Electric gourd and lorry using the same

A technology of electric hoist and walking trolley, which is applied in the direction of railway car body parts, loading and unloading of railway vehicles, freight cars, etc. It can solve the problems of small climbing ability, slipping cars, electric hoist climbing, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

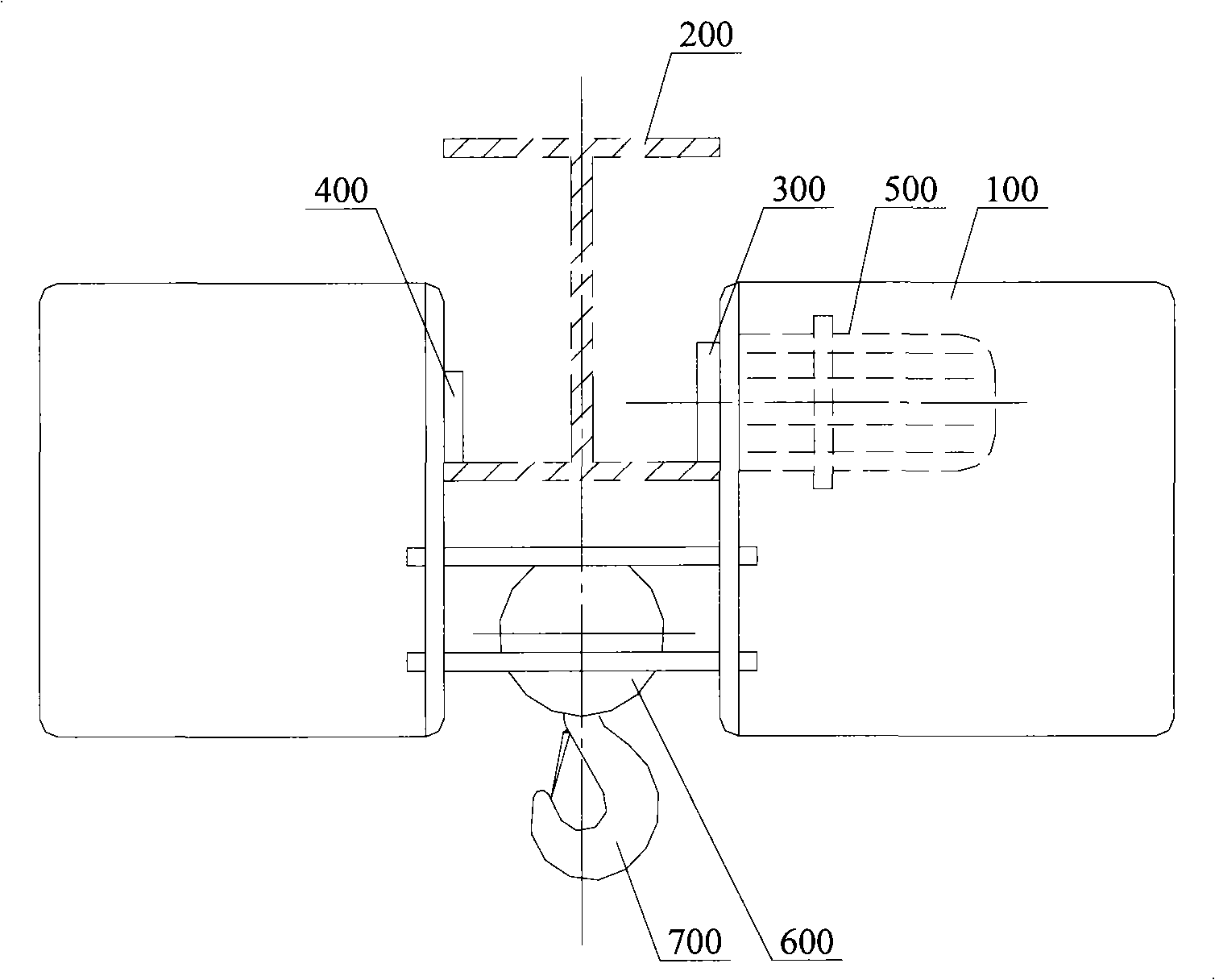

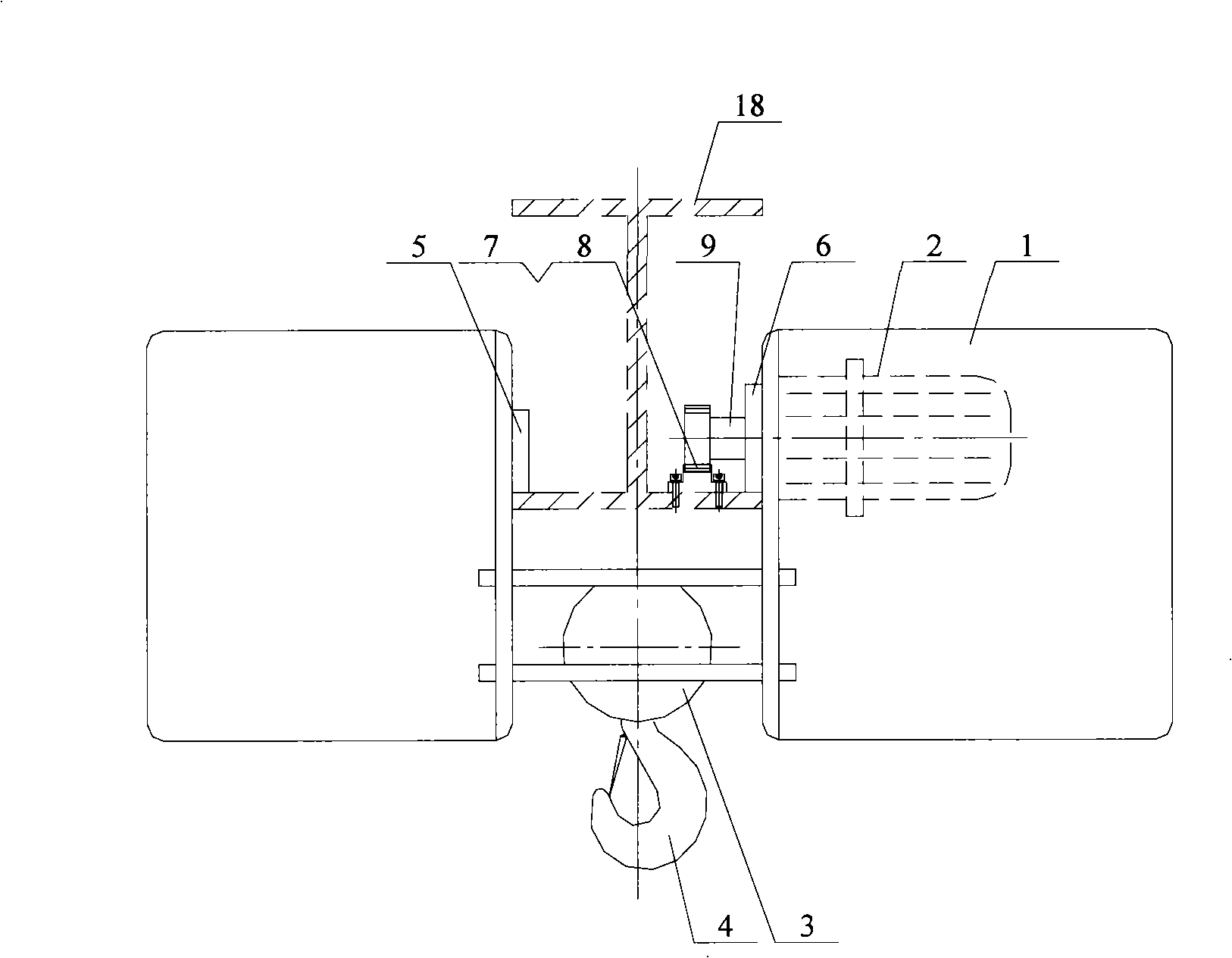

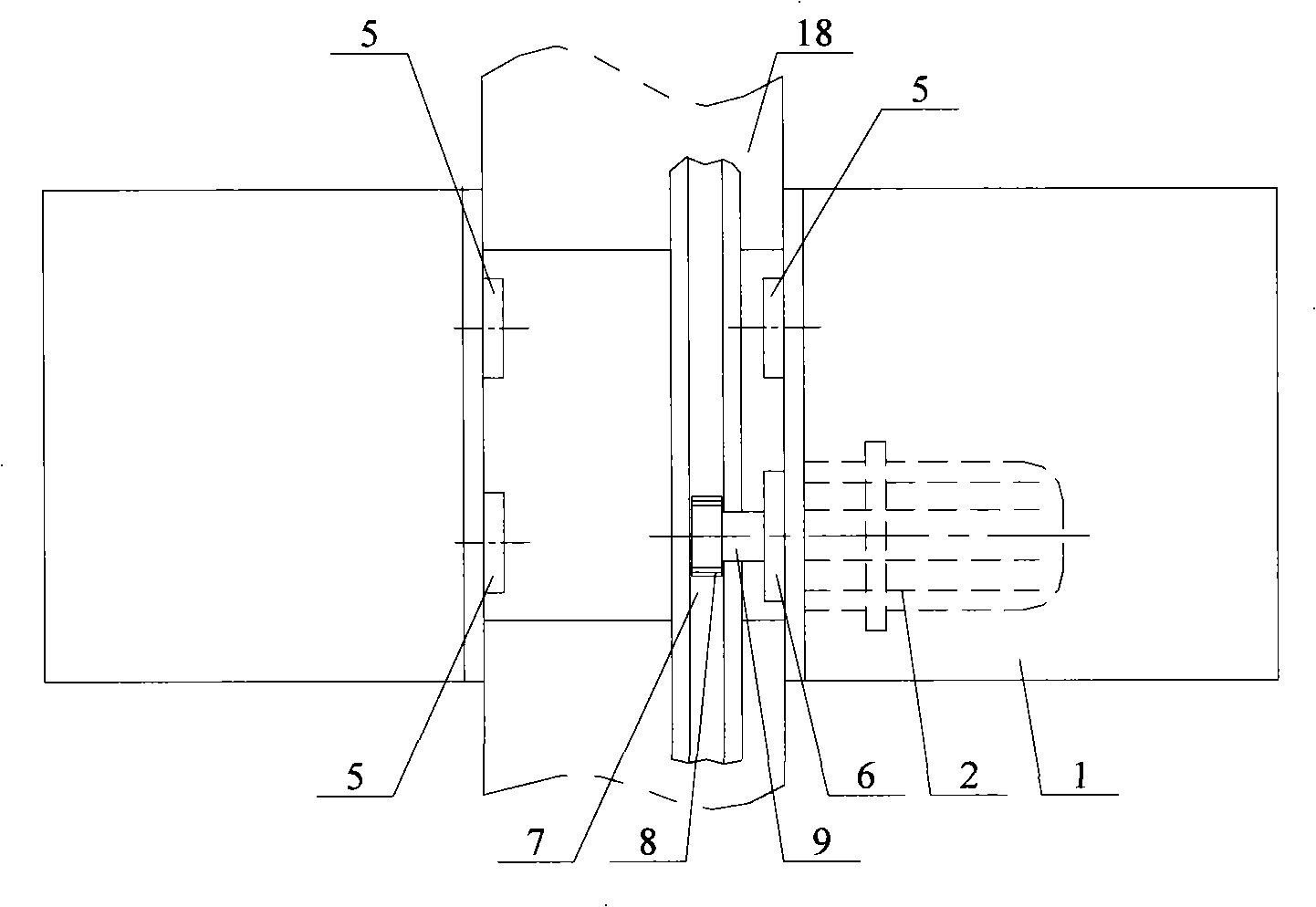

[0024] See Figure 2a , which is a front view of the electric hoist of the present invention.

[0025] Such as Figure 2a As shown, the present embodiment is mainly composed of a walking trolley 1, a traveling motor 2, a reel device 3, a hook device 4 and a rack and pinion transmission mechanism walking along the I-shaped steel beam, wherein the walking trolley 1 is left, The right two-part structure is composed of a supporting wheel 5 and a running wheel 6 on the walking trolley 1 on the left and right sides, and the traveling motor 2 is the power source for the trolley; the reel device 3 and the hook device 4 are in turn It is arranged under the walking trolley 1 and is used to complete the lifting and lowering operations of heavy objects. In order to describe the specific structure of the electric hoist of the present invention in detail, please refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com