Abalone shelling machine

A shelling machine and abalone technology, applied in the processing of crustaceans, slaughtering, food science, etc., can solve the problems of incomplete peeling of shell meat, increase processing difficulty, waste abalone meat, etc., so as to improve the quality of shelling and save money. Give time and ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

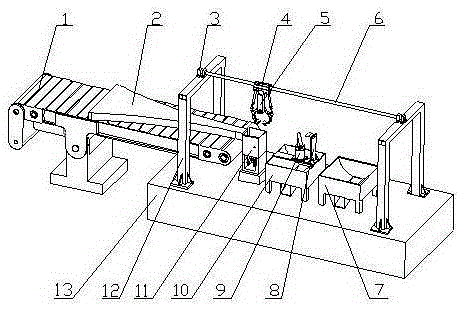

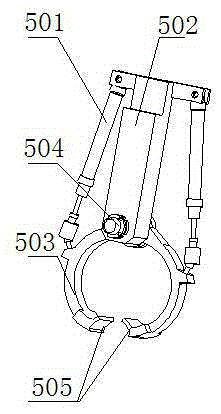

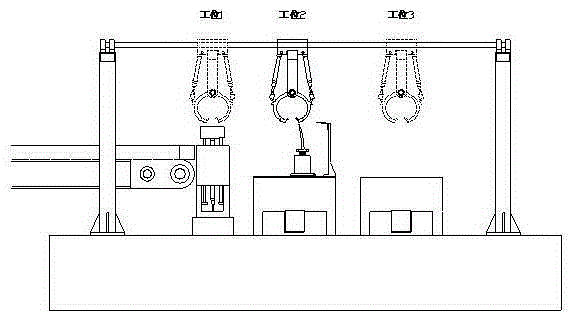

[0021] Such as Figure 1 to Figure 9 As shown, the abalone shelling machine includes a conveyor belt 1, an abalone arrangement shape organizer 2, a claw slider 4, a claw device 5, a slide rail 6, an abalone shell storage box 7, a cutting device 8, and a spring shelling knife device 9. Abalone meat container 10, top block device 11, support gantry 12 and base 13, abalone arrangement shape finisher 2 is installed on the conveyor belt 1, the discharge port of abalone arrangement shape finisher 2 is connected with the top block device 11 The feeding port is opposite, the supporting gantry 12 is installed at the front and rear ends of the base 13, the slide rail 6 is installed between the supporting gantry 12 through the guide rail fixing joint 3, and the claw device 5 is connected with the slide rail 6 through the claw slider 4 , the top block device 11, the abalone meat container 10, the spring shelling knife device 9, the cutting device 8 and the abalone shell container 7 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com