Patents

Literature

32results about How to "Fully peeled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

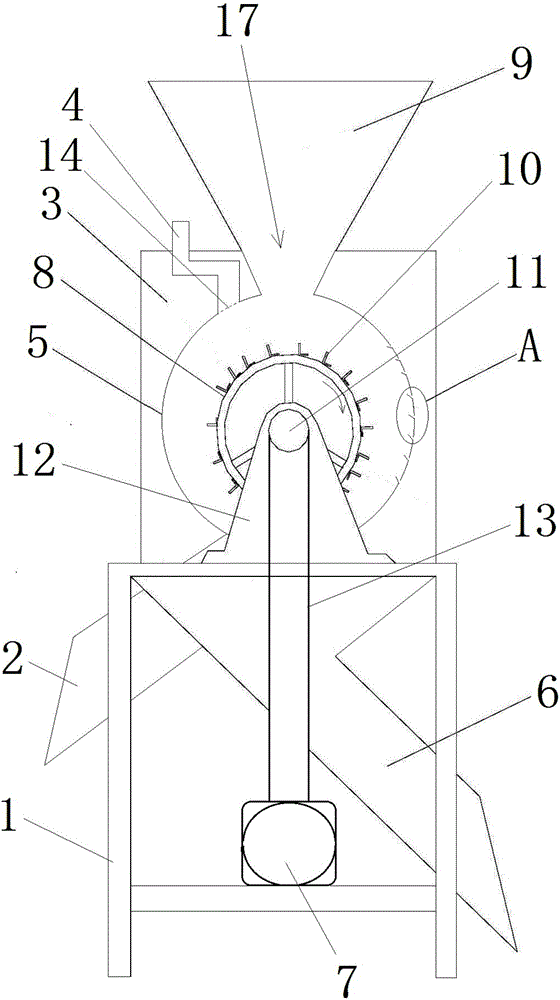

Manual operation-imitated sugarcane peeling and cutting machine

InactiveCN106078898ARealize automatic peeling and cuttingSimple imitation manual cutting modeVegetable peelingMetal working apparatusEngineeringMechanical engineering

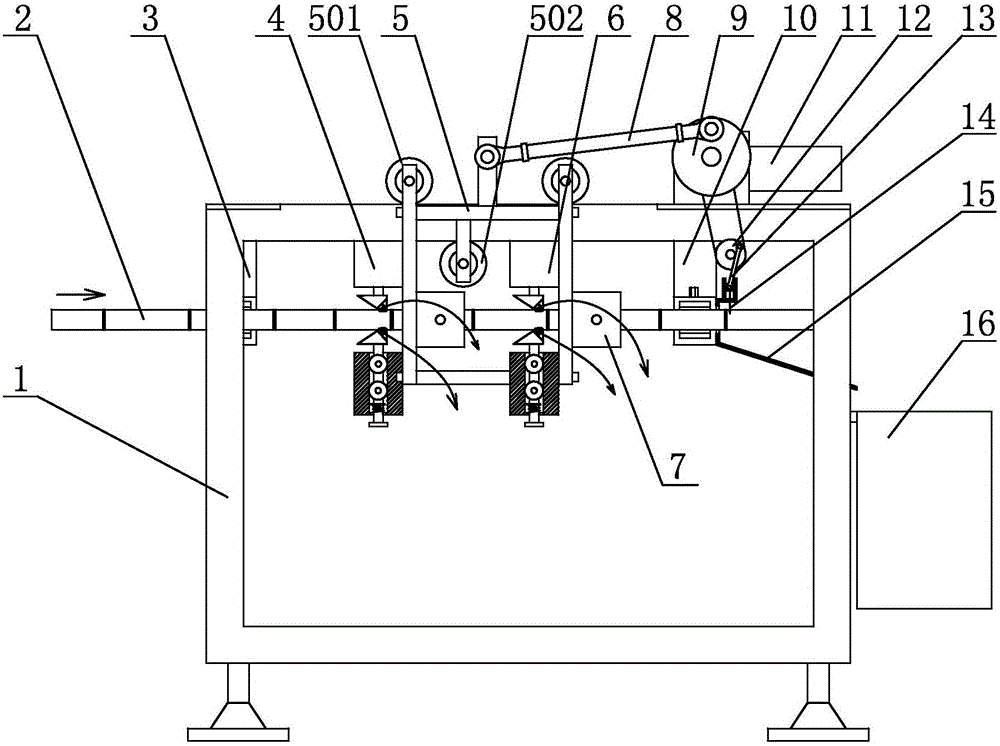

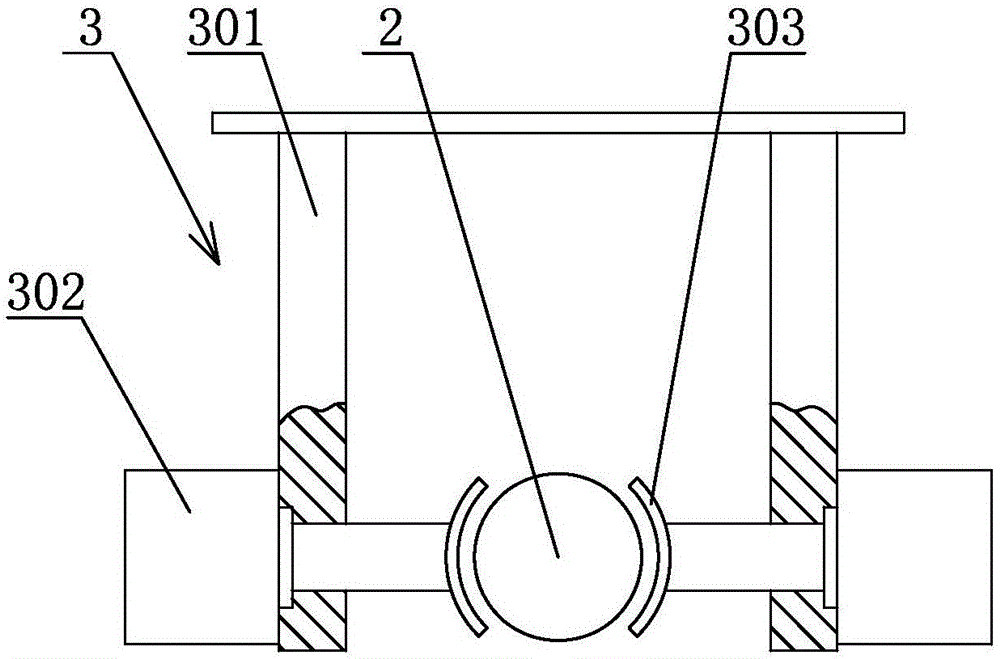

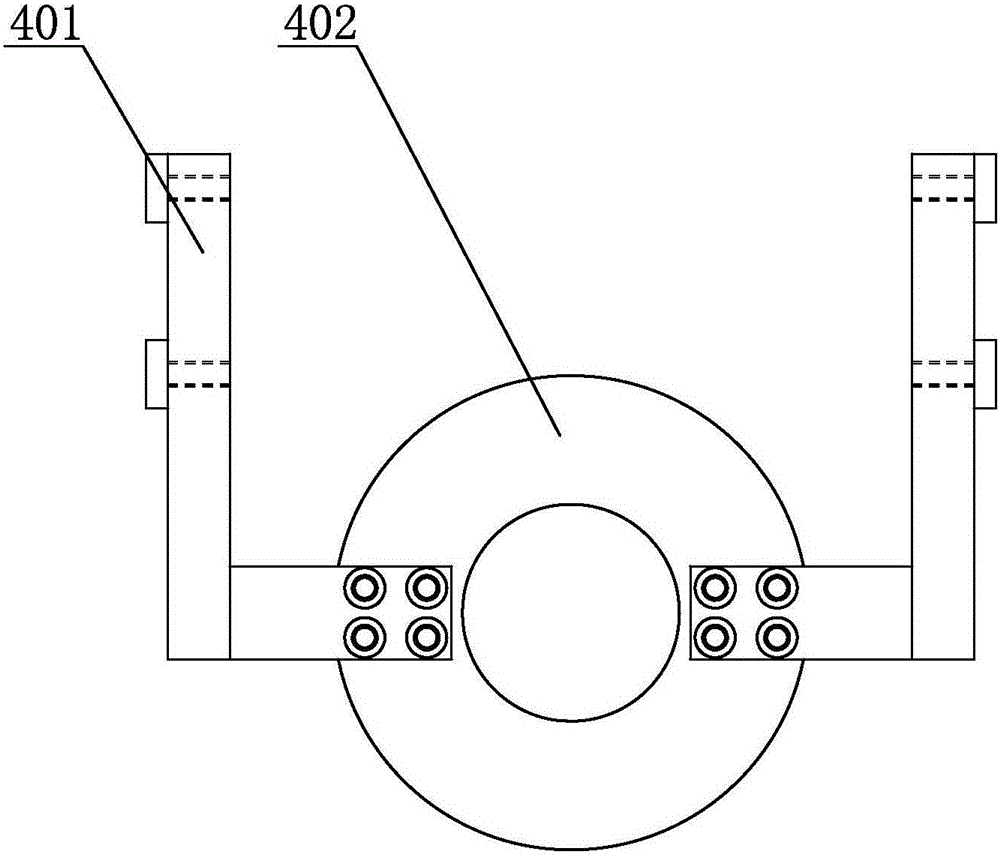

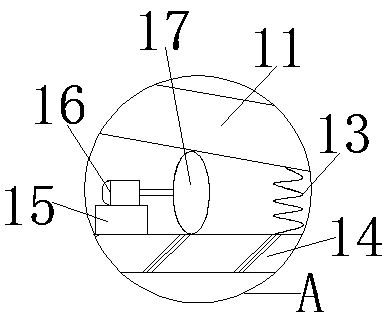

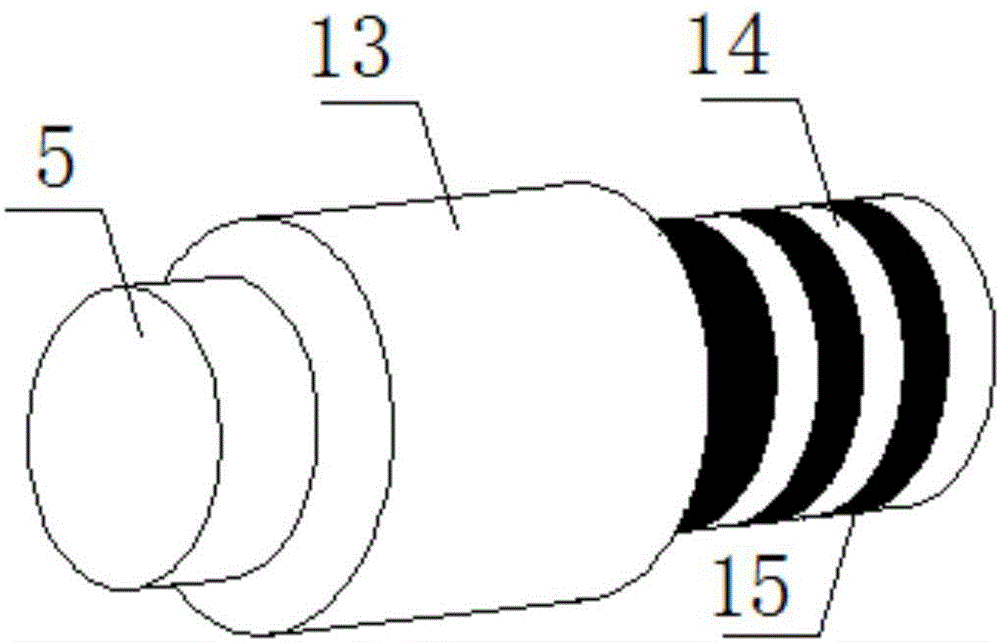

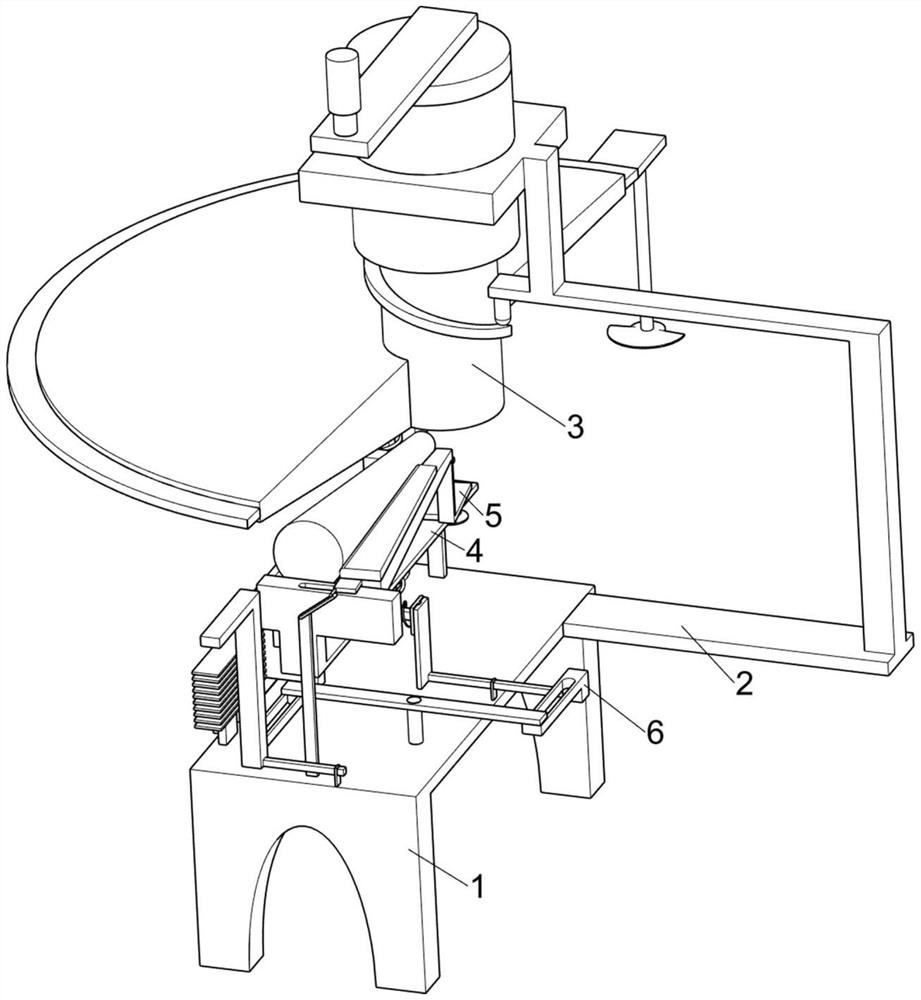

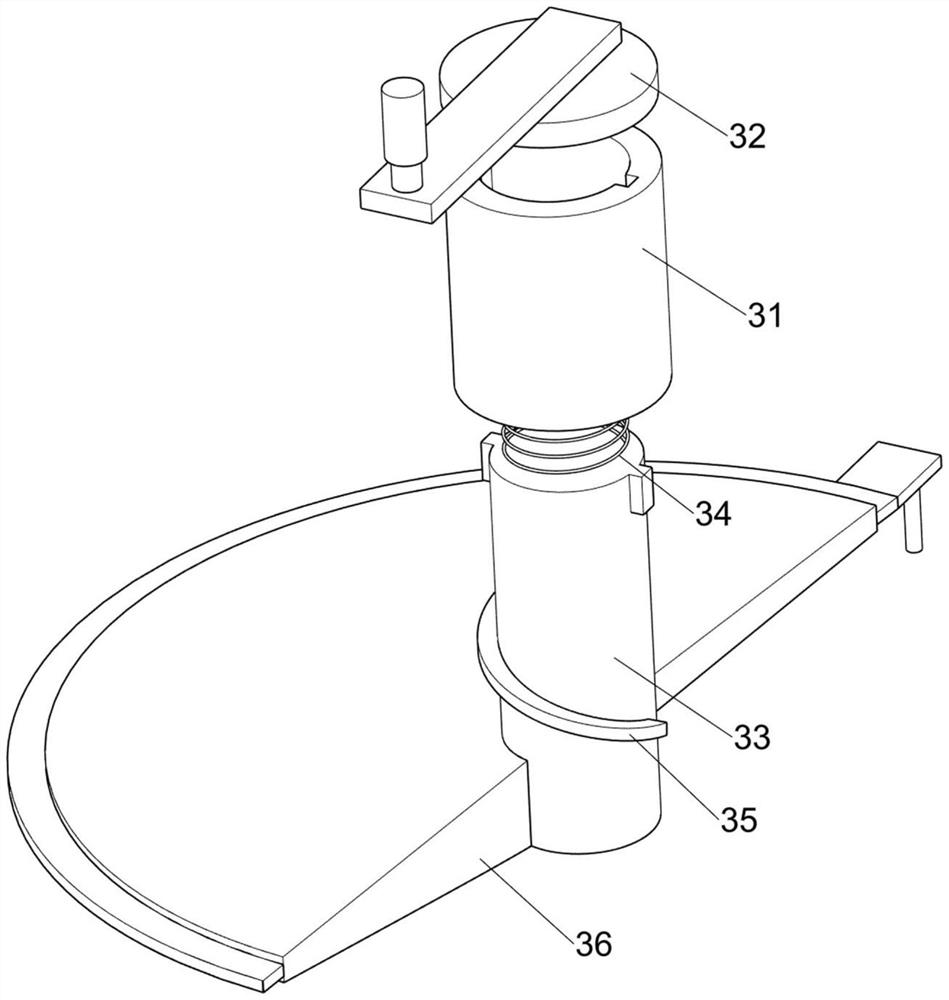

The invention relates to a manual operation-imitated sugarcane peeling and cutting machine which comprises a rack, a clamping device and a cutting device, and when the cutting device cuts a sugarcane, the clamping device clamps the sugarcane; the cutting device comprises a cutting bracket, cutting tool groups, a connecting rod, a rotating wheel and a power source for controlling the rotating wheel to rotate; the cutting bracket performs reciprocating limiting sliding relative to the rack, and the sliding direction is parallel to the sugarcane feeding direction; the cutting bracket is fixedly provided with front and rear cutting tool groups; the cutting surface of the front cutting tool group and the cutting surface of the rear cutting tool group are complemented to perform circumferential surface cutting on the sugarcane; one end of the connecting rod is movably hinged to the cutting bracket, and the other end of the connecting rod is movably hinged to a position, which is eccentric relative to a rotating shaft of the rotating wheel, on the rotating wheel; the rotating wheel is located on the rack in a rotatable manner; and the rotating wheel, the connecting rod and the cutting bracket are in linkage to realize reciprocating sliding of the cutting bracket relative to the rack. The manual operation-imitated sugarcane peeling and cutting machine is relatively reliable and stable in manual cutting imitation, can realize automatic peeling and cutting of the sugarcane and ensure that cutting is relatively complete and clean, and is suitable for being used as existing sugarcane peeling machine.

Owner:王奇勇

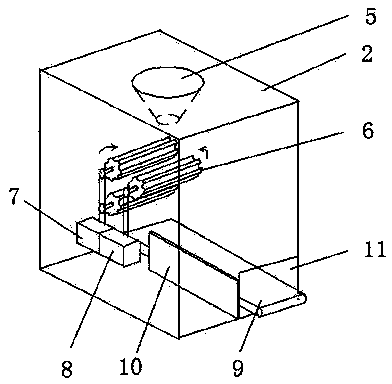

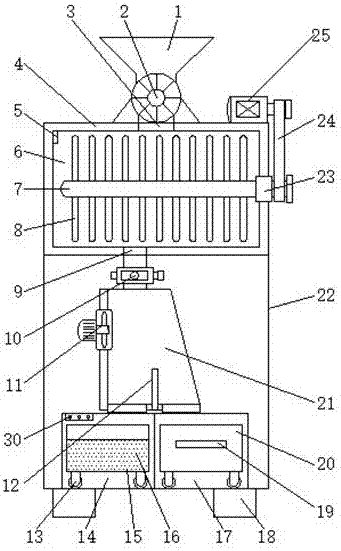

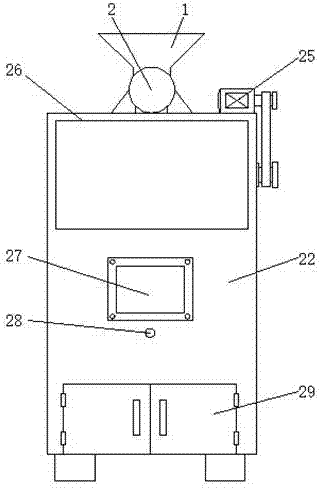

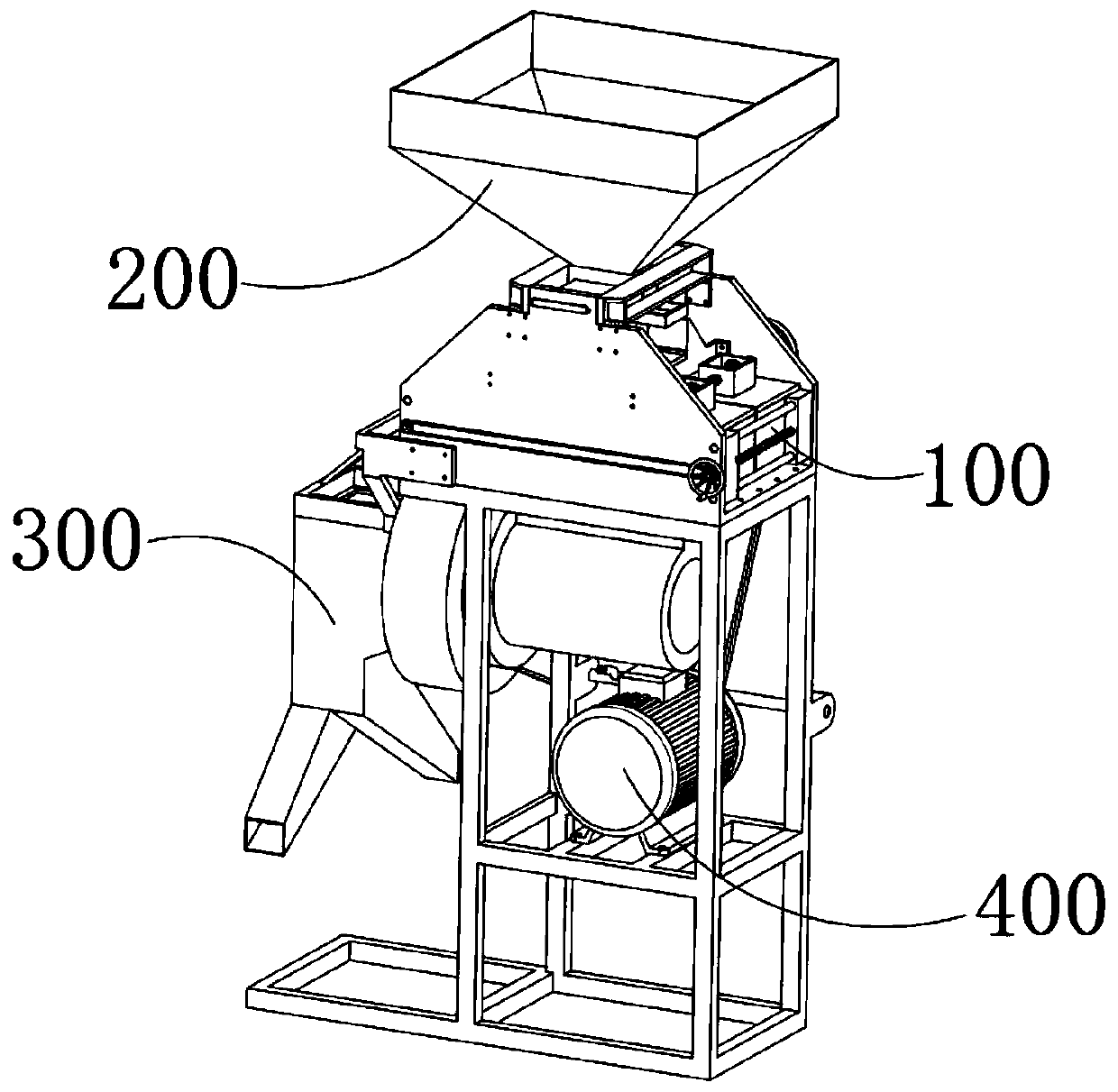

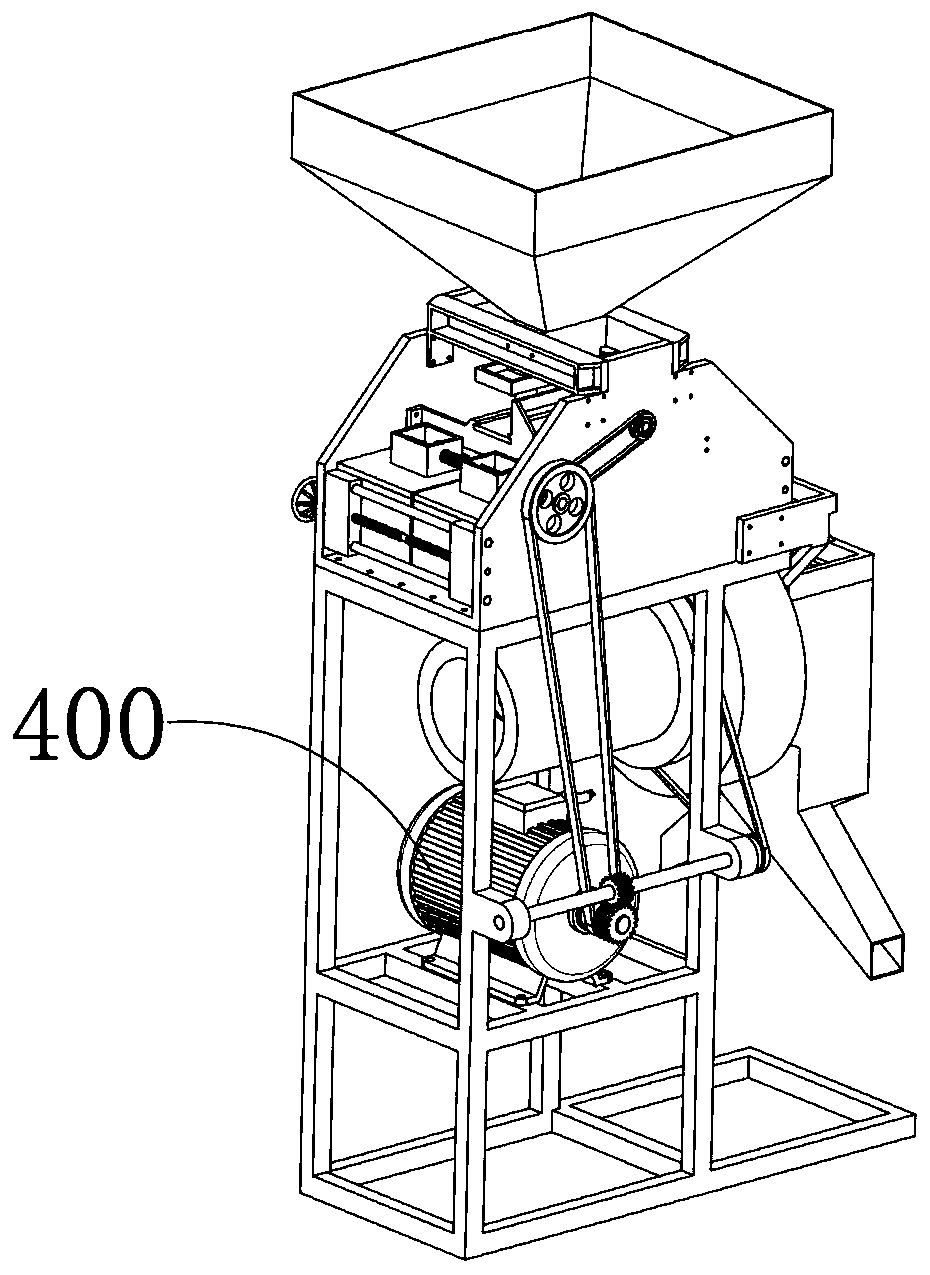

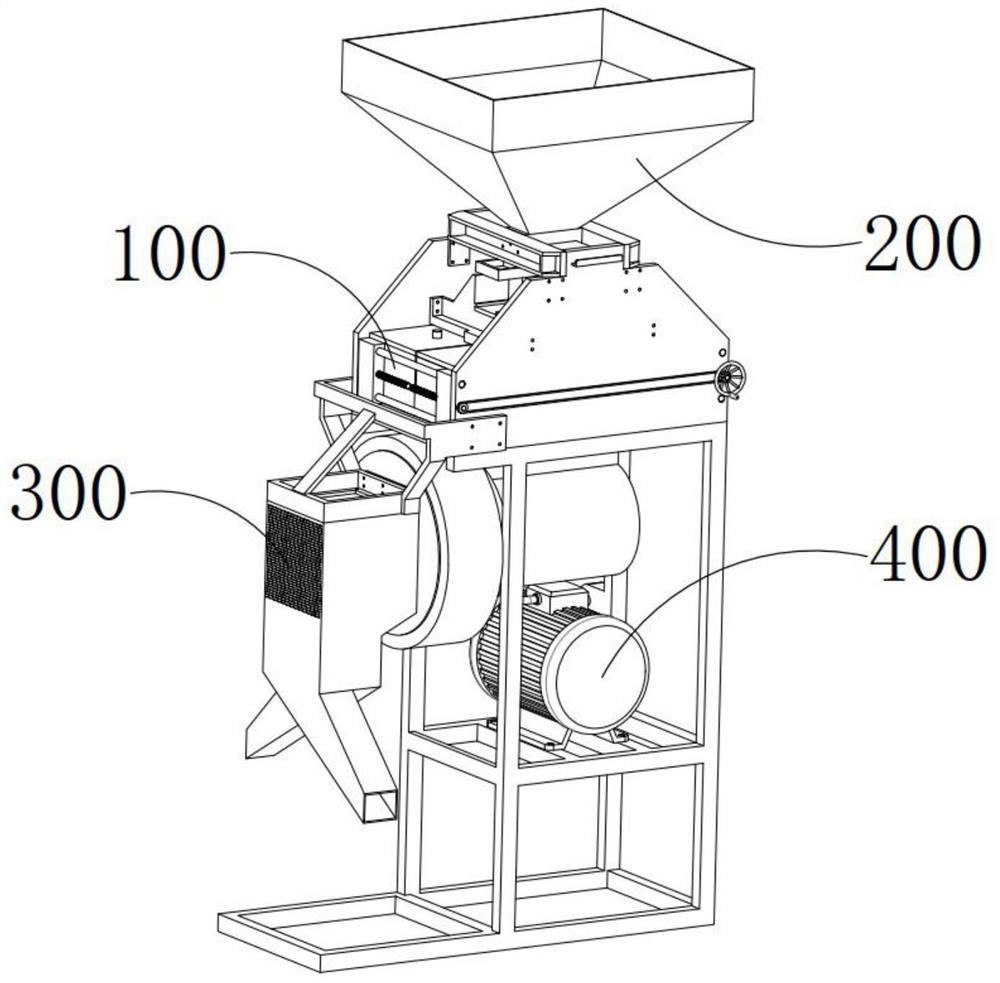

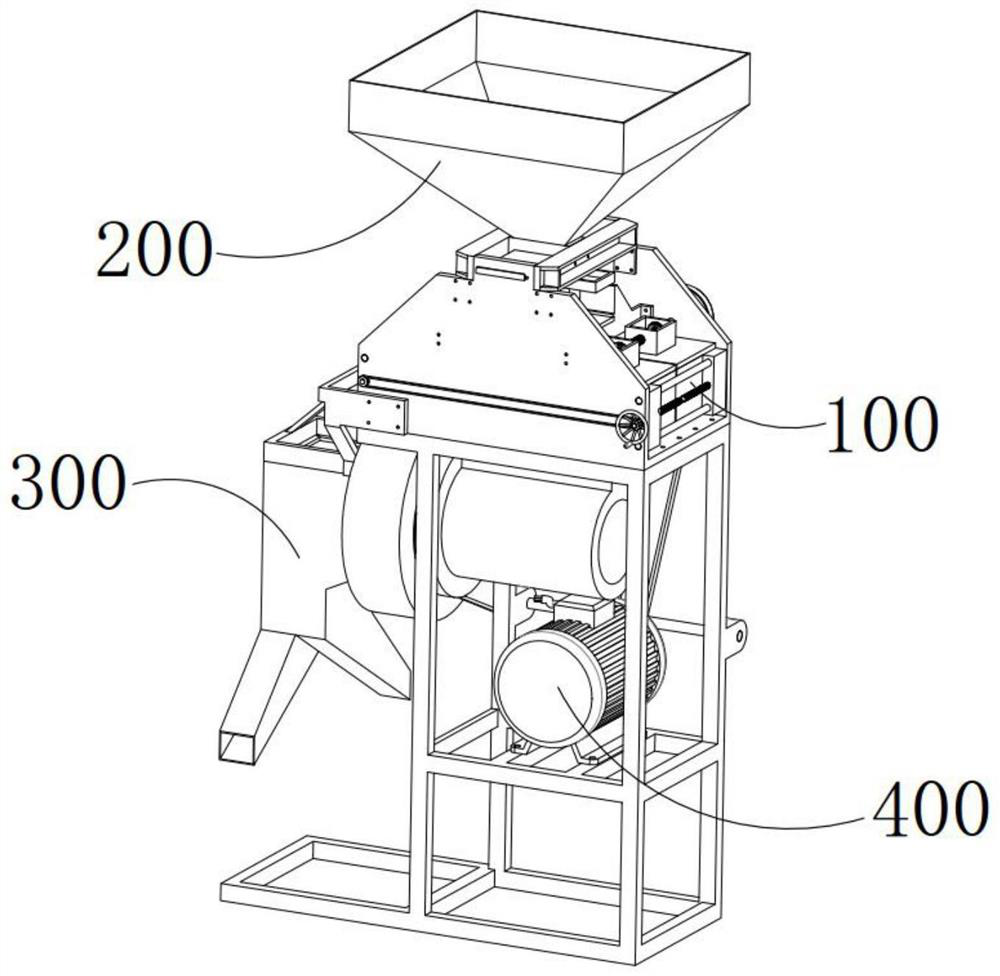

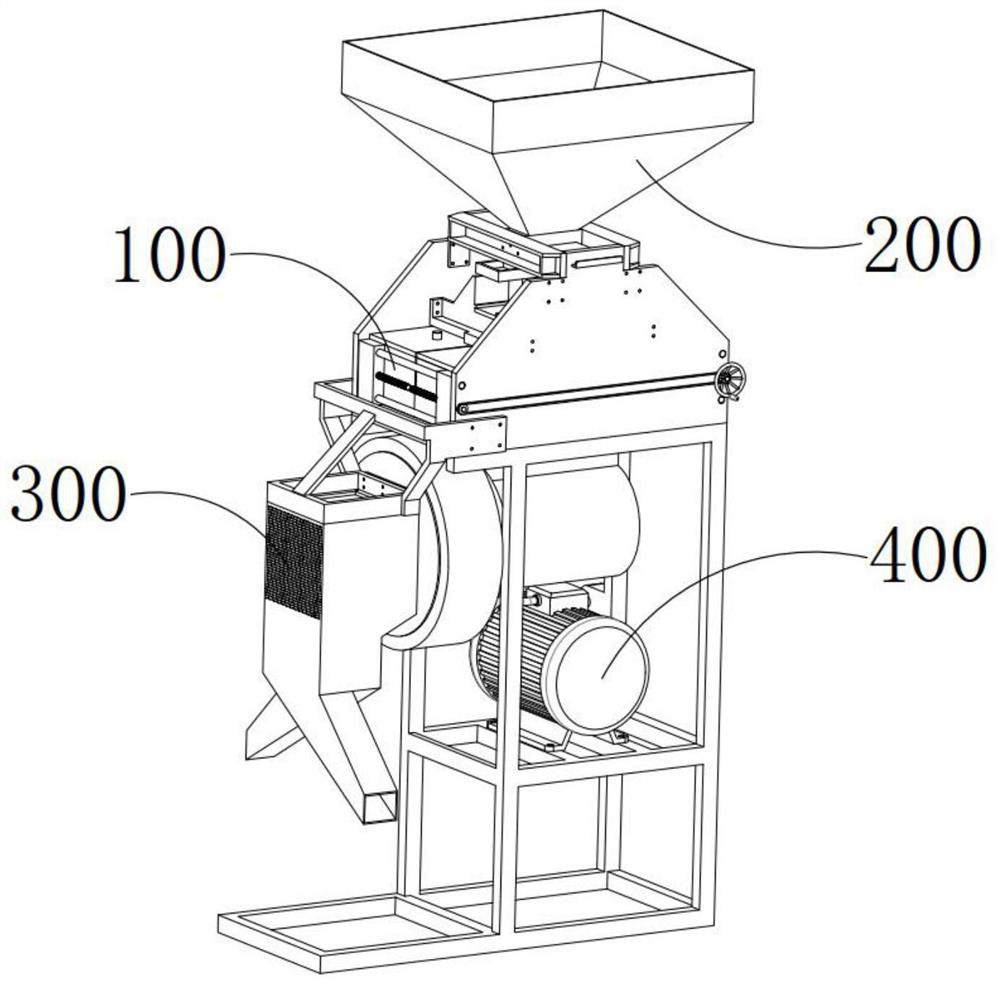

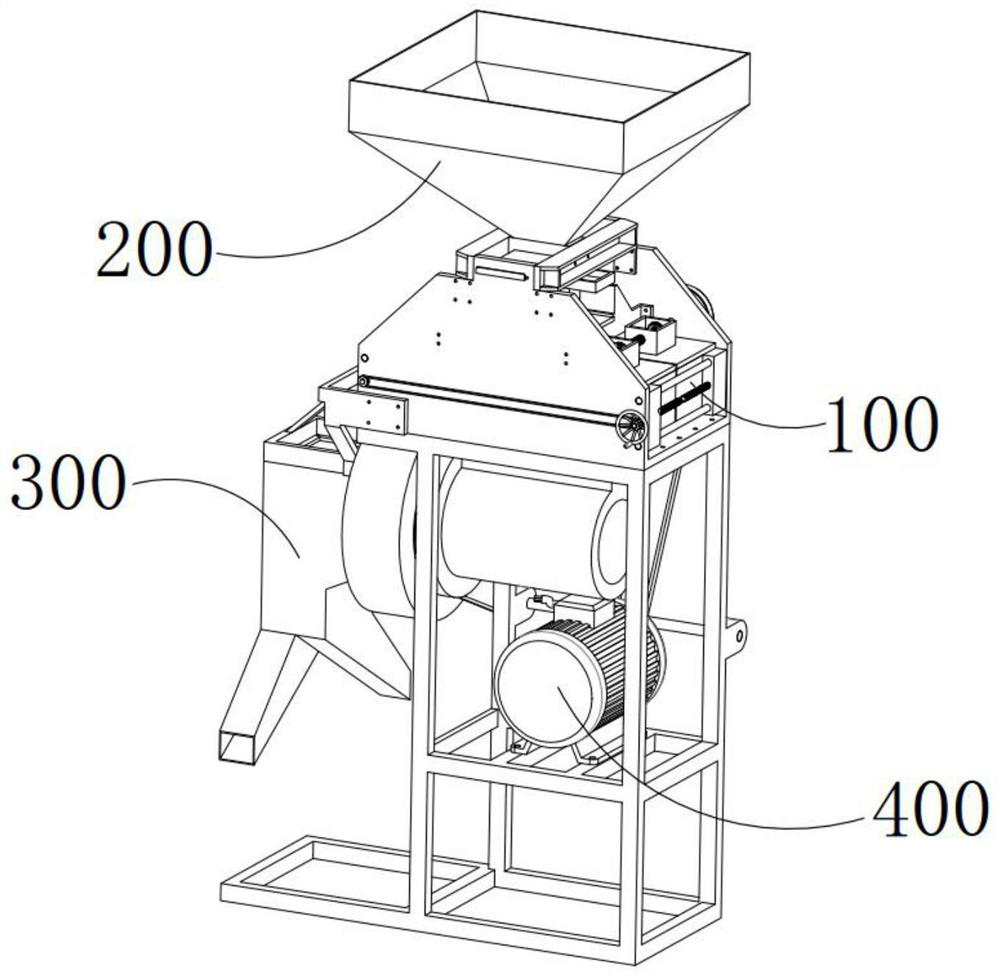

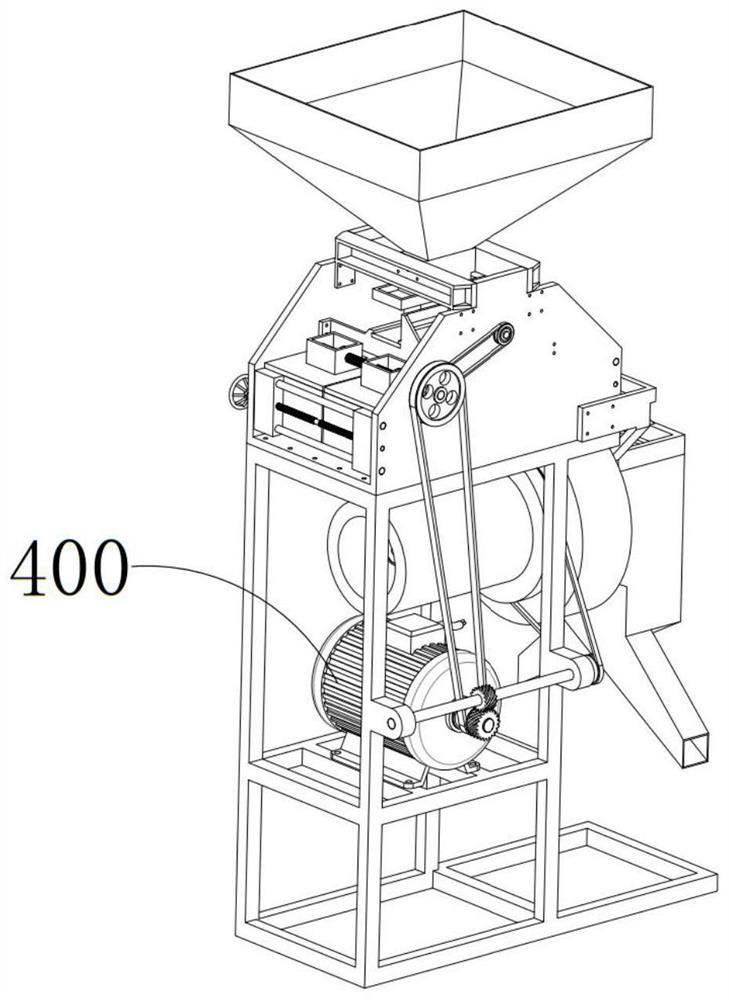

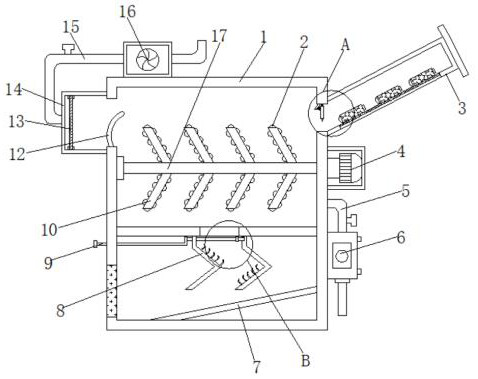

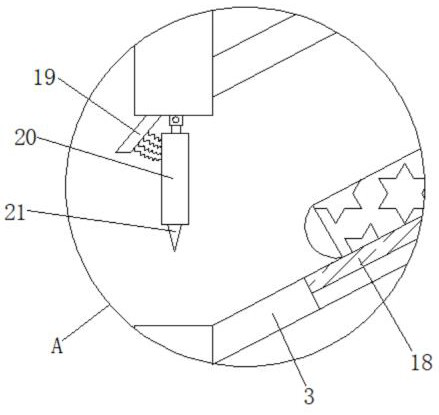

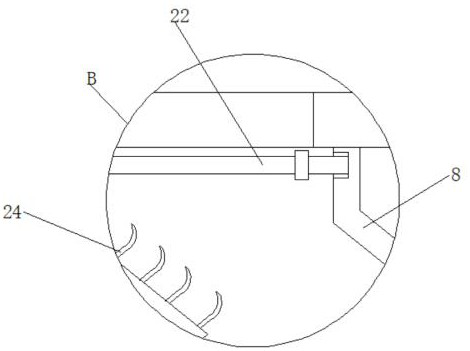

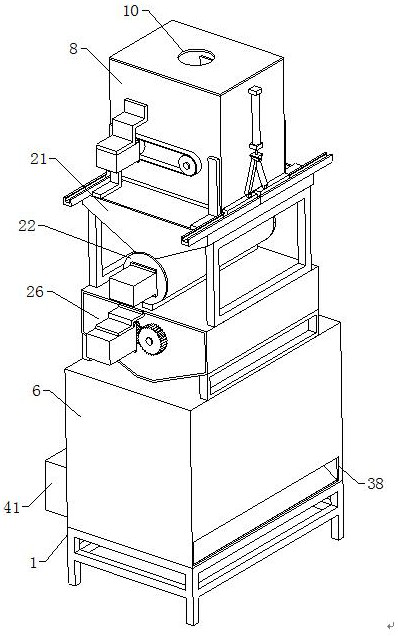

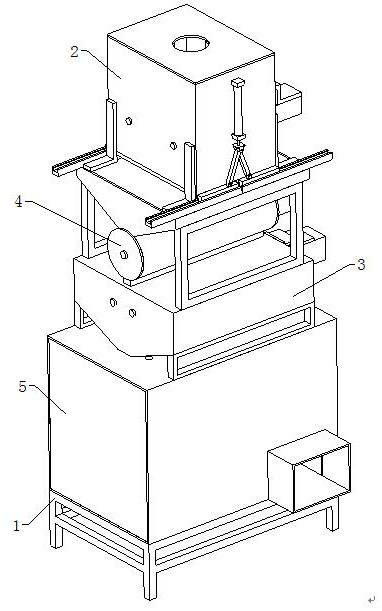

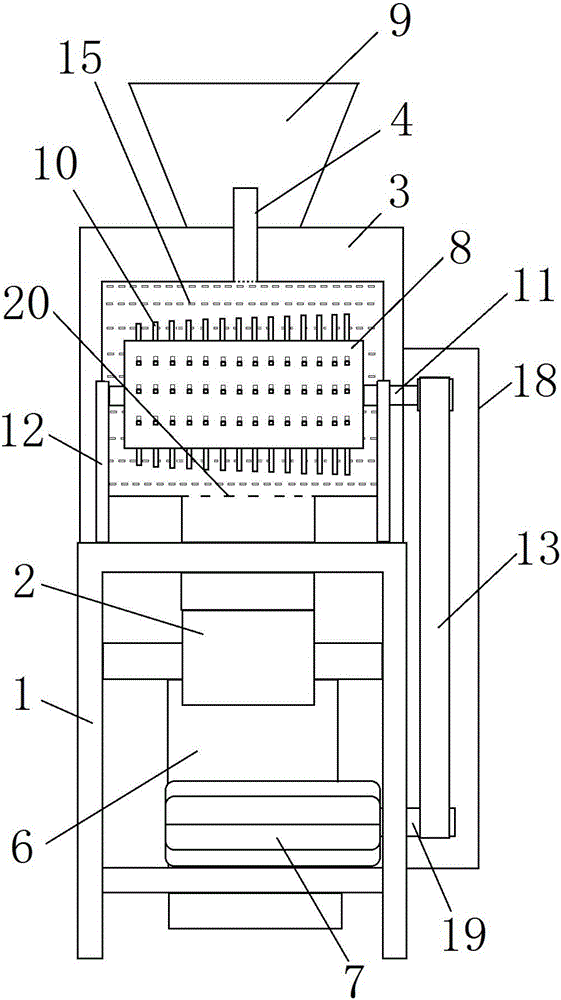

Peeling device for grain processing

PendingCN108421585APlay peelingPlay the role of feedingGrain huskingGrain polishingSpiral bladeEngineering

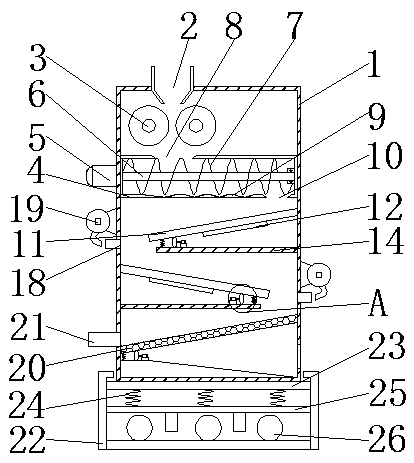

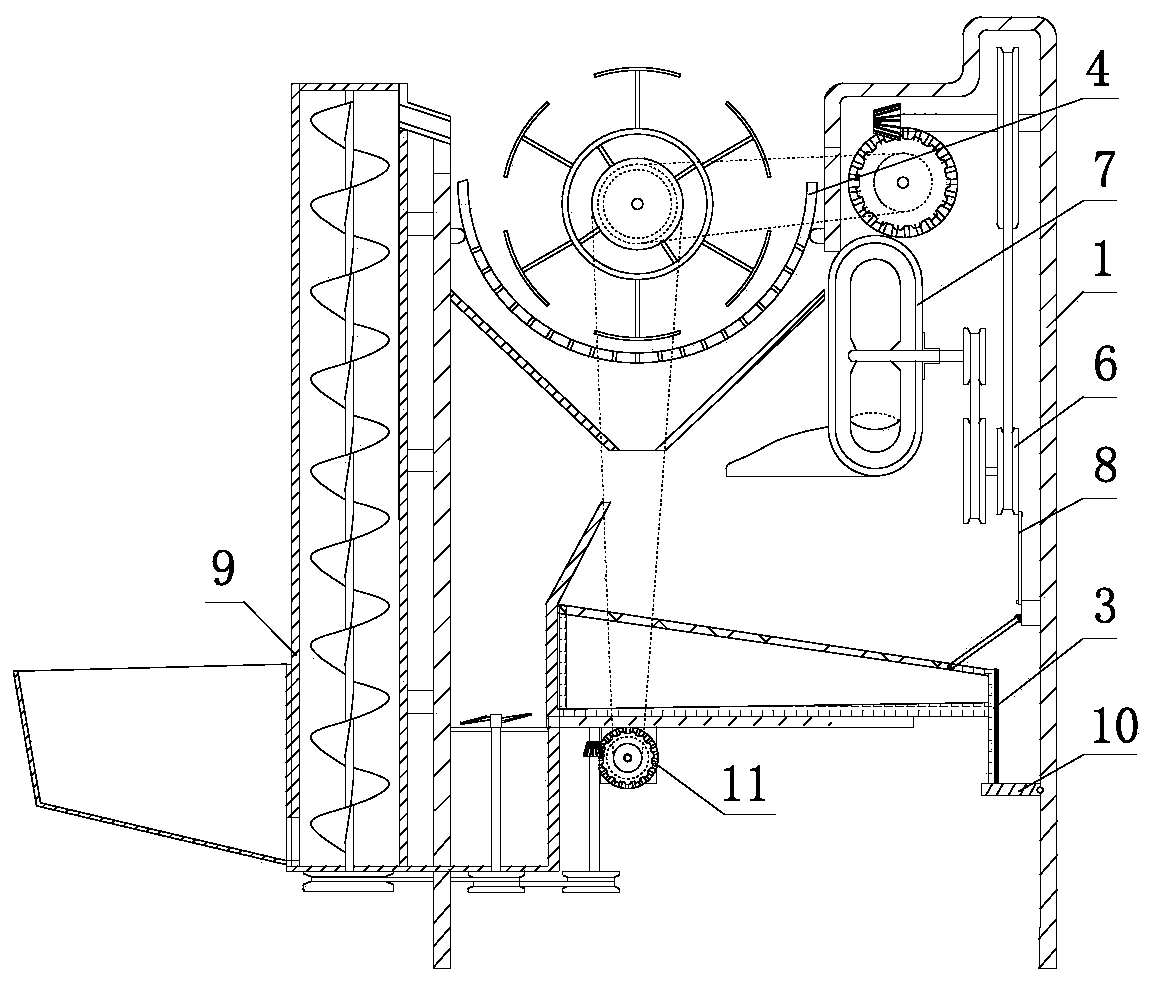

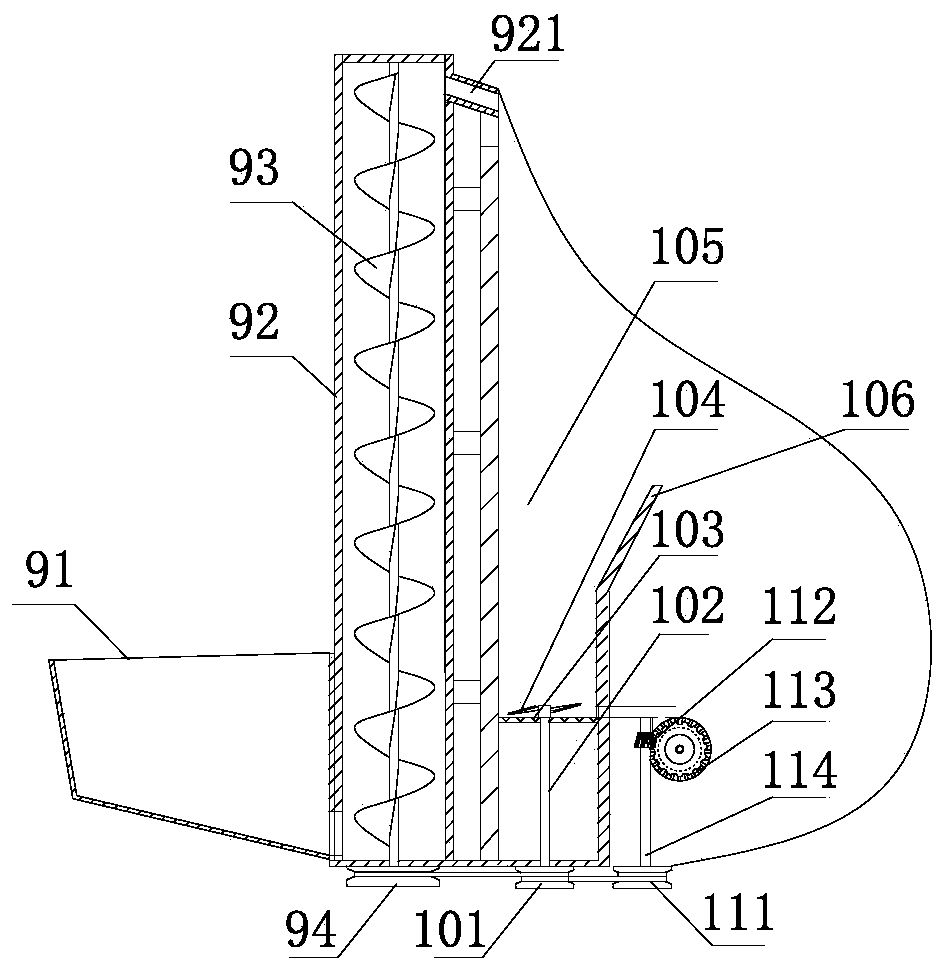

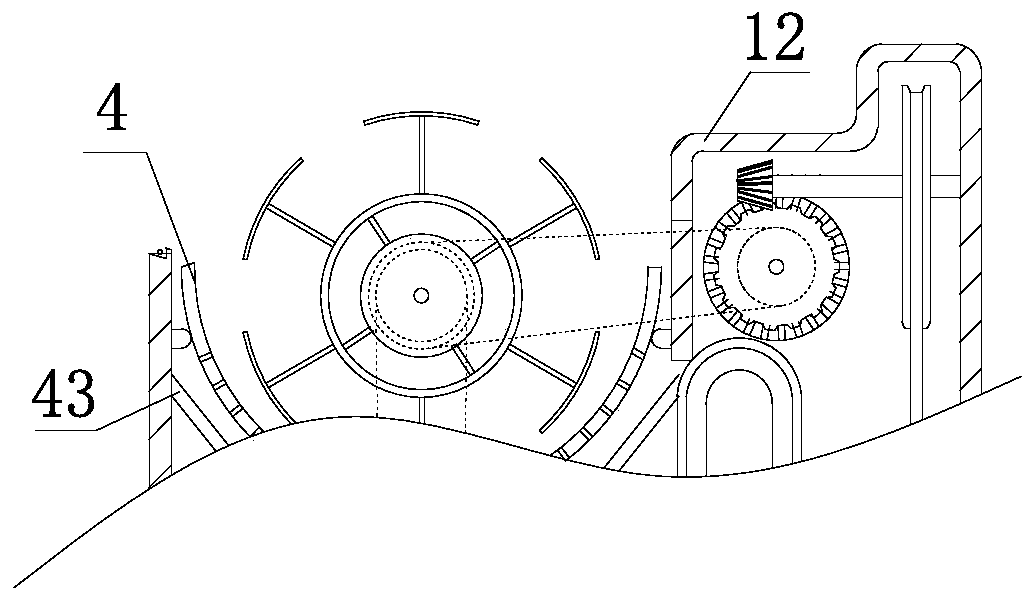

The invention relates to the technical field of grain processing machines and discloses a peeling device for grain processing. The peeling device for grain processing comprises a shell. A feed hopperis arranged at the top of the shell, rotating rollers are arranged at the bottom of the feed hopper, the inner walls of both sides of the shell are fixedly connected with the outer surfaces of both sides of a conveying box, a motor is arranged at one side of the shell, and the output end of the motor is fixedly connected with a rotating shaft; and one end of the rotating shaft penetrates and extends into the conveying box, a spiral blade is fixedly connected to the outer surface of the rotating shaft, a feed inlet is formed in the top of the conveying box, and separating plates fixedly connected to the inner wall of the shell are arranged at the bottom of the conveying box. According to the peeling device, materials can be peeled and fed through the rotating rollers, the motor, the rotating shaft, the spiral blade and protrusions, so that the feeding is uniform while the peeling effect is ensured, the cleaning effect can be improved, and the materials can be peeled more fully; and thespiral blade can prevent excessive materials from accumulating on the separating plates and is beneficial to improving the cleaning effect.

Owner:刘丽娜

Degumming preparation of mulberry bark fiber

Owner:四川省丝绸进出口集团有限公司

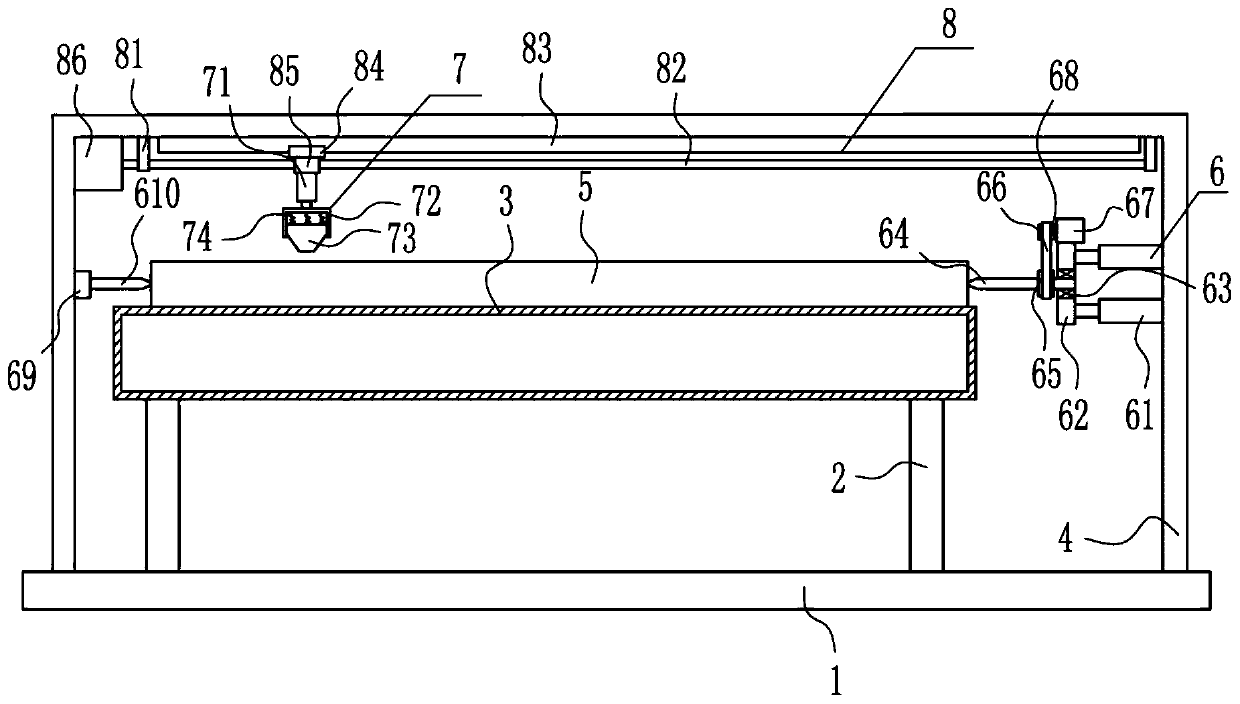

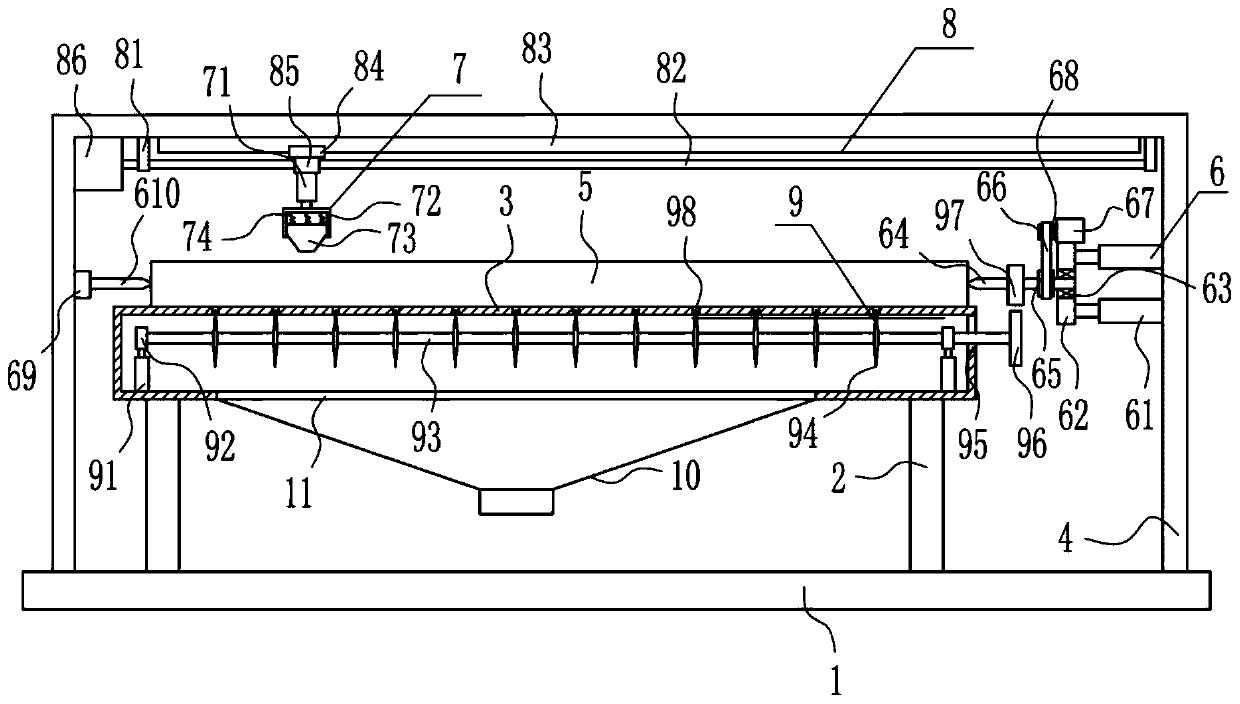

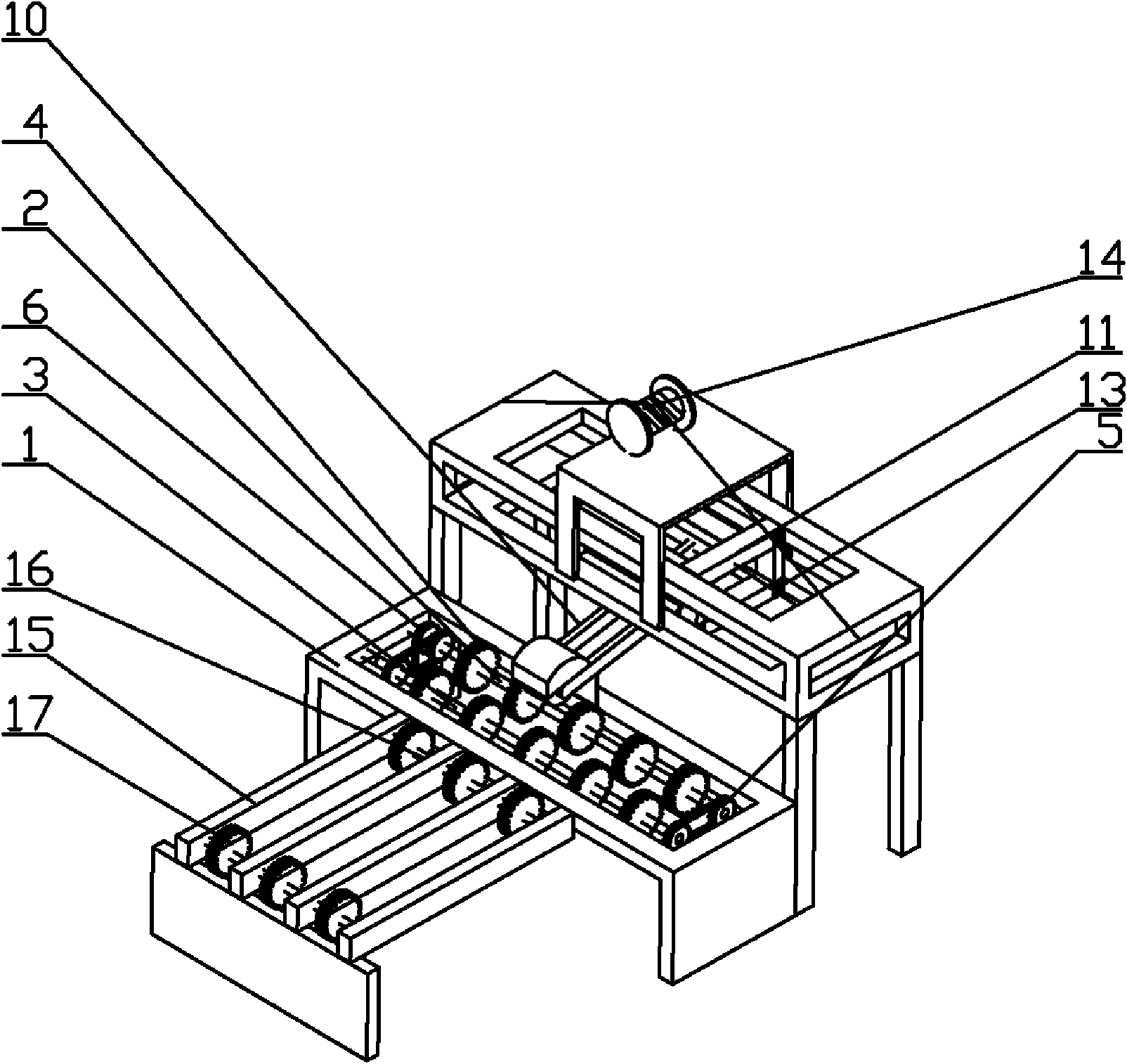

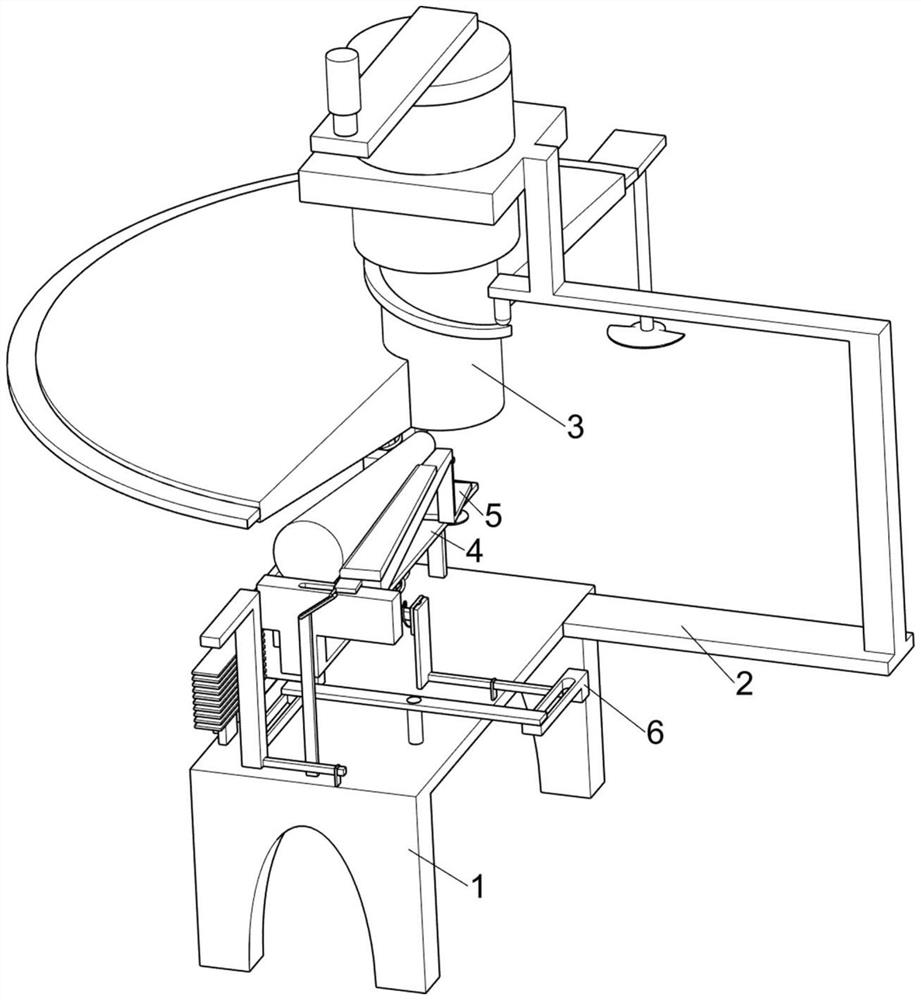

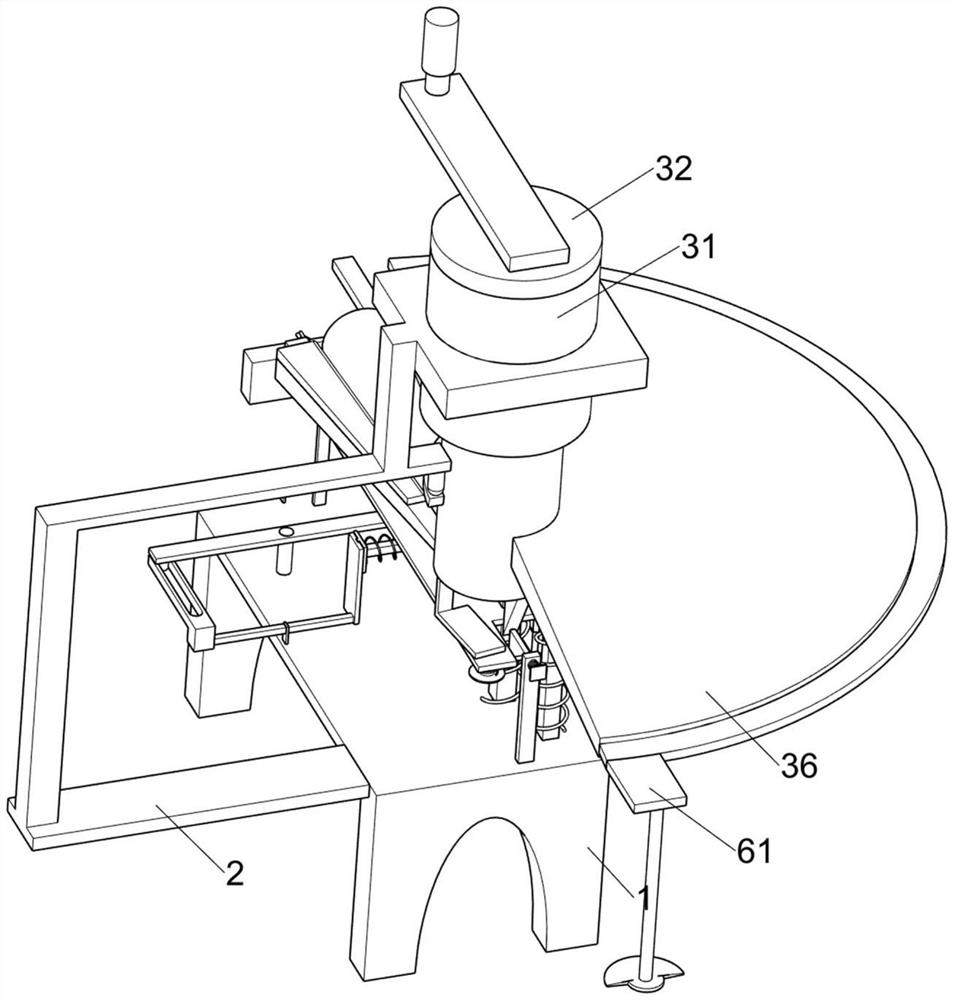

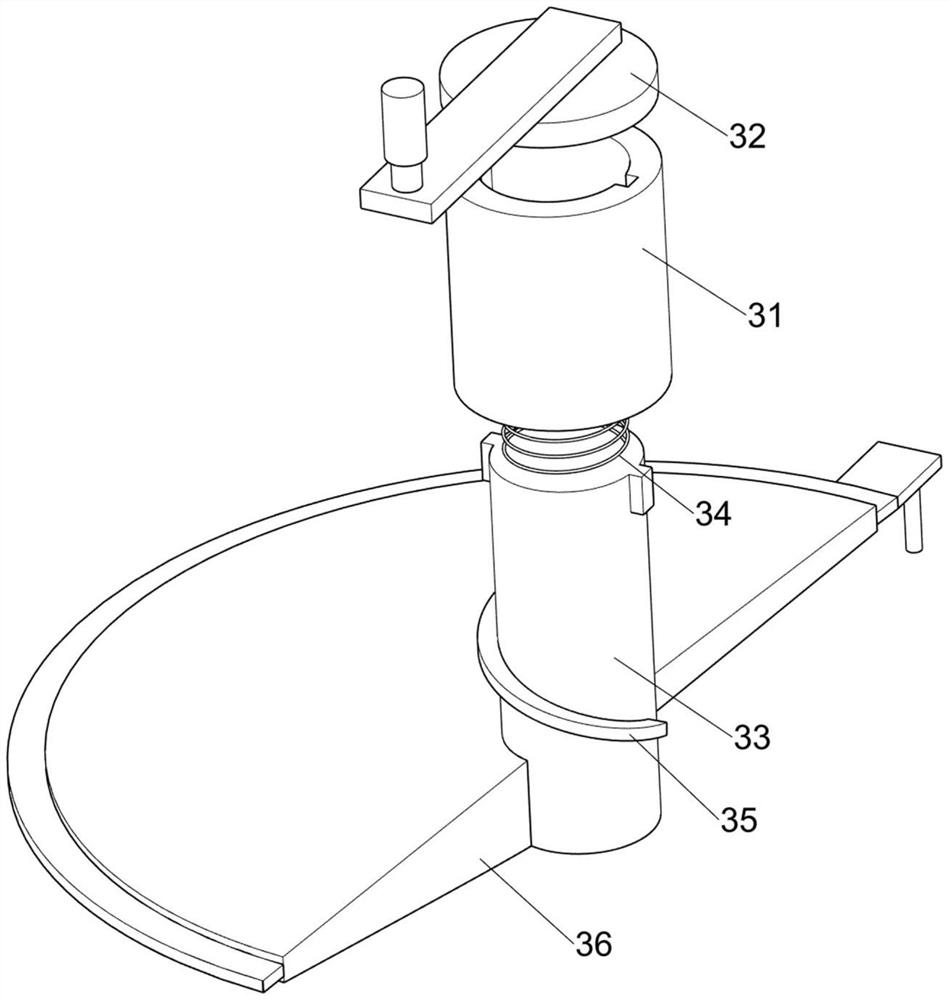

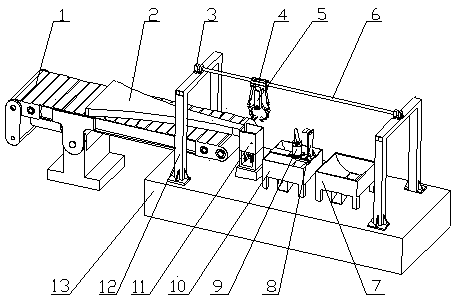

Abalone shelling machine

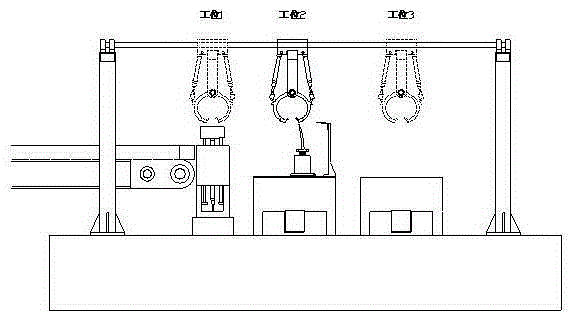

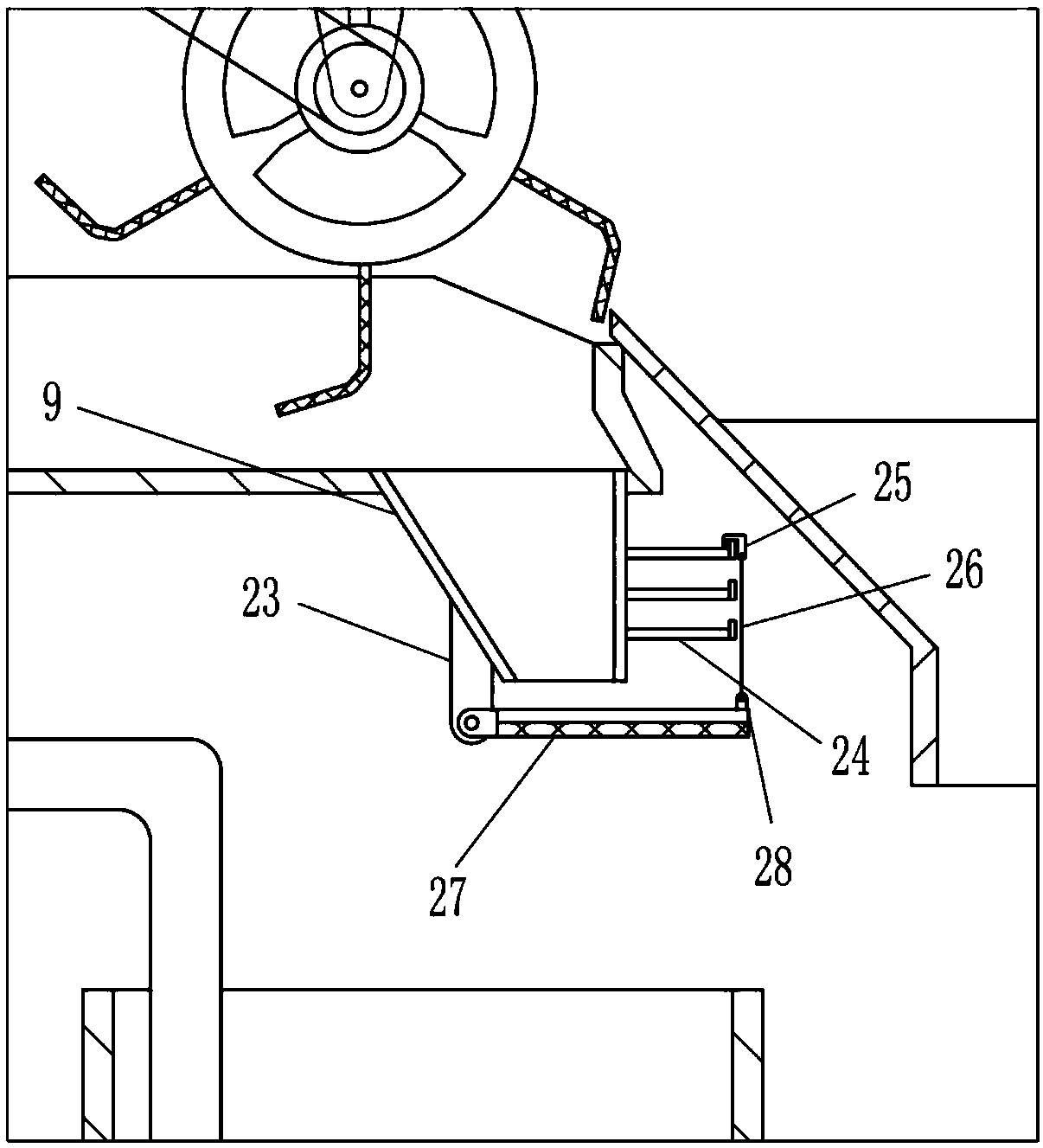

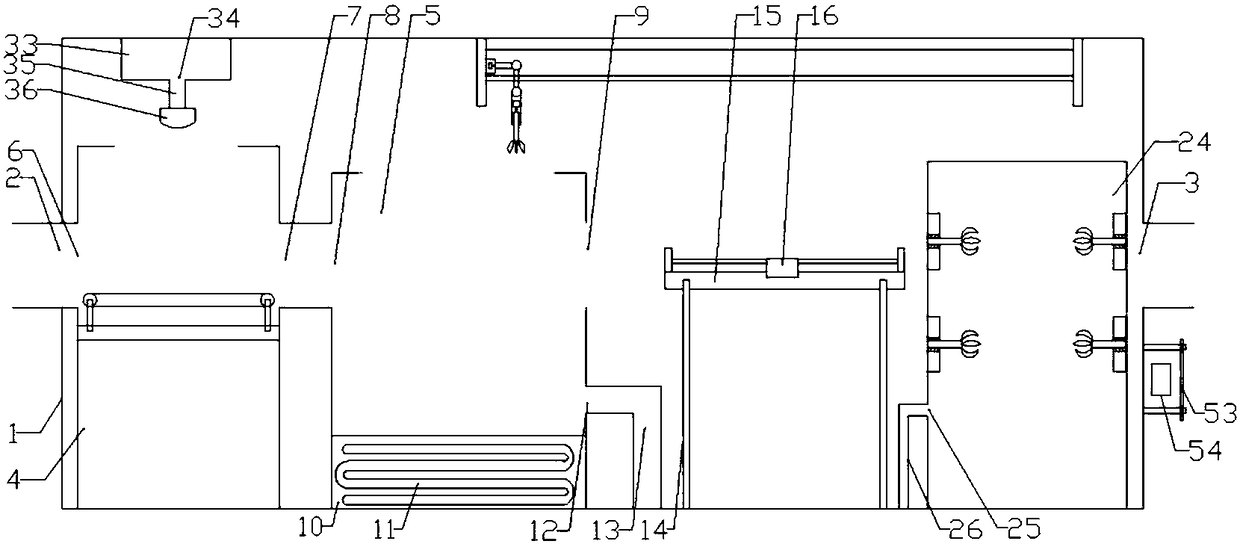

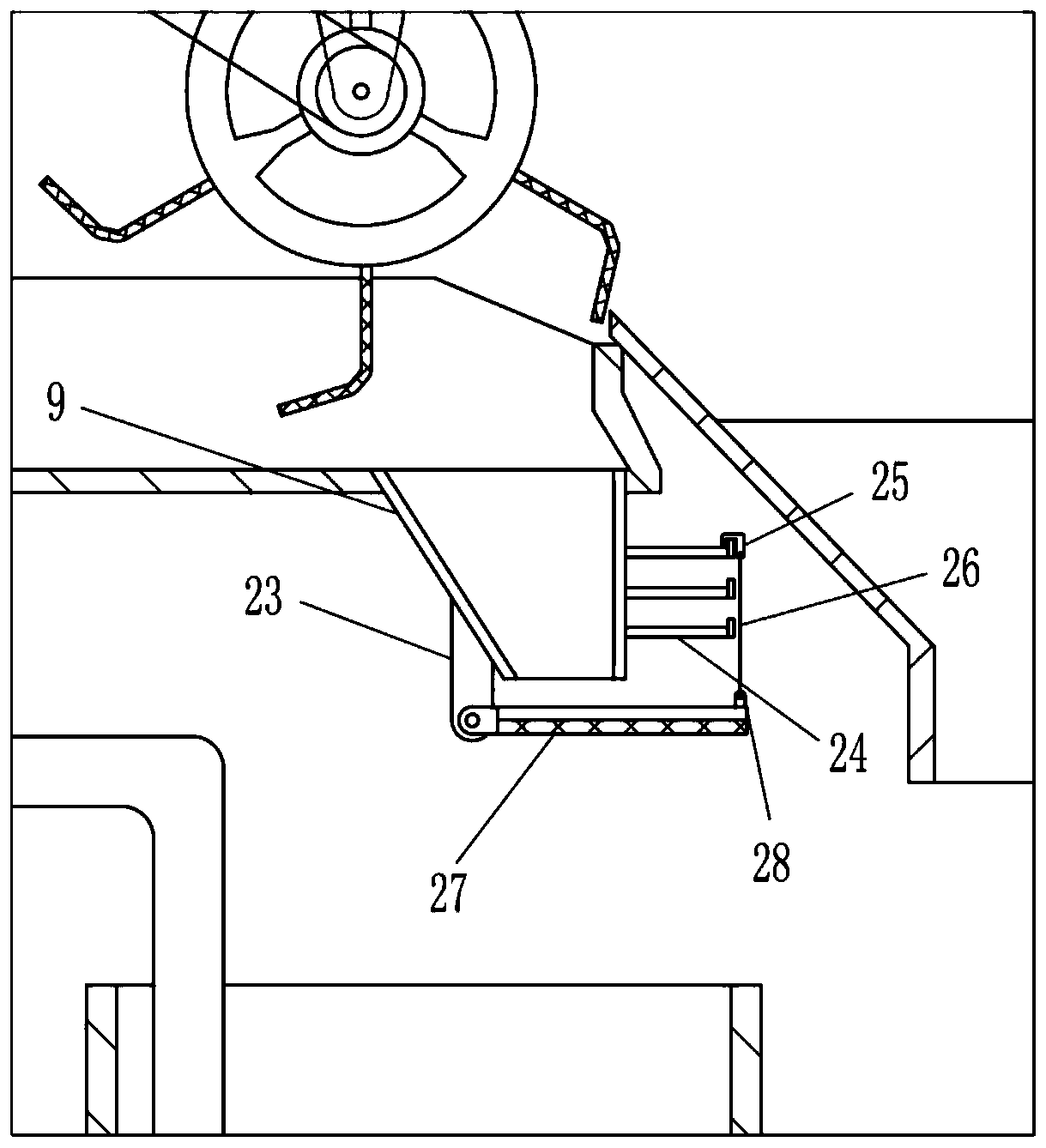

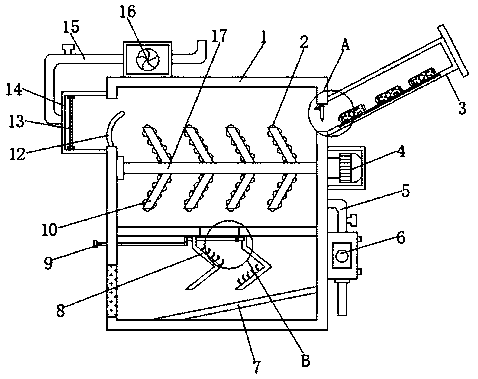

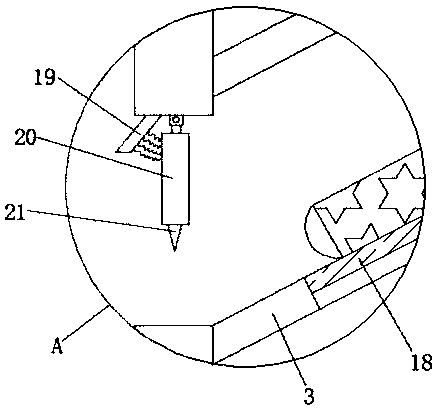

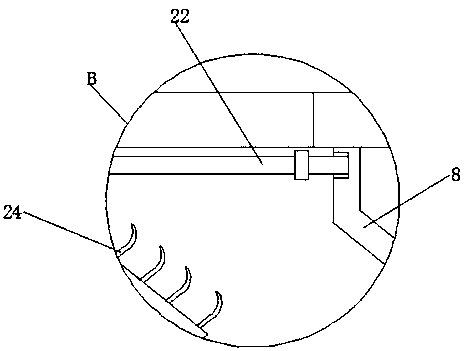

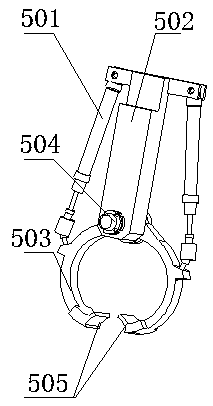

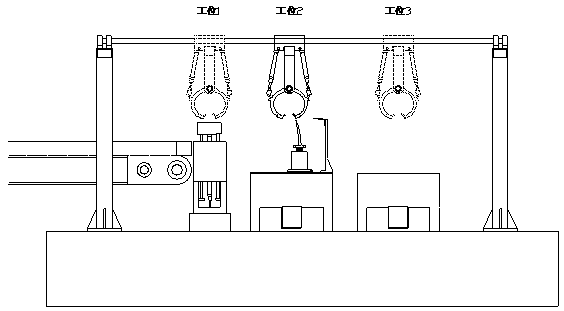

ActiveCN105285056AReduce consumptionRealize automatic feeding processShellfish processingConveyor beltEnergy consumption

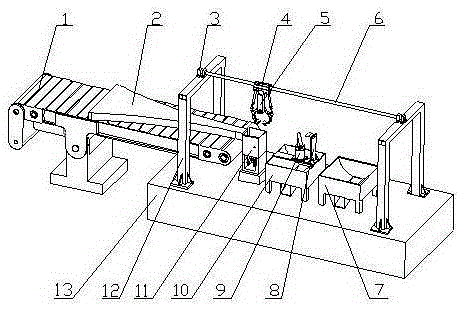

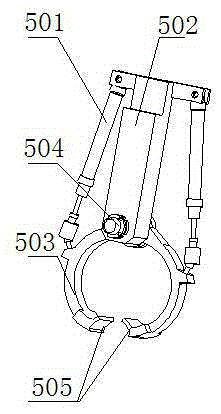

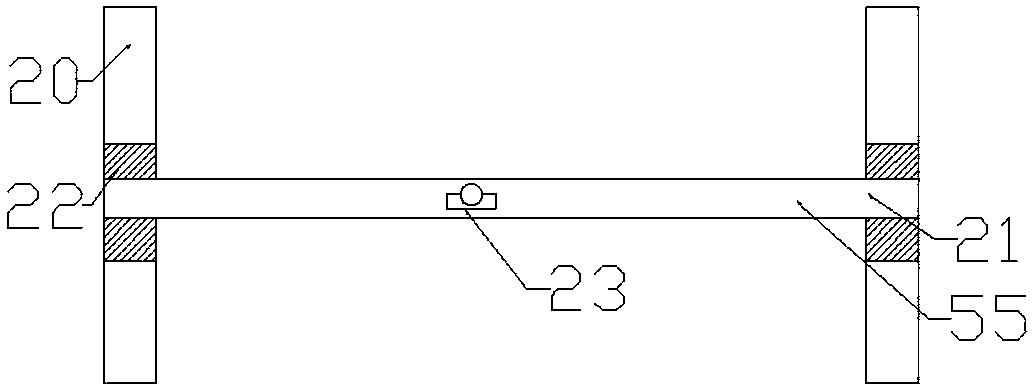

The invention discloses an abalone shelling machine. The abalone shelling machine comprises a conveyor belt, an abalone arraying shape collating machine, a clamping jaw sliding block, a clamping jaw device, a sliding rail, an abalone shell containing box, a cut-off device, a spring shelling knife device, an abalone meat containing box, a pushing block device, a support gantry and a base. According to the abalone shelling machine disclosed by the invention, the functions of automatically loading, automatically shelling, automatically classifying and collecting shells and meat, and the like can be realized, the shelling quality is improved, processing requirements for shelling rapidly, cleanly and comprehensively are realized, the feeding time is saved, the processing quality is guaranteed, and the energy consumption is reduced.

Owner:大连伟瑞达精密模具制造有限公司

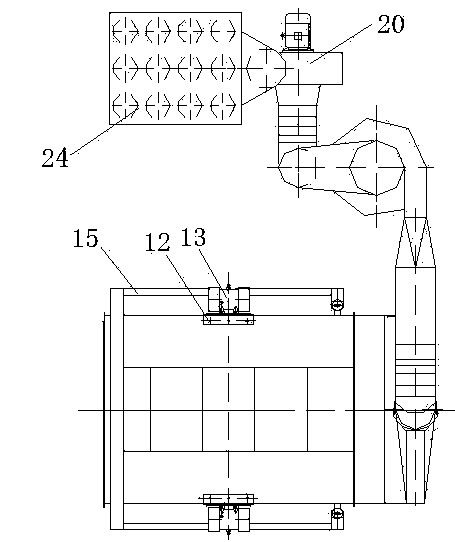

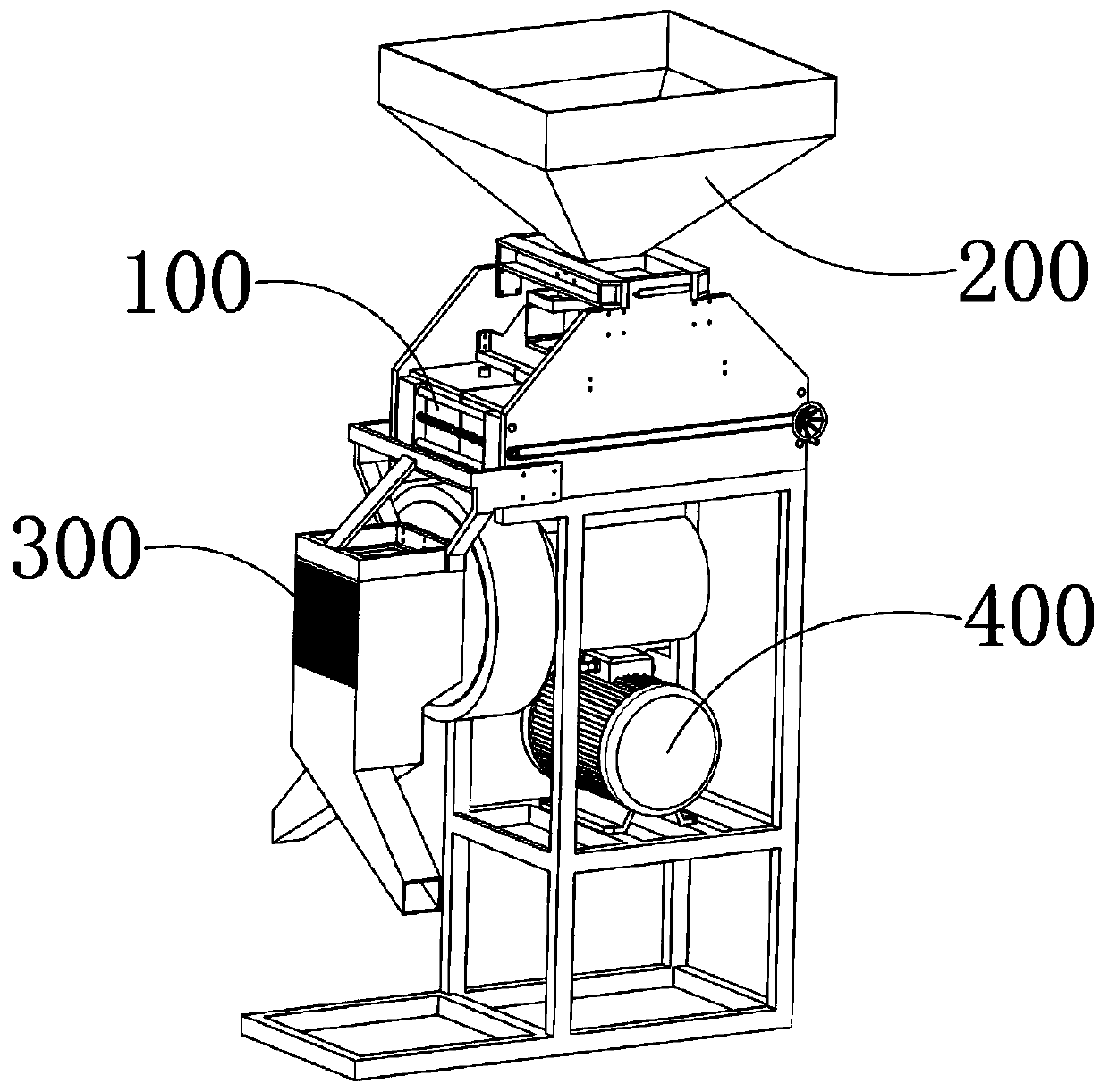

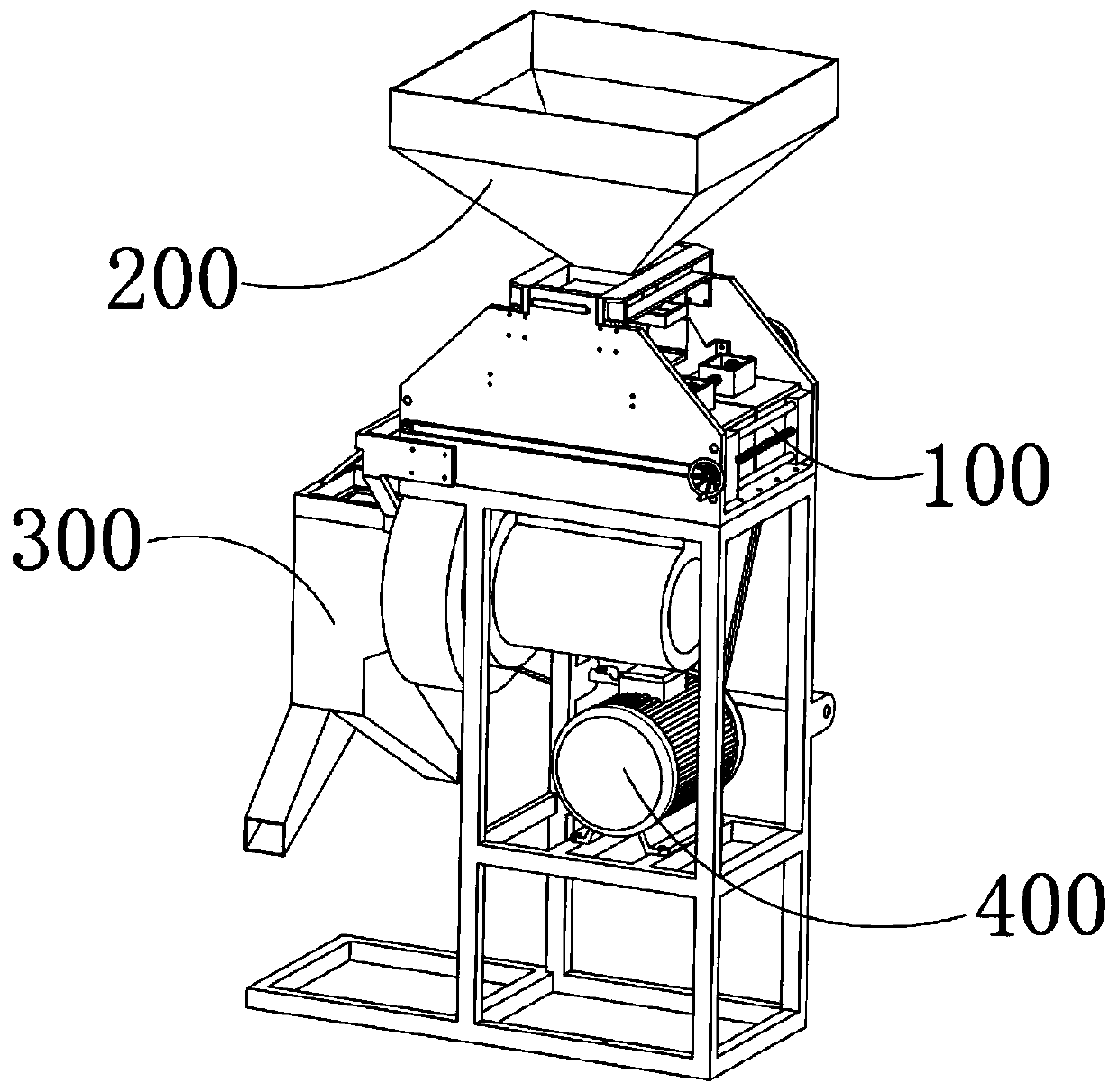

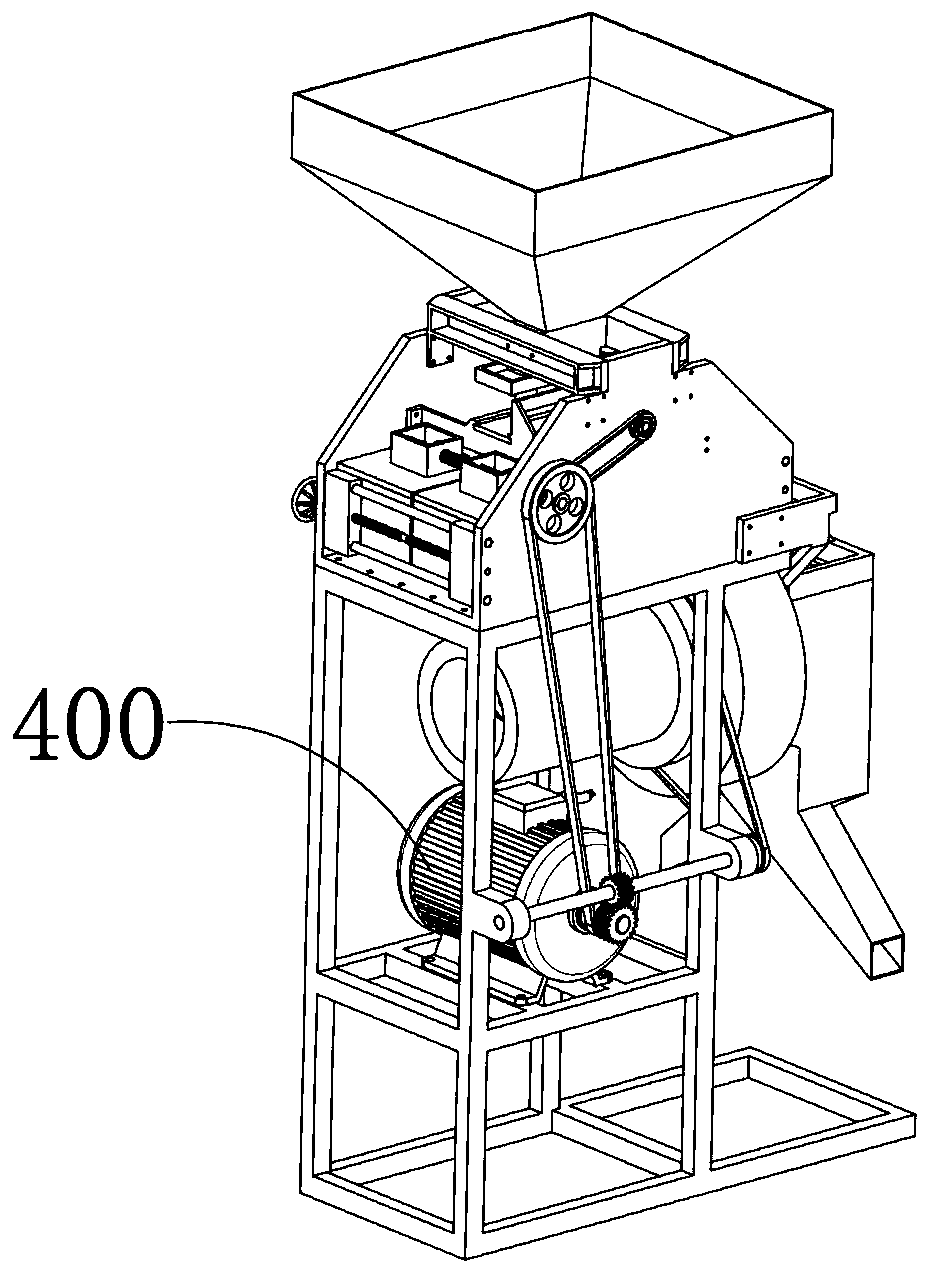

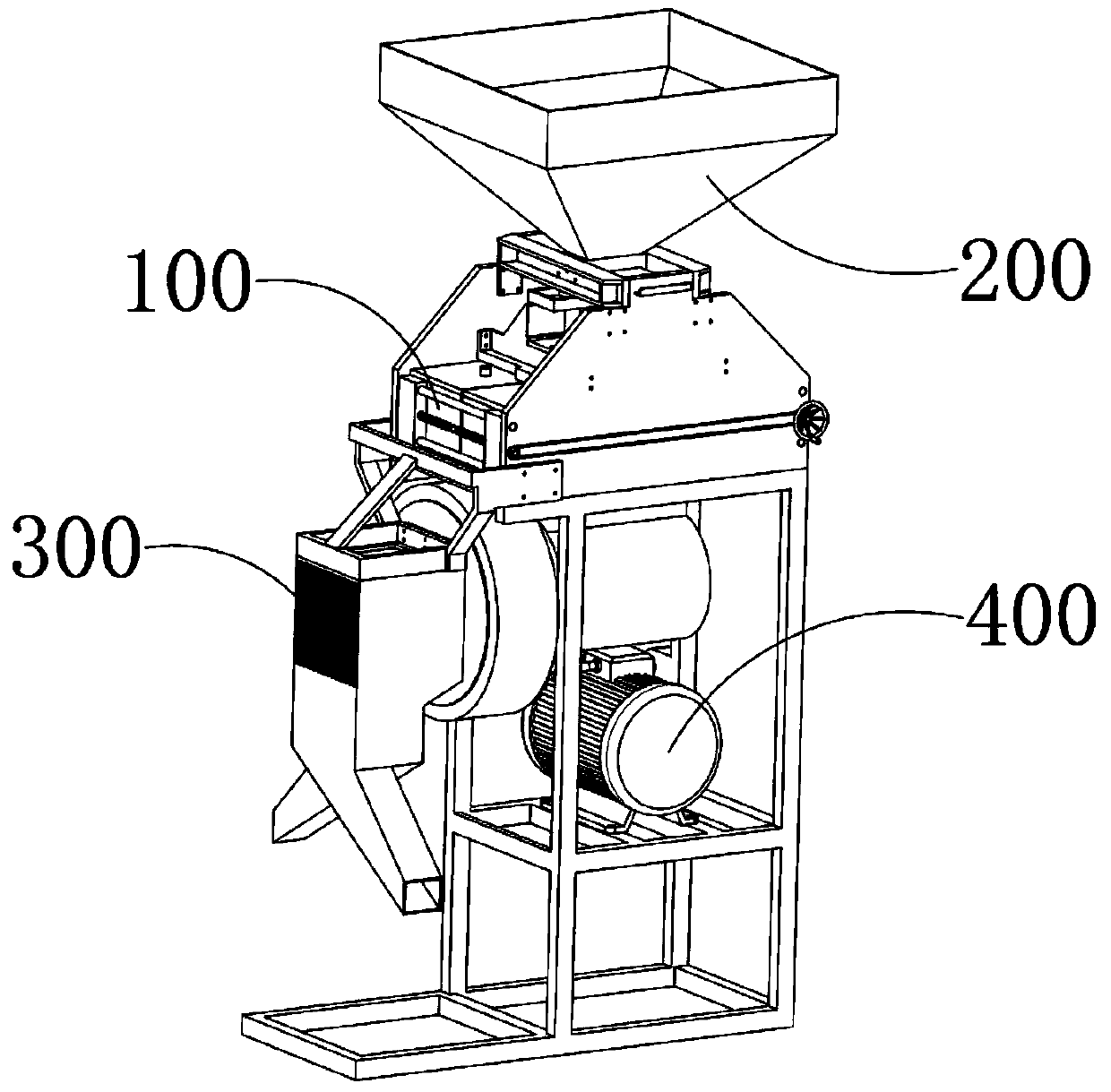

Garlic peeling device

InactiveCN104397843AQuality impactAvoid affecting product qualityVegetable peelingEngineeringAllium sativum

The invention relates to the field of garlic peeling, and in particular relates to a garlic peeling device. The garlic peeling device comprises a rack body, a sectioning box, a vibrating trough and a peel sucking machine, wherein the sectioning box, vibrating trough and peel sucking machine are fixed on a support. The garlic peeling device is characterized in that the sectioning box is connected to the upper end of the vibrating trough by virtue of a discharge opening; a garlic clove storage chamber is arranged at the rear end of the vibrating trough, and an opening is formed in the lower end of the garlic clove storage chamber; a garlic outlet pipe is connected with the lower end of the garlic clove storage chamber; the garlic outlet pipe is connected with a peel sucking air duct, and the upper end of the peel sucking air duct is connected with a drawing fan by virtue of a pipeline; the drawing fan is connected with a peel storage bag; and a garlic outlet is connected to the lower end of the peel sucking air duct. The garlic peeling device provided by the invention is convenient to use, is reasonable in design, ensures that garlic can be fully peeled, can finish peeling of garlic by virtue of mechanical operations and ensures the garlic peeling effect, and the entire peeling process has a relatively high efficiency and saves cost and human resources, so that the garlic peeling device has strong practicability and a wide application range.

Owner:SHANDONG SHUNBANG BIOTECH

Tea oilseed dehulling and separating device

InactiveCN107242581AImprove peeling efficiencyShell cleanFatty-oils/fats productionHuskingImpellerAdemetionine

The invention discloses a tea oilseed dehulling and separating device, comprising a dehulling cavity, a first cavity, a second cavity, a separation cavity, and a housing. The top of the housing is provided with a branch impeller. The inner wall of the dehulling cavity is provided with an electric heating layer. A stirring roller is arranged in the dehulling cavity through a bearing. The stirring roller is provided with a stirring paddle. The upper end of one side of the dehulling cavity is provided with a TR / 02013 temperature sensor. The inner wall of one side of the separation cavity is provided with an axial fan. The top end in the first cavity is provided with a microwave generator. A rinse tank is arranged in the first cavity. A seed husk collection tank is arranged in the second cavity. A MAM-330 controller is arranged on the housing under an observation window. Through arranging a series of structures, tea oilseed dehulling and separation effects are better, and quality of oil is better.

Owner:HUNAN SHENNONG CAMELLIA OLEIFERA TECH DEV

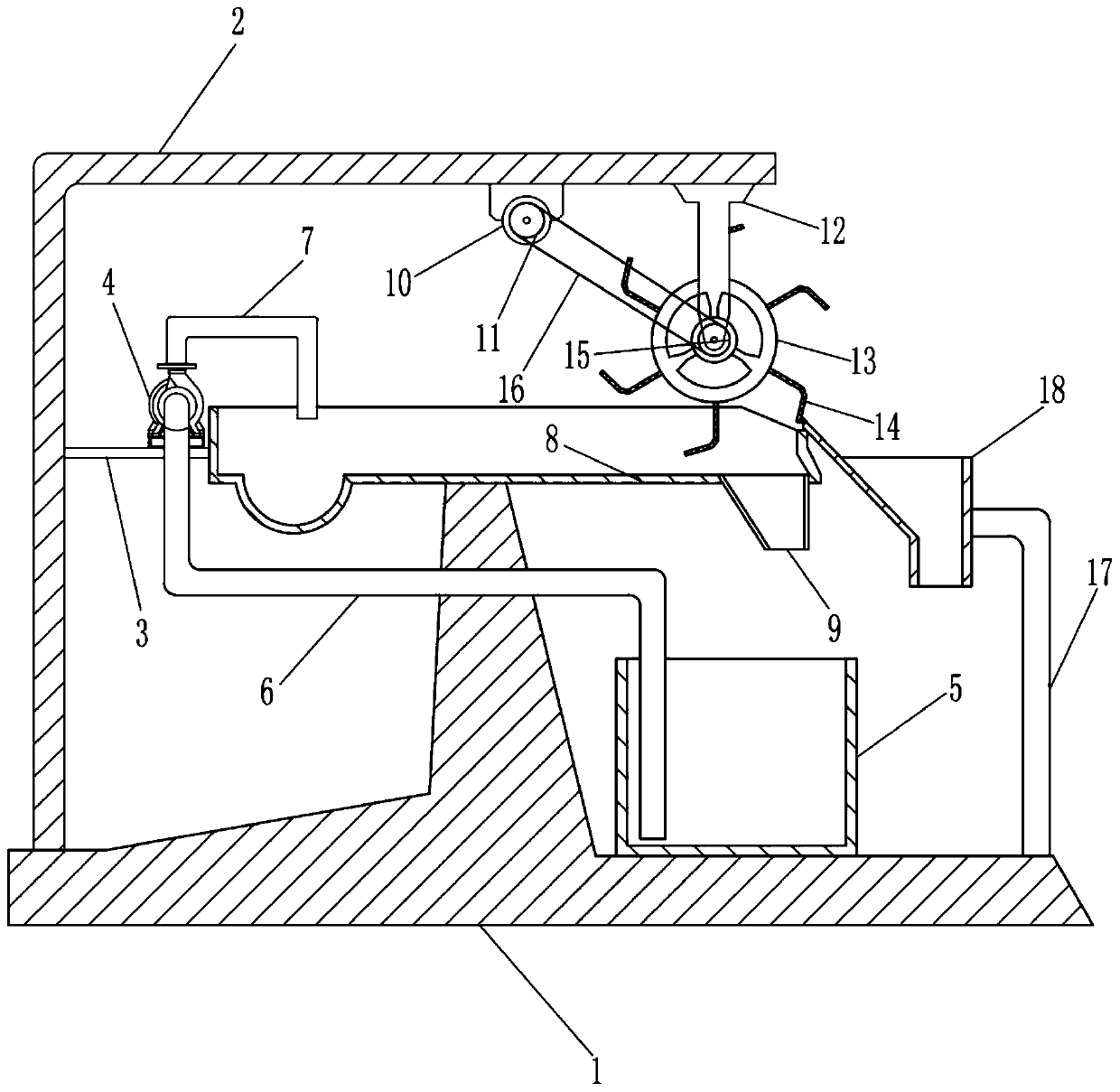

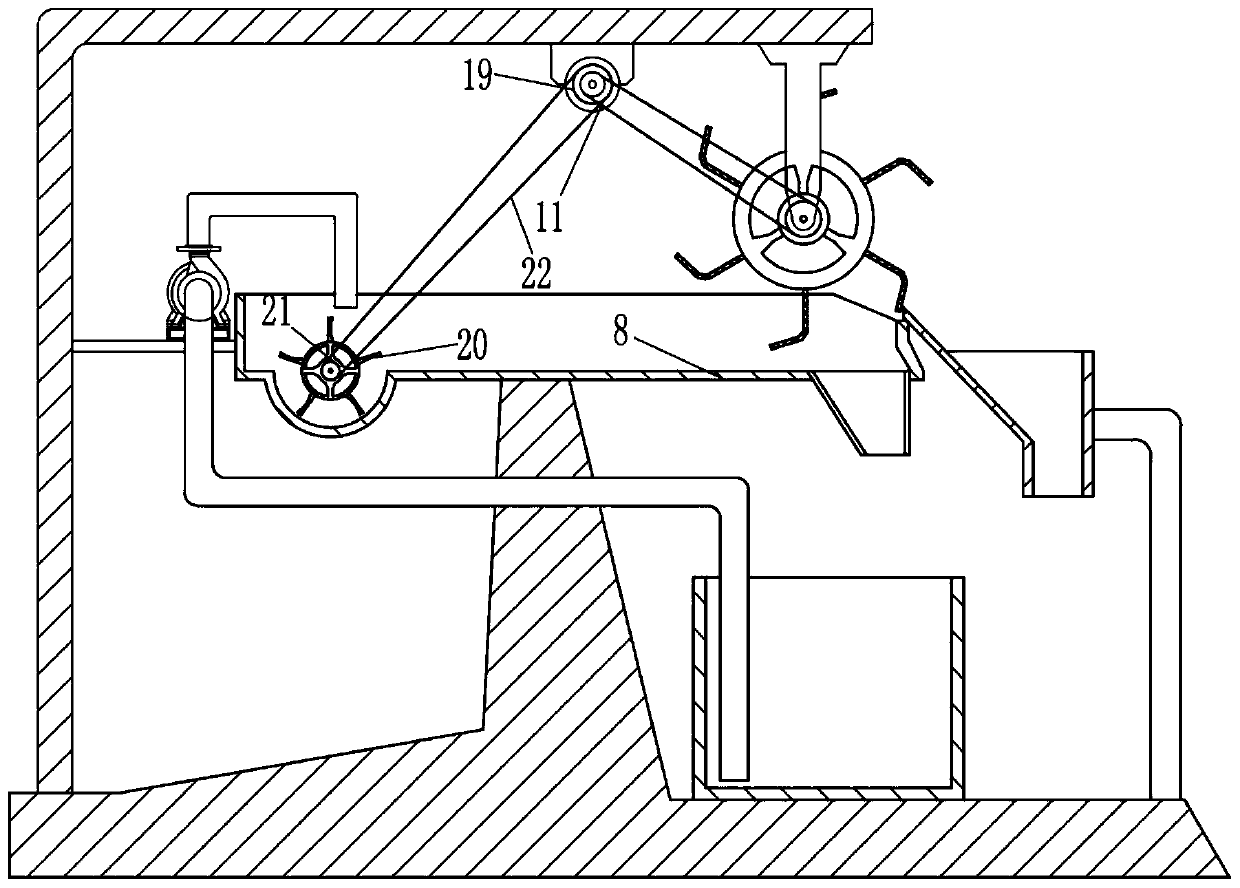

Bean sprout cleaning and peeling equipment

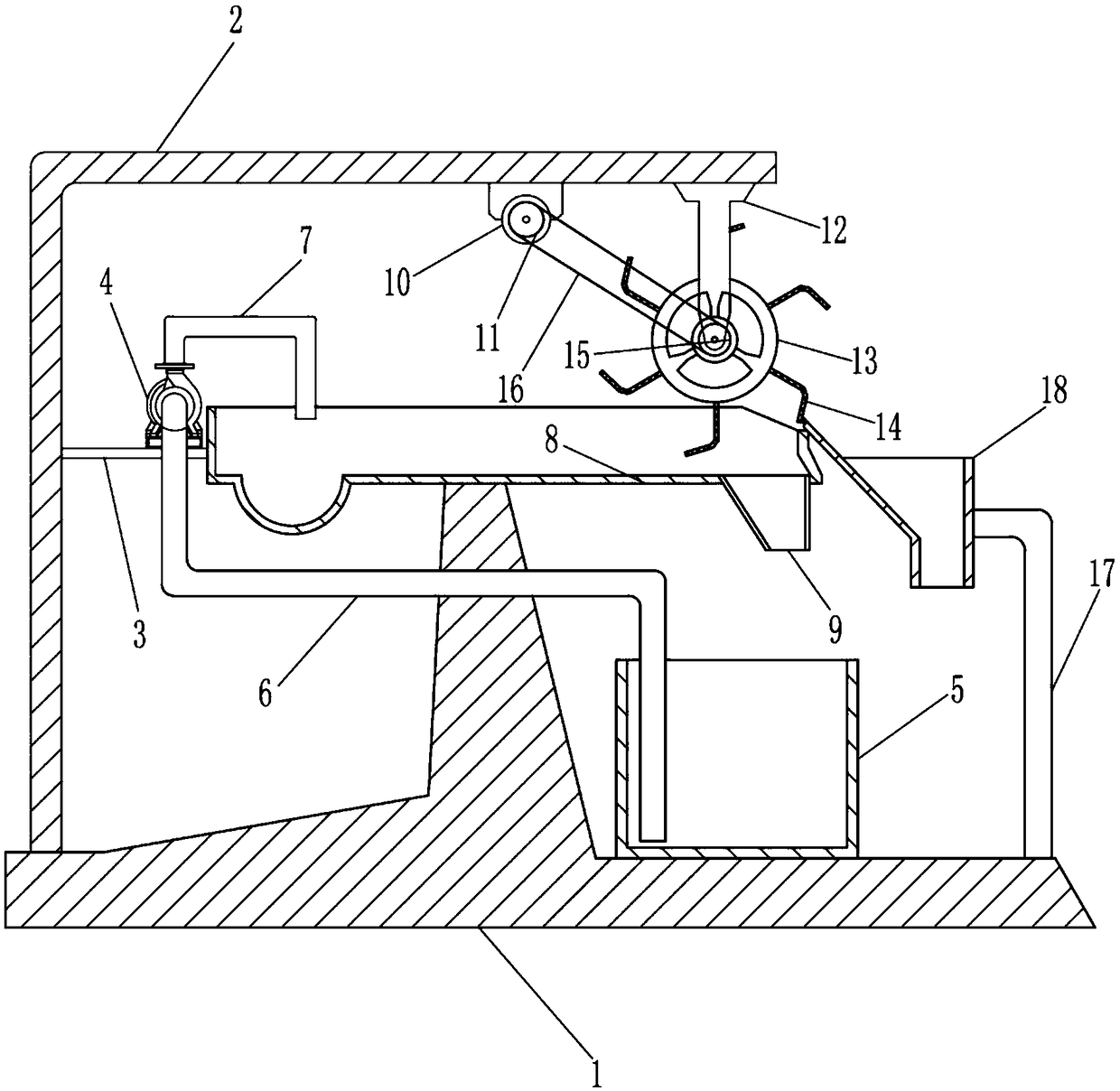

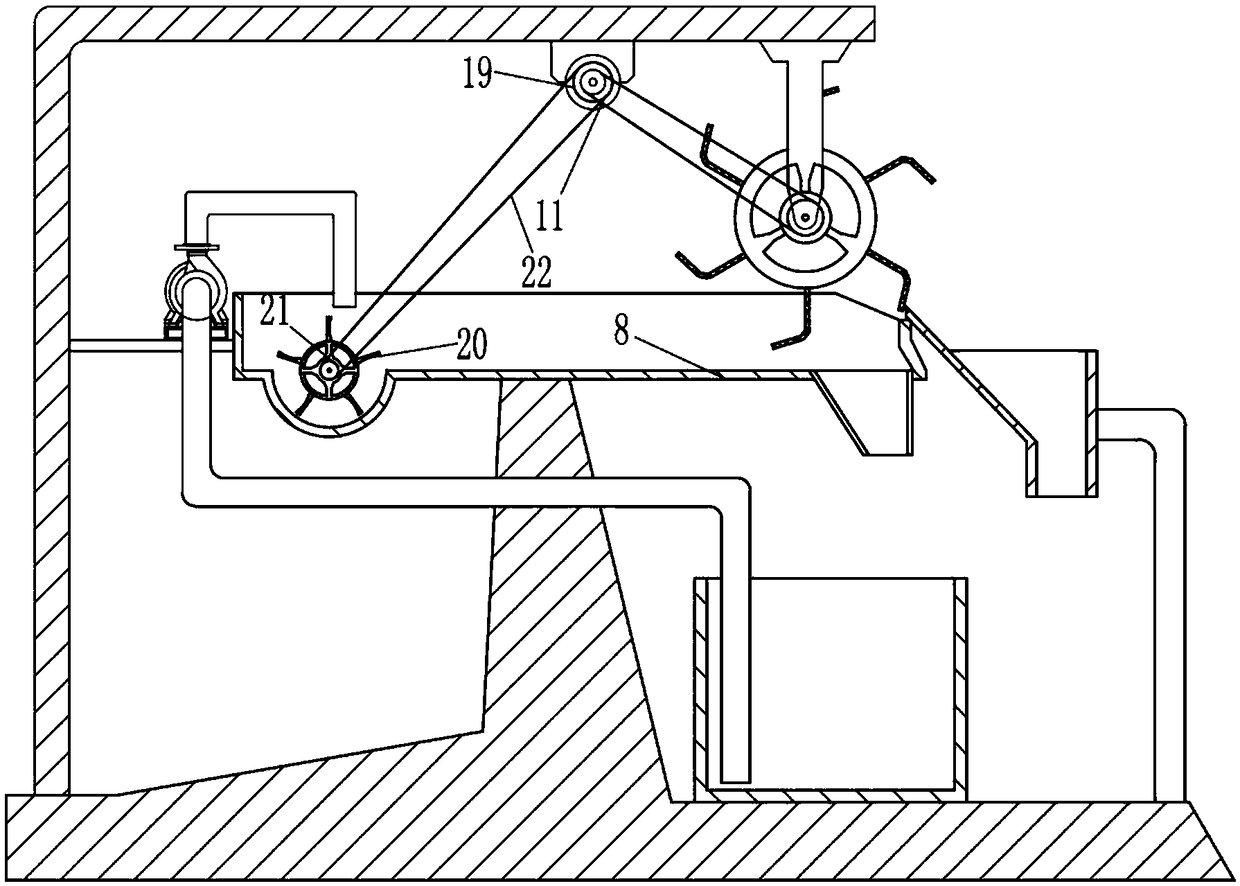

ActiveCN108851103AAchieve the function of cleaning and peelingThoroughly cleaned and peeledVegetable peelingFood treatmentEngineeringPulley

The invention relates to peeling equipment, in particular to bean sprout cleaning and peeling equipment. The bean sprout cleaning and peeling equipment aims at achieving the technical purpose that peeling is conducted thoroughly and quickly. In order to achieve the technical purpose above, the bean sprout cleaning and peeling equipment comprises a base, an L-shaped bracket, a first fixing plate, awater pump, a water tank, a water suction pipe, a water outlet pipe, a cleaning frame, a first funnel, a conveying motor, a first belt pulley, a support, a turntable, filtering and fishing hooks, a second belt pulley, a first belt, a supporting rod and a discharging hopper; the L-shaped bracket is fixedly connected to the left side of the upper portion of the base, the first fixing plate is fixedly connected to the upper portion of the right side of the L-shaped bracket, and the cleaning frame is fixedly connected to the top of the base. The bean sprout cleaning and peeling equipment achievesthe functions of cleaning and peeling bean sprouts.

Owner:上海清美食品有限公司 +1

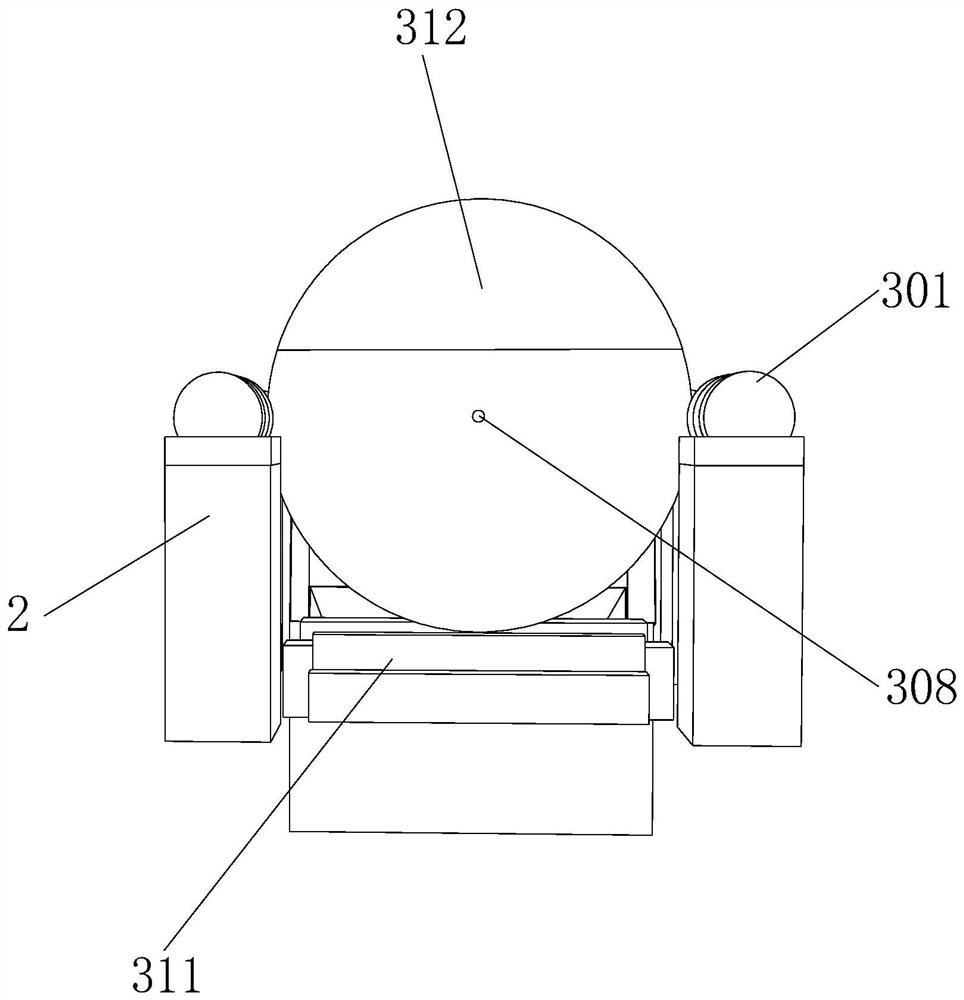

White peony root peeling device

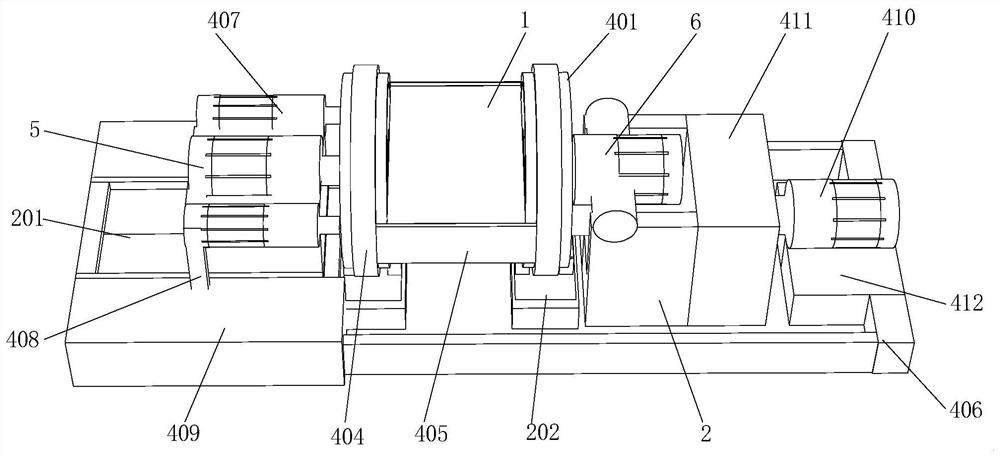

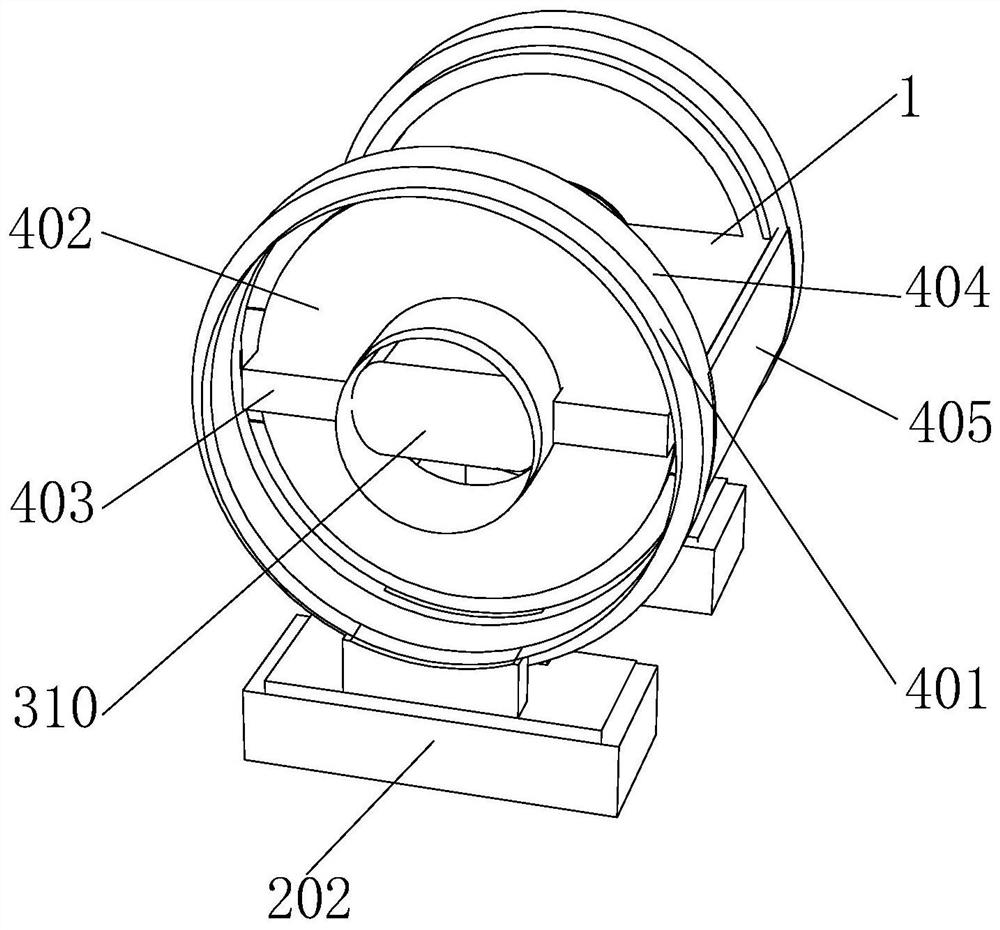

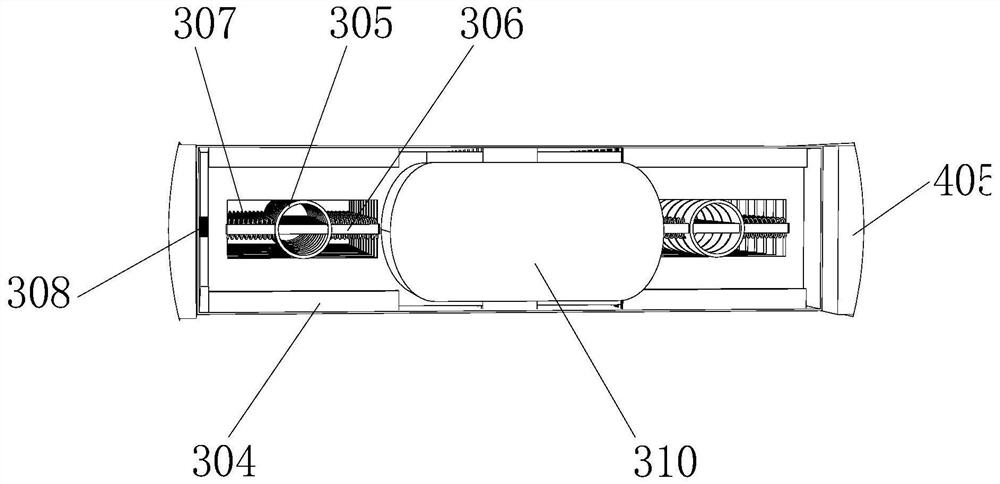

InactiveCN112167658AFully peeledGood peeling effectVegetable peelingFood treatmentEngineeringDrive motor

The invention provides a white peony root peeling device, and relates to the technical field of white peony root processing. The white peony root peeling device comprises a shell, bases, a peeling mechanism, cleaning mechanisms, a first driving motor and a second driving motor, wherein the bases are arranged on the two sides of the shell, the first driving motor is arranged on the base on the leftside of the shell, the bottom end of the first driving motor is fixedly connected with the top ends of the bases, the second driving motor is arranged on the base on the right side of the shell, thebottom end of the second driving motor is rotationally connected with the top ends of the bases, the peeling mechanism is arranged inside the shell and is used for peeling white peony roots and removing root hairs, the two ends of the peeling mechanism are fixedly connected with the first driving motor and the second driving motor, the cleaning mechanisms are arranged on the two sides of the peeling mechanism, so that the white peony root skins are prevented from being adhered to the white peony roots after the white peony roots are peeled; and the cleaning mechanisms are fixedly connected with the two ends of the peeling mechanism, so that the problems that the root hairs on the surfaces of the white peony roots cannot be removed in the peeling process of the white peony roots and a largenumber of white peony root skins are adhered to the surfaces of the white peony roots after the white peony roots are peeled are solved.

Owner:陈永年

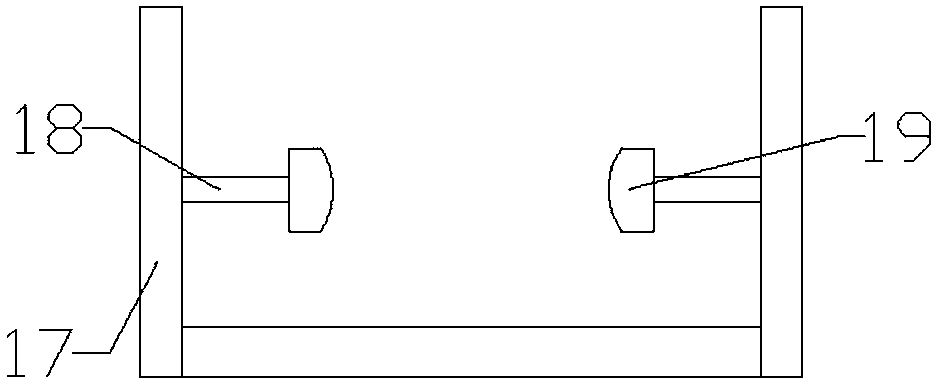

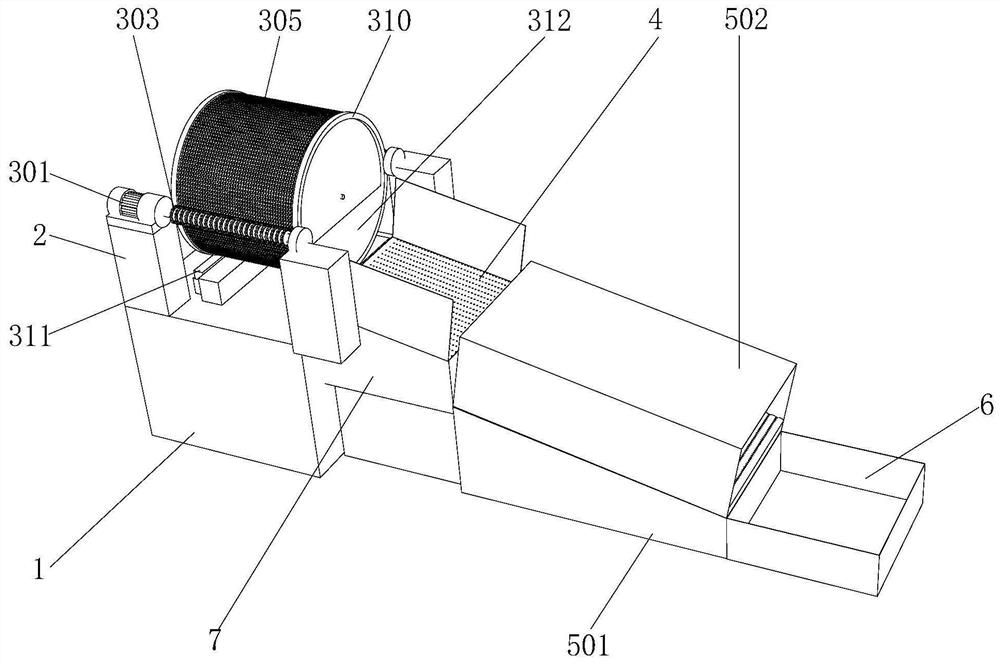

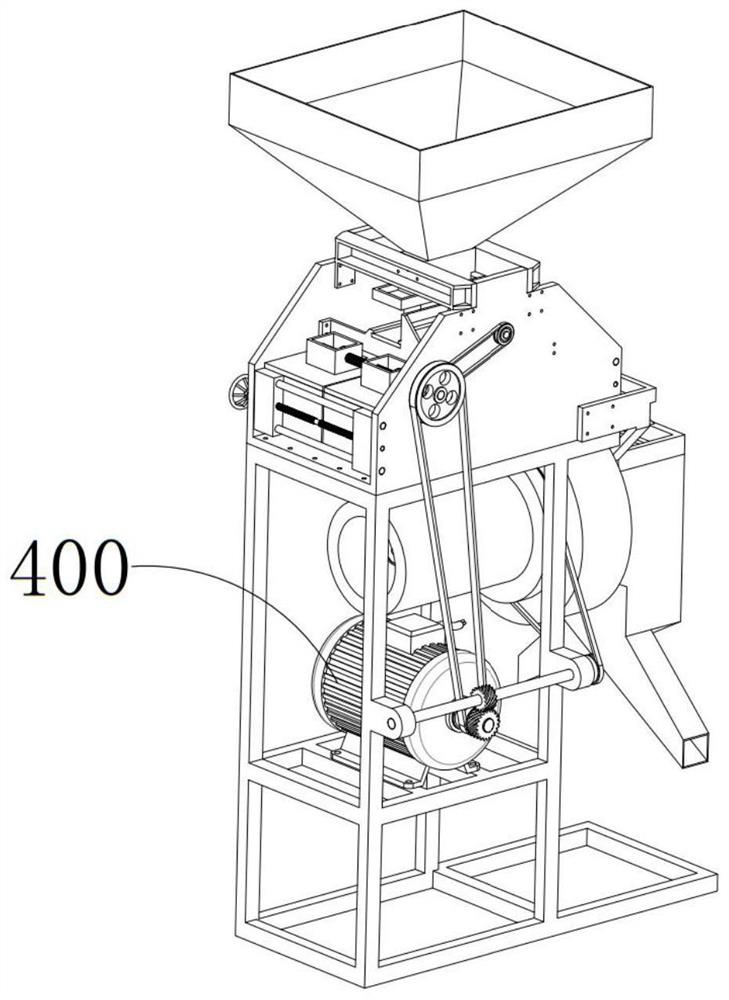

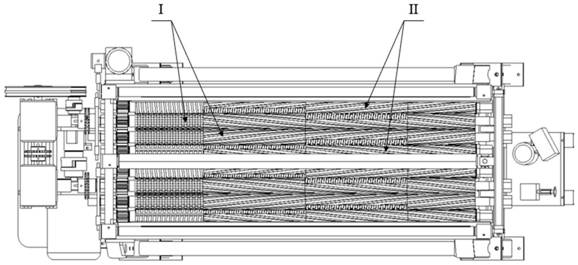

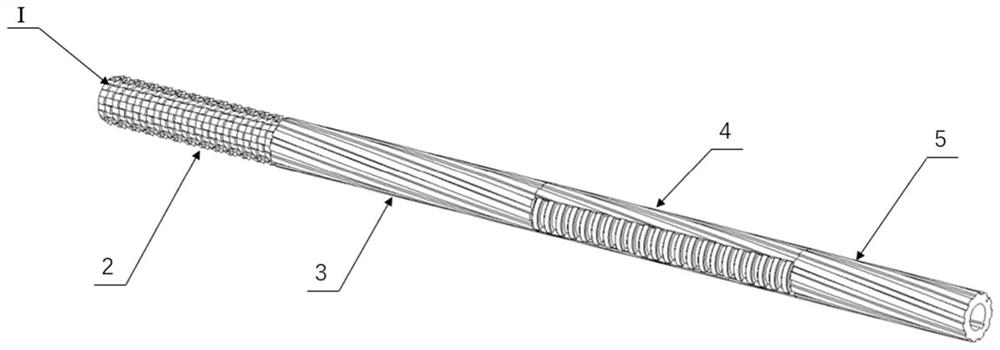

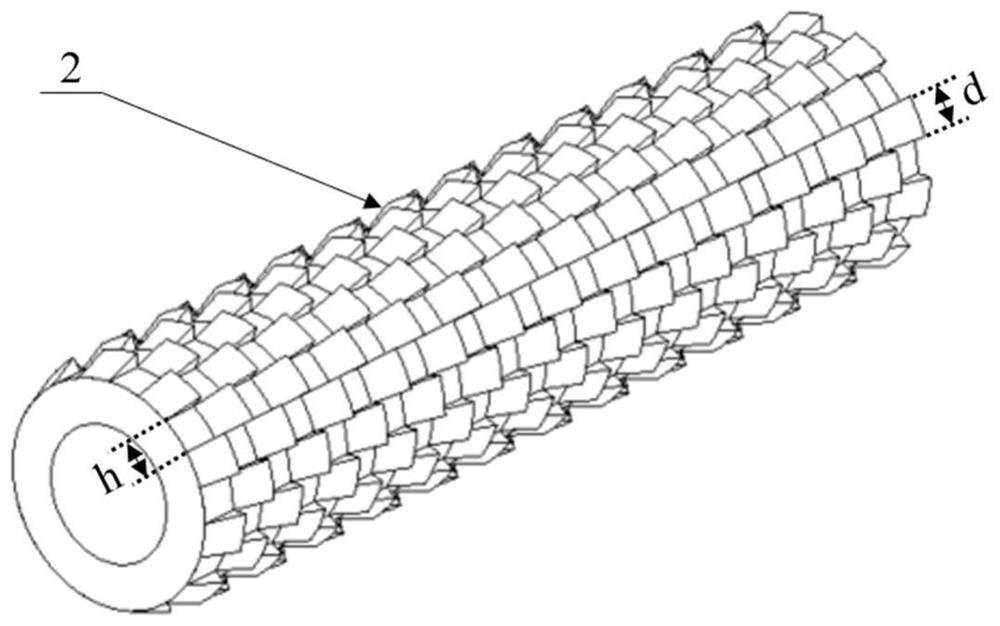

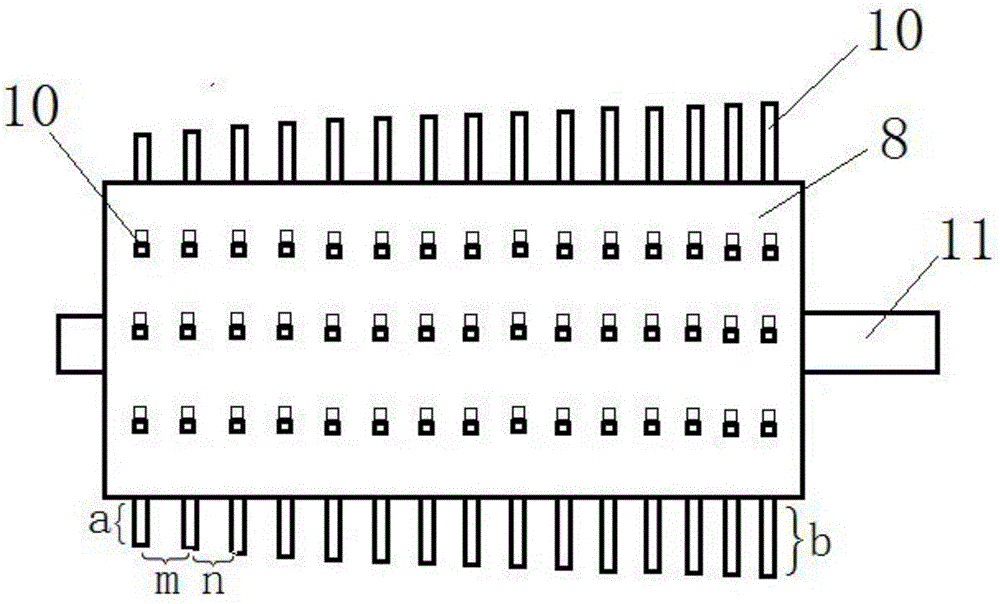

Chain type grinding plate structure applied to rice husking process

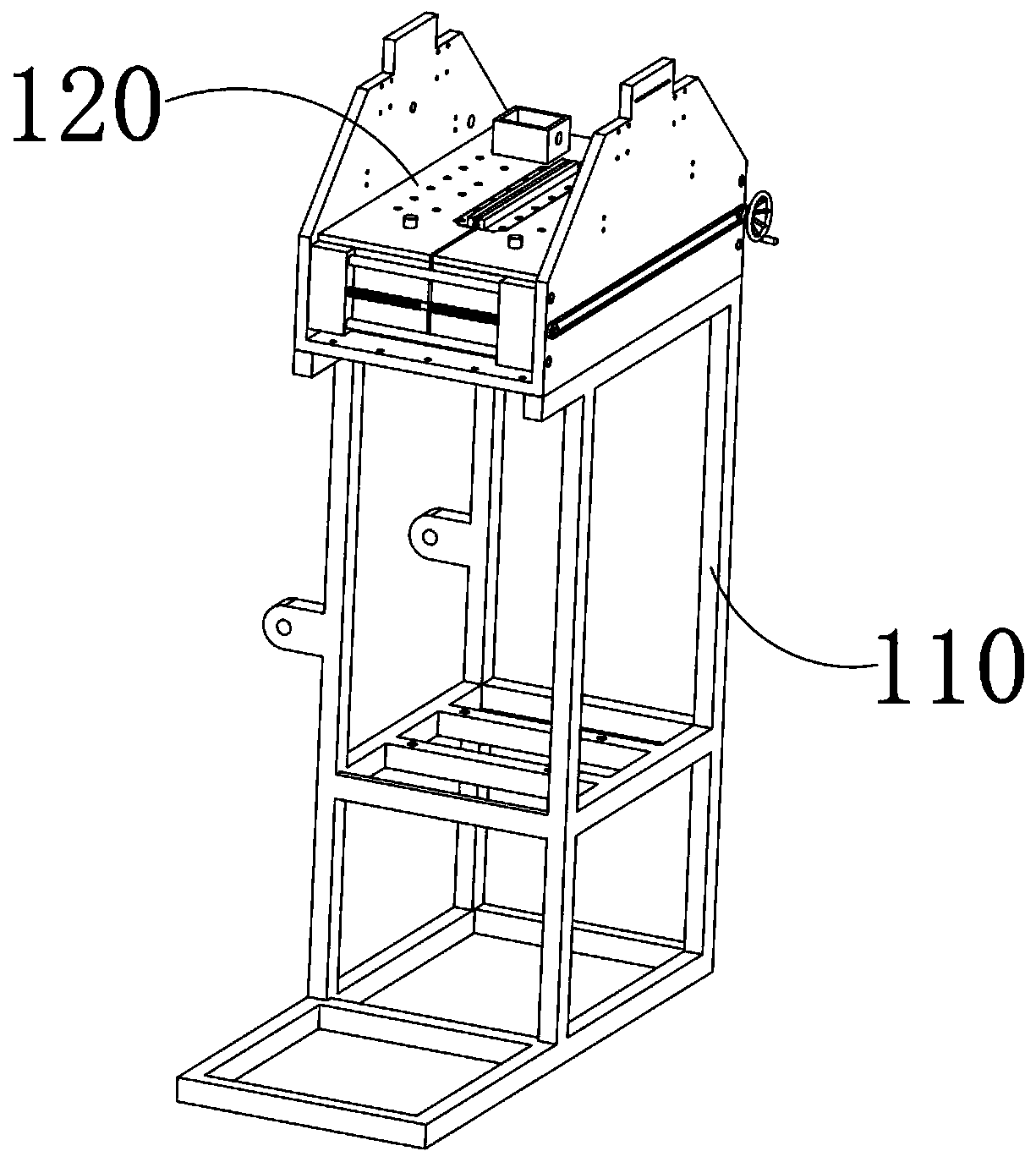

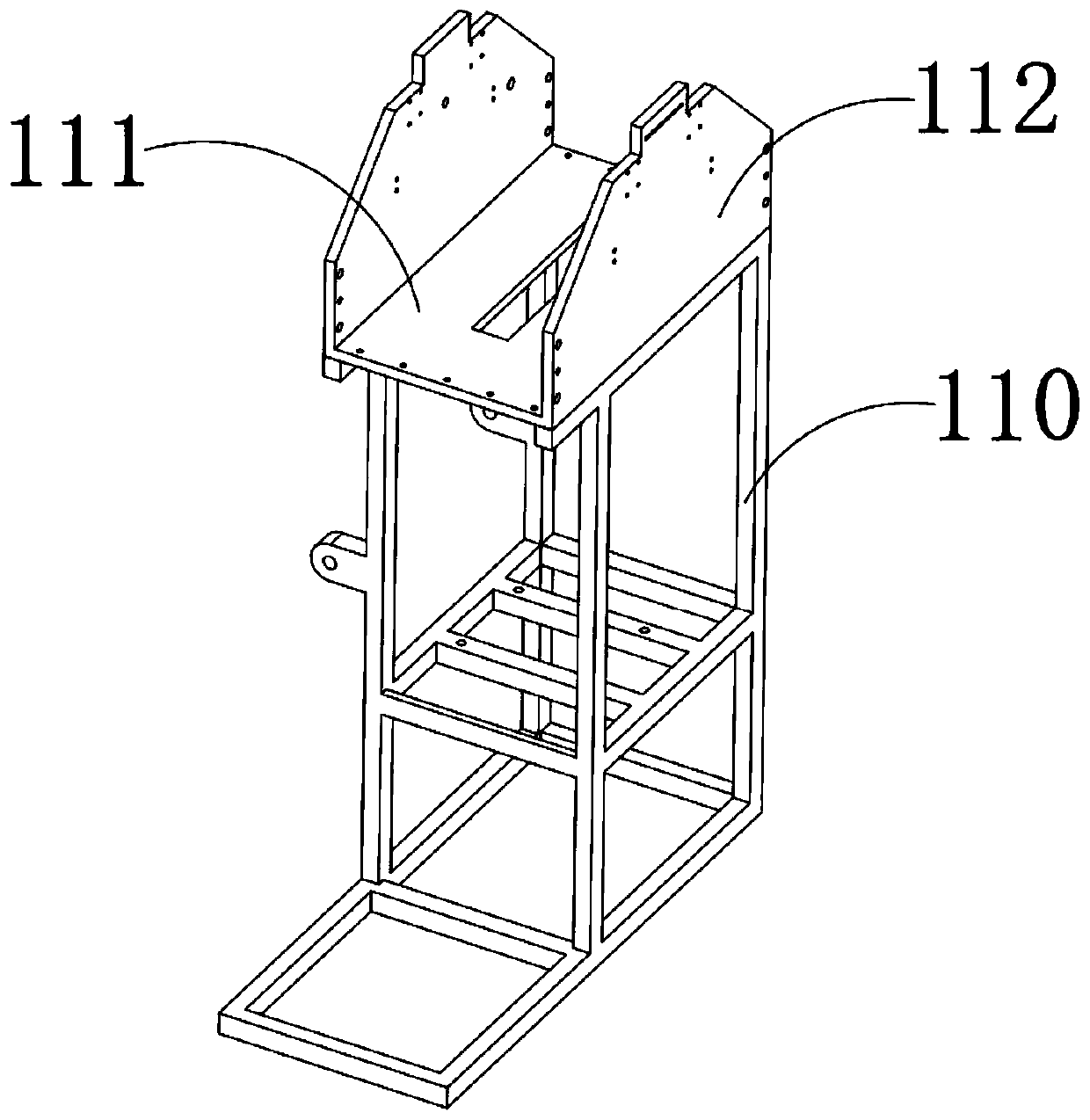

ActiveCN110614132AFully peeledIncrease contact areaGrain huskingGrain polishingAgricultural engineeringChain type

The invention provides a chain type grinding plate structure applied to a rice husking process, comprising a floor mounting rack (110); a rectangular horizontal plate (111) is fixedly arranged on thetop of the mounting rack (110); two vertical plates (112) are fixedly arranged on the upper end face of the horizontal plate (111), and disposed at an interval; two chain plate mechanisms (120) arranged in parallel are disposed between the two vertical plates (112), and the distance between the two chain plate mechanisms (120) is adjustable; two connecting mechanisms (130) are fixedly arranged onthe sides, close to each other, of the two chain plate structures (120); the two connecting mechanisms (130) and the two chain plate mechanisms (120) surround to form a whitening chamber (133) which is narrow and long and has an upper opening and a lower opening; a grinding plate (128) runs reversely to squeeze to husk brown rice in the whitening chamber (133), the brown rice is filled from the upper opening of the whitening chamber (133), and a mixture of white rice and bran is discharged from the lower opening.

Owner:六安市洪达农业综合服务股份有限公司

Precise chain-type brown rice husking process

ActiveCN110614133AFully peeledIncrease contact areaGrain huskingGrain polishingTransmitted powerChain type

The invention provides a precise chain-type brown rice husking process, including the steps: firstly, users put brown rice into a feeding device to spread the brown rice in the feeding device to a long narrow whitening chamber uniformly from to to bottom; a power drive device transmits power to one of rotating shafts and drives the same to rotate, the rotating shaft drive a chain wheel to rotate synchronously, the chain wheel drives a pulley chain to run circularly, the chain drives two grinding plates to run synchronously circularly, the two grinding plates arranged in symmetry run in opposite directions, the grinding plate running reversely squeeze and rub brown rice in the whitening chamber so as to husk the brown rice to obtain white rice and rice bran; finally, mixture of the white rice and the rice bran falls into a discharging device from the lower end of the whitening chamber, the white rice and the rice bran are separated by fans, the white rice which is heavy relatively fallsto a white rice passage first and then is discharged outwards, while the rice bran which is light relatively is discharged outwards through a rice bran passage.

Owner:安徽晨阳粮油股份有限公司

Peeling and processing device for potatoes

InactiveCN108420085AFully peeledImprove work efficiencyVegetable peelingFood treatmentEngineeringWaste management

The invention discloses a peeling and processing device for potatoes. The peeling and processing device comprises a processing tank, wherein the processing tank is fixedly mounted on the ground, and jointly consists of a processing inlet formed in the middle position on the left side surface, a processing outlet formed in the middle position on the right side surface, a first washing device mounted on one third of the left side of the processing tank, a heating device mounted close to the washing device, a peeling device mounted close to the heating device and a second washing device mounted close to the peeling device. The peeling and processing device disclosed by the invention has the beneficial effects of being simple in structure and high in practicality.

Owner:东阳市天齐科技有限公司

Peanut shelling device for agricultural production

InactiveCN111387518AReduce in quantitySolve technical problems of inconvenient installationSievingGas current separationAgricultural scienceAgricultural engineering

The invention relates to a peanut shelling device for agricultural production. A first rotating shaft is arranged in a shelling tube in a penetrating manner and can rotate relative to the shelling tube, a guiding tube is mounted below the shelling tube, a winnowing mechanism comprises a wind box, a second rotating shaft and rotating blades fixedly mounted on the second rotating shaft, an air blastnozzle communicating with the wind box is mounted on the wind box and faces to a discharging opening of the guiding tube, a pressing plate is fixedly mounted at one side of a feed collection bin, andextruding passages are formed between the pressing plate and internal walls of a box body; and an isolating plate is arranged in the box body, a crushing chamber is formed in the internal cavity of the box body by the isolating plate, a filter screen is arranged in the crushing chamber, and crushing blades are rotatably connected with the filter screen. The peanut shelling device integrates the functions of automatic peanut charging, peanut shelling, screening of kernels and shells, small-grained peanut shelling, shell crushing and the like and has the beneficial effects that requirements ona quantity of power sources are low, the production manufacturing cost is low, the work efficiency is high, the processing cycle is short, and the like.

Owner:芜湖拓云农业技术有限公司

A kind of bark peeling equipment for papermaking

ActiveCN108214784BGood cutterQuick peelTree debarkingBark-zones/chip/dust/waste removalPapermakingEngineering

The invention relates to peeling equipment, in particular to a bark peeling device for papermaking. According to the bark peeling device for papermaking, time and labor are saved, peeling is comprehensive, fallen barks can be collected, so that treatment is facilitated by people. The bark peeling device for papermaking comprises a bottom plate and the like; supporting rods are installed on the left side and the right side of the top part of the bottom plate, and a box body is installed between the top ends of the left side and the right side of the supporting rods; the top part of the bottom plate is provided with a frame, and the box body is located in the frame; rotating devices are arranged between the upper part of the left side surface in the frame and the upper part of the right sidesurface of the frame, and the rotating devices are located above the box body; and a moving device is arranged at the top part of the frame. According to the bark peeling device, by means of a cutting device, the barks can be cut so that a cutter can better and quickly peel a tree, time and labor are saved, and peeling is comprehensive, the fallen barks can be collected, and therefore the effectthat the treatment is facilitated by people is achieved.

Owner:南通江海港建设工程有限公司

A bean sprouts cleaning and peeling equipment

ActiveCN108851103BAchieve the function of cleaning and peelingThoroughly cleaned and peeledVegetable peelingFood treatmentAgricultural scienceAgricultural engineering

Owner:上海清美食品有限公司 +1

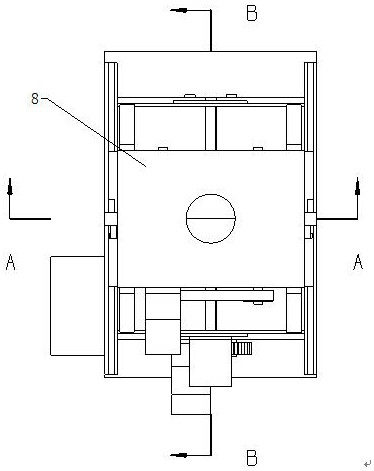

Corn husking equipment for agricultural machinery

ActiveCN111247947AImprove peeling efficiencyAvoid blocked situationsHarvestersAgricultural scienceAgricultural engineering

The invention discloses corn husking equipment for agricultural machinery. The corn husking equipment comprises a box body, wherein a feeding cylinder is inserted into the outer wall of one side of the box body; an exhaust fan is arranged on the outer wall of the top part of the box body; an air suction pipe is inserted into the outer wall of one side of the exhaust fan; and a material collectingbox is inserted into one end of the air suction pipe. According to the invention, after corn enters the box body through the feeding cylinder, people start an air blower and a motor firstly, and the air blower can apply a pushing force to the husk of the corn, while the pushing force can break the husk of the corn by blowing, so the requirement for corn husking is met; the suction fan is then started and can apply a pulling force to the husk of the corn, and the husk of the corn can be broken through pulling, so a positive force and a negative force circularly act on the husk of the corn to fully husk the corn, and the surface of the corn cannot be damaged at the same time; meanwhile, the motor can drive a rotating rod to slowly turn over the corn, so the corn husking efficiency of the corn husking equipment is improved.

Owner:温州普奈机械科技有限公司

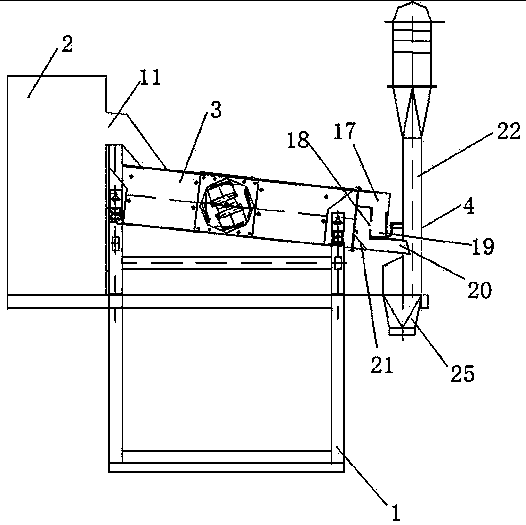

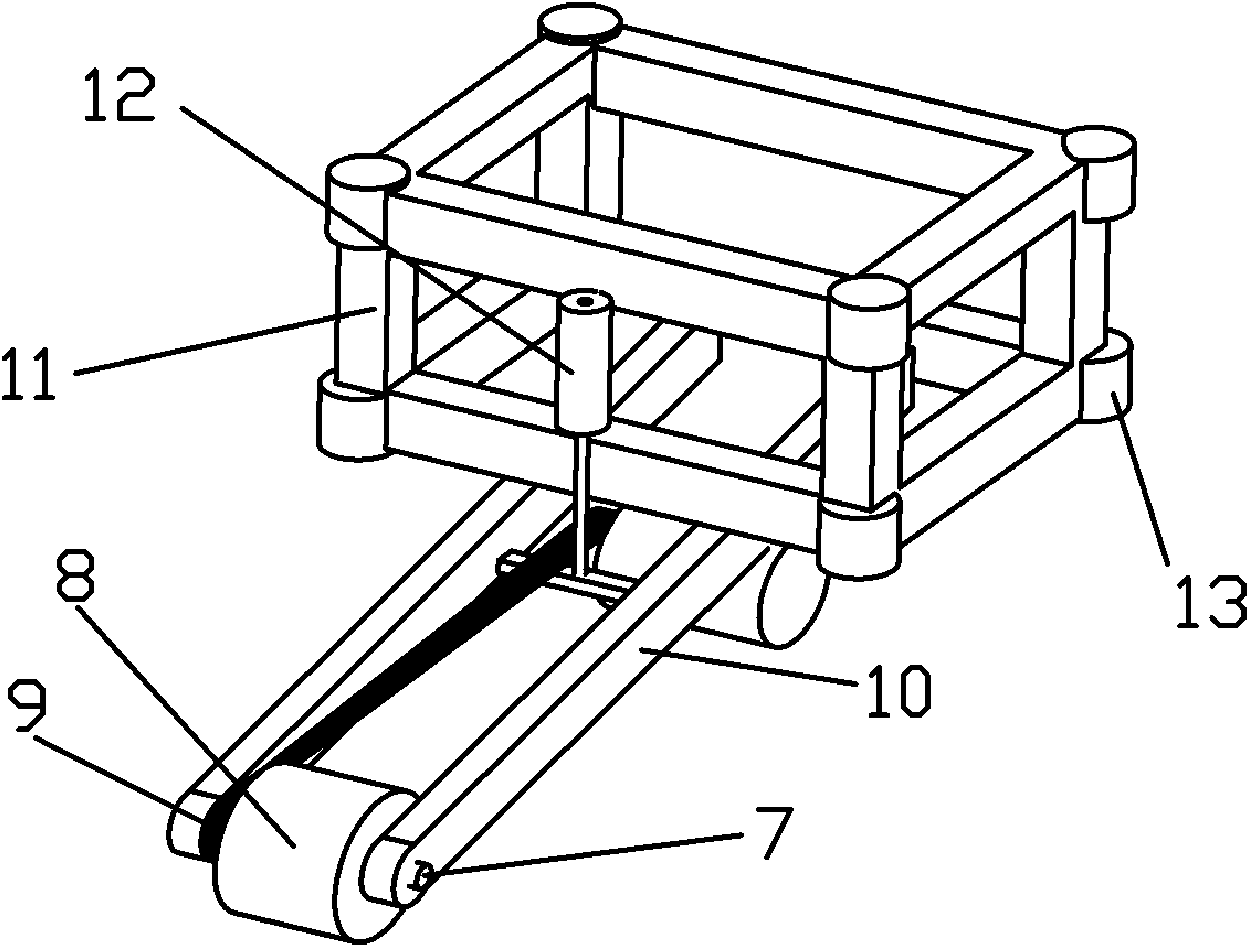

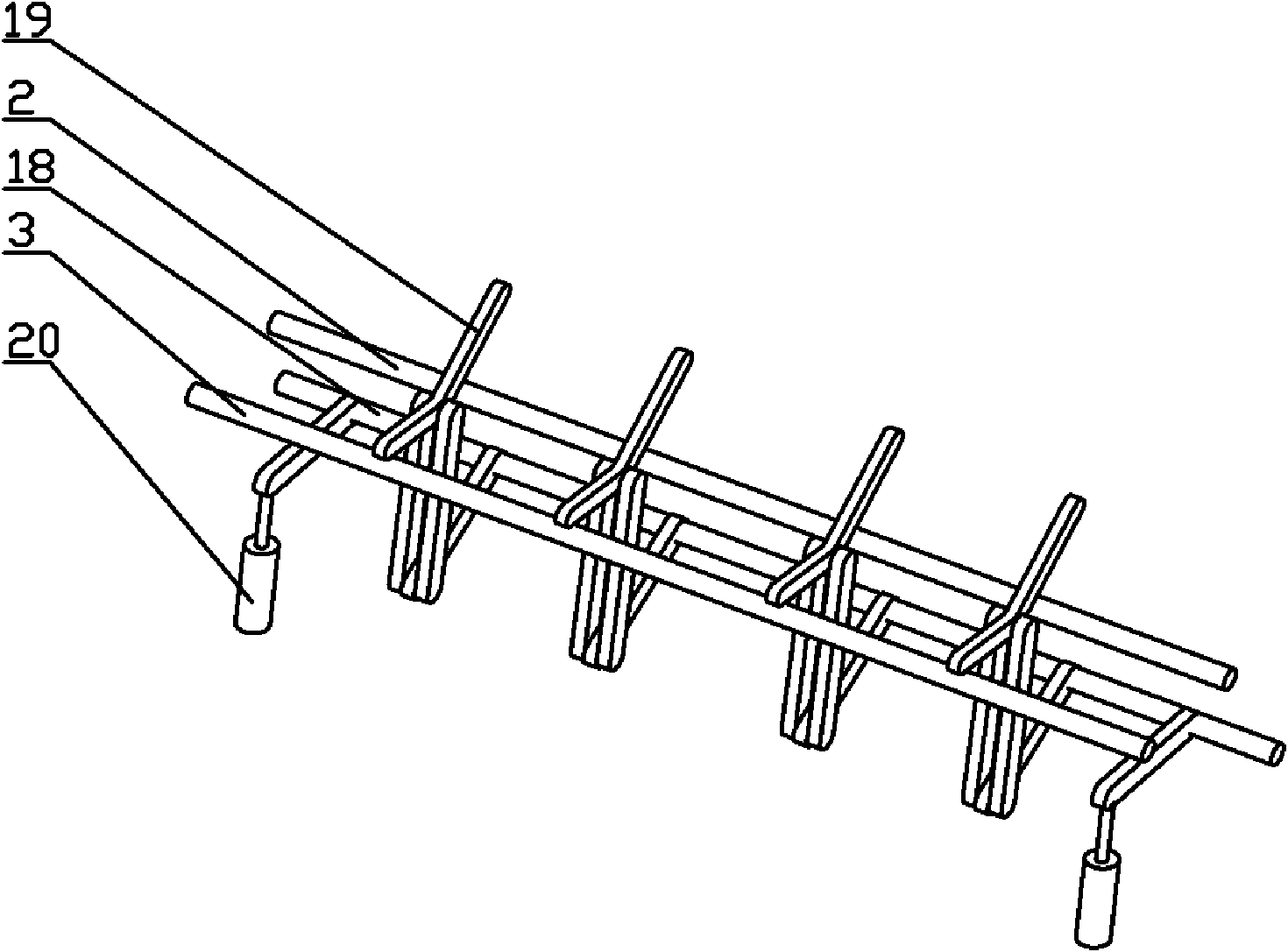

Peeling method and device of small diameter log

The invention discloses a peeling method of a small diameter log, which is characterized in that an integrated machine is used to peel the small diameter log, which comprises a feeding mechanism mounted in the front end of a seat frame, a delivering gear mounted above the seat frame, peeling tools mounted in the front end of the delivering gear and a discharging mechanism mounted below the seat frame; wherein, chains can be used by the feeding mechanism to transport the small diameter log for feeding; cables or chains can be used by the delivering gear to pull a delivering movablestand back and forth to carry out lateral movement, and a delivering cylinder is adopted by the delivering gear to act so as to drive tool arms on the delivering movablestand to carry out vertical movement; tool axis can be used by the peeling tools to spur cut heads on the peeling tools to rotate at high speed for peeling; a discharging cylinder can be used by the discharge mechanism to act so as to spur a discharging linkage to throw away the peeled small diameter log outward for discharging. The invention has the advantages of simple structure, low cost of manufacturing and maintenance, fully peeled log, good peeling effect, high peeling efficiency and convenient and stable delivering.

Owner:张勇

Iron sand white paeony root peeling device

InactiveCN112338788AQuick peelImprove peeling efficiencyEdge grinding machinesSievingEngineeringScreen filter

The invention provides an iron sand white paeony root peeling device, and relates to the technical field of white paeony root processing. The iron sand white paeony root peeling device comprises a base, a support, a peeling mechanism, a filter screen, an iron sand removing mechanism, a collecting box and an iron sand collecting box, the support is arranged at the top end of the base, the top end of the base is fixedly connected with the bottom end of the support, and the peeling mechanism is arranged at the top end of the support. Boiled white paeony roots are peeled through the peeling mechanism, and the top end of the support is fixedly connected with the peeling mechanism. The filter screen is arranged on the right side of the peeling mechanism, iron sand and the peeled white paeony roots are separated through the filter screen, the bottom end of the filter screen is fixedly connected with the base, the iron sand removing mechanism is arranged on the right side of the filter screen,and the iron sand adsorbed on the peeled white paeony roots is removed through the iron sand removing mechanism. The collecting box is arranged on the right side of the iron sand removing mechanism,and the iron sand collecting box is arranged at the bottom end of the filter screen. The iron sand collecting box is movably connected with the filter screen, so that the problem that a large amount of white paeony root peel remains on the surfaces of the white paeony roots and is not completely removed after white paeony root peeling is solved.

Owner:赵满英

Rotary manual peeling machine for bamboo shoot processing

ActiveCN112914120AFully peeledImplement classificationVegetable peelingFood treatmentBamboo shootIndustrial engineering

The invention relates to the field of bamboo shoot processing, in particular to a rotary manual peeling machine for bamboo shoot processing, which comprises a mounting base, a first supporting frame, a rubbing assembly, a pressing assembly, a limiting assembly and the like, wherein the first supporting frame is fixedly installed on the mounting base, the rubbing assembly is rotationally connected to the first supporting frame, the pressing assembly is arranged on the mounting base, and the limiting assembly is rotationally connected to the downward pressing assembly. The supporting shaft and devices on the supporting shaft are driven to rotate through the rubbing assembly and a sliding sleeve, through the guiding effect of a guiding strip, the first supporting frame pushes the guiding strip and devices on the guiding strip to move downwards, a first spring is stretched, a rubbing disc rotates and is matched with the downward movement, the rubbing disc pushes bamboo shoots to rotate, and a cutting knife peels the bamboo shoots.

Owner:江西省金桥农业科技发展有限公司

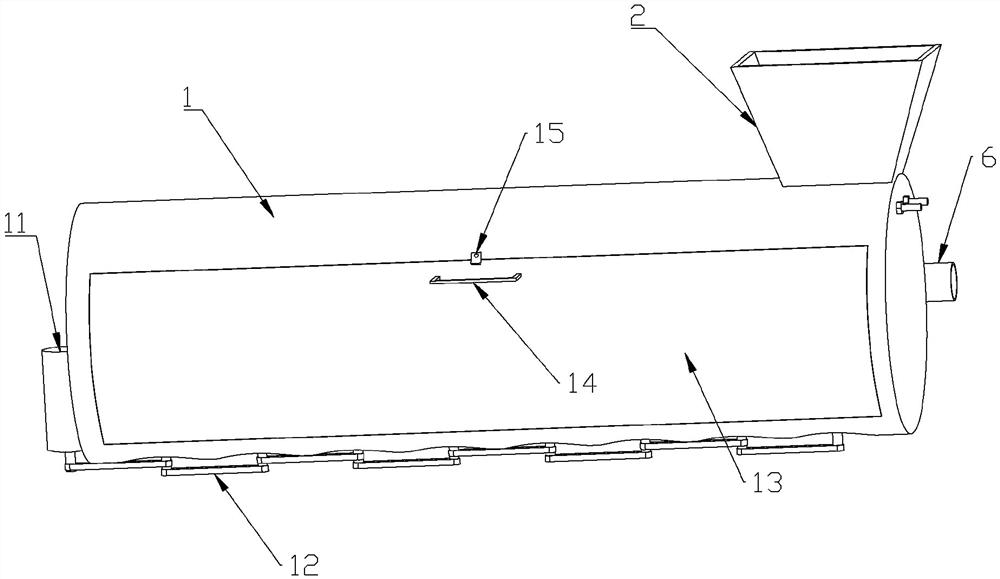

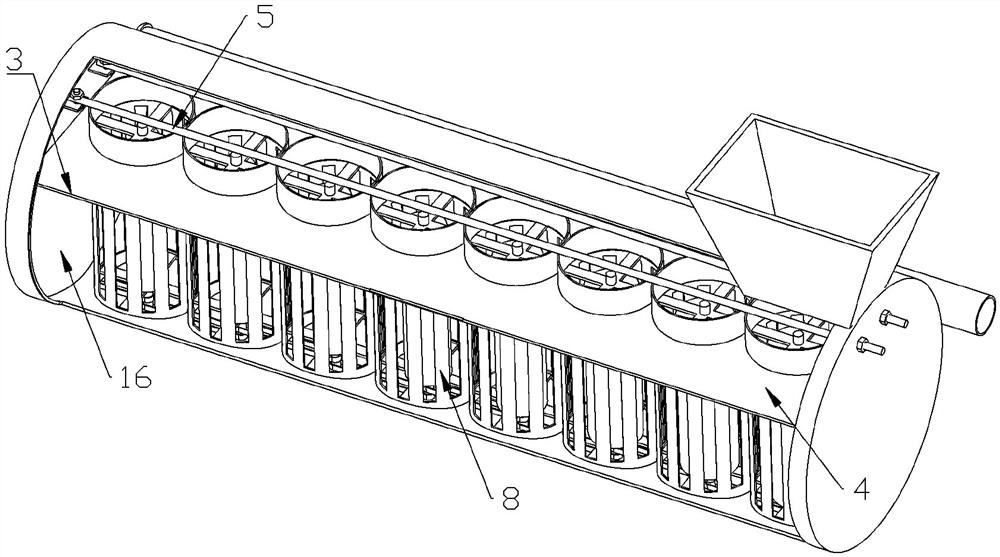

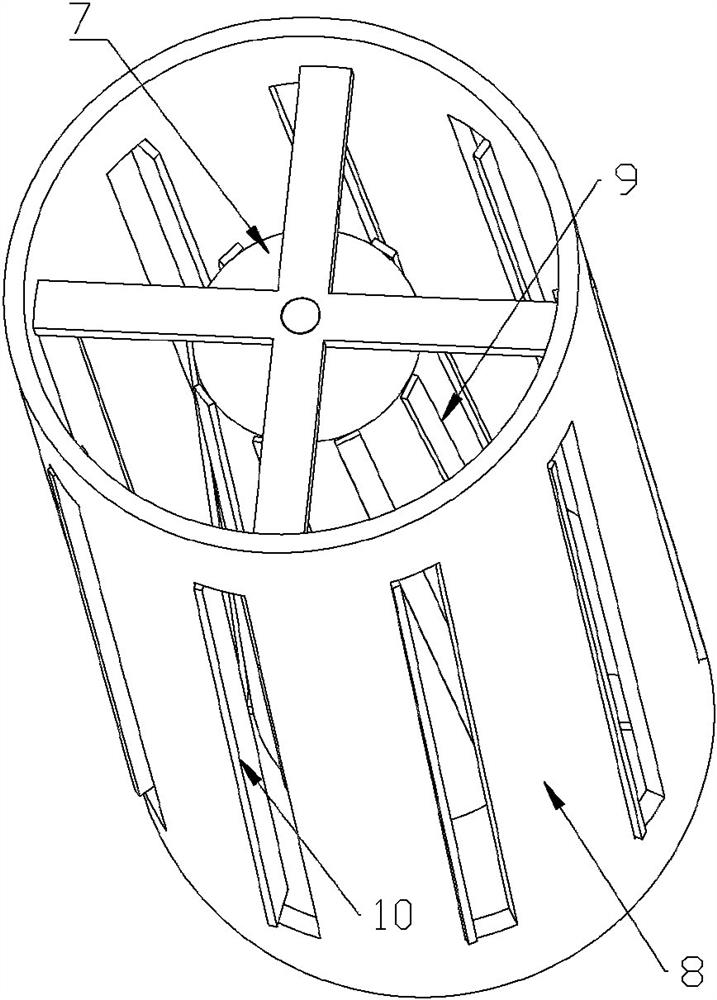

Green walnut peeling machine

The invention relates to the technical field of walnut peeling machines, and discloses a green walnut peeling machine which comprises a screening cylinder, the axis of the screening cylinder is inclined to the horizontal plane, a feeding hopper is arranged on the screening cylinder, a partition plate is arranged in the screening cylinder, an inner cavity of the screening cylinder is divided into a screening cavity and a drying cavity through the partition plate, and a pair of transverse rods is arranged in the screening cavity. The pair of transverse rods are arranged in a splayed shape along the axis of the screening barrel, the feeding hopper is located above the narrow-interval section of the pair of transverse rods, a peeling assembly is arranged in the drying cavity, the feeding end of the peeling assembly penetrates through the partition plate to the position below the transverse rods, a hot air pipe is further arranged on one side of the screening barrel, and the hot air pipe communicates with the drying cavity. The green husk walnut peeling machine has the advantages that green husk walnuts fall on the transverse rod through the feeding hopper, are screened in the rolling process along the transverse rod and fall into different peeling assemblies according to the size to be peeled, the peeled green husks are left in the drying cavity to be dried and used as medicinal materials for long-term storage, the functions are diversified, and the labor intensity of workers is reduced.

Owner:徽县鑫核缘山核桃手工艺品加工专业合作社

Refined chain peeling process of brown rice

ActiveCN110614133BFully peeledIncrease contact areaGrain huskingGrain polishingAgricultural engineeringWhite rice

The invention provides a refinement chain peeling process of brown rice, the steps of which are as follows: firstly, the user puts brown rice into the feeding device, and the feeding device evenly sprinkles the brown rice inside it from top to bottom in a narrow and long whitening strip. Indoor; then, the power drive device transmits the power to one of the rotating shafts and drives the rotating shaft to rotate, the rotating shaft drives the sprocket to rotate synchronously, the sprocket will circulate the pulley chain, and the chain will drive the grinding plate to rotate synchronously, and the symmetrically arranged The running directions of the two milling plates are opposite, and the counter-rotating grinding plates will squeeze and rub the brown rice in the whitening chamber, so that the brown rice is peeled and separated into white rice and rice bran; finally, the mixture of white rice and rice bran will fall from the lower end of the whitening chamber. Into the discharge device, the discharge device separates the white rice and rice bran through the fan, so that the "heavier" white rice first falls to the white rice passage and discharged outward, so that the "lighter" rice bran is discharged from the rice bran passage.

Owner:安徽晨阳粮油股份有限公司

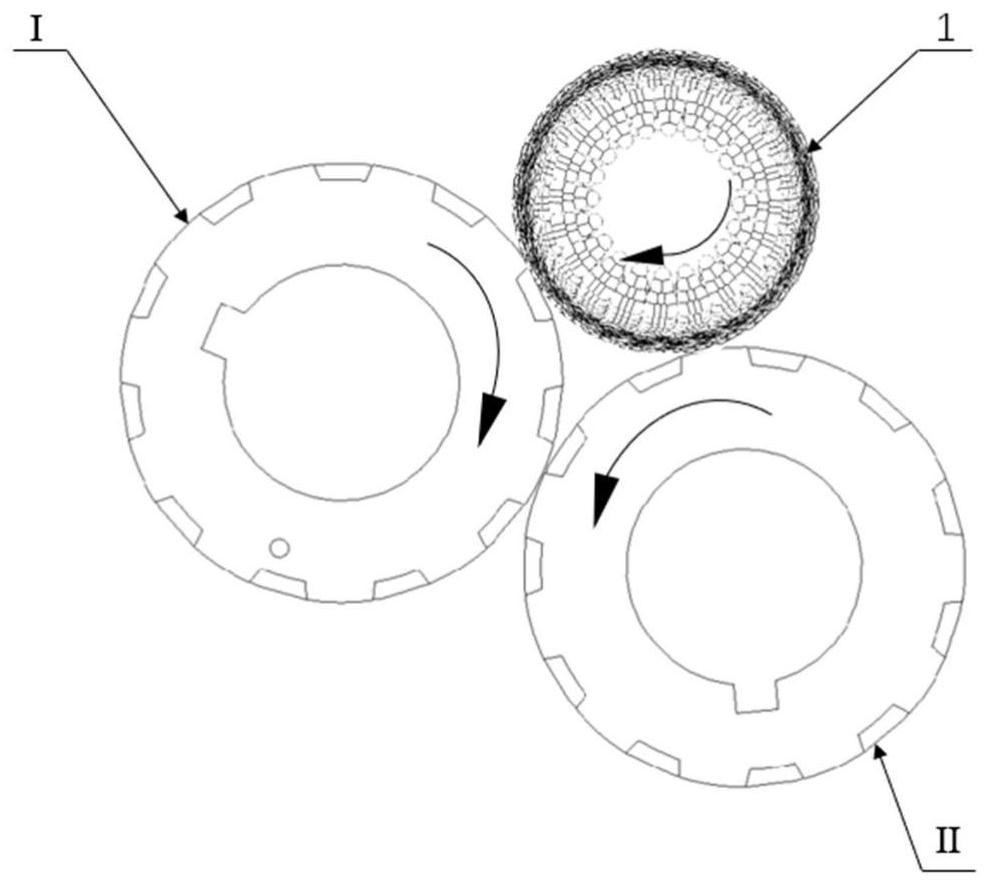

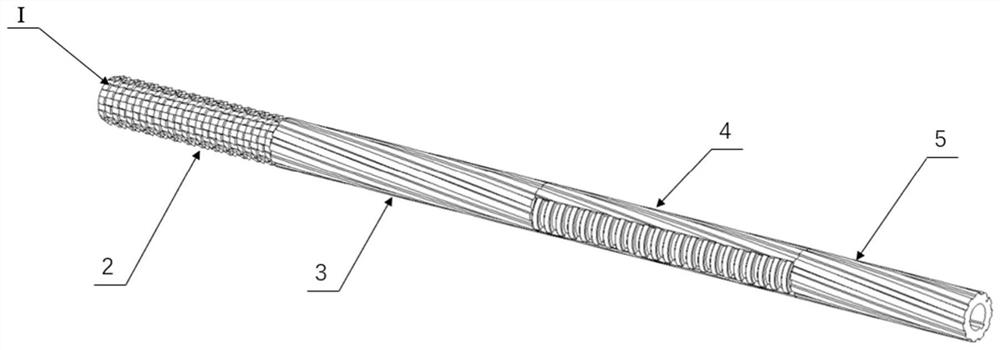

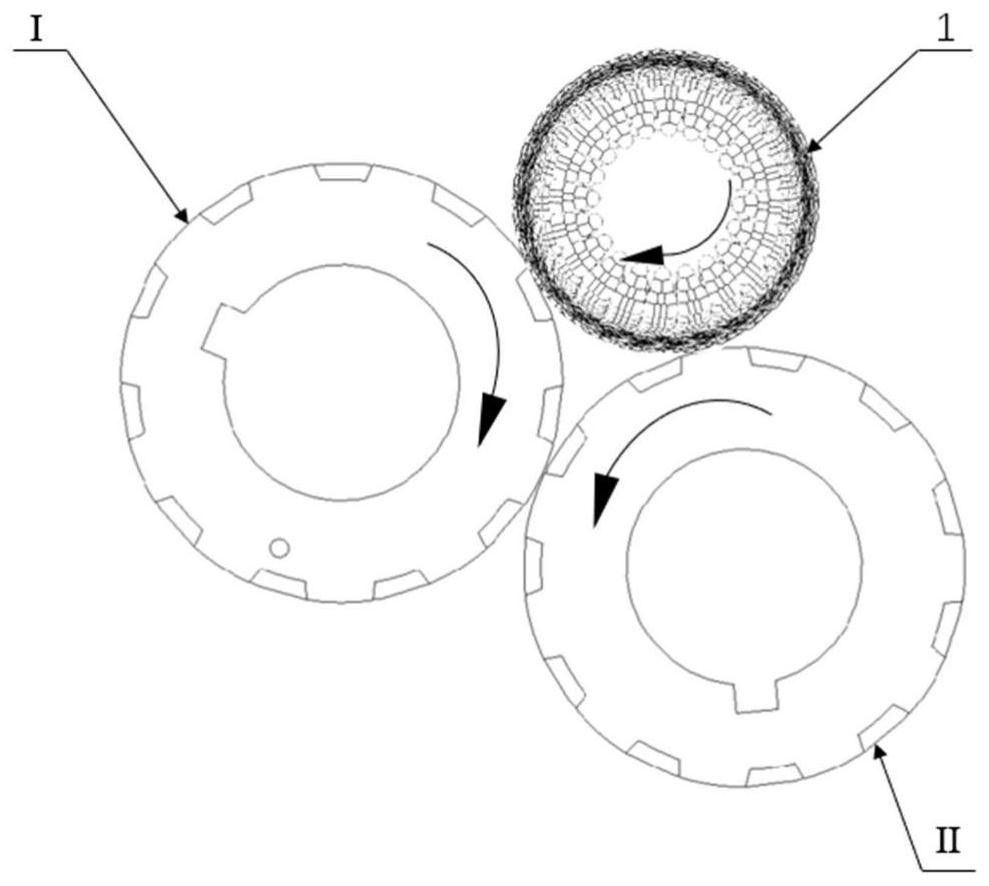

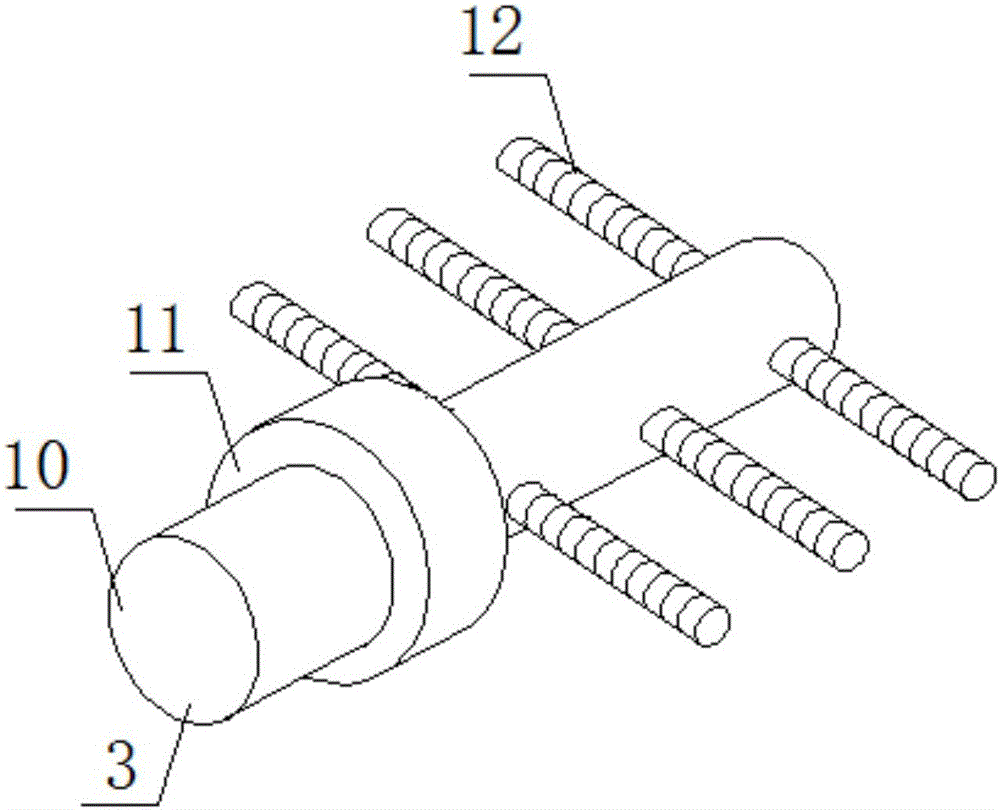

Husking roller combined structure suitable for corn seeds

ActiveCN113039930AImprove peeling efficiencyUniform horizontal distributionHarvestersAgricultural engineeringMechanical engineering

The invention belongs to the technical field of corn husking in agricultural machinery, and particularly relates to a husking roller combined structure suitable for corn seeds. The husking roller combined structure comprises a high-position husking roller and a low-position husking roller which are arranged in a high-low roller mode; the high-position husking roller is sequentially provided with a first high-position husking roller section, a second high-position husking roller section, a third high-position husking roller section and a fourth high-position husking roller section from the material inlet end to the material outlet end; the low-position husking roller is sequentially provided with a first low-position husking roller section, a second low-position peeling husking section, a third low-position husking roller section and a fourth low-position husking roller section from the material inlet end to the material outlet end. Corn husking is divided into four stages, and corresponding protruding lines on the surfaces of the husking rollers are designed for each husking stage, so that the damage rate of the surfaces of seed corn kernels in the husking process is effectively reduced, and the husking rate and husking efficiency of seed corn ears are improved.

Owner:CHINA AGRI UNIV

Chain grinding plate structure applied to rice peeling processing

ActiveCN110614132BFully peeledIncrease contact areaGrain huskingGrain polishingAgricultural engineeringStructural engineering

The invention provides a chain-type grinding plate structure applied to rice peeling processing, which includes a floor-standing installation frame (110), and a rectangular horizontal plate (111) is fixedly installed on the top of the installation frame (110). The horizontal plate (111) A vertical plate (112) is fixedly installed on the upper end surface, two vertical plates (112) are provided and arranged at intervals, a chain plate mechanism (120) arranged side by side is arranged between the two vertical plates (112), and the two chain plates The distance between the mechanisms (120) can be adjusted, and the chain plate mechanisms (120) are fixedly provided with a docking mechanism (130) on one side close to each other. The long and narrow whitening chamber (133) with upper and lower openings is composed of grinding boards (128) that rotate in reverse to squeeze, rub and peel the brown rice between the whitening chambers (133), and the whitening chamber (133 ) into the upper opening of brown rice, and discharge the mixture of white rice and rice bran from the lower opening.

Owner:六安市洪达农业综合服务股份有限公司

Corn peeling equipment for agricultural machinery

ActiveCN111247947BImprove peeling efficiencyAvoid blocked situationsHarvestersAgricultural scienceElectric machine

The invention discloses a corn peeling equipment for agricultural machinery, which comprises a box body, a feeding barrel is plugged into one side of the outer wall of the box body, and an exhaust fan is arranged on the top outer wall of the box body, and one side of the exhaust fan is The outer wall is plugged with a suction pipe, and one end of the suction pipe is plugged with a collection box. In the present invention, when the corn enters the inside of the box through the feeding cylinder, people first start the blower and the motor, and the blower can apply a thrust to the corn skin, and the thrust can break the corn skin to achieve the corn peeling requirement, and then start the suction The fan and the suction fan can apply a pulling force to the corn skin, which can tear the corn skin. The positive and negative force cycles act on the corn skin, which can fully peel the corn without causing damage to the corn surface. At the same time, the motor can drive the rotating rod to slowly turn over the corn, which improves the efficiency of the device for peeling the corn.

Owner:温州普奈机械科技有限公司

Abalone shelling machine

ActiveCN105285056BReduce consumptionRealize automatic feeding processShellfish processingEngineeringConveyor belt

The invention discloses an abalone shelling machine. The abalone shelling machine comprises a conveyor belt, an abalone arraying shape collating machine, a clamping jaw sliding block, a clamping jaw device, a sliding rail, an abalone shell containing box, a cut-off device, a spring shelling knife device, an abalone meat containing box, a pushing block device, a support gantry and a base. According to the abalone shelling machine disclosed by the invention, the functions of automatically loading, automatically shelling, automatically classifying and collecting shells and meat, and the like can be realized, the shelling quality is improved, processing requirements for shelling rapidly, cleanly and comprehensively are realized, the feeding time is saved, the processing quality is guaranteed, and the energy consumption is reduced.

Owner:大连伟瑞达精密模具制造有限公司

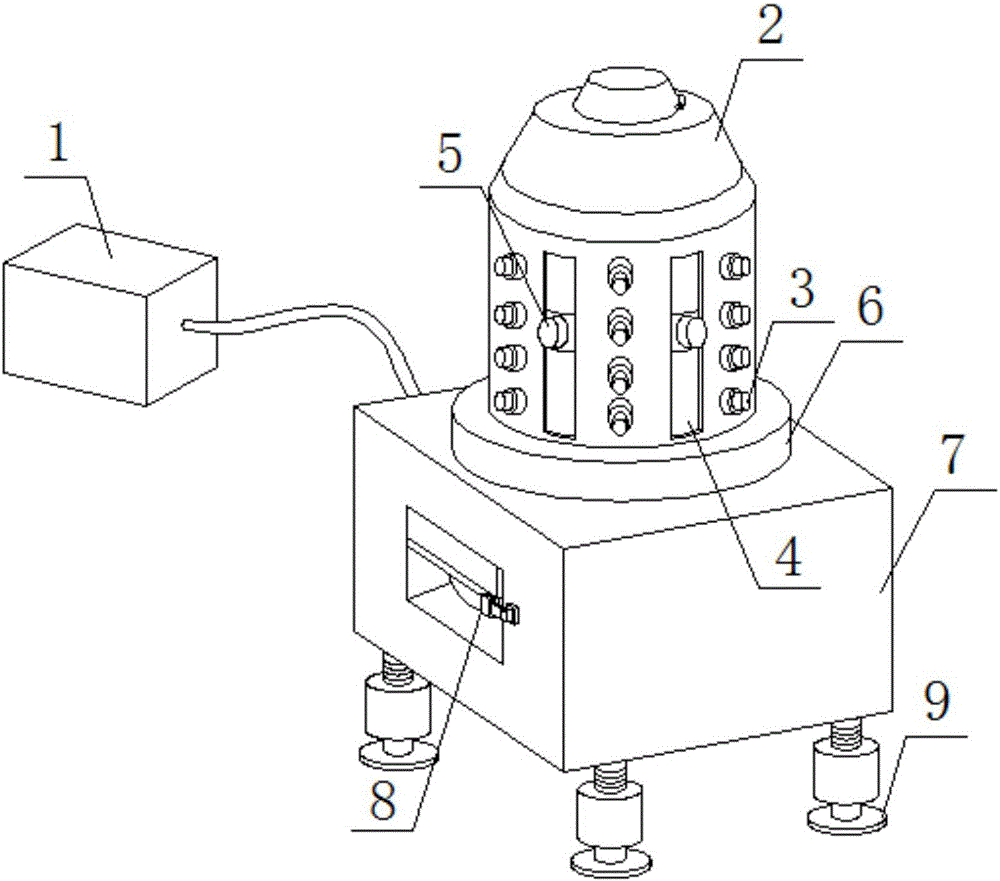

Integrated primary treatment equipment for impurity removal and sterilization of flaxseeds based on electrostatic separation

InactiveCN112337651AFully peeledNo transit timeElectrostatic separationFood scienceElectrostatic separationBiology

The invention relates to the technical field of flaxseed processing, in particular to flaxseed impurity removal and sterilization integrated primary treatment equipment based on electrostatic separation. The equipment comprises a pedestal; a sterilization mechanism which is arranged on the base and used for sterilizing the flaxseeds to be processed; a peeling mechanism which is arranged on the base and used for shelling the sterilized flaxseeds; a material guide mechanism which is arranged on the base and used for guiding the flaxseeds treated by the sterilization mechanism into the peeling mechanism; an electrostatic separation mechanism which is arranged on the base and used for separating flaxseed pulp and flaxseed skin of the flaxseeds treated by the peeling mechanism; the electrostatic separation device is characterized in that the electrostatic separation mechanism comprises a rectangular electrostatic treatment box vertically mounted on the base; an electrostatic synchronous belt whcih can be rotationally arranged in the length direction of the interior of the electrostatic treatment box. According to the invention, flaxseeds can be sterilized, peeled and separated in an integrated mode, the transfer time of workers is saved, and the production efficiency is improved.

Owner:肖乐

A combination structure of peeling rollers suitable for seed corn

ActiveCN113039930BImprove peeling efficiencyUniform horizontal distributionHarvestersAgricultural engineeringStructural engineering

The invention belongs to the technical field of corn peeling in agricultural machinery, in particular to a combined structure of peeling rollers suitable for seed corn. The combined structure of peeling rollers includes high-position peeling rollers and low-position peeling rollers configured with high and low rollers; the high-position peeling rollers are sequentially provided with a high-position peeling roller section, a high-position stripping roller section two, and a high-position stripping roller three sections from the material inlet end to the material outlet end. One section and four sections of high-position peeling rollers; the low-position stripping rollers are successively provided with one section of low-position stripping rollers, two sections of low-position stripping rollers, three sections of low-position stripping rollers and four sections of low-position stripping rollers from the material inlet end to the material outlet end. The invention divides corn peeling into four stages, and each peeling stage has a corresponding design of protrusions on the surface of the peeling roller, which effectively reduces the damage rate on the surface of seed corn grains during the peeling process and improves the peeling rate of seed corn ears and peeling efficiency.

Owner:CHINA AGRI UNIV

Machine for removing green husks of walnuts with green husks

The invention discloses a machine for peeling green walnuts, which includes a frame and a protective cover. A roller is arranged inside the protective cover, and a rotating shaft is arranged at both ends of the roller. The rotating shaft is connected with a bearing seat placed outside the protective cover. A motor; a cutter is installed on the roller; a fixed cylinder is arranged on the periphery of the roller, the fixed cylinder is coaxial with the roller, a scraper is arranged in the fixed cylinder, and green skin outlet holes are arranged on the fixed cylinder at the root of the scraper. The walnut green peeling machine of the present invention has long service life, high working efficiency, comprehensive peeling, simple overall mechanism, small weight, and is convenient for movement and transportation.

Owner:云南永平红喻核桃产业有限公司

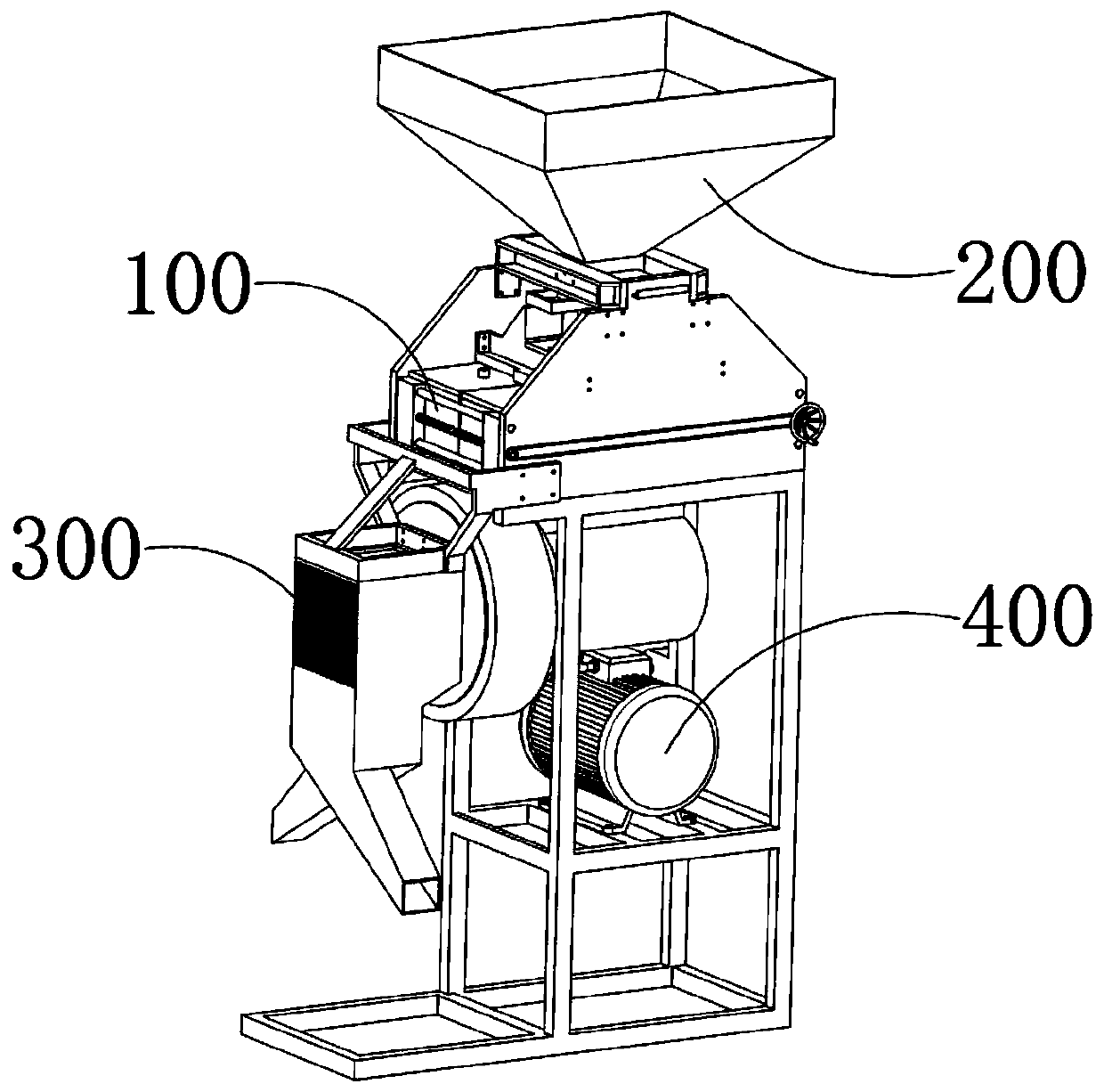

Separated-type rice husking machine

ActiveCN110586223AFully peeledIncrease contact areaGrain huskingGrain polishingEngineeringWhite rice

The invention provides a separated-type rice husking machine. The rice husking machine comprises a friction husking device internally provided with a whitening chamber, a feeding device, a dischargingdevice and a power driving device, the feeding device is communicated with the input end of the whitening chamber, and the discharging device is communicated with the output end of the whitening chamber; the feeding device is used for uniformly conveying brown rice into the whitening chamber, the friction husking device is used for conducting extrusion and friction husking on the brown rice located in the whitening chamber, so that the brown rice is fully separated into white rice and rice bran, and the discharging device receives the white rice and rice bran which are discharged from the whitening chamber, separates the white rice from the rice bran and discharges the white rice and the rice bran outwards separately; the friction husking device comprises a chain plate mechanism, the chain plate mechanism comprises friction plates driven by chains, and the brown rice in the whitening chamber is subjected to extrusion and friction through the friction plates reversely working, so thatthe brown rice is husked and separated into the white rice and the rice bran; the husking machine has the advantages that the brown rice is subjected to extrusion and friction husking through the friction plates, the area of contact with the brown rice during processing is increased, the efficiency is high, and the friction pressure to the brown rice can be quickly adjusted.

Owner:湖南湘益丰茂科技有限公司

Cleaning and peeling device used for peony roots in agriculture

InactiveCN107432483AEffective peelingFully peeledVegetable peelingFood treatmentEngineeringWater spray

The invention discloses a cleaning and peeling device used for peony roots in agriculture. The cleaning and peeling device comprises a distribution box, a material charging cover, rotary plates, sliding grooves, a transmission ring, a forward-flow bin, a rotary feeding rack, height adjusting bases, water receiving columns, locking rings, water spraying rotation columns, feeding and telescoping bins, telescoping columns, grinding and scraping rings, guide screw stripes, a pushing rod, extension columns and rotating rings. The cleaning and peeling device has the advantages that the peony roots are scraped, turned and peeled by the device through rotational grinding rings in the mode of moving up and down, and the telescoping columns rotate, stretch out and draw back in a reciprocating mode, so that the peony roots are more efficiently and comprehensively peeled by the device; water is sprayed through the water spraying rotation columns on the rotary plates so as to clean the peony roots, rotational stirring is conducted through the water spraying rotation columns, so that the mobility of the peony roots is accelerated, and the peony roots are more comprehensively and thoroughly cleaned and peeled; people can freely adjust the working heights of the height adjusting bases by rotating the rotating rings according to the actual use needs, so that the height of the device is changed, and the use flexibility is ensured; the device is convenient to operate, and all the components are flexibly connected.

Owner:LIUZHOU FANYI TECH CO LTD

A rotary manual peeler for bamboo shoot processing

ActiveCN112914120BFully peeledImplement classificationVegetable peelingFood treatmentAgricultural engineeringBamboo shoot

The invention relates to the field of bamboo shoot processing, in particular to a rotary manual peeler for bamboo shoot processing, which includes a mounting base, a first support frame, a rubbing component, a pressing component, a limit component, etc.; The first support frame is rotatably connected with a rubbing assembly, the pressing assembly is arranged on the installation base, and the limit assembly is rotatably connected with the pressing assembly. Through the rubbing assembly, the sliding sleeve drives the support shaft and its upper device to rotate, and through the guiding effect of the guide bar, the first support frame pushes the guide bar and its upper device to move downward, the first spring is stretched, the rubbing disc rotates and Cooperating with the downward movement, the rubbing disc pushes the bamboo shoots to rotate, so that the cutting knife peels off the bamboo shoots.

Owner:江西省金桥农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com