A Compliant Parallel Micromanipulator Driven by Multiple Sources

A source-driven, micro-operation technology, applied in the direction of instruments, instrument parts, etc., can solve limitations and other problems, and achieve the effects of convenient operation, light weight, and high guiding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Next, the technical solutions in the embodiments of the present invention will be described in the following examples, and the embodiments described below are apparent from the embodiments of the present invention, not all embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

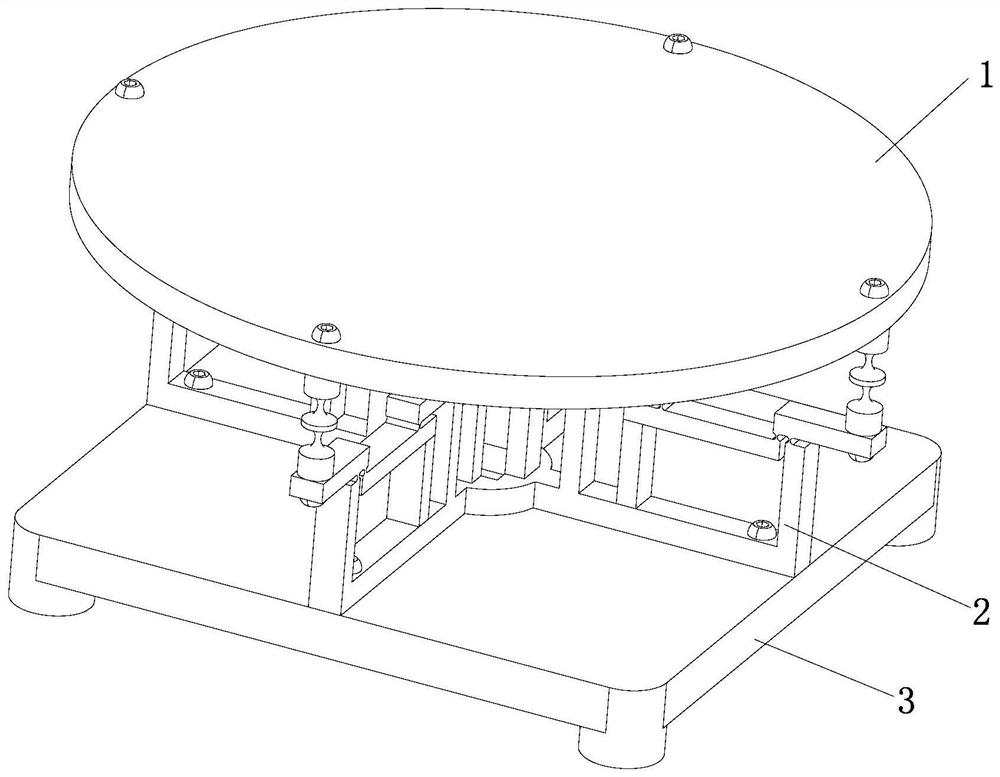

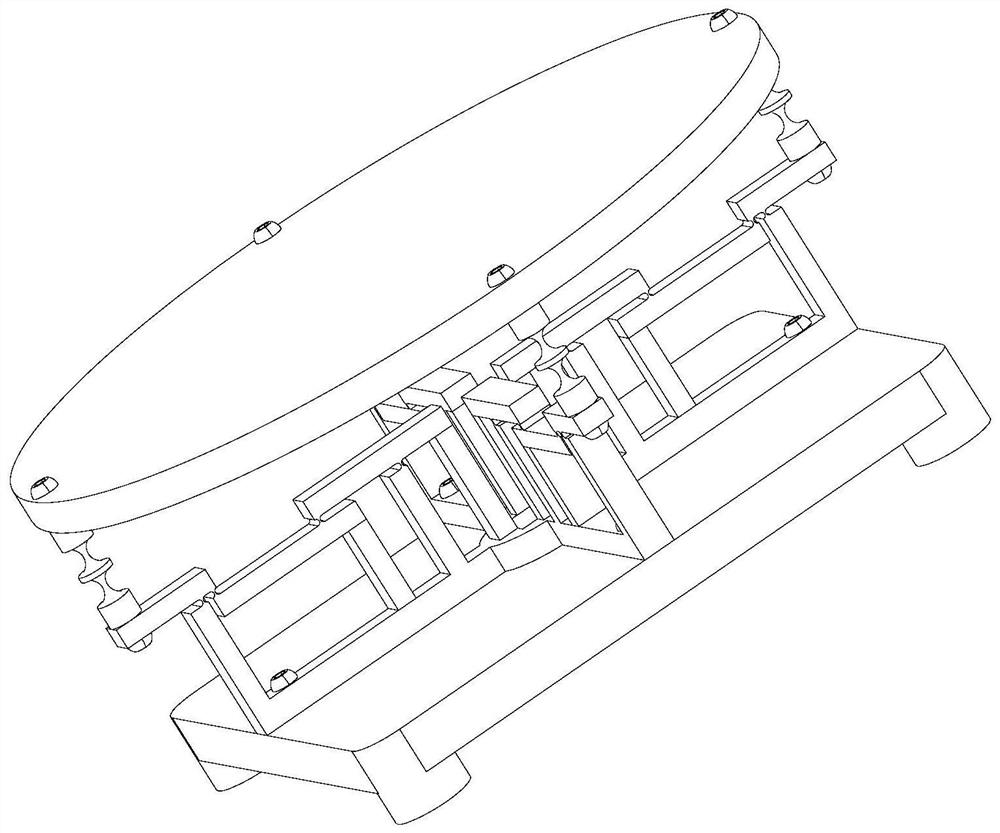

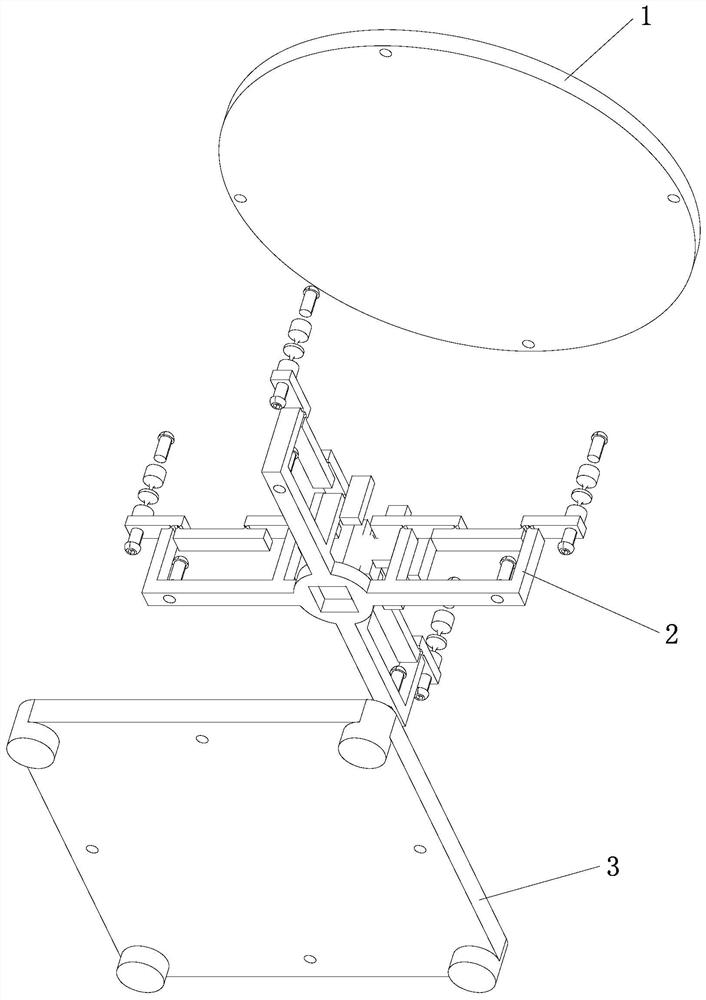

[0029]SeeFigure 1 - Figure 5 As shown, multi-source driving compliance parallel microcaton includes a work platform 1, an enlargement mechanism 2 and a base 3;

[0030]The base 3 is fixed to an enlarged mechanism 2, and the working platform 1 is supported on the amplification mechanism 2;

[0031]The amplifying mechanism 2 includes a support disk 208 and an N amplifying mechanism unit as the same as the wound in the support plate 208; wherein N ≥ 4, n is an even number;

[0032]Each of the amplifying mechanism unit includes a support rod 204, a piezoelectric accumulation driver 125, a piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com