A Micro-displacement Platform Driven by Piezoelectric Ceramics

A piezoelectric ceramic drive, piezoelectric ceramic technology, applied in the field of micro-displacement platform, can solve the problems of single amplification ratio, poor replacement, low output stiffness, etc., and achieve the effect of large output force, small size and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

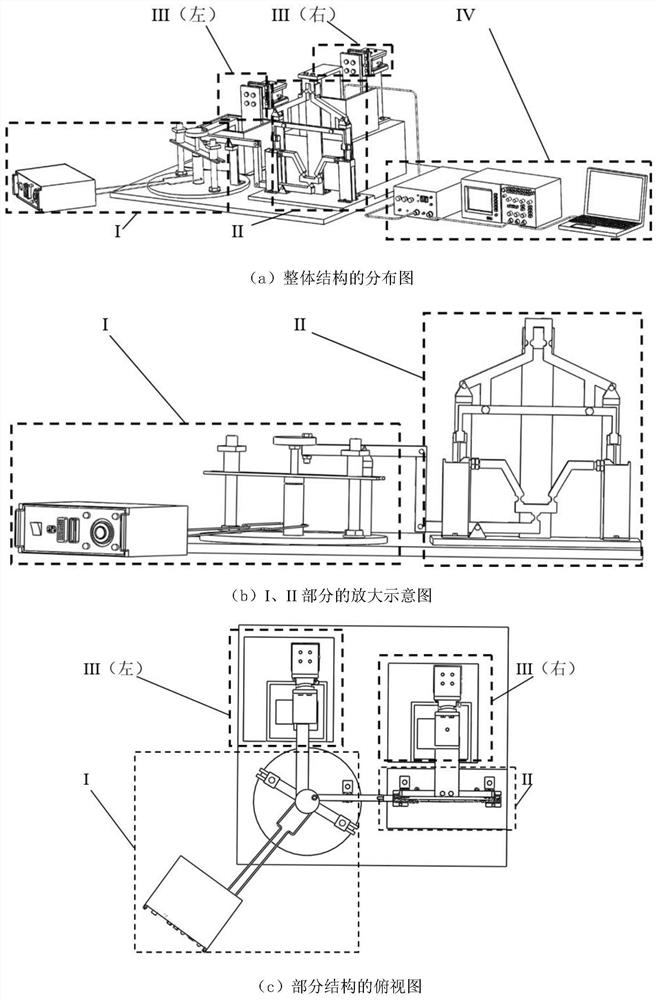

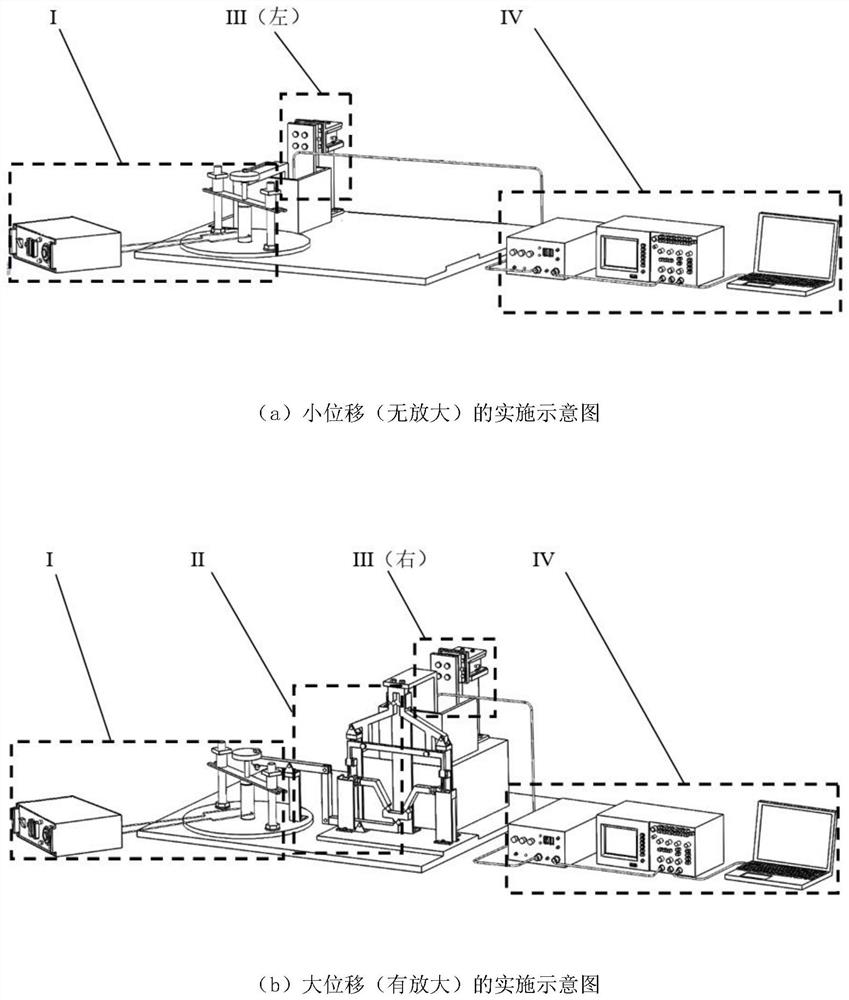

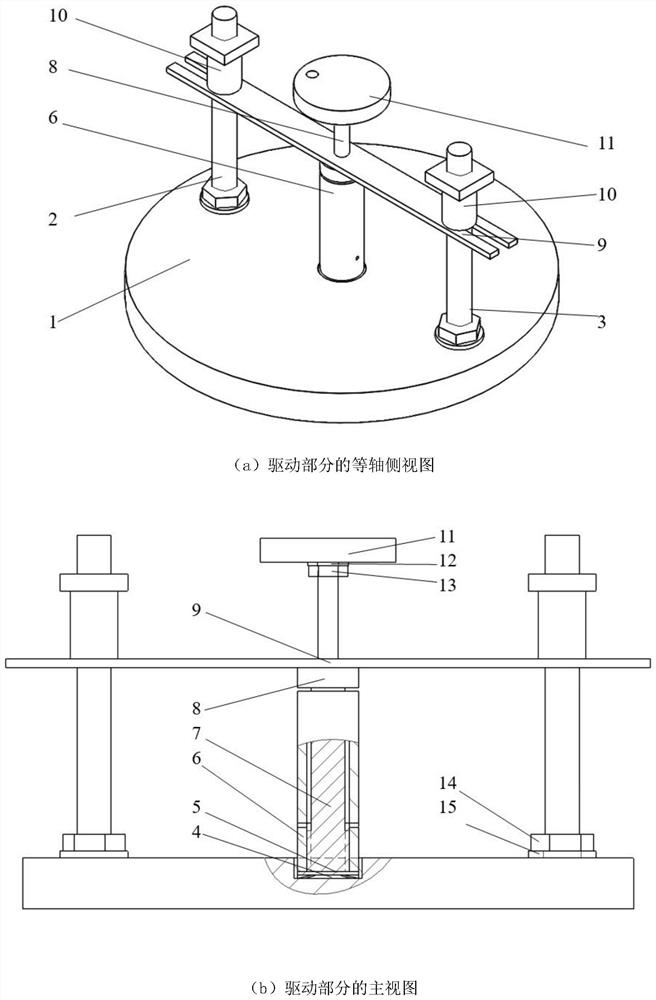

[0050] A micro-displacement platform driven by piezoelectric ceramics involved in this embodiment is realized through the following technical solutions:

[0051] A micro-displacement platform driven by piezoelectric ceramics, the main structure of which includes four parts: a driving part I, an amplifying part II, a motion execution part III, and a measuring part IV, wherein the main structure of the driving part I includes a 1-small base , 2-left column, 3-right column, 4-disc spring, 5-disc spring gasket, 6-piezoelectric ceramic shell, 7-piezoelectric ceramics, 8-output shaft, 9-deformation plate, 10-preload Bolt, 11-conversion plate, 12-lock nut washer, 13-lock nut, 14-lock nut M10, 15-lock nut washer M10, 39-piezoelectric ceramic power supply; main structure of enlarged part II Including 16-connecting parts (connecting bolts, connecting washers, connecting nuts), 17-transmission rod 1, 18-intermediate rod, 19-transmission rod 2, 20-U-shaped rod guide rail, 21-first-stage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com