Full-automatic silkworm cocoon stripping production line

A stripping production line, fully automatic technology, applied in silk fiber production, mechanical treatment, fiber treatment, etc., can solve problems such as low stripping quality and efficiency, large equipment volume, tight cocoon winding, etc., to shorten operating time, improve efficiency and Quality, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

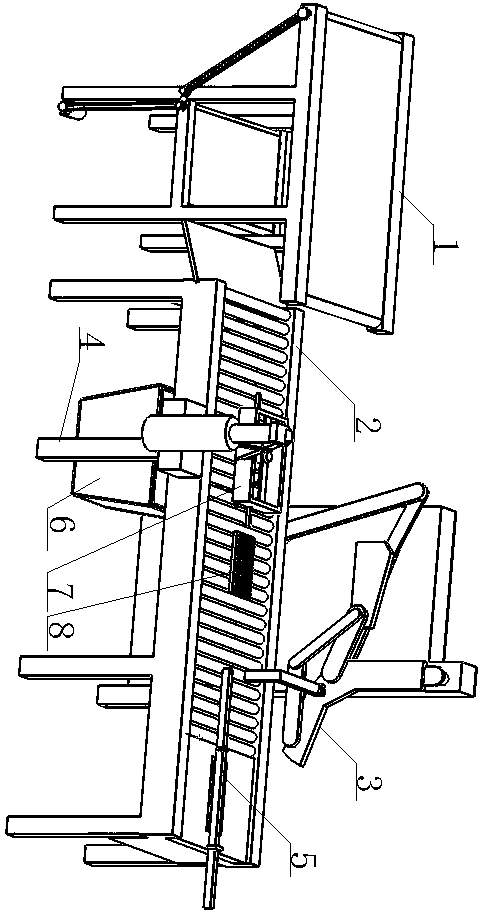

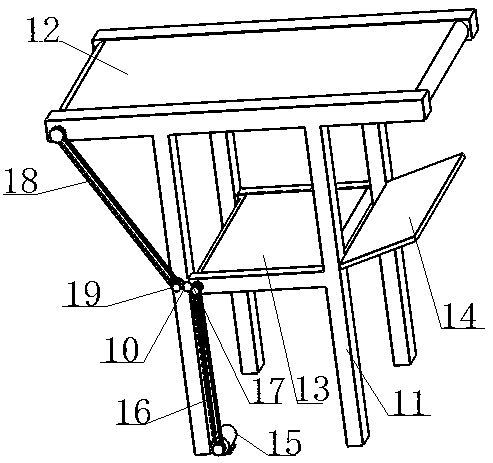

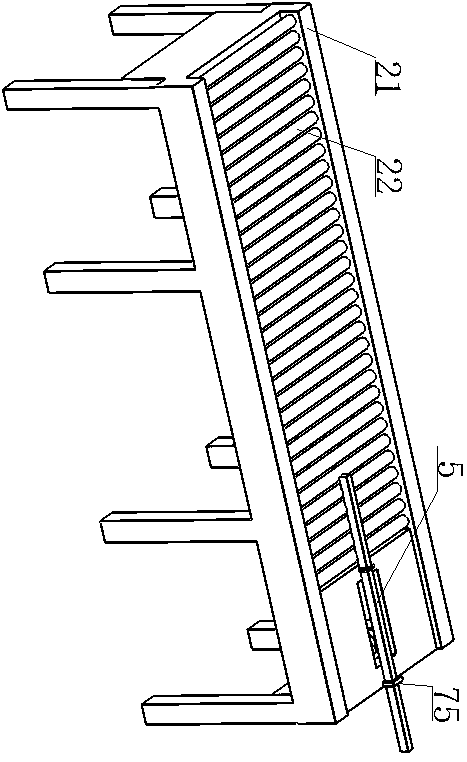

[0039] Attached below figure 1 -89 illustrates the technical solution of the present invention.

[0040] The present invention includes a cocoon box transmission device 1, a cocoon processing platform 2 is arranged on one side of the cocoon box transmission device 1, and a cocoon processing platform 2 is respectively provided with a cocoon box pick-and-place device 3, a cocoon stripping device 4, and a cocoon processing platform along the length direction. 2 The free end is provided with a cocoon box pushing device 5, and the cocoon stripping device 4 is correspondingly provided with a cocoon collection box 6 under the cocoon processing platform 2;

[0041] Wherein, silkworm cocoon peeling device 4 comprises the cylinder 41 that is fixed on one side of silkworm cocoon processing platform 2, and cylinder 41 is provided with driving rod 43 through rotating shaft through the free end of piston rod 42, and the free end of driving rod 43 is fixed with peeling part 7, and cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com