Long-service-life offset type gear and rack pneumatic actuator

A pneumatic actuator, rack and pinion technology, applied in the direction of engine components, valve devices, mechanical equipment, etc., can solve the problems of accelerated wear of seals and guides, short service life of actuators, limited speed increase, etc., to improve the action Speed, increased service life, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

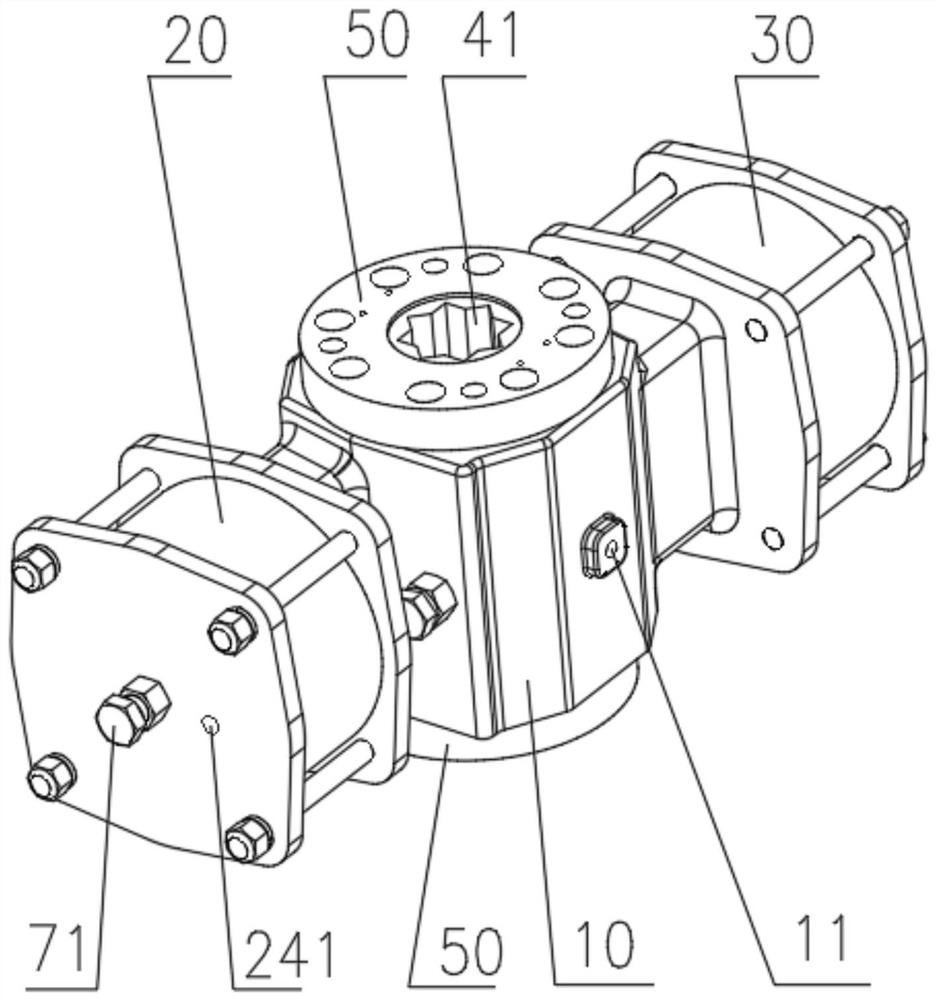

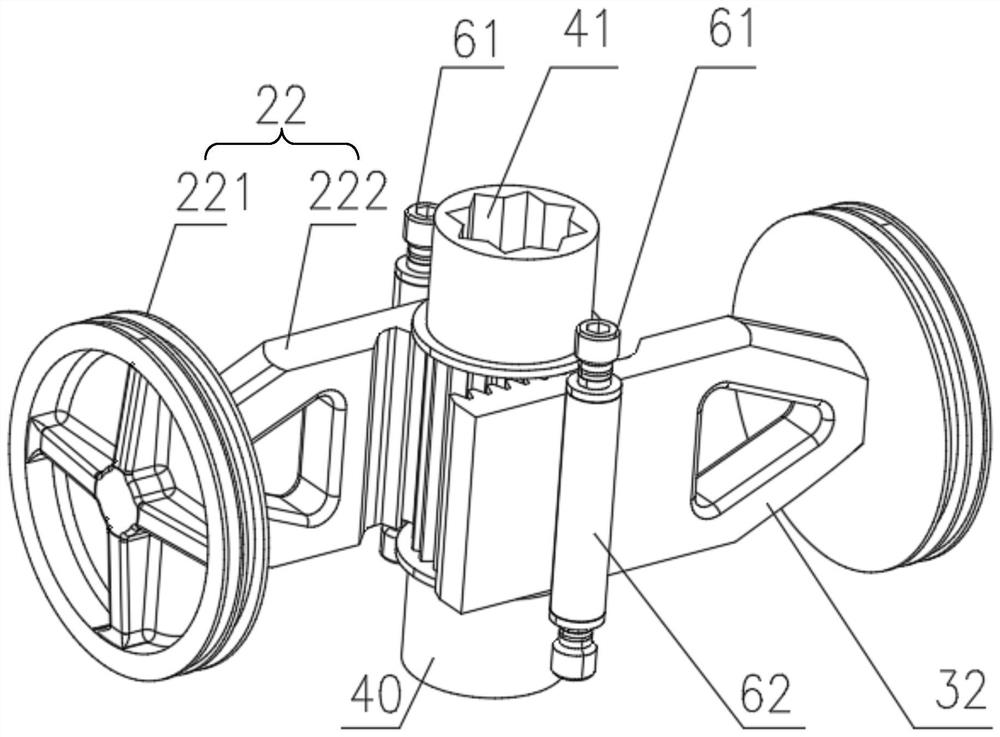

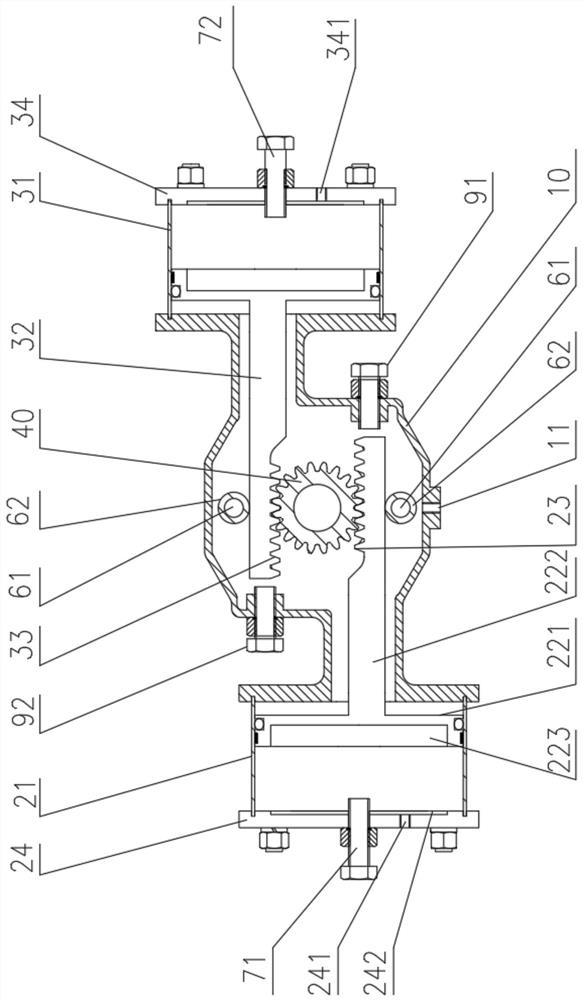

[0023] like Figure 1-4 As shown, the high-life offset rack and pinion pneumatic actuator of the present embodiment includes a cylinder one 20, a cylinder two 30 and a box body 10, and a left opening, a right opening and two opposite openings are provided on the box wall of the box body 10. The upper opening and the lower opening, the upper opening and the lower opening of the box body 10 respectively fix the flange 50, the cylinder body-21 of the cylinder-20 is fixed at the left opening of the box body 10, and the piston rod-22 of the cylinder-20 overhangs To the inside of the casing 10, the piston rod one 22 is provided with the rack one 23, the cylinder body two 31 of the cylinder two 30 is fixed on the right opening of the casing 10, and the piston rod two 32 of the cylinder two 30 extends to the casing 10 The inside of the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com