Process for the mould closure of an injection moulding machine, and mould closure

A closure device, injection molding machine technology, applied in the field of mold closure devices, can solve problems such as cracking of supporting elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

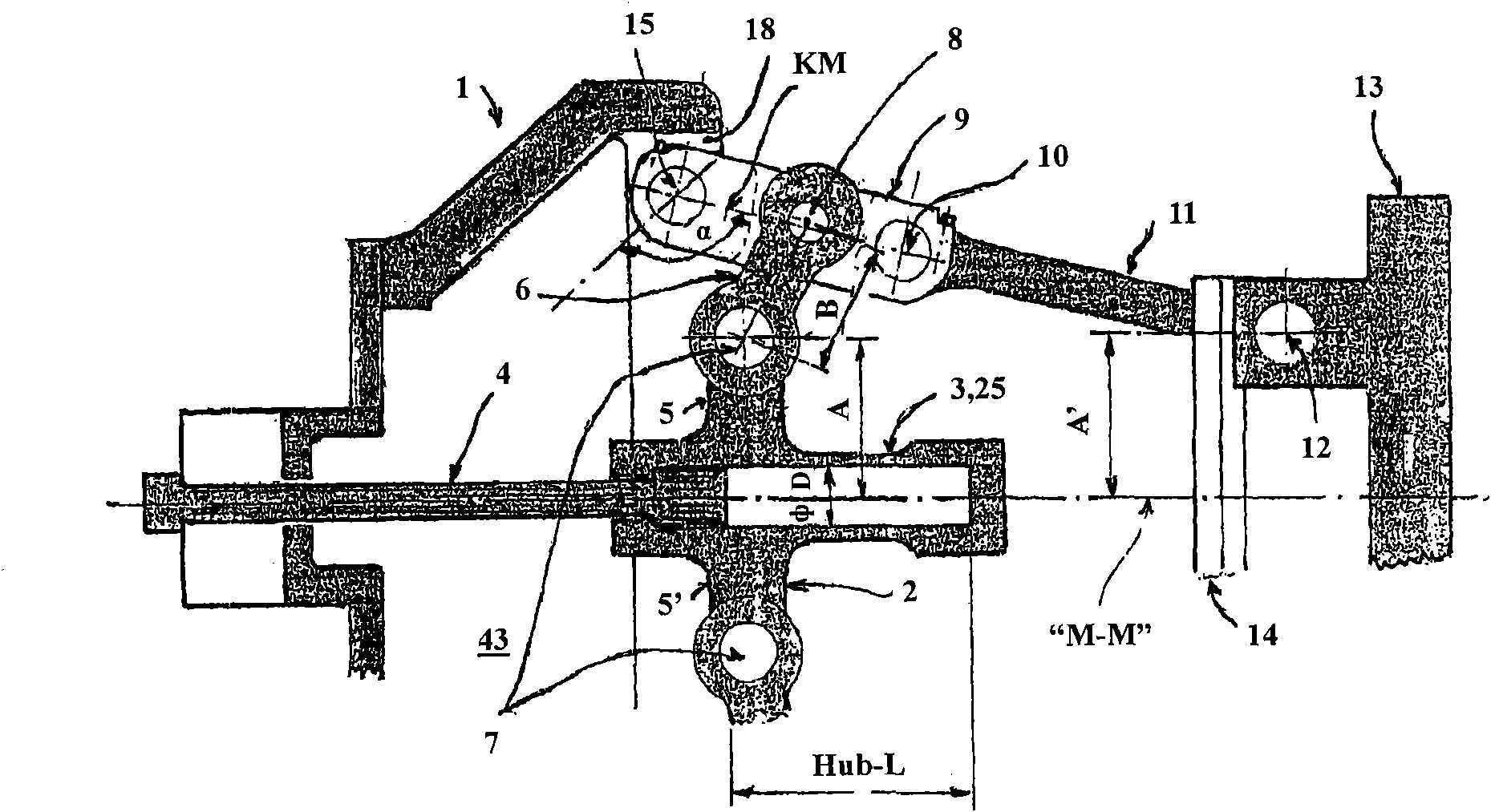

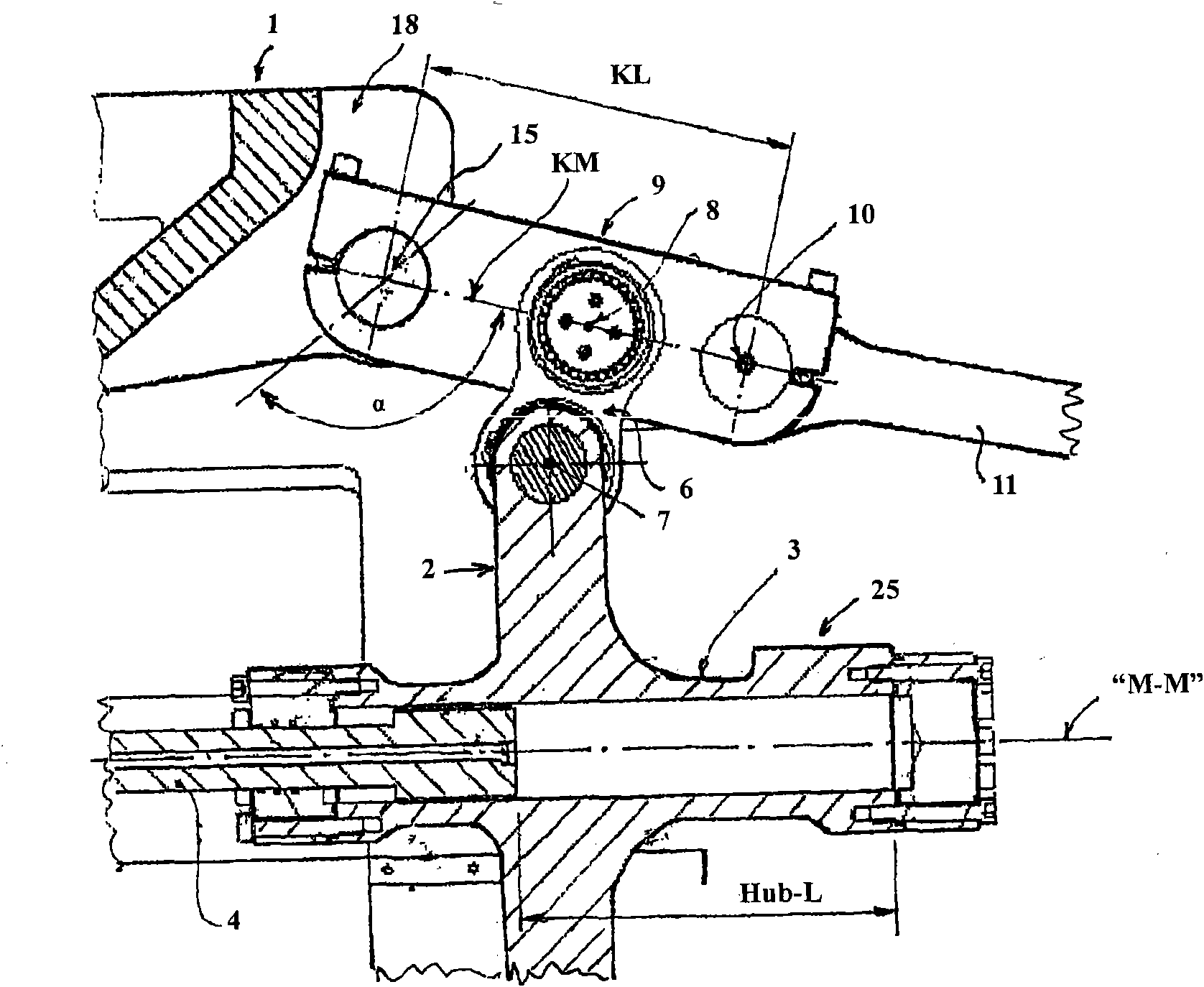

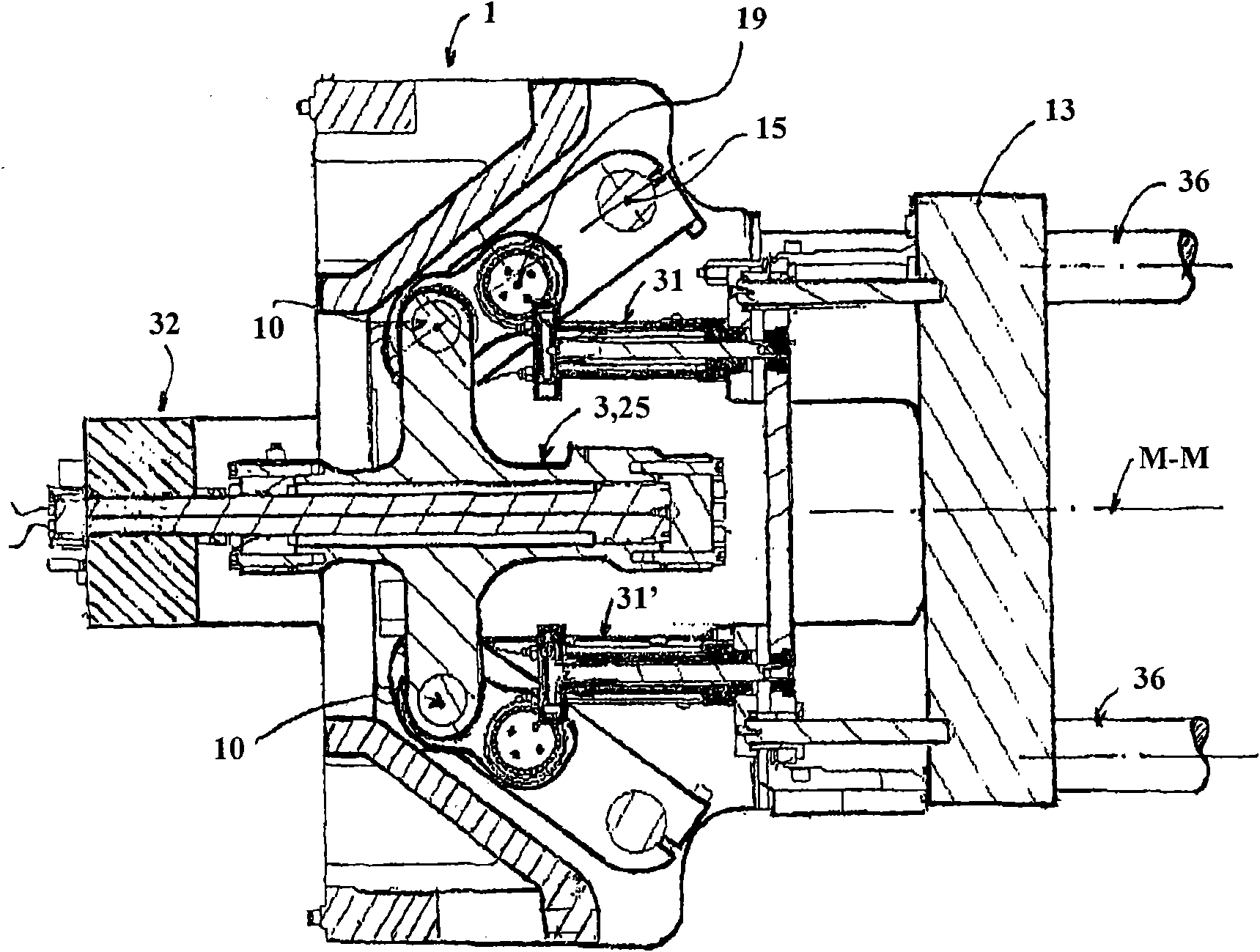

[0050] Refer below figure 1 . figure 1 Schematically shows the main elements on the side of the mold closing device with a 5-point toggle. On the left side of the figure is the support element 1, at which the support element 1 is hinged for the mold height adjustment member 26 ( Figure 7 ) drivers and crosshead drivers. Integrated in the crosshead 2 is a hydraulic cylinder 3 or a hydraulic drive 25 , the piston rod 4 of which is articulated on the outside of the bearing element 1 . The crosshead 2 has two vertically arranged projections 5, 5' on which a support plate 6 is mounted via an inner support plate bearing 7. The support plate engages at the toggle lever 9 via the support plate bearing 8 on the outside. On the left, the toggle lever 9 is articulated via a bearing hinge axis 15 at an articulation 18 of the bearing element 1 . On the opposite side, the toggle lever 9 is connected via a toggle hinge 10 to a mold moving lever 11 . On the right side of the drawing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com