Cooking, pulping and stirring all-in-one machine

An all-in-one machine and stirring motor technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of time-consuming, laborious, material waste, etc., to improve fluency, stability, and meshing degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

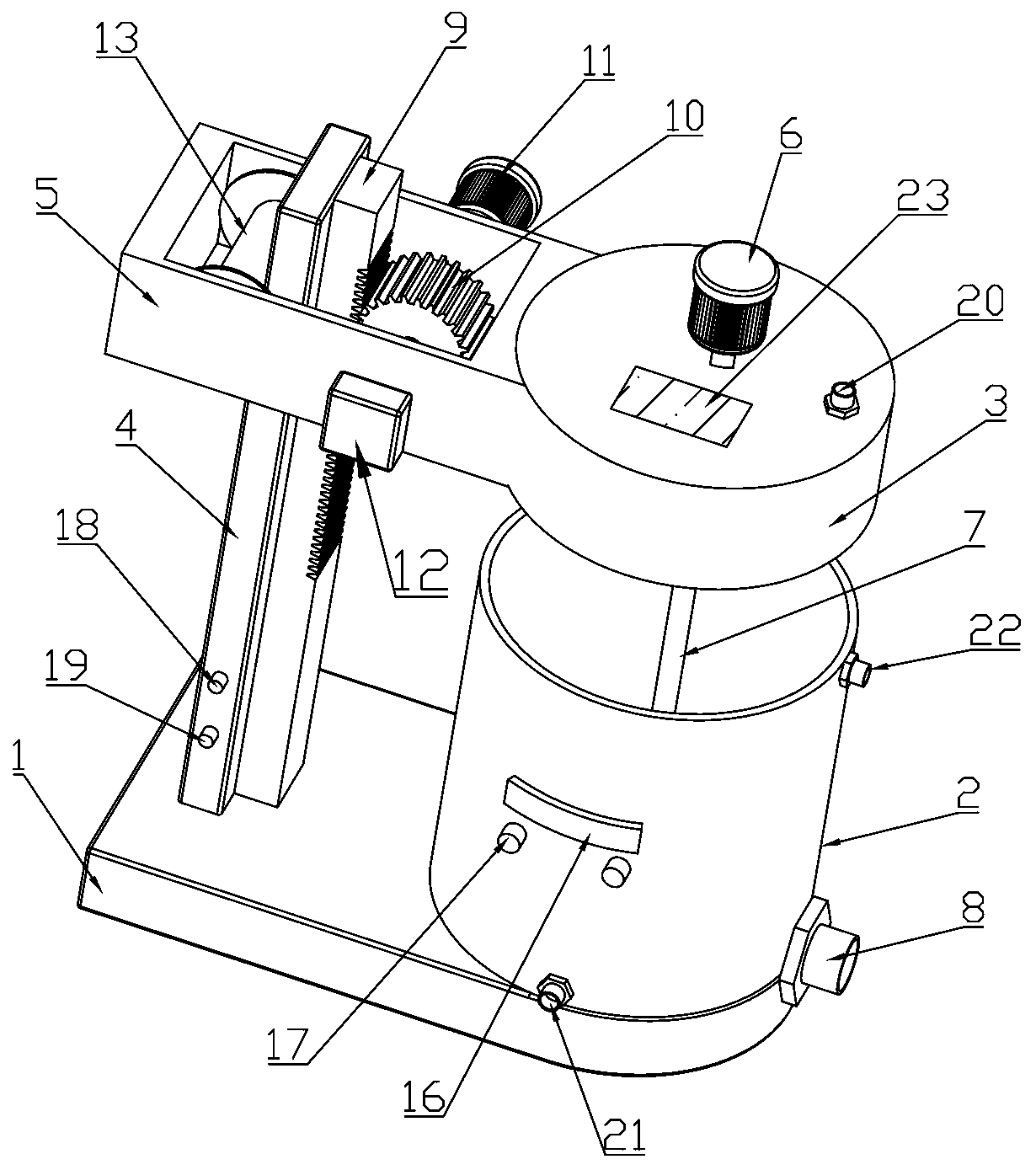

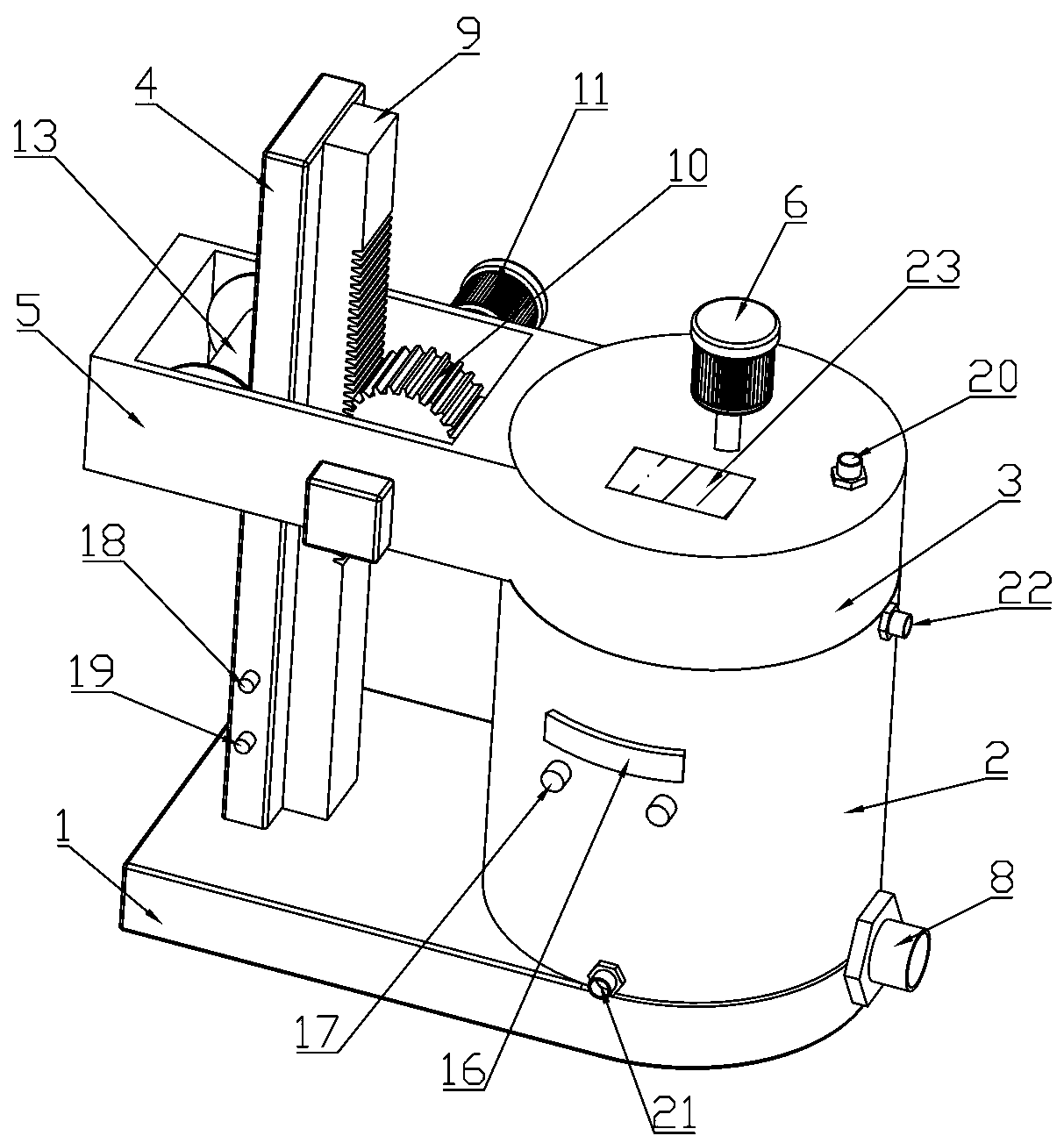

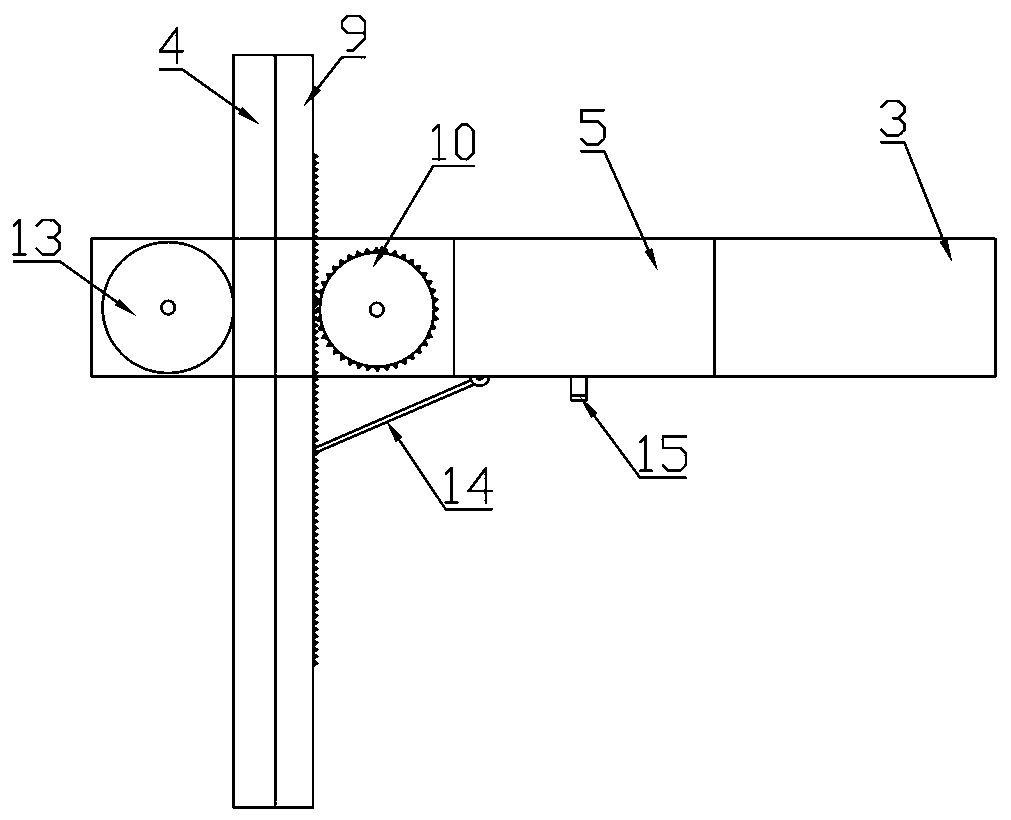

[0041] A cooking, beating and mixing machine, such as figure 1 with figure 2 As shown, including a base 1, a tank body 2 is fixed on the base 1, a tank cover 3 is provided on the tank body 2, an observation window 23 and a pressure relief valve 20 are provided on the tank cover 3, and a tank cover 3 is also provided with A sealing ring matched with the tank body 2. The tank body 2 is a sandwich structure, and the interlayer of the tank body 2 is provided with a heating structure and a cooling structure; a stirring motor 6 is fixed on the upper part of the tank cover 3, and the stirring motor 6 is a forward and reverse motor; A stirring structure 7 fixedly connected to the rotating shaft; a slurry outlet 81 is provided at the bottom of the tank body 2 . By setting a heating structure in the interlayer of the tank body 2, it is convenient to heat the inside of the tank body 2, thereby heating and cooking the materials placed in the tank body 2; The pressure in the tank body ...

Embodiment 2

[0062] The difference between this device and Embodiment 1 is only that the structure of the paddle is as Figure 7 As shown, the paddle 72 is detachably connected to the stirring shaft 71 through a pin 74; the paddle 72 is set in a detachable manner, which facilitates maintenance operations such as removing the paddle 72 for cleaning and replacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com