Device and method for measuring excitation force of camshaft to camshaft bearing cover

A technology of cam bearings and measuring devices, applied in measuring devices, force/torque/work measuring instruments, force sensors related to bearings, etc., can solve the problem of large force errors in strain gauge measurement, inability to obtain force values, and excitation Complex force and other problems, to achieve accurate measurement, not easy to be disturbed, precise boundary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0052] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

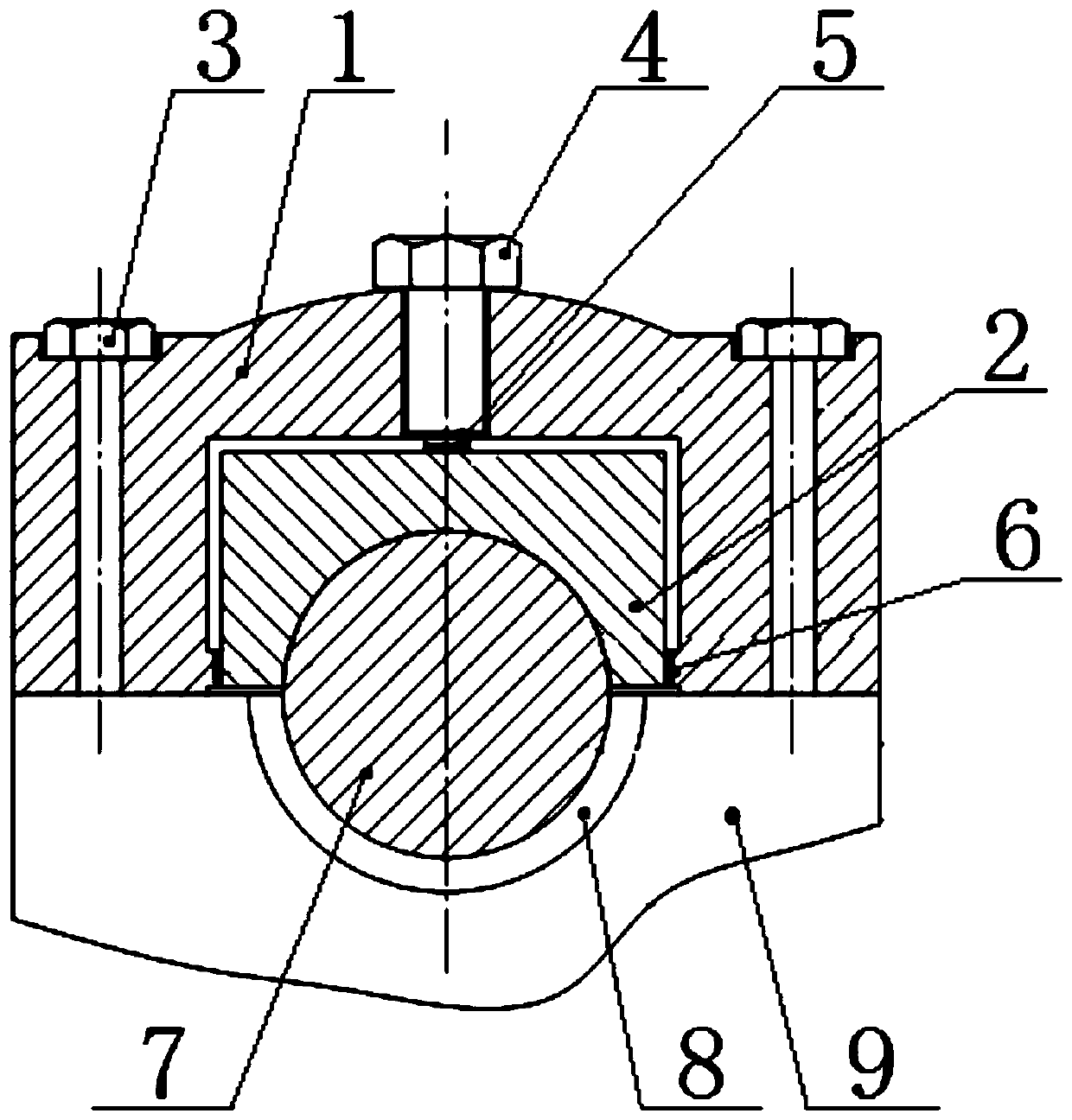

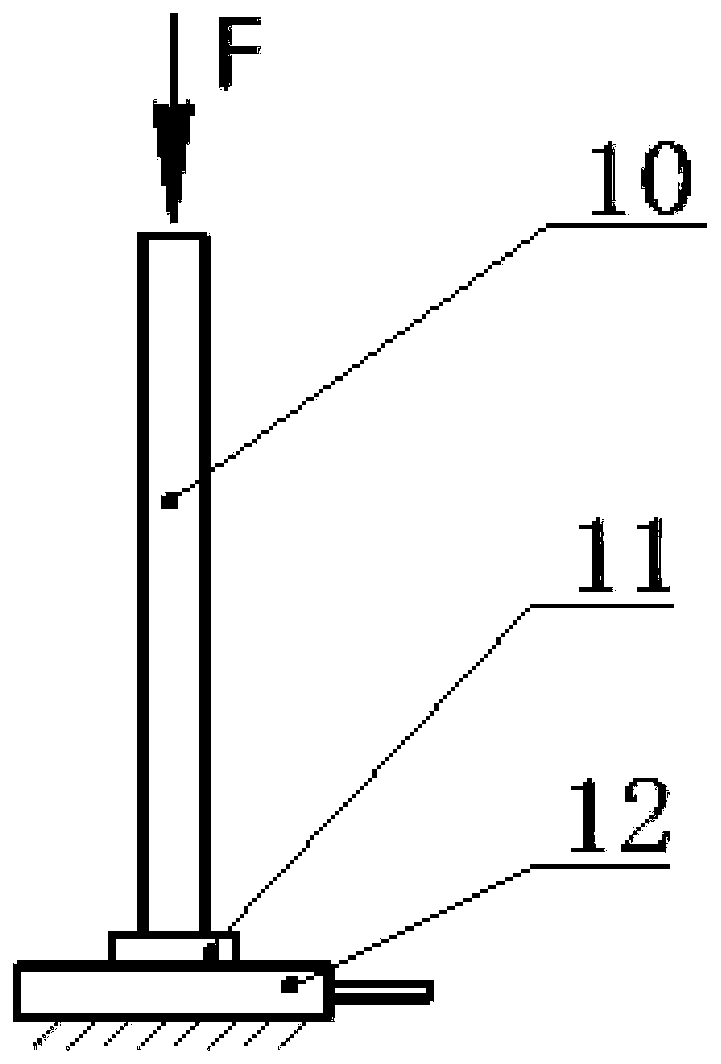

[0053] Such as figure 1 As shown, the present invention discloses a camshaft-to-cam bearing cover excitation force measuring device, which includes an outer member 1, an inner member 2, a fastening bolt 3, an adjustment bolt 4, a vertical pressure sensing plate 5 and a horizontal pressure sensing slice 6.

[0054] The camshaft 7 is directly installed in the cam bearing seat 8, so that the first circumferential surface of the camshaft 7 is matched with the arc surface in the installation groove of the cam bearing seat 8, and the cam bearing seat 8 is arranged on the engine cylinder head 9, and the cam The upper surface of the bearing seat 8 is flush with the connecting surface on the engine cylinder head 9;

[0055] The inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com