Micro-displacement amplification and conversion device

A conversion device, displacement conversion technology, applied in the direction of piezoelectric devices/electrostrictive devices, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

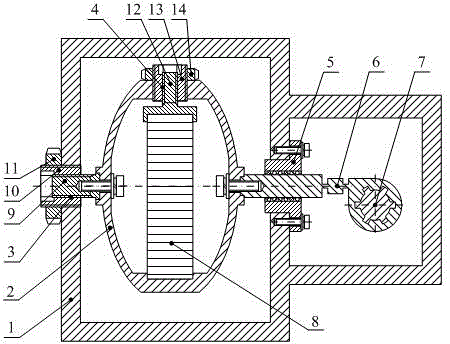

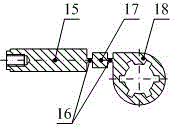

[0011] A micro-displacement amplification conversion device, including: a base 1, a micro-displacement amplification mechanism 2, and an intelligent material driver 8, and also includes: a micro-adjustment zero mechanism 3, a pretension adjustment mechanism 4, a linear bearing 5, a displacement conversion mechanism 6, and an output shaft 7; wherein the fine-tuning zero mechanism 3 includes: fine-tuning zero screw rod 9, fine-tuning zero screw sleeve 10 and fine-tuning zero lock nut 11; the pre-tightening mechanism 4 includes: adjusting pre-tightening screw rod 12, adjusting pre-tightening screw sleeve 13 and adjusting pre-tightening Lock nut 14; displacement conversion mechanism 6 includes: transmission rod 15, flexible hinge 16, connecting rod 17 and eccentric wheel 18.

[0012] The base 1 is a cuboid metal frame, with a vertical bearing beam on the left side and the middle part, a threaded hole on the left bearing beam, and a threaded hole on the left bearing beam on the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com