Rectangular enameled wire head flexible brush scraping rotary milling stripping system

An enameled wire and flexible technology, applied in the field of rectangular enameled wire wire head flexible brush scraping, rotary milling and peeling system, can solve the problems of poor cleanliness of peeling off the paint, difficult to damage the wire substrate, affecting the quality of soldering, etc. The contradiction of processing efficiency, simple and reliable operation and adjustment of equipment, and the effect of improving peeling quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

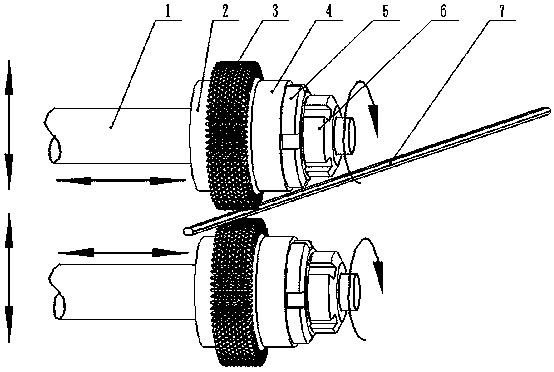

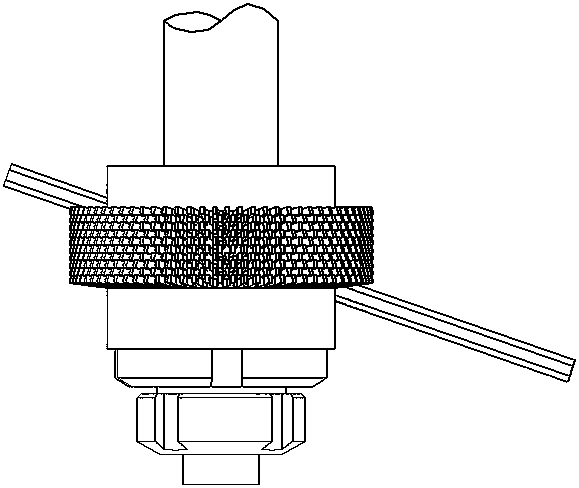

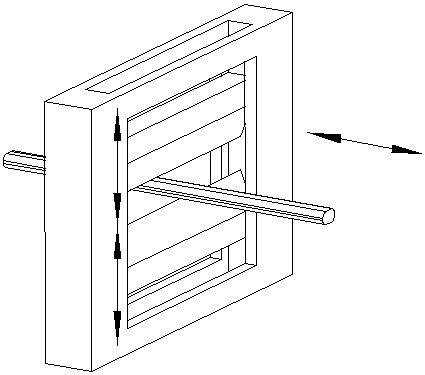

[0025] Below, the present invention combines the attached figure 1 For further clarification:

[0026] Movement features: the main rotation axis rotates in the same direction, providing and ensuring peeling, extrusion, scraping and cutting movement, and the direction of feed movement in the vertical direction of the double soft knife of the rotary milling head is close to the flat line 7 (workpiece) at the same time. When the blade (3) is in contact with the copper wire, the blade (3) starts to rotate and scrape the insulating paint on the copper wire. In order to ensure a certain stripping length, the double soft knife lead moves along the direction of the workpiece. When the length required for the rotary milling brush to scrape the insulating paint on the copper wire has been reached, the moving direction of the quick reset is to leave the flat wire 7 (workpiece) and return to the initial position of the rotary milling head at the same time, so that the double soft cutters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com