A combination structure of peeling rollers suitable for seed corn

A combined structure and seed corn technology, which is applied in applications, harvesters, agriculture, etc., can solve the problems of low peeling rate of corn ears and difficult peeling, so as to meet the grain damage rate, reduce the damage rate and the shattering rate , Improve the effect of stripping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below with reference to the accompanying drawings and embodiments.

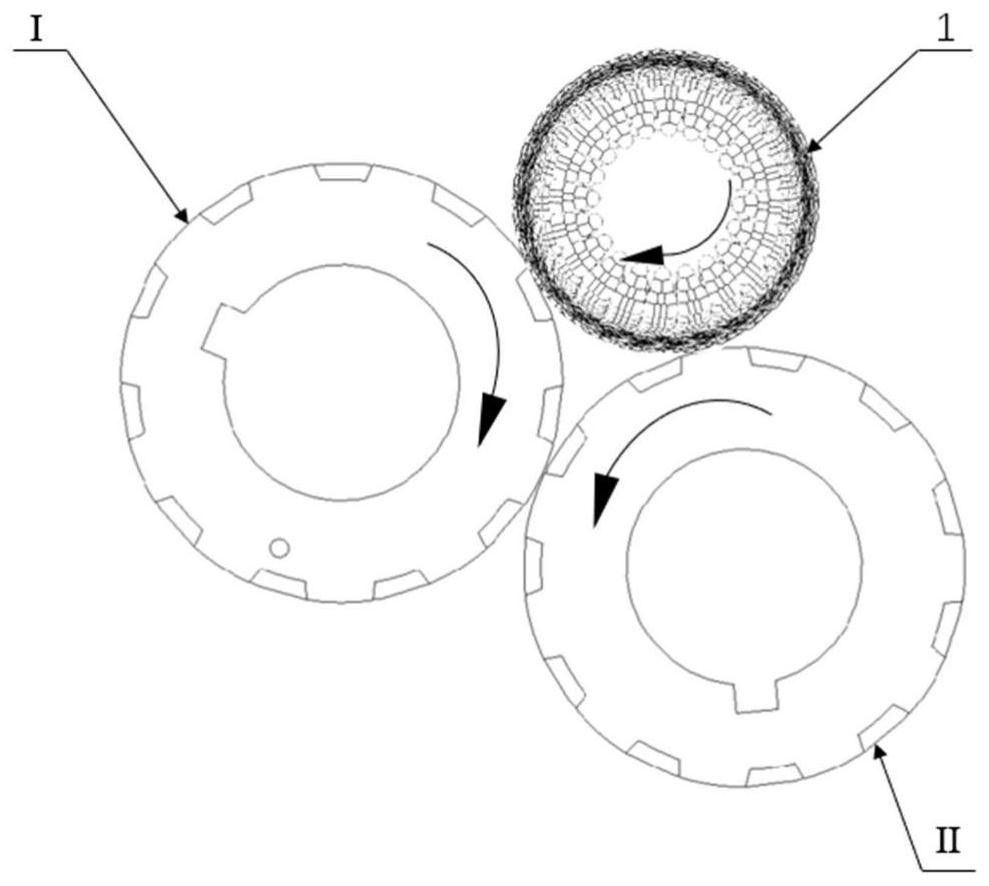

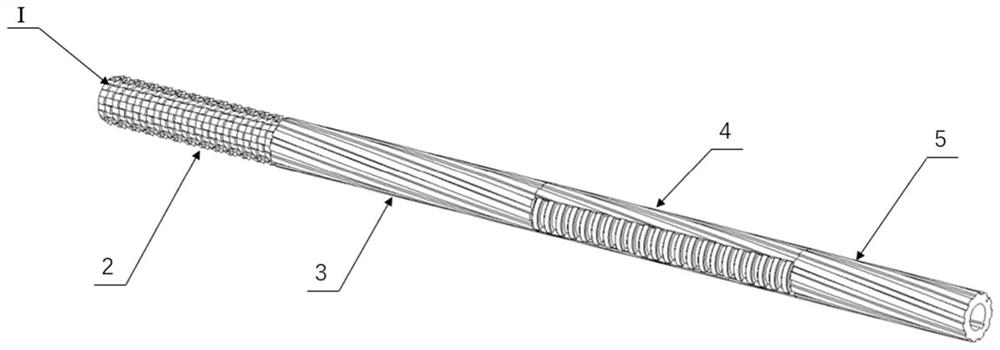

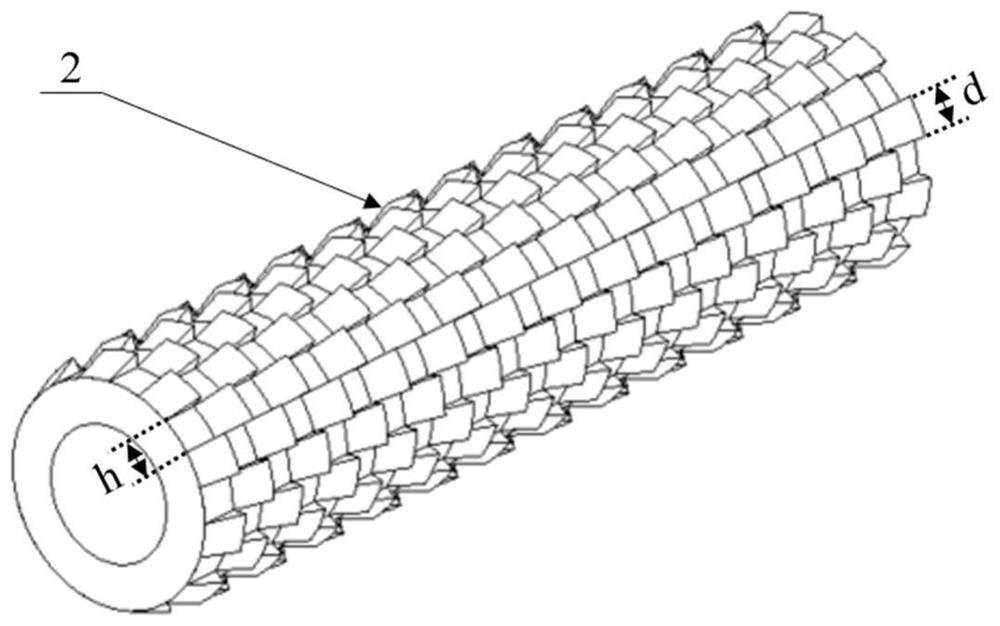

[0060] like Figure 1 to Figure 7 As shown, a combined structure of a peeling roller suitable for seed corn of the present invention includes a high-level peeling roller I and a low-level peeling roller II in a high-low roller configuration.

[0061] The present invention adopts a high-low roller configuration, two high-level peeling rollers I and two low-level peeling rollers II constitute a peeling unit, wherein the level of the middle two high-level peeling rollers I is higher than the two low-level peeling rollers on both sides. The horizontal height of II; a low-level peeling roller II and a high-level peeling roller I adjacent to it form a peeling unit. A transmission gear 11 is fixedly connected to one end of the roller shaft 12 of each peeling roller, and the adjacent transmission gears 11 mesh with each other.

[0062] like figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com