Device capable of automatically adjusting coating machine scraper gap

An automatic adjustment and coating machine technology, which is applied to the surface coating liquid device, coating, electrode manufacturing, etc., can solve the problems of difficulty in ensuring consistent height, tilting of the scraper coating roller, and long adjustment time, so as to avoid Inconsistent adjustment height, precise clearance accuracy, and small effective stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

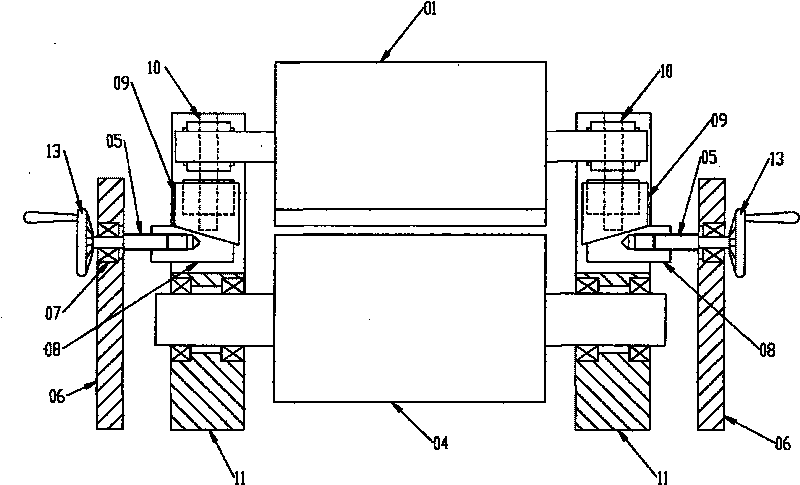

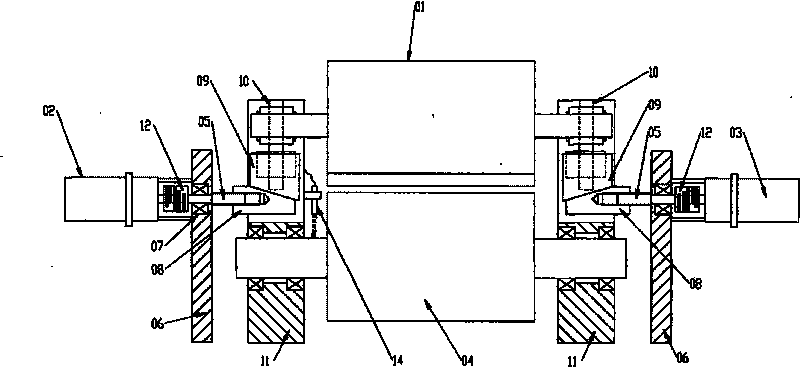

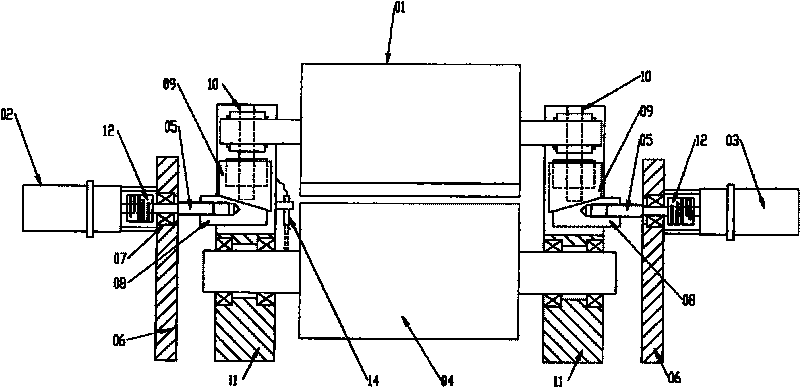

[0019] Such as figure 2 Shown: a kind of automatic adjustment coating machine scraper gap device of the present invention, comprises scraper 01, coating roller 04, screw rod 05, fixed inclined block 09, movable inclined block 08, linear guide rail 10, is characterized in that: has two Servo motors A and B are respectively connected to the movable inclined blocks 08 at both ends of the scraper through a shaft coupling 12, a bearing 07, a screw seat 06 and a screw 05.

[0020] The two servo motors 02 and 03 are centralized controlled by the same PLC.

[0021] Described inclination block 09 is also equipped with high-precision displacement sensor 14, and is connected with PLC.

[0022] The high-precision displacement sensor 14 collects and adjusts the spacing feedback information in good time and sends it to the PLC control center to form a closed-loop control system.

[0023] Using the stability of the movement of the closed-loop control system of the servo motor, the gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com