Leveling device for flat steel belt of power station boiler and manufacturing method of leveling wheels

A technology of a power station boiler and a manufacturing method, which is applied in the directions of furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of the surface of the flat steel strip being too smooth and the inconvenient adjustment of the gap of the leveling wheel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

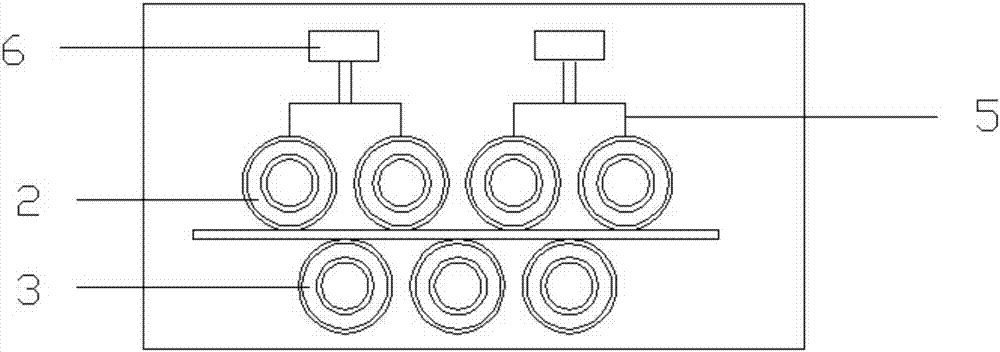

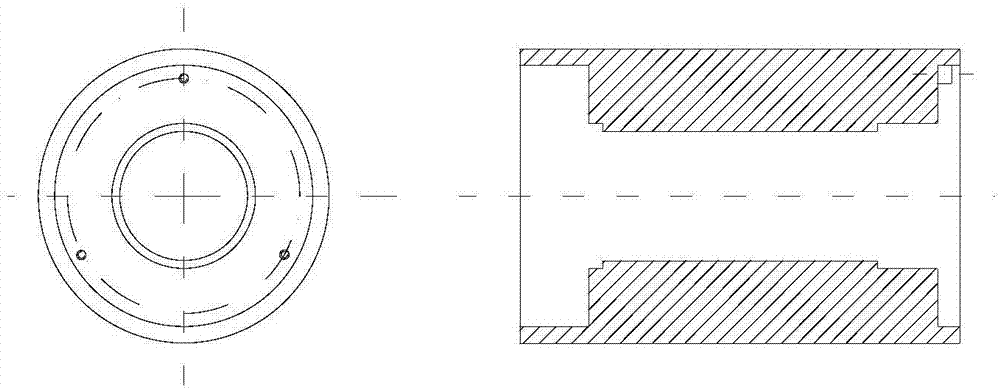

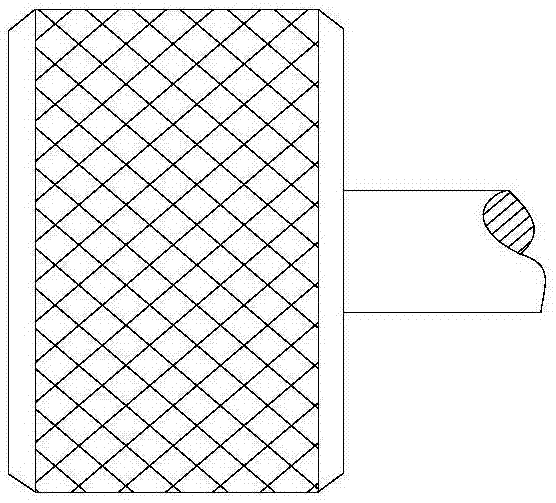

[0022] refer to figure 1 , the leveling device of the utility boiler flat steel belt of the present invention, comprises figure 2 Shown leveling wheel, fixed frame 5 and hydraulic system 6, described leveling wheel comprises upper pressure wheel 2 and lower pressure wheel 3, and described upper pressure wheel 2 rotates and is arranged on fixed frame 5, and described hydraulic system 6 The piston rod is connected to the fixed frame 5, and the lower pressure roller 3 is below the upper pressure roller 2, referring to image 3 , the surface of the leveling wheel is provided with a knurled texture.

[0023] refer to Figure 4 , the height h of the knurled pattern of the leveling wheel is 0.2-0.5 mm, and the pitch p is 0.9-1.5 mm.

[0024] When leveling, place the flat steel belt on the lower pressure roller 3, start the hydraulic system 6, drive the fixed frame 5 to move downward through the piston rod of the hydraulic system 6, make the upper pressure roller 3 contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com