Device and method for measuring excitation force of camshaft to cam bearing cover

A technology of cam bearings and measurement methods, which is applied in the direction of measuring devices, force/torque/work measuring instruments, and force sensors related to bearings, and can solve the problem of large force errors measured by strain gauges and the inability to obtain force values and changes Problems such as high frequency, to achieve accurate measurement, not easy to be interfered, accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0052] In order to clearly, the technical solutions of the present invention and the specific operation of the present invention are described, and the specific embodiments of the present invention are as follows:

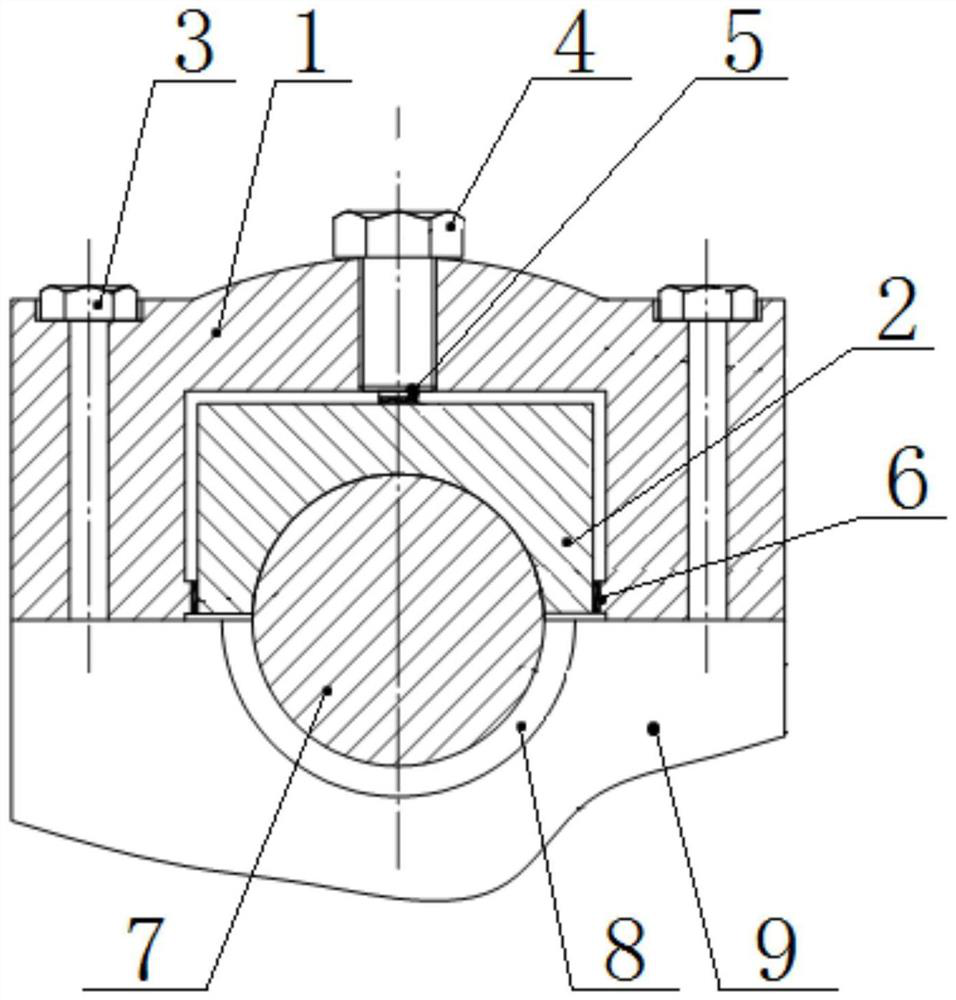

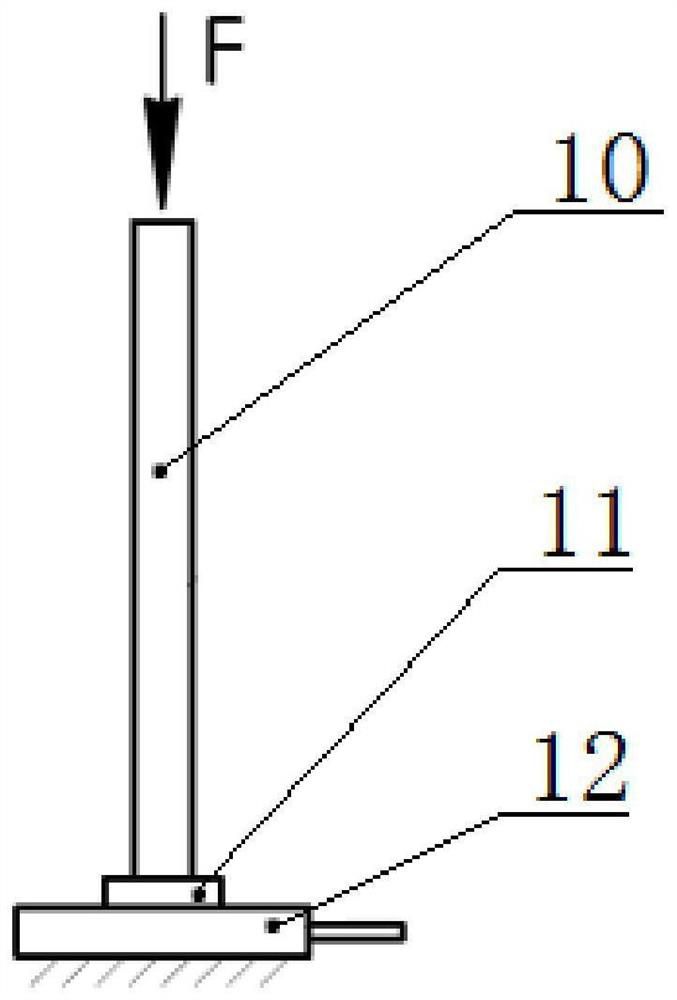

[0053] like figure 1 As shown, the present invention discloses a cam shaft to cam bearing cap excitation measuring device, including outer member 1, inner member 2, fastening bolt 3, adjusting bolt 4, vertical pressure sensing sheet 5, and horizontal pressure sensing Table 6.

[0054] The camshaft 7 is mounted directly in the cam bearing 8, and the first circumference surface of the cam shaft 7 is fitted with the arc surface in the cam bearing 8 mounting groove, and the cam bearing 8 is disposed on the engine cylinder head 9, and the cam The upper surface of the bearing housing 8 is parallel to the engine cylinder head 9;

[0055] The inner surface of the inner member 2 is an arc surface that matches the circumferential surface of the camshaft 7, and the inner member 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com