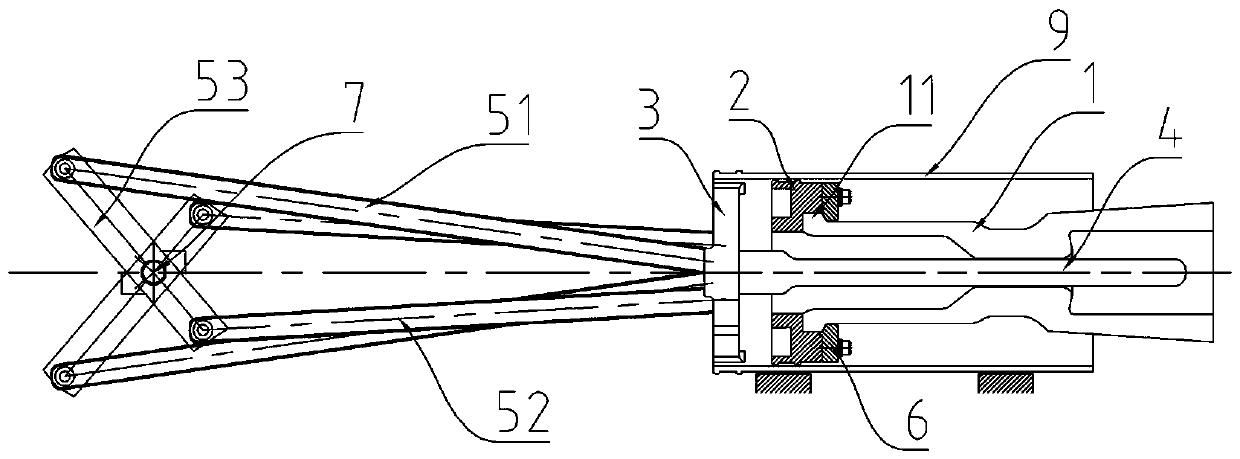

Double-acting arc extinguish chamber transmission structure, arc extinguish chamber adopting same and circuit break

A technology of transmission structure and arc extinguishing chamber, which is applied to high-voltage air circuit breakers, contact drive mechanisms, circuits, etc., and can solve the problems of large volume and large space occupation of arc extinguishing chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

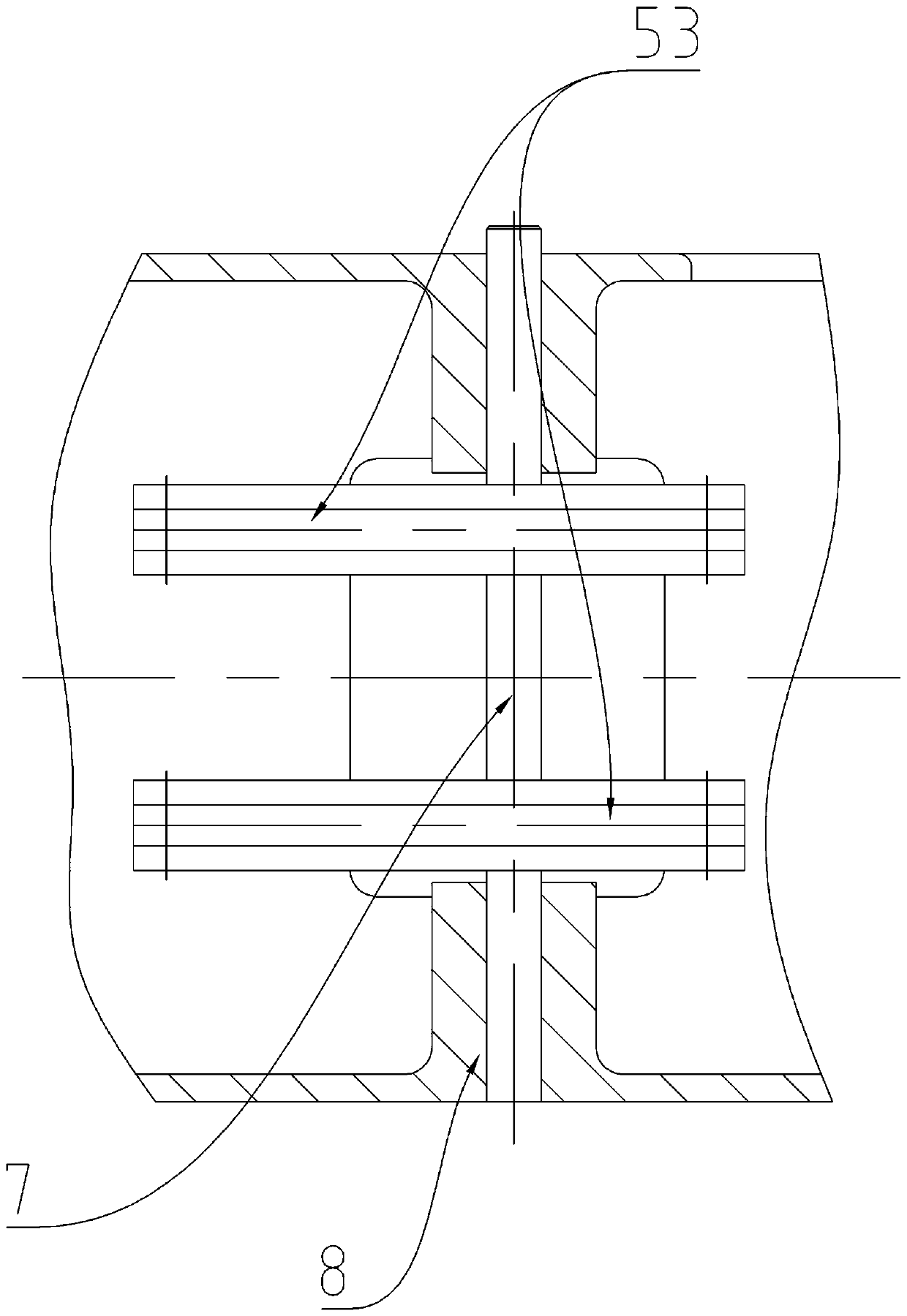

[0068] The specific embodiment 2 of the transmission structure of the double-action interrupter of the present invention, the difference between the implementation of the transmission structure of the double-action interrupter in this embodiment and the above-mentioned specific embodiment 1 is only that: as Figure 10 As shown, in this embodiment, the rotating link 53 of the linkage mechanism is respectively rotatably assembled on the two rotating shafts 7 .

Embodiment 3

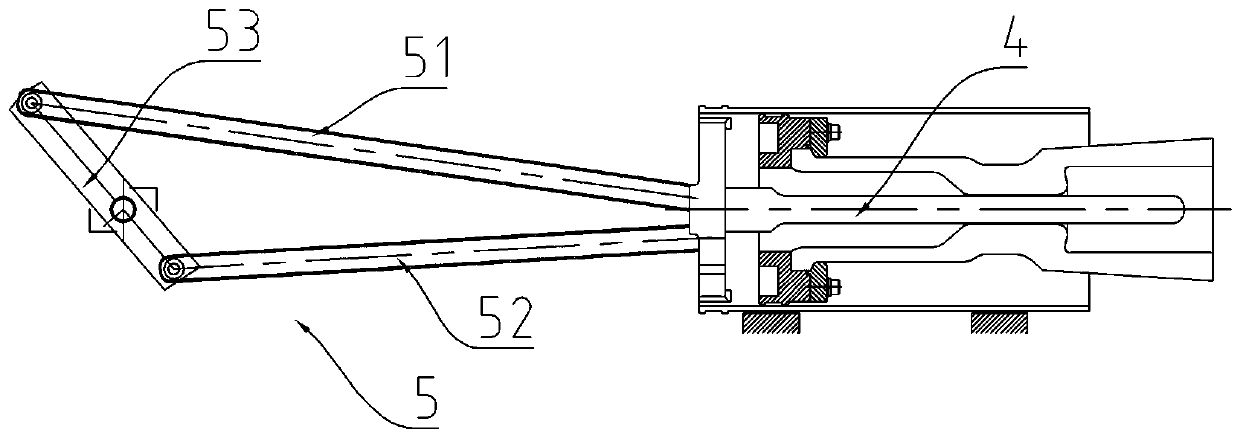

[0069] The specific embodiment 3 of the transmission structure of the double-action interrupter of the present invention, the difference between the implementation of the transmission structure of the double-action interrupter in this embodiment and the above-mentioned specific embodiment 1 is only that: Figure 11 As shown, in this embodiment, there are two pairs of connecting rod mechanisms, and there are four rotating connecting rods 53 in this embodiment.

Embodiment 4

[0070] The specific embodiment 4 of the transmission structure of the double-action interrupter of the present invention, the difference between the implementation of the transmission structure of the double-action interrupter in this embodiment and the above-mentioned specific embodiment 1 is only that: Figure 12 As shown, in this embodiment, the hinge axes of the two second connecting rods 52 coincide with the hinge joints of the contact mounting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com