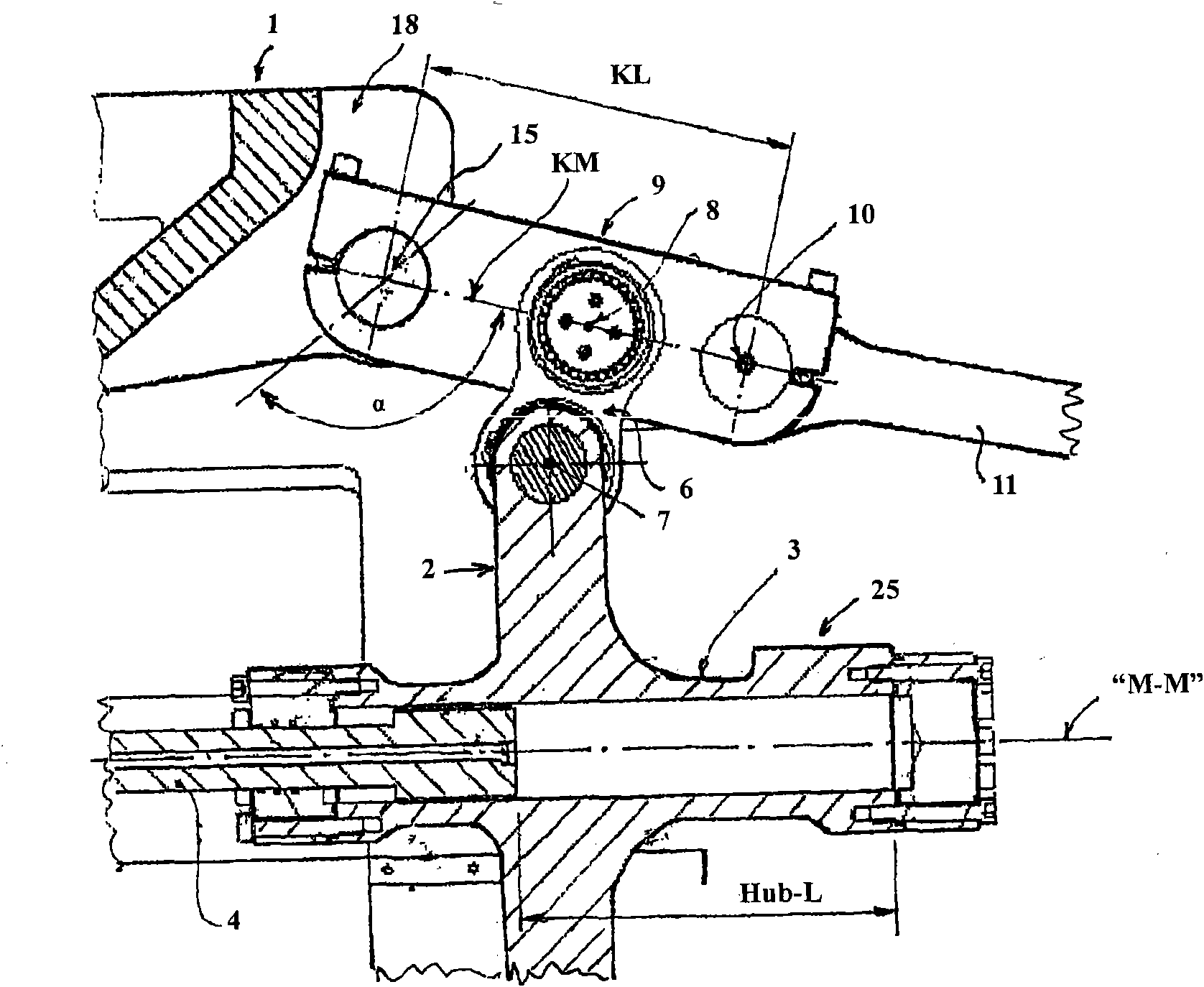

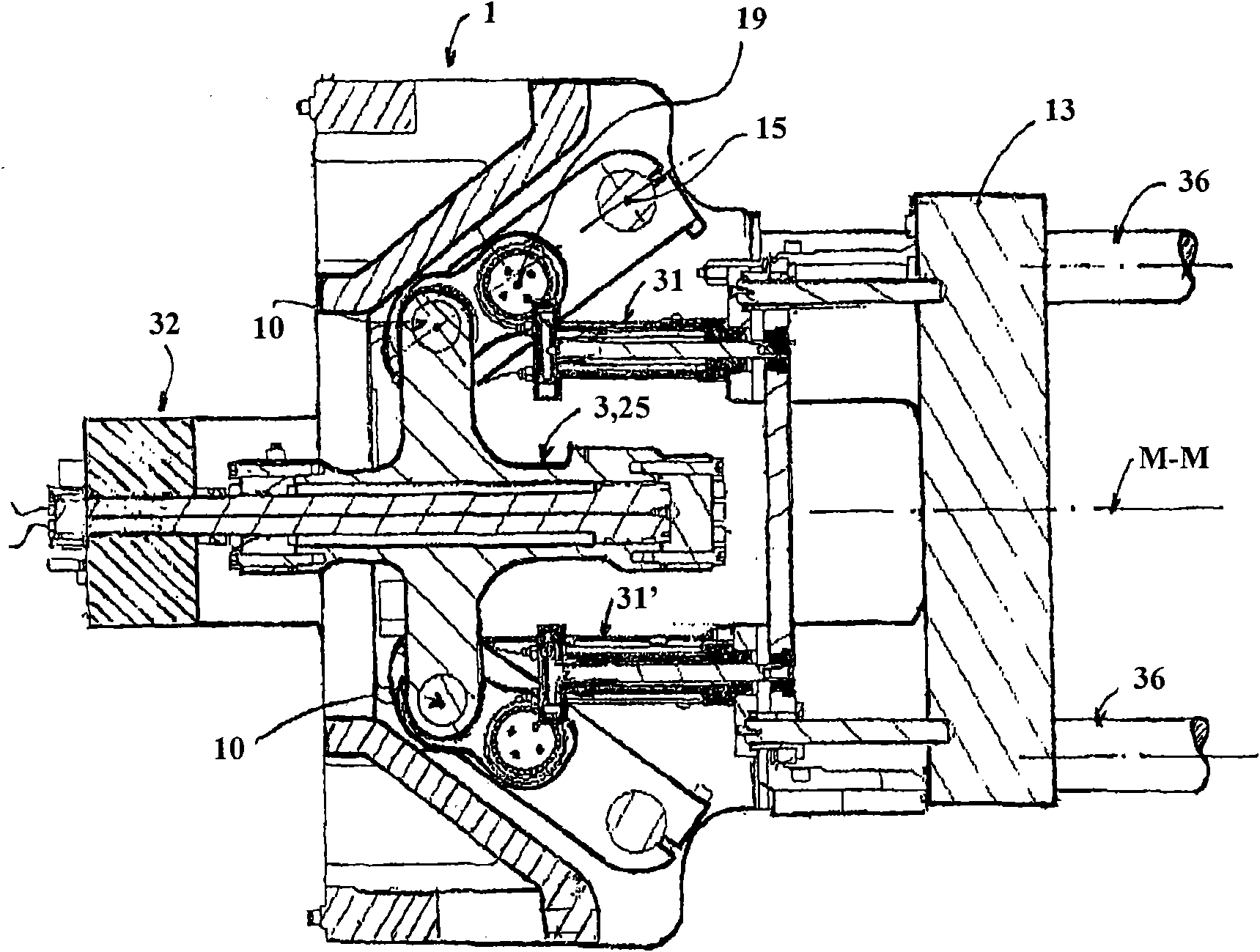

Process for the mould closure of an injection moulding machine, and mould closure

The invention relates to a process for the mould closure of an injection moulding machine comprising a supporting element (1), a moveable tool clamping plate (13), 5-point toggle levers and a hydraulic drive (25) for the crosshead (2), and also to a mould closure. The crosshead drive is arranged between the supporting element (1) and the moveable tool clamping plate (13). The individual 5-point toggle levers are each embodied with a toggle lever (9), a mould movement lever (11, 11') and an expanding bracket (6). The movements for the mould closure are transmitted to the toggle levers (9) via expanding brackets (6). The expanding brackets (6) act in a central region of the toggle levers (9). The toggle levers (9) are embodied as articulated forks (20, 21), wherein the expanding brackets (6) act in a transverse web (22) of the articulated forks. The principal reaction forces of the mould forces are transmitted symmetrically to the supporting element (1) without lateral forces. The solution makes it possible to achieve a maximum pivot angle for the toggle levers (9), to use long toggle levers (9) and to achieve a maximum opening stroke for the mould halves.

Owner:NETABTAL MASCHEN

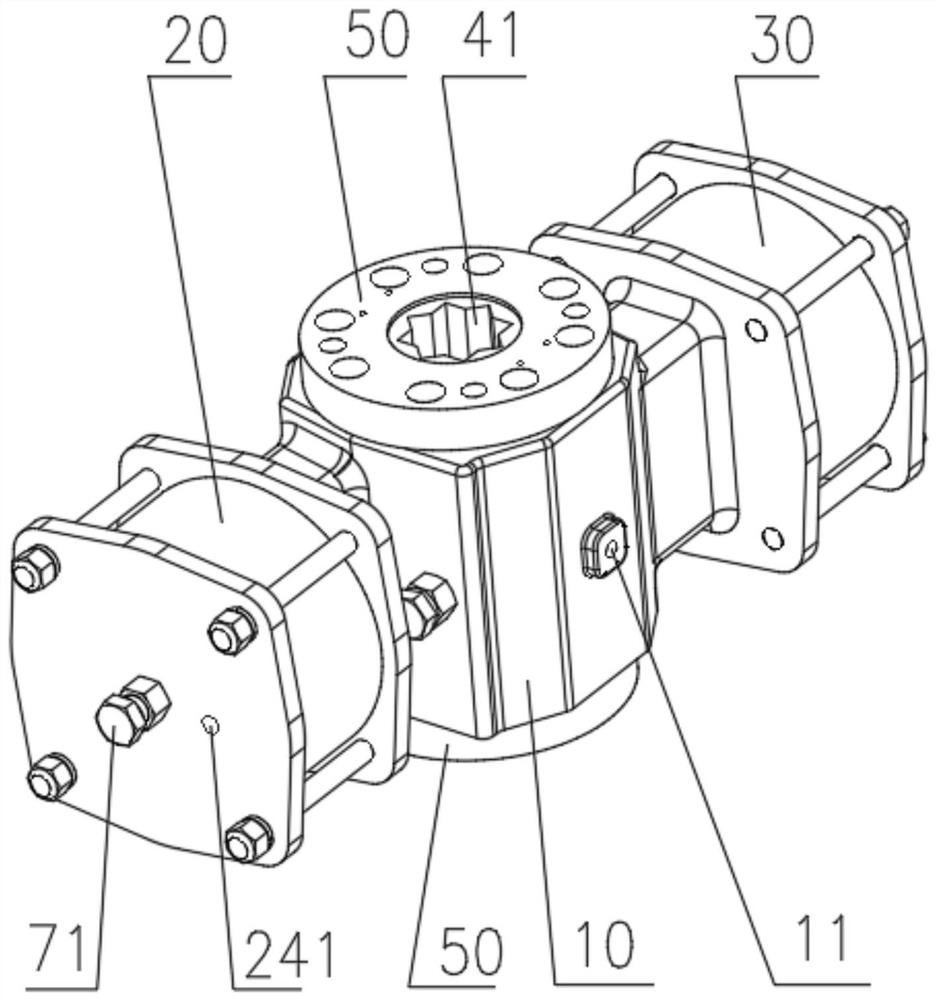

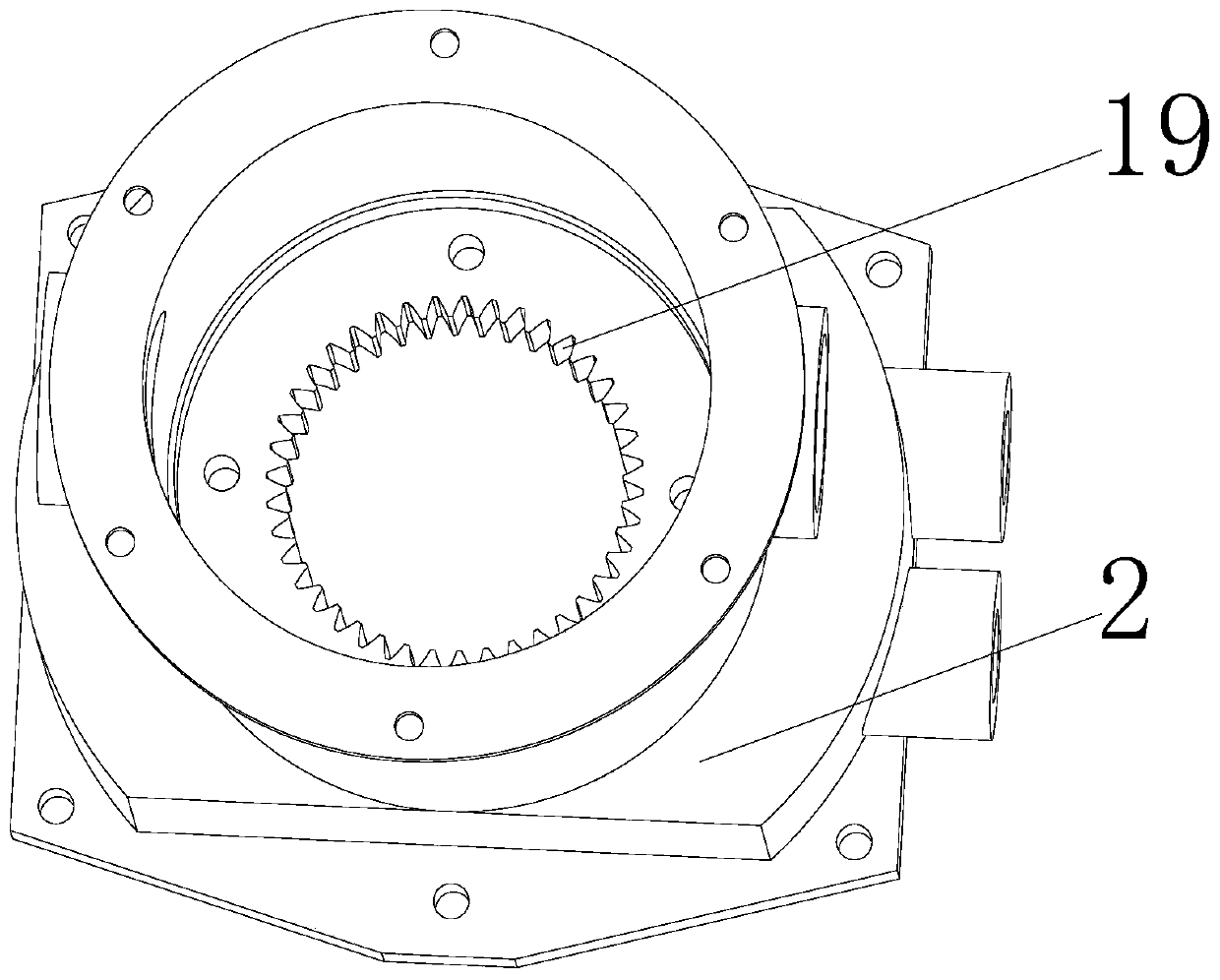

Long-service-life offset type gear and rack pneumatic actuator

PendingCN112728198AAvoid side forceReduce wearOperating means/releasing devices for valvesGear wheelEngineering

The invention relates to the technical field of valve process control, in particular to a long-service-life offset type gear and rack pneumatic actuator. The long-service-life offset type gear and rack pneumatic actuator is characterized in that a cylinder block I of a cylinder I is fixed to a left opening of a box body; a rack I is arranged on a piston rod I of the cylinder I; a cylinder block II of a cylinder II is fixed to a right opening of the box body; a rack II is arranged on a piston rod II of the cylinder II; the two ends of a gear shaft in the box body are rotationally inserted into two flanges respectively; one end of the gear shaft is used for being connected with a valve rod of a valve; the rack I and a rack II are meshed with the gear shaft respectively; an air port I is formed in the box wall of the box body; an air port II is formed in a cylinder cover I of the cylinder I; and an air port III is formed in a cylinder cover II of the cylinder II. When the box body is inflated or exhausts air outwards through the air port I, the piston rod I and the piston rod II move to drive the gear shaft to rotate in two different directions so as to drive the valve rod to rotate to achieve opening or closing of the valve. According to the long-service-life offset type gear and rack pneumatic actuator, long service life is achieved, the action speed is increased, one machine has a plurality of purposes, and batch production is facilitated.

Owner:无锡福斯拓科科技有限公司

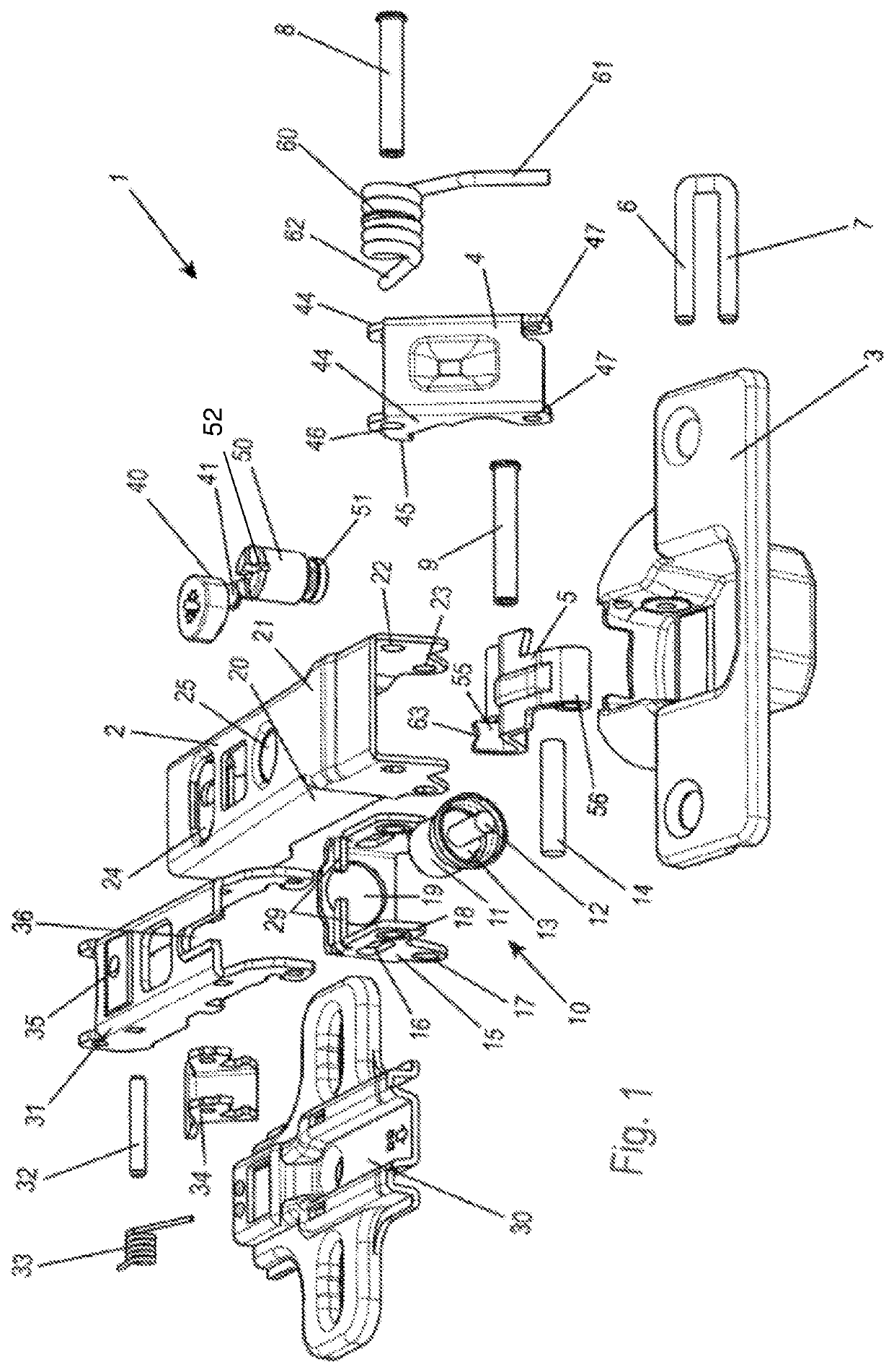

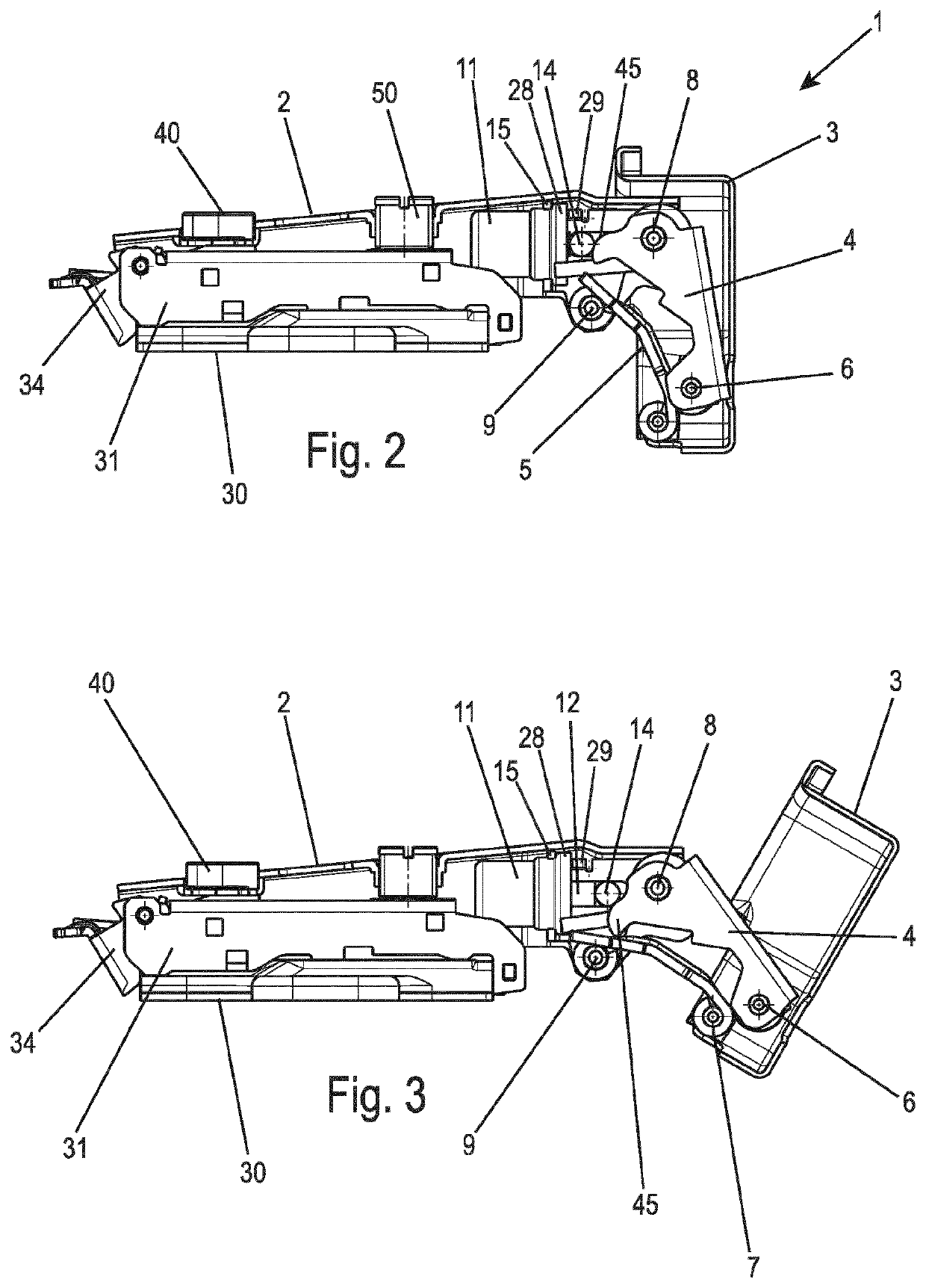

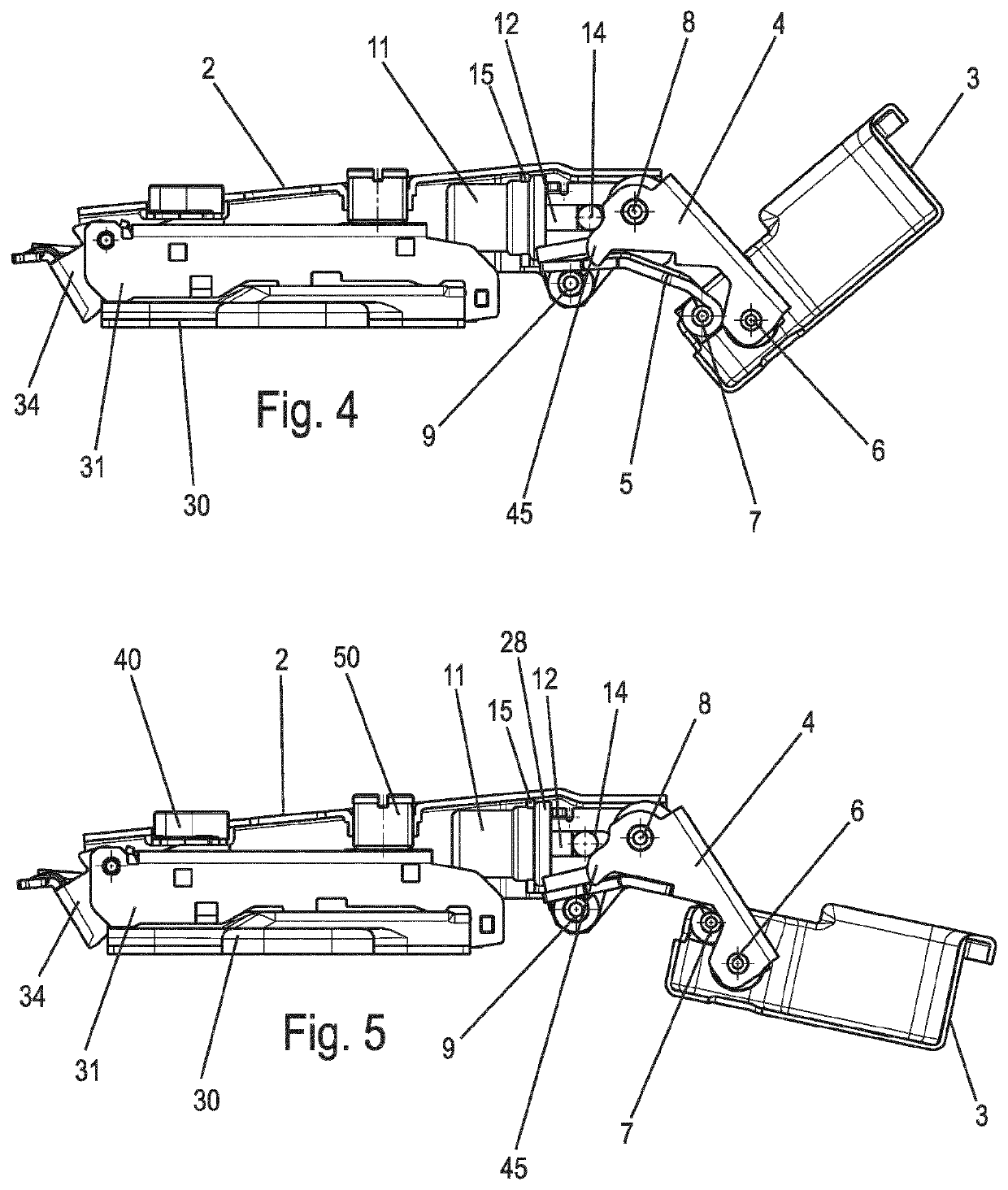

Hinge and method for opening and closing a hinge

ActiveUS11072959B2Optimized damping behaviorSmall installation spaceBuilding braking devicesPin hingesMechanicsPiston rod

A hinge has a side part fixable on a wall and a hinge part, which is pivotable in relation to the side part and is fixable on a door. Two levers are provided on the side part and the hinge part, which are each rotatably mounted on the side part and on the hinge part, and a linear damper having a housing and a piston rod is arranged in the side part.

Owner:HETTICH ONI

Retractable arm type crane and arm pin device thereof

The invention discloses an arm pin device for a retractable arm type crane. The arm pin device comprises a pin shaft, wherein the pin shaft is used for detachably fixing adjacent two joint arms; the pin shaft is provided with a central hole which extends along an axial direction of the pin shaft; a first bolt penetrates through the central hole and is fixedly connected with the axial direction of the pin shaft and movably connected with the peripheral direction of the pin shaft. The arm pin device further comprises a core shaft, wherein one end of the core shaft is fixedly connected with a support of an inner joint arm; the core shaft is provided with a first inner thread matched with the first bolt; the core shaft penetrates through the first thread to be engaged with the first bolt. Therefore, the arm pin device disclosed by the invention adopts a central lifting and pressing structure which takes the core shaft as a main body; in a pressing-down process of the arm pin device, a stressing direction is arranged along the axis of the pin shaft, so that the generation of lateral force is avoided and the joint arms can be smoothly detached. The invention further discloses the retractable arm type crane comprising the arm pin device.

Owner:XUZHOU HEAVY MASCH CO LTD

Drive unit for actuators in a motor vehicle

InactiveUS7992465B2Extended service lifeSuppresses development of noiseGearboxesDrilling rodsMotorized vehicleActuator

Owner:ROBERT BOSCH GMBH

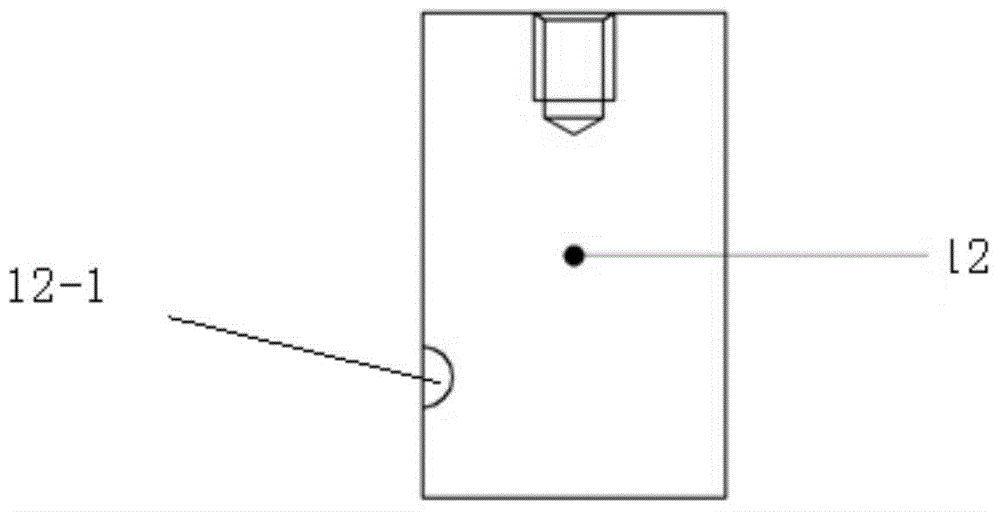

Device and method for measuring excitation force of camshaft to camshaft bearing cover

The invention provides a device and a method for measuring excitation force of a cam shaft on a cam bearing cover. The device takes an existing cam bearing cover as a prototype, is divided into an inner component and an outer component, and is provided with pressure sensing sheets in the horizontal direction and the vertical direction between the inner component and the outer component; the two sides of the horizontal pressure sensing piece make plane contact with the inner component and the outer component respectively, the vertical pressure sensing piece is pre-tightened to the top part of the inner component through using an adjusting bolt at the top part of the outer component, thereby guaranteeing that the excitation force of the cam shaft is accurately transmitted to the pressure sensing piece by adjusting the position relation among the outer component, the inner component, the adjusting bolt and the pressure sensing piece. According to the method, the measuring device is adopted to collect the excitation force generated by the cam shaft in the horizontal direction and the vertical direction respectively, signals output by the pressure sensing piece are converted according to the calibrated relation, and stress data can be obtained. The device and the method can be used for measuring the stress of the cam bearing cover in the horizontal direction and the vertical direction accurately , so as to accurately reflect the excitation force of the cam shaft on the cam bearing cover.

Owner:CHINA FIRST AUTOMOBILE

Double-action cutter driving device of combine harvester

The invention discloses a double-action cutter driving device of a combine harvester. The device includes a bottom cover, a box body, a pulley, a small bevel gear, a large bevel gear, a gear frame welding assembly and a gear welding assembly. The upper portion of the bottom cover is provided with a box body, the box body is internally provided with an inner gear ring, the upper portion of the box body is provided with an upper cover, a belt pulley shaft is installed between the upper cover and the box body, the right end of the belt pulley shaft is provided with a pulley, the small bevel gear is installed on the belt pulley shaft, the small bevel gear is meshed and connected with the large bevel gear, the large bevel gear is installed on the gear frame welding assembly, and the lower portion of the gear frame welding assembly is provided with the gear welding assembly. A cutter bar is connected with a drive device through a rack connection rod with a thread, cutter bar lateral force caused by manufacturing errors and installation errors can be effectively avoided, and the problems are solved that an existing double-action cutter crank connecting rod driving mechanism has large inertia force, low transmission efficiency and a crank offset phenomenon because of a crank and a connection rod, a cutter bar produces lateral force, the operation reliability is poor, and the size of the mechanism is large.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

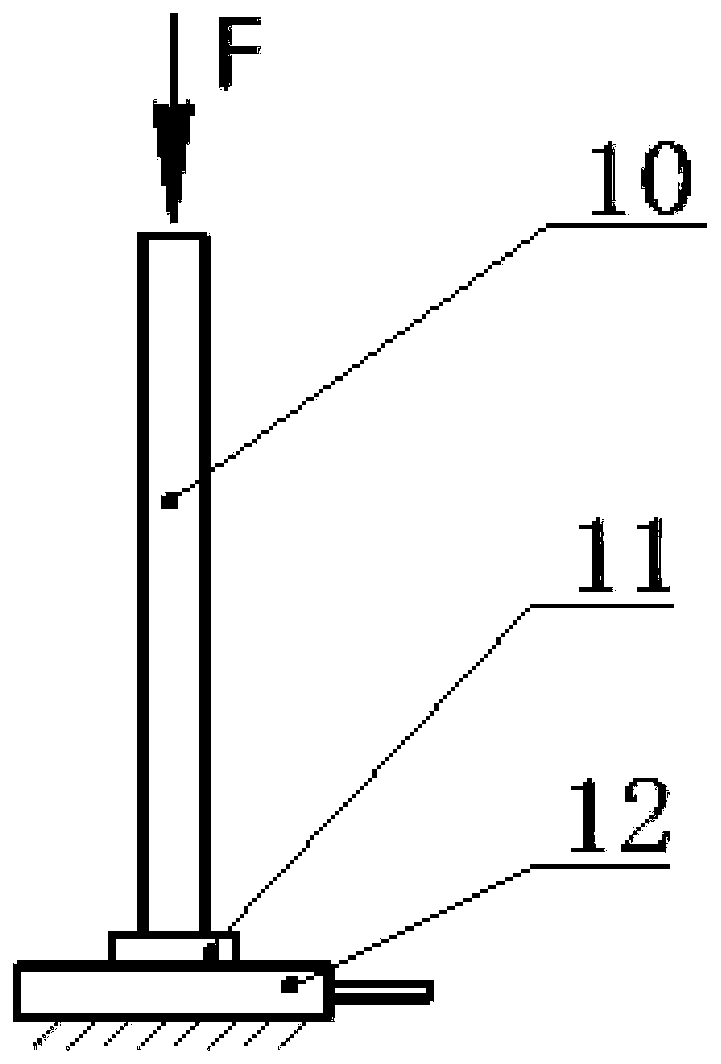

Guide assembly as well as vertical loading device and method

ActiveCN107389448AAvoid deflectionReduce the labor intensity of adjustment and assemblyMaterial strength using tensile/compressive forcesEngineeringRoller bearing

The invention relates to a guide assembly as well as a vertical loading device and method and belongs to the technical field of vertical loading test devices. The guide assembly comprises a first annular sleeve, second annular sleeves and linear roller bearings, wherein the first annular sleeve is located between the two adjacent second annular sleeves, the first annular sleeve and the second annular sleeves are coaxially arranged, a guide hole allowing penetration of a loading mandrel is formed, a plurality of grooves are formed in the inner surfaces of the second annular sleeves and extend in the axial directions of the second annular sleeves, and the linear roller bearings are arranged in the grooves, in one-to-one correspondence with the grooves and in clearance fit with the loading mandrel. By means of the vertical loading device equipped with the guide assembly, deflection of the loading mandrel due to lateral force is avoided effectively; with adoption of the vertical loading method, vertical load can be transferred effectively, the lateral force is prevented, high load and large-displacement loading of an actuator can be realized, test precision is high, and demands of various vertical loading tests can be met.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com