Three-axis cutter servo device based on compliant parallel mechanism

A servo device, parallel technology, used in feeding devices, manufacturing tools, metal processing mechanical parts, etc., can solve problems such as high precision, high stiffness, low coupling/full decoupling, large bearing capacity, high speed/acceleration, etc. , to achieve the effect of high bandwidth, excellent decoupling performance, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

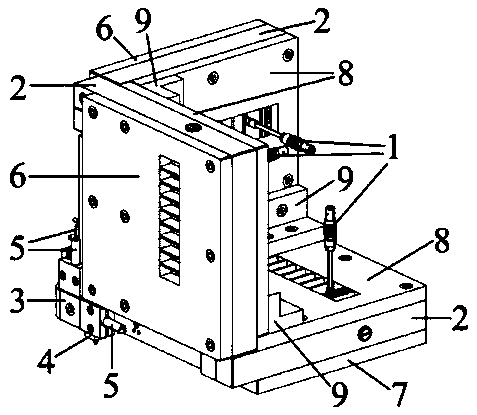

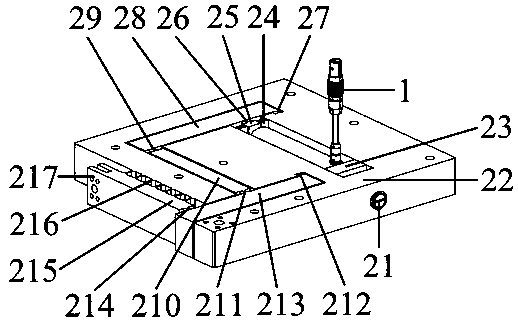

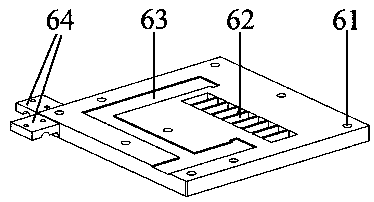

[0036] Such as Figure 1 to Figure 7 Shown is an embodiment of the three-axis tool servo device based on the compliant parallel mechanism of the present invention, including an outer fixed base, an inner fixed base 8, a single-axis nanopositioning platform 2 that transmits motion through the first motion branch chain, and a second The three-axis end effector 3 guided and decoupled by two motion branch chains, three sets of outer fixed bases, inner fixed bases 8, and single-axis nanopositioning platform 2 are all orthogonal to each other, and are located on the XOY plane, XOZ plane and YOZ plane respectively. Plane, the single-axis nanopositioning platform 2 is arranged between the outer fixed base and the inner fixed base 8, and the single-axis nanopositioning platform 2 is connected with the three-axis end effector 3; the first kinematic branch chain and the second kinematic branch chain are both Including a variety of compliant hinges and flexible rods, the first kinematic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com