Chain grinding plate structure applied to rice peeling processing

A technology for grinding plate and rice, applied in the field of rice processing, can solve the problems of inability to control the fineness of white rice, inconvenient pressure adjustment, limited contact area, etc., and achieves the effect of ingenious structure, convenient operation and use, and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

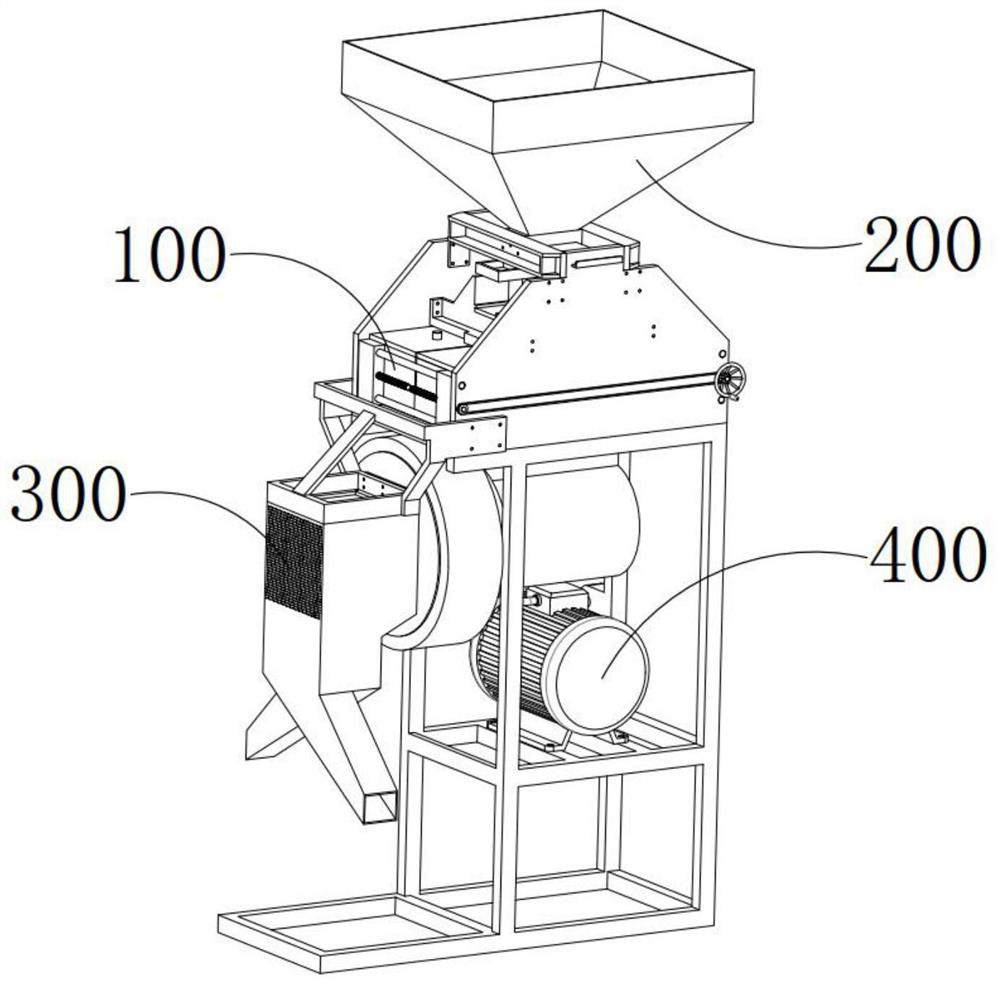

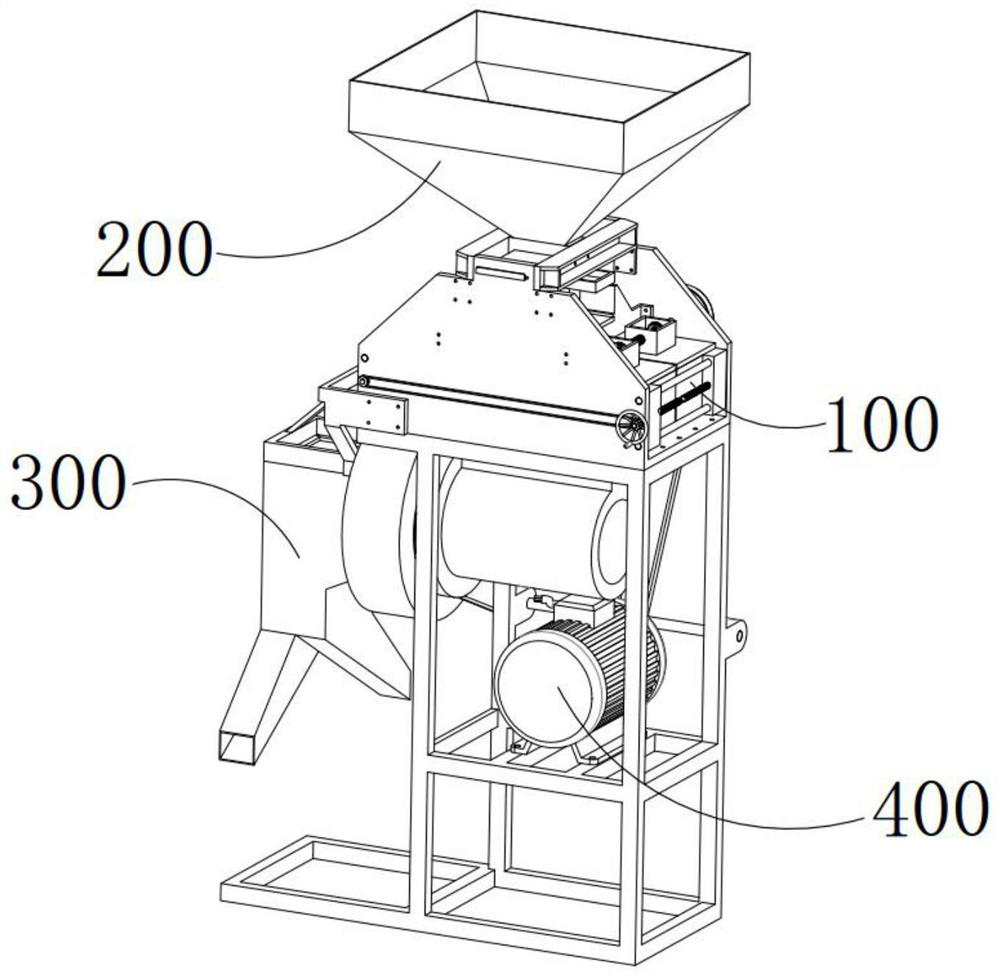

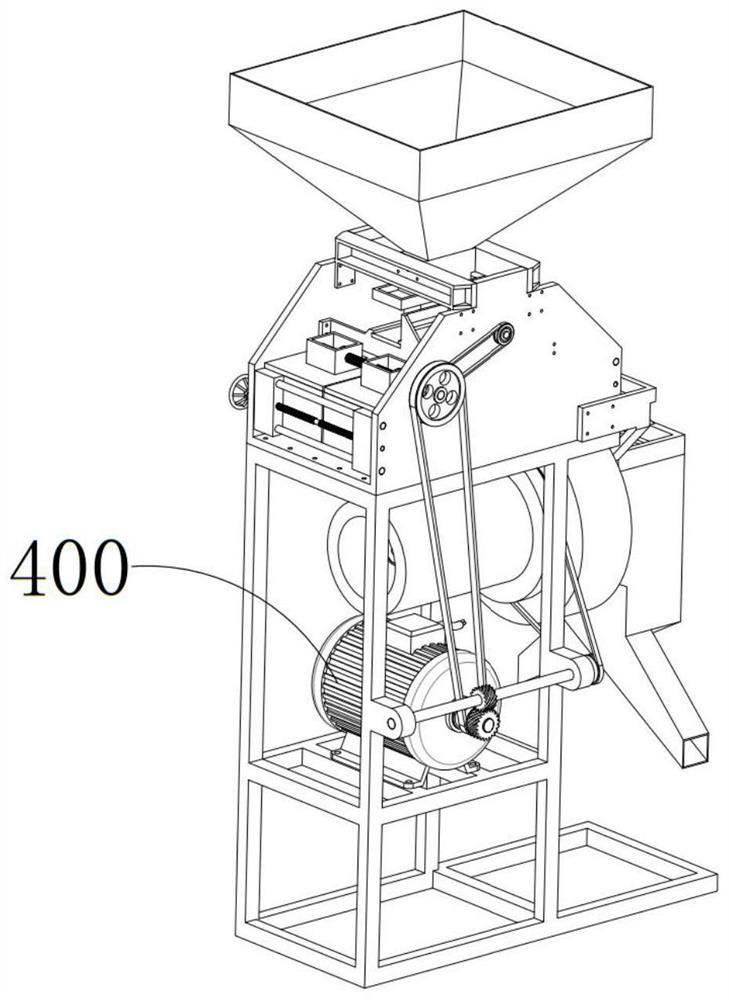

[0056] see Figure 1-36 , a chain-type grinding plate automatic separation rice mill, which includes a friction peeling device 100 containing a whitening chamber 133, a feeding device 200, a discharge device 300 and a power drive device 400, the feeding device 200 and the whitening device The input end of the chamber 133 is connected and connected, the discharge device 300 is connected with the output end of the whitening chamber 133, the feeding device 200 is used to evenly input brown rice in the whitening chamber 133, and the friction peeling device 200 is used for The brown rice located in the whitening chamber 133 is extruded, rubbed and peeled, and the brown rice is fully separated into white rice and rice bran. The discharge device receives the white rice and rice bran discharged from the whitening chamber 133 and separates them and discharges them separately. The power drive device 400 is used to provide driving power for the friction peeling device 100 , the feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com