Guide assembly as well as vertical loading device and method

A technology of guiding components and vertical loading, which is applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., and can solve problems such as inability to avoid lateral force, time and labor, and test failure. Achieve the effects of reducing the labor intensity of adjustment and assembly, avoiding deflection, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

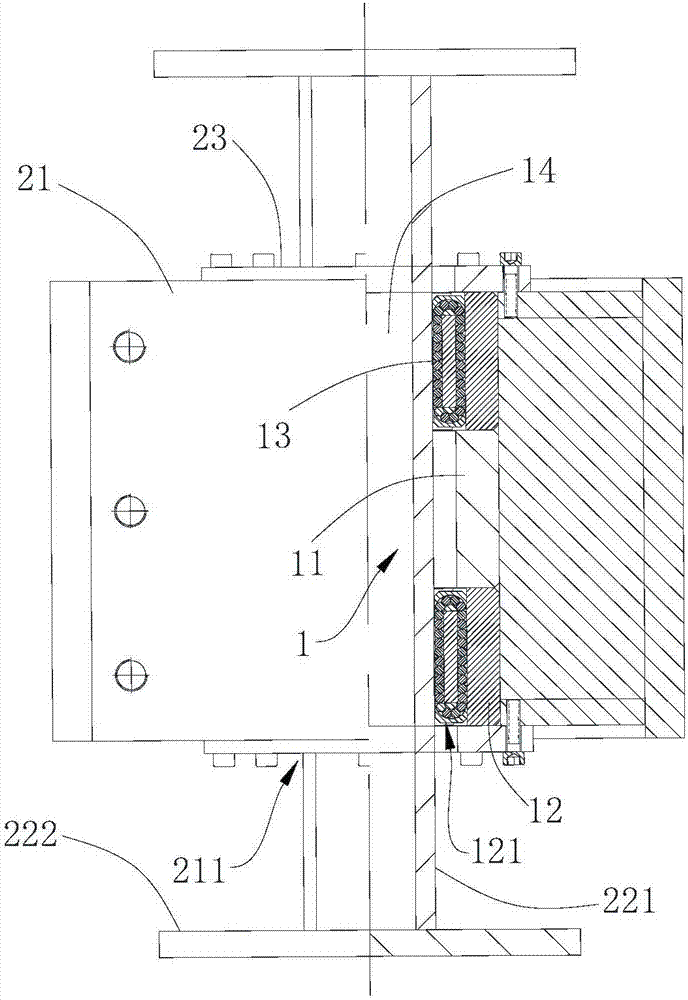

[0033] Please refer to figure 1 , the embodiment of the present invention provides a guide assembly 1 for installation on the guide beam 21 and for vertical loading, including at least one first annular sleeve 11, at least two second annular sleeves 12 and a plurality of linear roller bearings 13.

[0034] In this embodiment, the guide assembly 1 is used to prevent lateral force when the test piece is vertically loaded, and is used together with the guide beam for vertical loading test of the test piece. The guide assembly 1 includes two kinds of annular sleeves, the first annular sleeve 11 and the second annular sleeve 12, the two annular sleeves are superimposed on all, the two annular sleeves are coaxially arranged and form a guide hole 14 for passing through the loading mandrel, The first annular sleeve 11 is located between two adjacent second annular sleeves 12, and the inner surface of the second annular sleeve 12 is provided with a vertically arranged groove 121 (the ...

no. 2 example

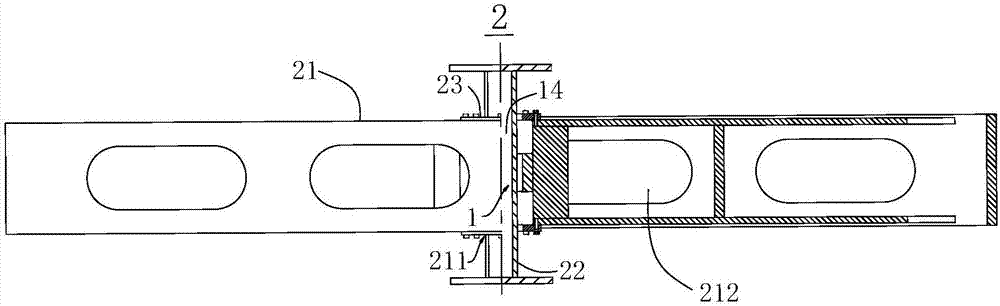

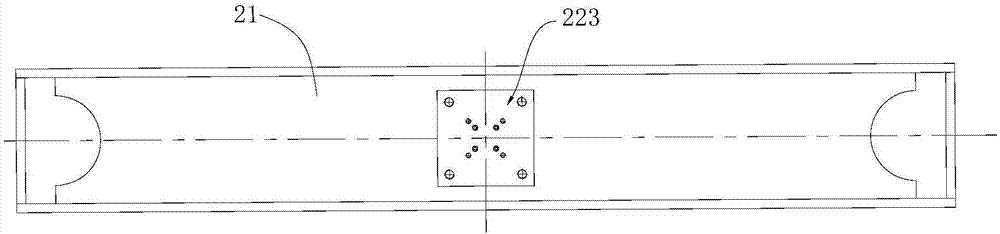

[0049] Please refer to figure 1 and figure 2 As shown, this embodiment provides a vertical loading device 2, including a guide beam 21, at least one loading mandrel 22 and at least one guide assembly 1 provided in the first embodiment.

[0050] In this embodiment, the guide beam 21 plays the role of fixing the guide assembly 1, the guide assembly 1 is installed in the guide beam 21, the loading mandrel 22 is passed through the guide hole 14, and the connection between the loading mandrel 22 and the linear roller bearing 13 There is a gap between them, the loading mandrel 22 can move along the axial direction of the guide hole 14, and the actuator acts on the loading mandrel 22 vertically, effectively avoiding the deflection of the loading mandrel 22 caused by the lateral force, and avoiding adjustment and assembly.

[0051] The specific structure and mutual positional relationship of each component of the vertical loading device 2 will be described in detail below.

[0052]...

no. 3 example

[0065] After research, the researchers found that the vertical loading device 2 provided by the present invention, on the basis of the above-mentioned second embodiment, can also make the following optional other structural solutions, which are specifically described as follows:

[0066] The gap between the loading mandrel 22 and the linear roller bearing 13 is 0.25 mm. When the gap between the loading mandrel 22 and the linear roller bearing 13 is 0.25 mm, the loading device (such as an actuator) is loaded on the loading mandrel 22 The vertical load on the test piece can be effectively transferred to the test piece, and the lateral force can be prevented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com